High frequency oscillator, high frequency welding system and method for controlling the frequency using said type of high frequency oscillator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

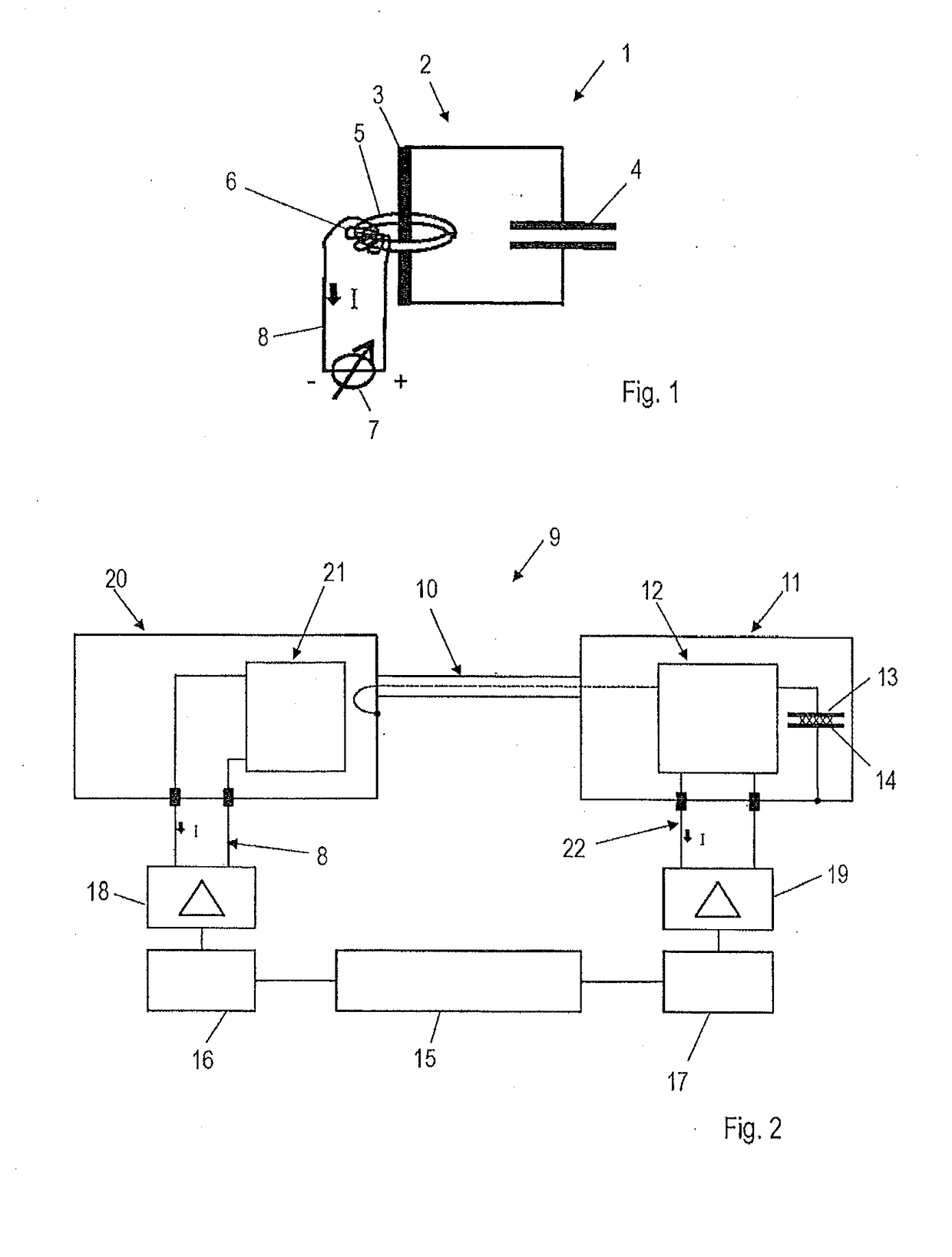

[0025]FIG. 1 shows a schematic diagram of a high frequency oscillator 1 comprising an electric resonant circuit 2. In the electric resonant circuit 2, the electronic component 3 that provides an inductance L is a coil. In addition, the resonant circuit comprises a capacitor 4 having a capacitance C. In its structural principle, the resonant circuit is a conventional LC resonant circuit. In this example, the electronic component 3 is designed as a coil with at least one copper tube. However, it is also possible to provide several coils as well as several capacitors.

[0026]The electronic component 3 is passed through a ring 5 made of a ferromagnetic material, around which a magnetic coil 6 is wound. The magnetic coil 6 is integrated in a control circuit 8 that comprises a controllable direct current source 7.

[0027]Through appropriate actuation of the direct current source 7, the magnetic coil 6 generates a magnetic field, which is superimposed on the field of the electronic component 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical inductance | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

| Electric impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com