Method of and system for hauling a marine equipment unit, a marine equipment unit and a carrier

a marine equipment and carrier technology, applied in the field of marine equipment and carrier hauling methods and systems, can solve the problem that the auv may easily crash into the hull of the carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

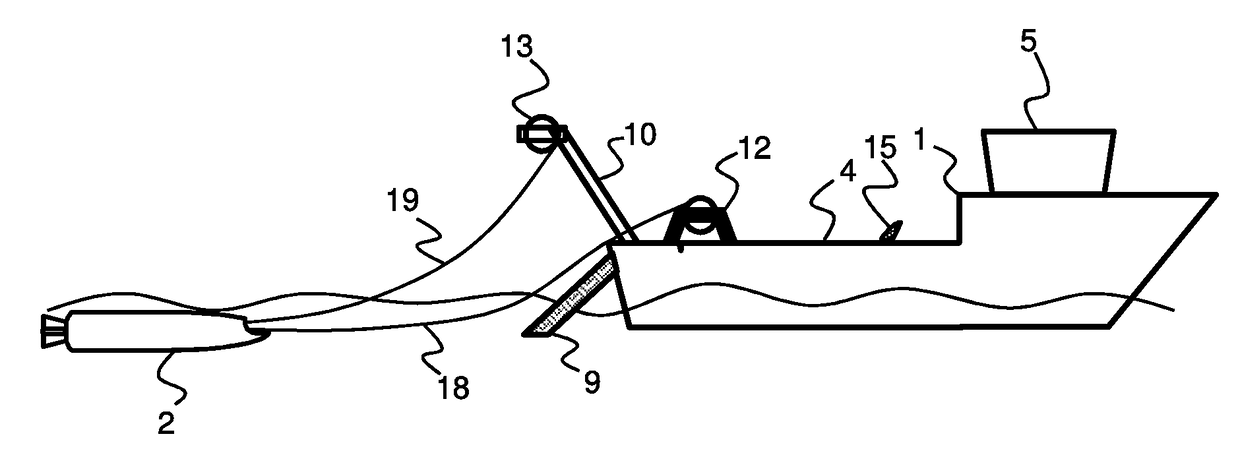

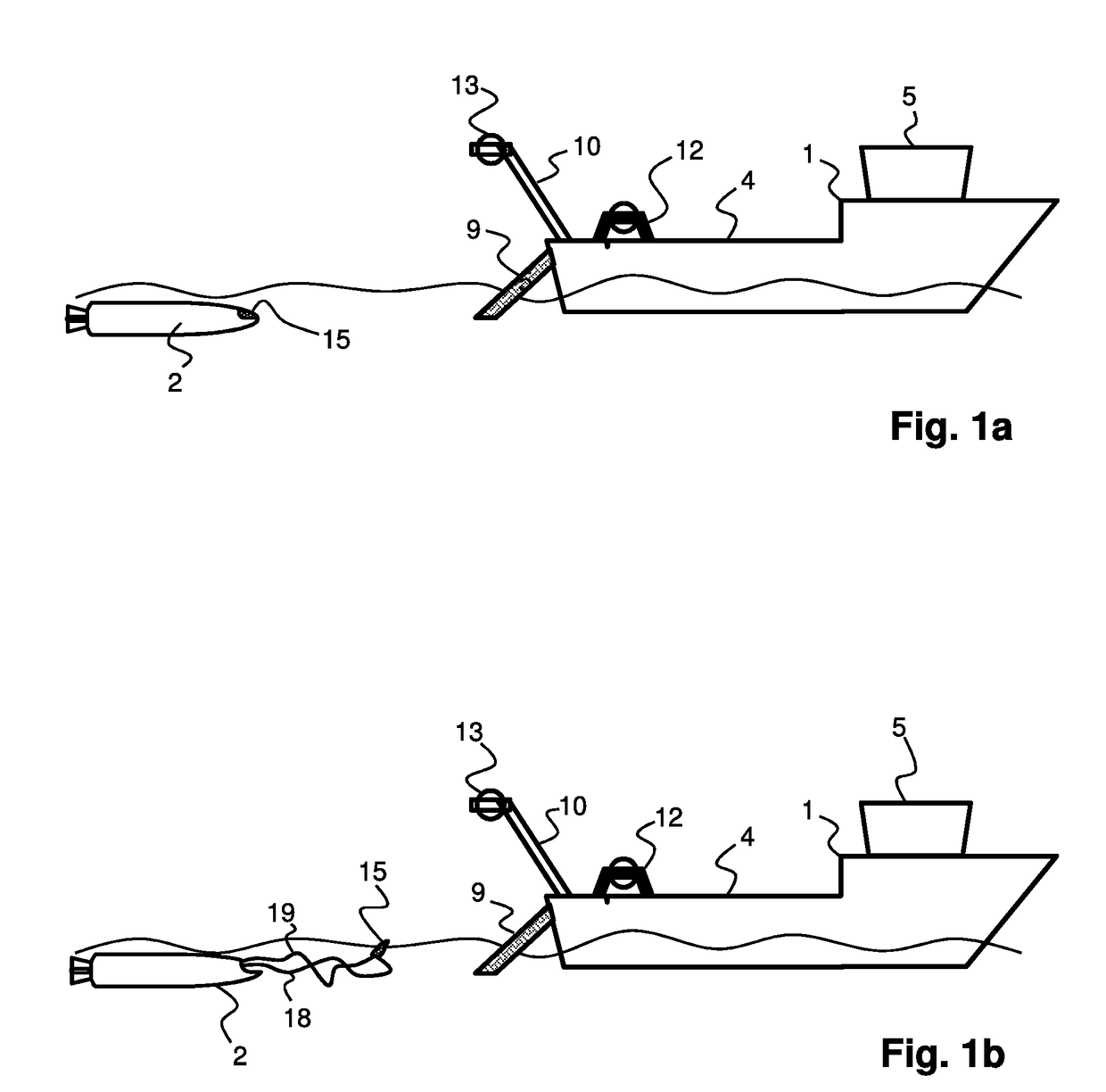

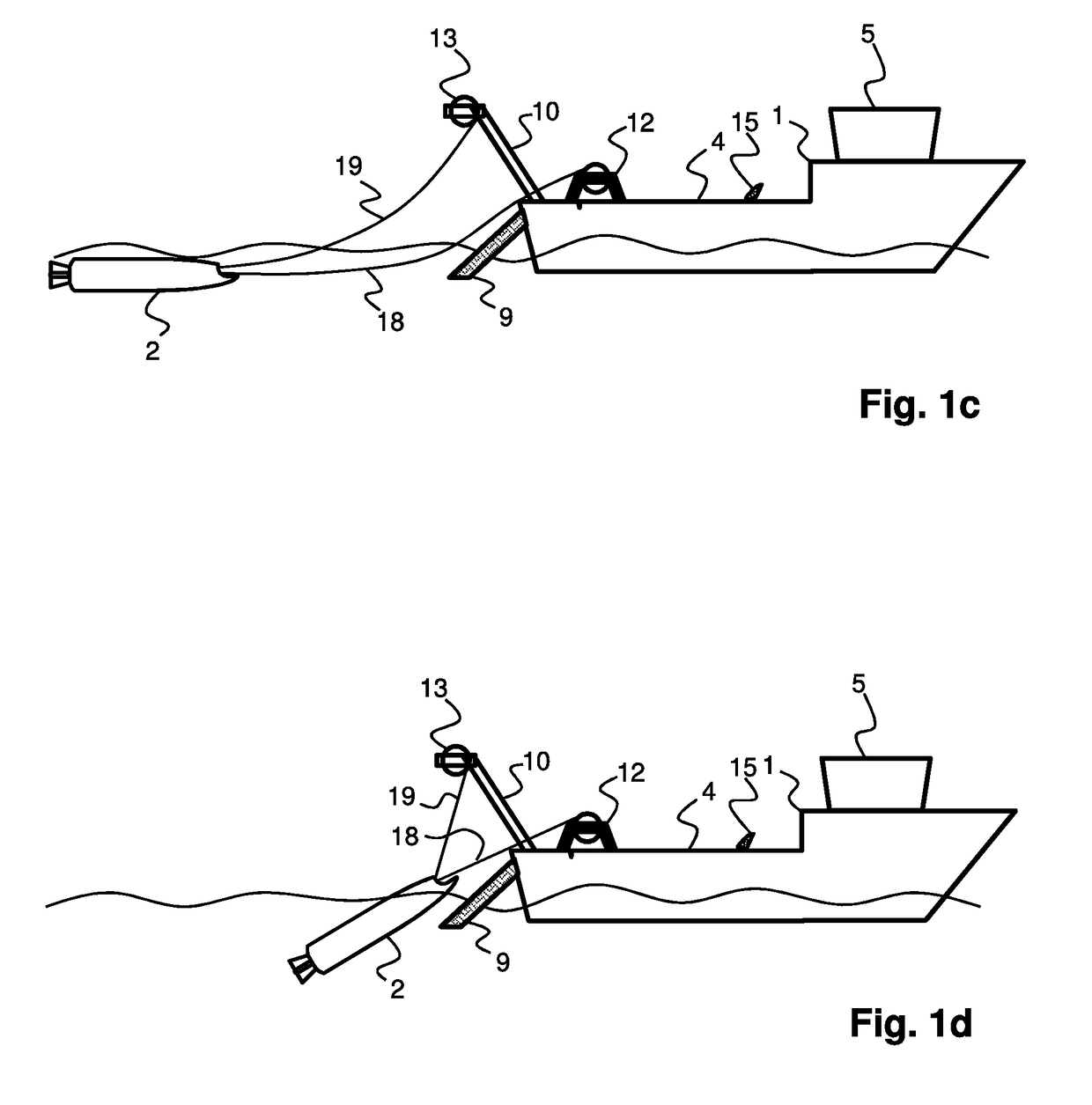

[0025]FIGS. 1A through 1D schematically illustrate a method in accordance with the present invention, for hauling an equipment unit 2 from the water onto a vessel 1. The vessel 1 has installed thereon a system for hauling equipment units such as autonomous underwater vehicles (AUV's) 2 for recovery. Autonomous underwater vehicles such as equipment unit 2 can be used for a variety of different tasks, amongst which are investigation and survey of the sea floor. For example, an AUV 2 may be used search for mining locations, wreckage, geological underwater structures (e.g. volcanoes, abysses, etc.). Other tasks that may be performed using an AUV is to perform seismic surveys of sub-bottom structures, such as to find possible locations of oil and gas fields. Moreover AUV's may be applied for all kind of defensive tasks.

[0026]To perform these tasks, the AUV 2 comprises a variety of sensor units, communication units, processing means and other sensitive equipment, which may easily be damag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com