Sensor element

a technology of sensor elements and elements, applied in the field of sensor elements, can solve the problems of increasing the heat dissipation resistance value over time, and the probability of pt disassembly is more likely to occur, so as to prevent or reduce the diffusion of pt, increase the lifetime, and increase the lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

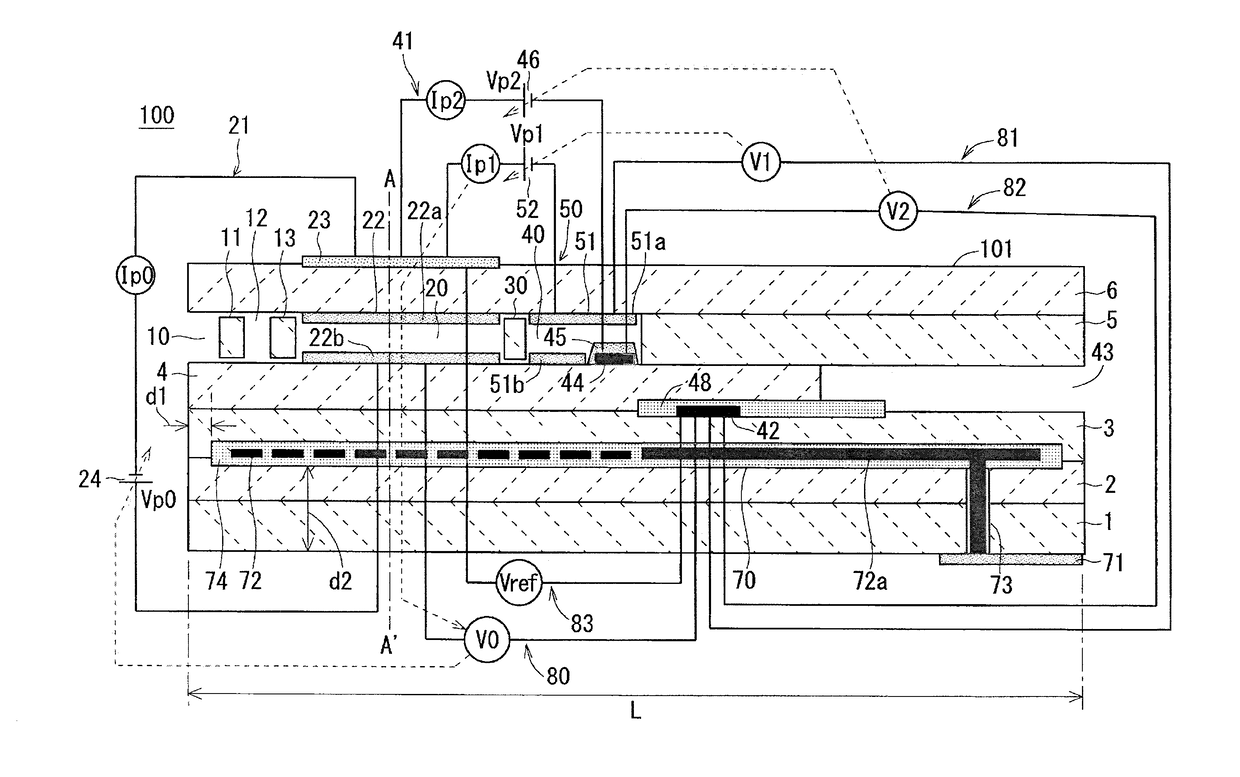

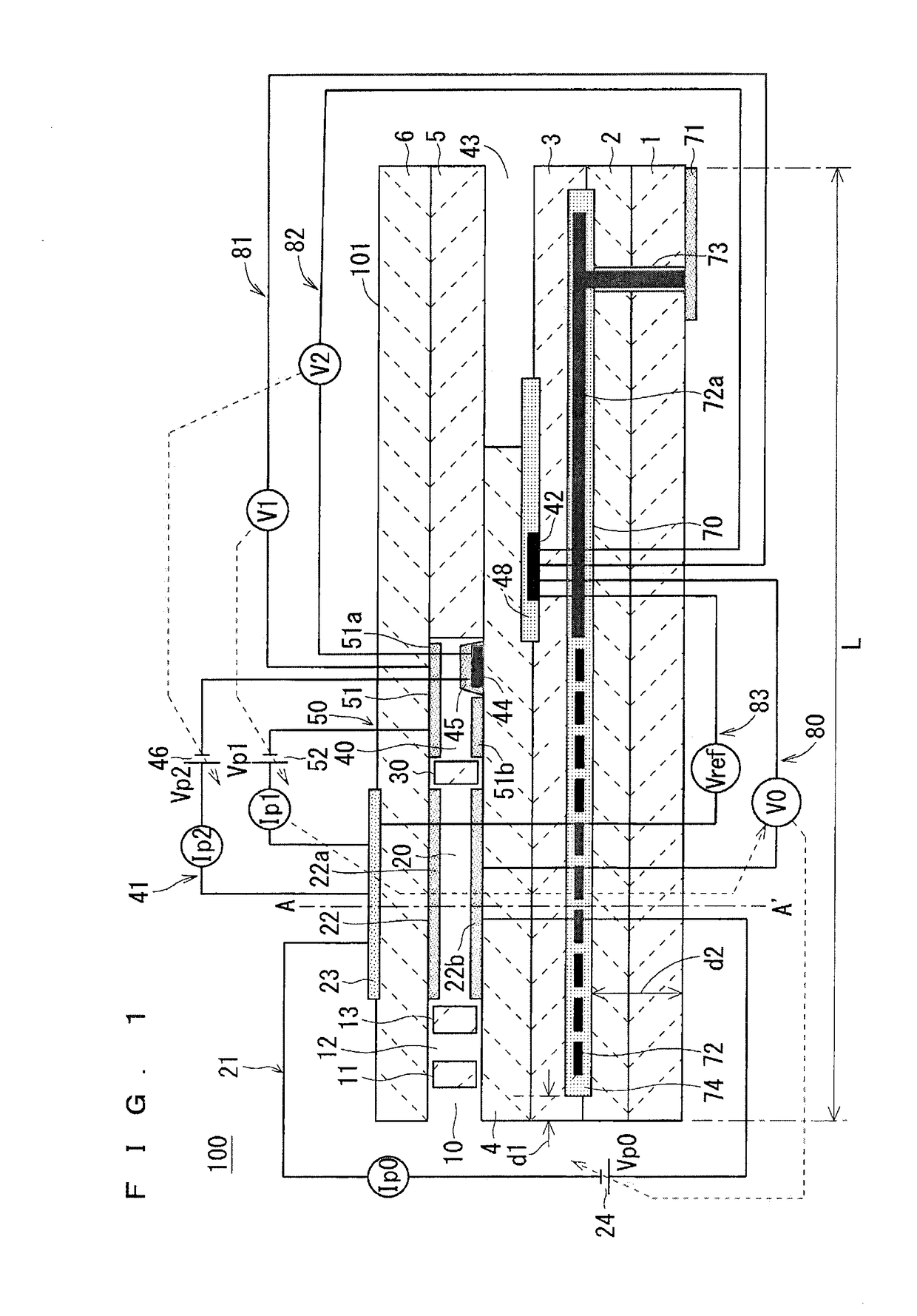

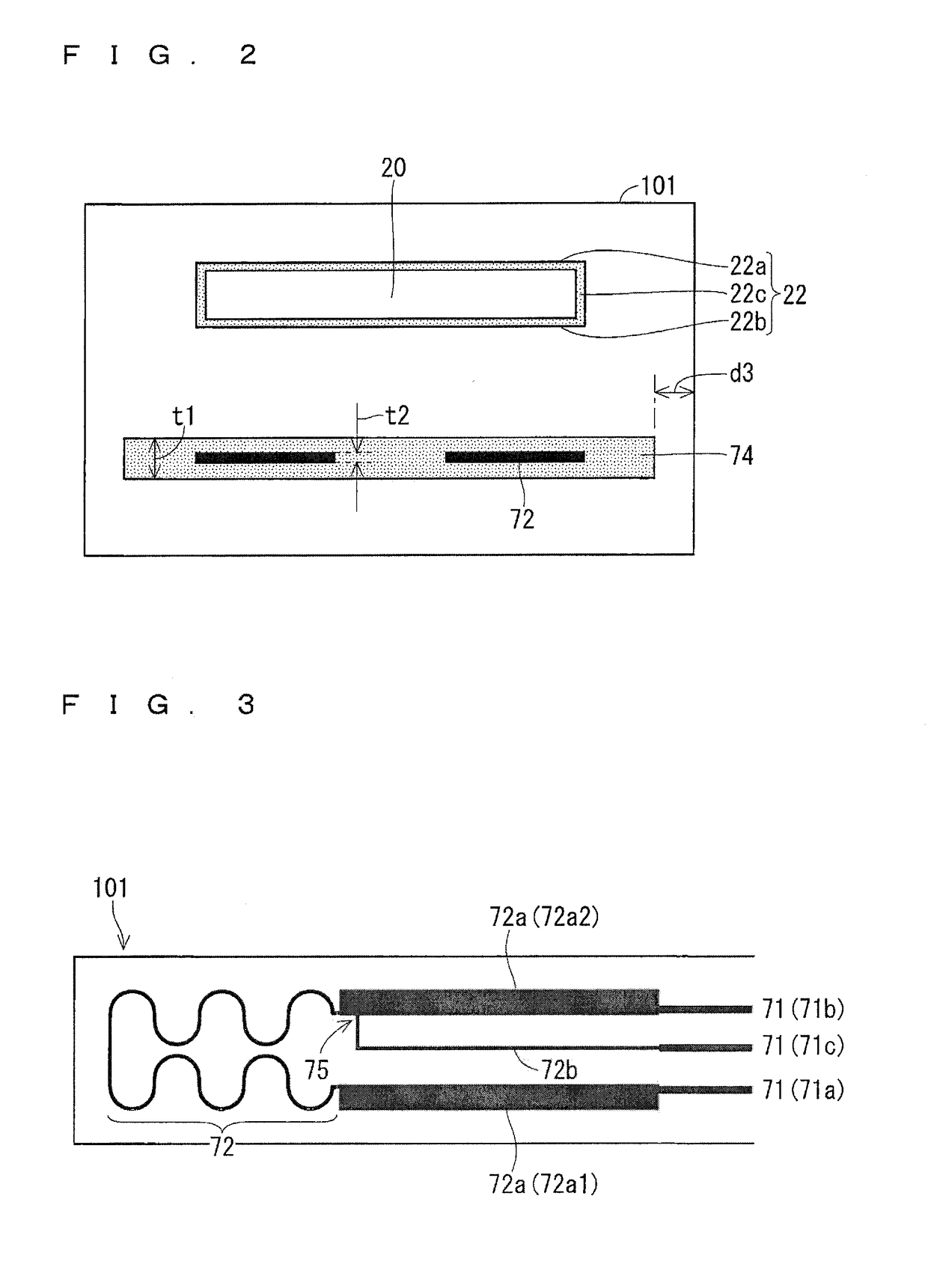

[0119]A total of 21 types (all Examples and all Comparative Examples) of sensor elements 101 having different combinations of conditions to manufacture the insulating paste for forming the heater insulating layer 74, the porosity of the heater insulating layer 74, and the dimensions at the six locations of the sensor element 101 directed to the sensor element dimensional conditions (the thickness t1 of the heater insulating layer 74, the thickness t2 of the heater element 72, the end portion distance d1, the thickness direction distance d2, the side portion distance d3, and the total length L of the sensor element 101) were manufactured. For each of the sensor elements 101, a durability test was conducted through continuous heating using the heater part 70 for a long period of time, and the state after the test was evaluated.

[0120]As for the conditions to manufacture the insulating paste, a material species of Al2O3 (alumina) used as a material was set to be at two levels, and an ad...

examples 1 to 11

[0137]The material species of alumina was set to the material species “A”, and, regarding Example 1 as a reference, the porosity of the heater insulating layer 74 in Example 2 was set to have a value smaller than that in the other examples. The thickness t1 of the heater insulating layer 74 was set to be smaller in Example 3 than that in the other examples, and was set to be greater in Example 4 than that in the other examples. The thickness t2 of the heater element 72 was set to be smaller in Example 5 than that in the other examples, and was set to be greater in Example 6 than that in the other examples. The values of the end portion distance d1, the thickness direction distance d2, and the side portion distance d3 were set to be smaller in Example 7 than those in the other examples, and were set to be greater in Example 8 than those in the other examples. The value of the total length L of the sensor element 101 was set to be greater in Example 9 than that in the other examples. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com