Yankee dryer cylinder operating without steam

a dryer cylinder and steam technology, applied in the field of machines, can solve the problems of reducing the surface available for heat exchange, high running costs, and large amount of steam that is needed in these types of machines, and achieve the effect of uniform heat distribution and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

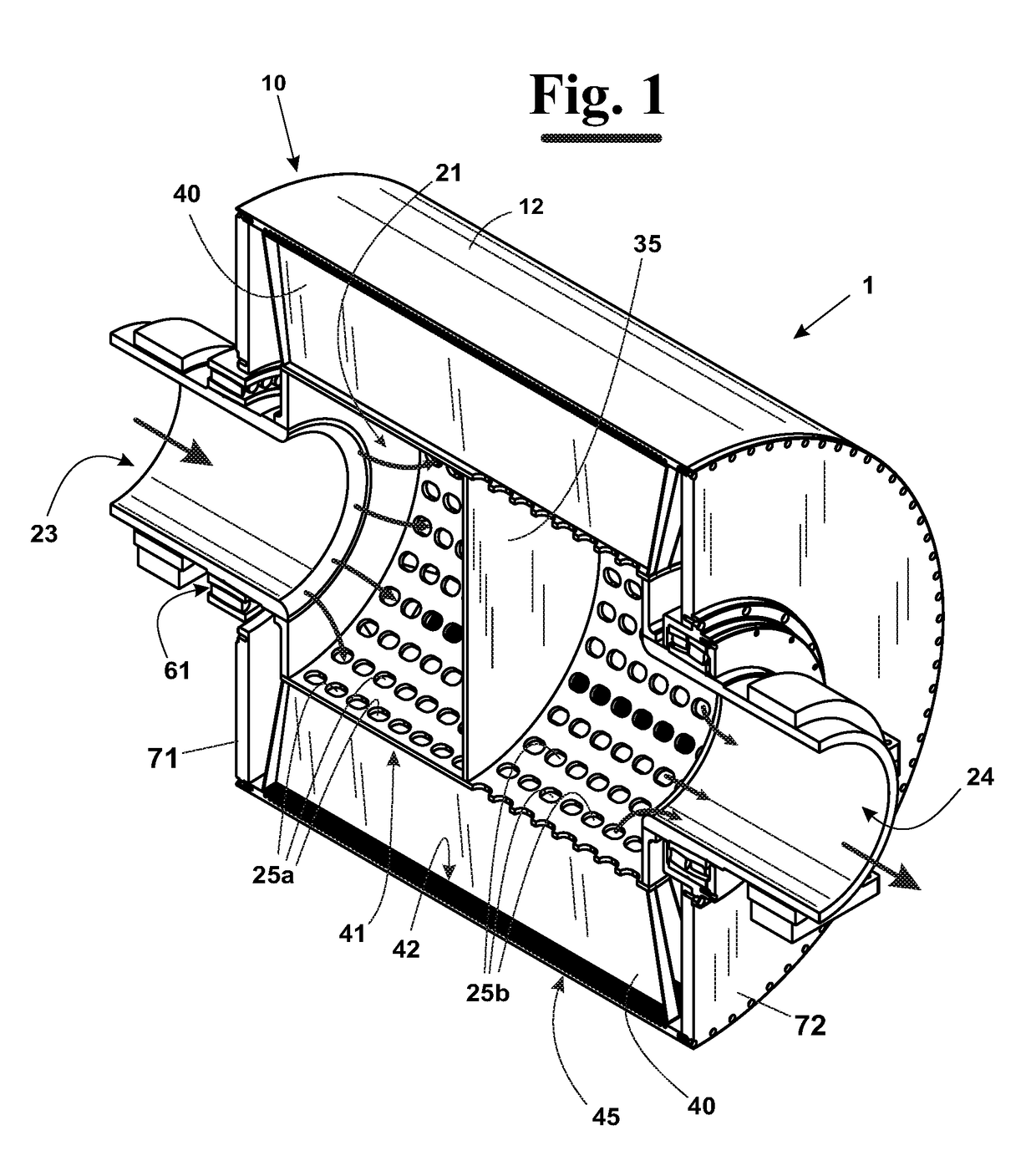

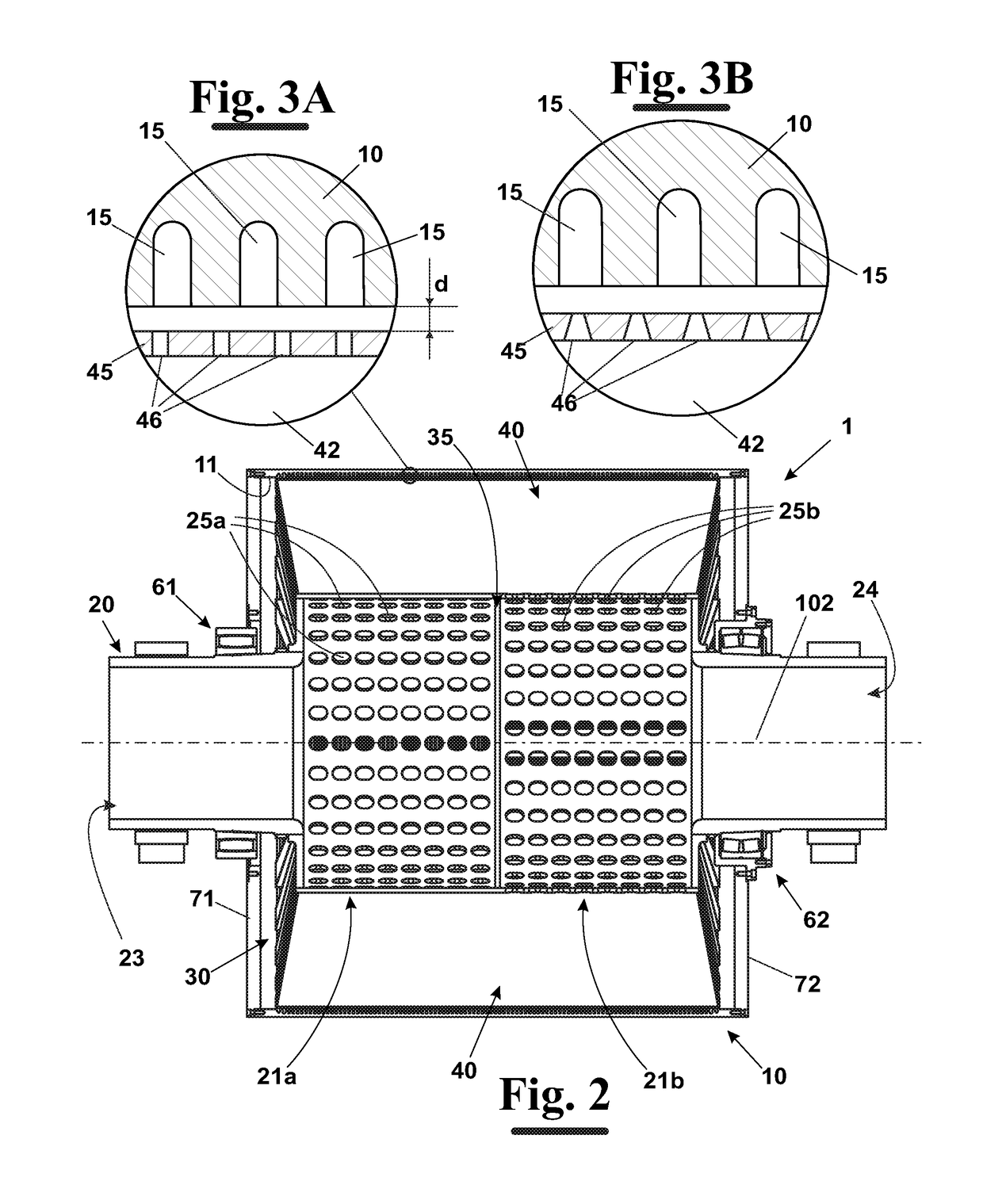

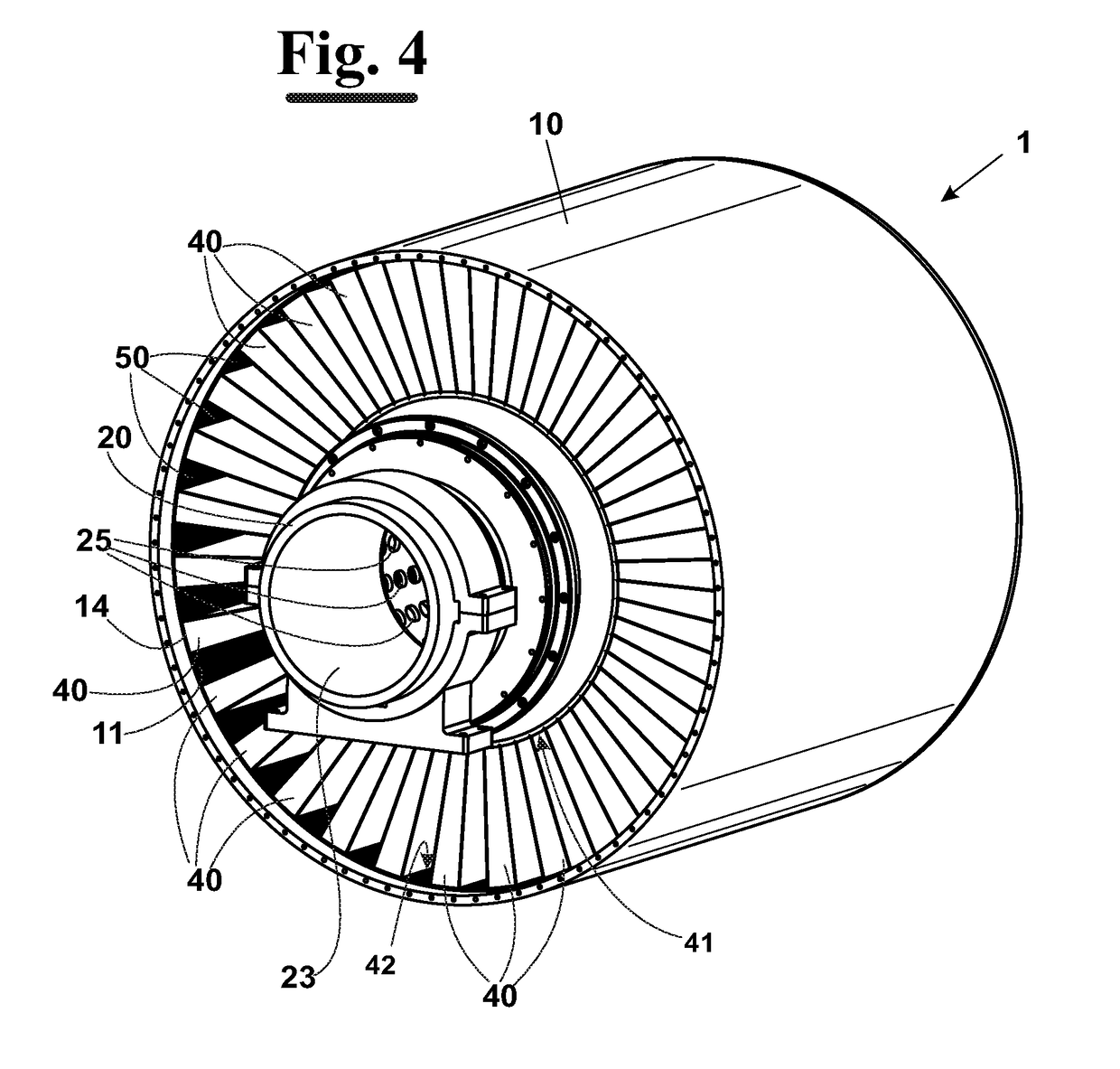

[0076]As diagrammatically shown in FIG. 1 a structure of Yankee dryer cylinder 1, according to the present invention, comprises a cylindrical shell 10 having a internal surface 11. Furthermore, a first and a second heads, or end walls, 71 and 72, are provided that are fixed at the opposite ends of the cylindrical shell 10. This latter is rotatably mounted about a fixed hollow shaft 20 having a cavity 21 and a lateral surface 22 provided with a plurality of holes 25. The fixed hollow shaft 20 is provided, in particular, with an inlet mouth 23, through which a flow of hot gas 100, preferably a flow of hot air, in particular having a temperature higher than 100° C., is fed into the cavity 21. The temperature of the hot air is advantageously less than 700° C. in order to avoid to generate too high thermoelastic stresses on the structure of cylinder 1.

[0077]The fixed hollow shaft 20 is, then, provided with an outlet mouth 24 provided at the opposite side of inlet mouth 23. Through the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com