System and method of guard rail installation and alteration

a guardrail and system technology, applied in the direction of roadways, load-supporting pillars, roadway safety arrangements, etc., can solve the problems of hardware often rather difficult to disassemble, paperwork trail for material verification at risk, etc., and achieve the effect of increasing the efficiency of guardrail alteration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

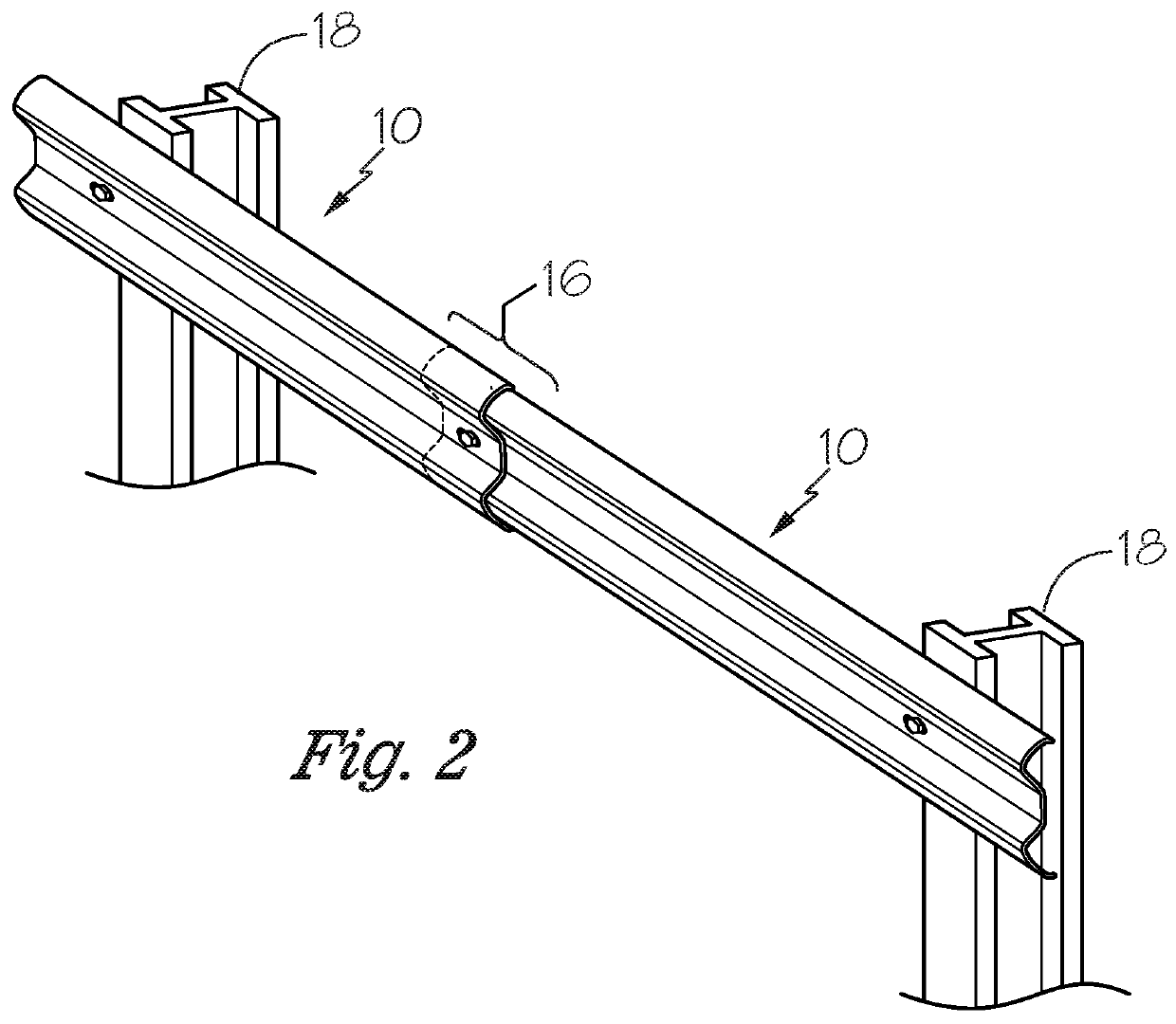

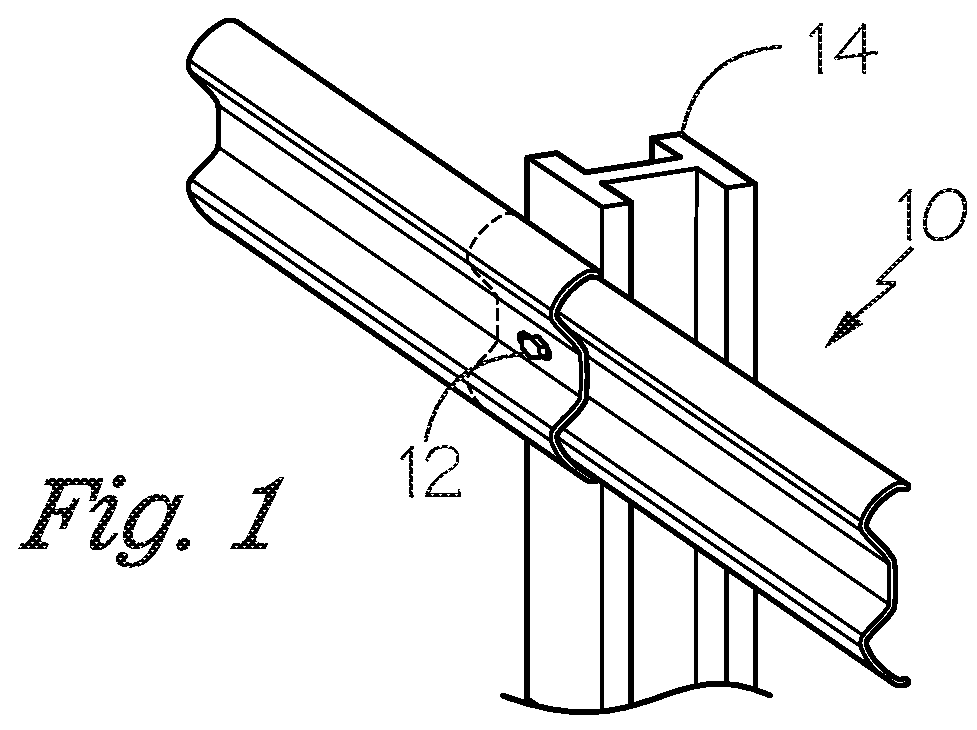

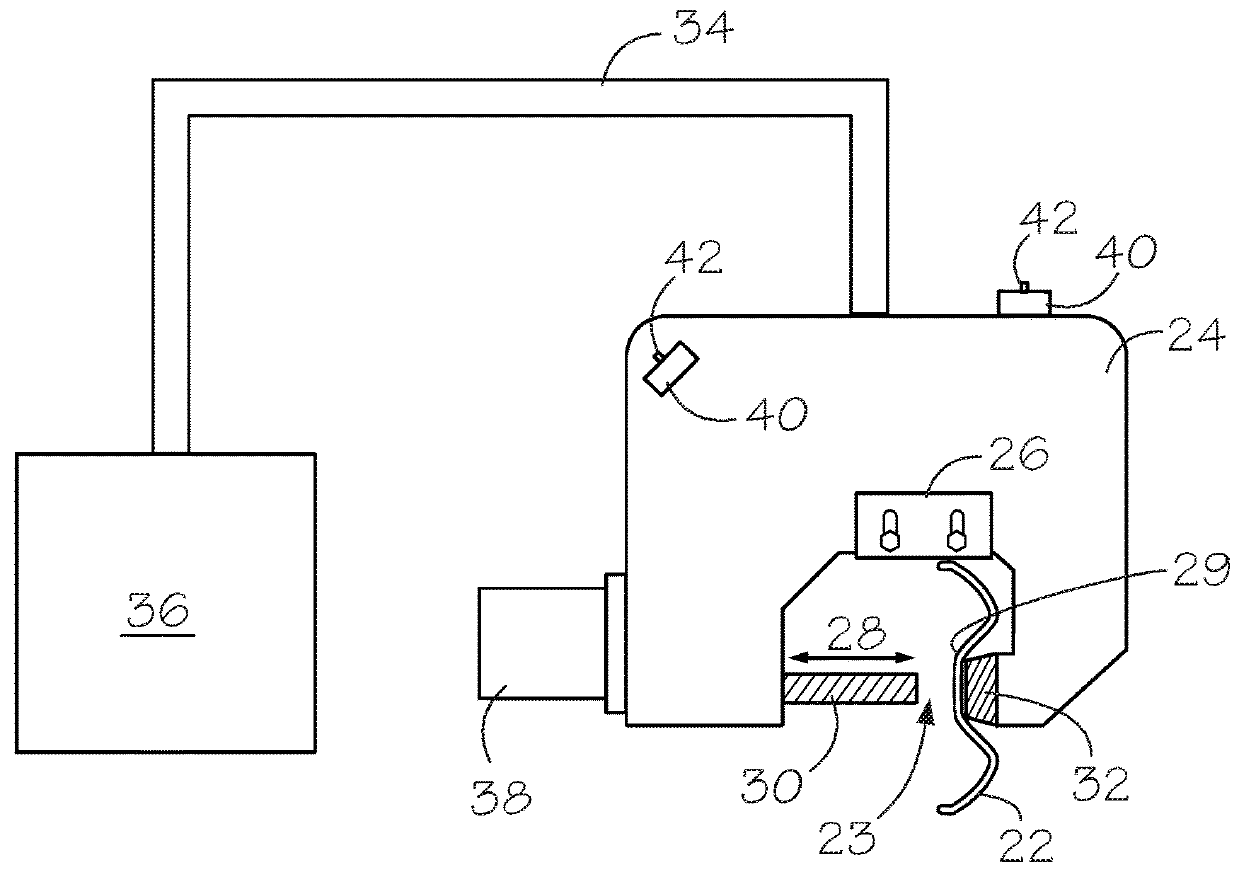

[0025]The present invention is an improved system and method of installation or alteration of guardrail. More specifically, the present invention provides a system and method of alteration of an installed guardrail system that does not require removing the guardrail that is already installed (on-site), thereby eliminating the transport or replacement thereof.

[0026]A particular advantage of the instant invention is the minimization of environmental impact when changing from the use of overlap guardrail post spacing to mid-splice post spacing. Millions of feet of guardrail can be retrofitted and allowed to remain in service as opposed to being removed due to not having preexisting mid-splice through-bolt holes. Furthermore, the used guardrail and the vast majority of highway guardrail hardware would not have removed, transported and then handled In scrap yards and waste dumps.

[0027]This can be Important from an environmental standpoint because most guardrail is manufactured with galva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com