Metal powder atomization manufacturing processes

a technology of metal powder and manufacturing process, which is applied in the direction of improving process efficiency, increasing energy efficiency, and improving flowability. it can solve the problems of clogging and/or sticking pipes, and affecting the flowability of powder in the form of agglomerates, so as to improve the flowability and facilitate the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experiment 1

[0212]Four different lots of powder were produced by plasma atomization under the same experimental conditions except for the composition of the atomization mixture contacting the heated metal source.

[0213]The atomizing gas is high purity argon (>99.997%).

[0214]In Tests 1 and 2, only the atomizing gas was used to contact the heated metal source during the atomization process.

[0215]In Test 3, air was injected to the high purity argon to form an atomization mixture of 80 ppm of air with argon. Heated metal was contacted with the atomization mixture during the atomization process.

[0216]In Test 4, O2 was injected to the high purity argon to form an atomization mixture of 50 ppm of O2 with argon. Heated metal was contacted with this second atomization mixture during the atomization process.

[0217]After contacting with the atomizing gas (Test 1 and 2) or the atomization mixture (Test 3 and 4), formed raw reactive metal powder is sieved to isolate the 15-45 μm particle size distributions.

[0...

experiment 2

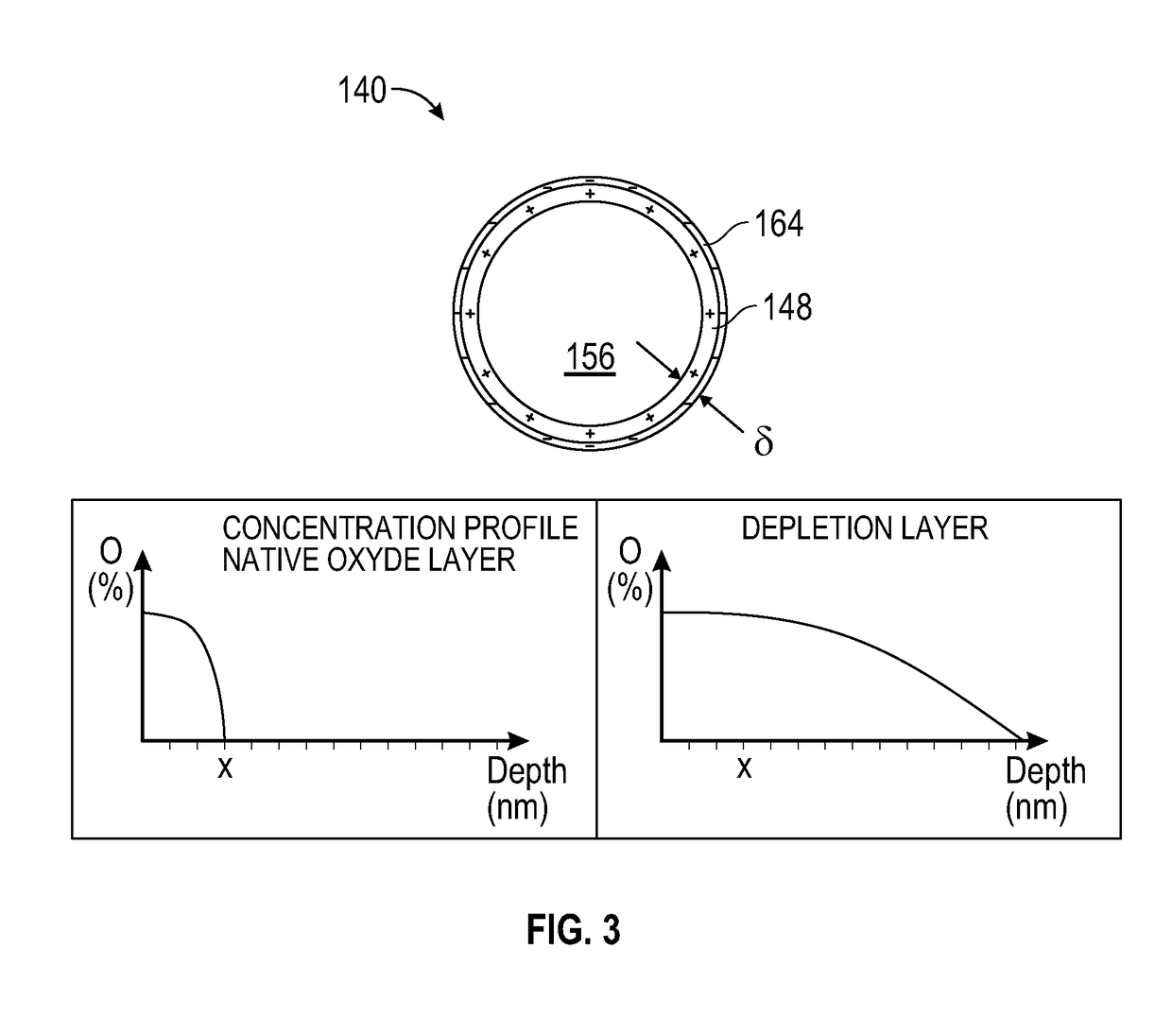

[0231]Heat treatment was performed a posteriori on already-formed metal powder that was formed from a process in which additive gas was not used.

[0232]More specifically, the already-formed metal powder was heated in air atmosphere at about 250° C. for 12 hours. It was expected that this heating would cause addition of oxygen to surface of particles of the raw metal powder and increase the thickness of the native oxide layer.

[0233]It was observed that oxidation / nitridation a posteriori did not produce a similar result to that of contacting the additive gas in the atomization zone of an atomization process. The improvement of the flowability of the metal powder was not observed.

[0234]It seems that a posteriori heating of already-formed metal powder will only thicker the native oxide layer and did not have the ability to provide a sufficient deep and depletion oxide / nitride layer on the particle. The thicker oxide layer will also remain quasi stoichiometric and will not be able to prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com