Frame for polymeric pistol with metal rail

a polymeric pistol and metal rail technology, applied in the direction of pistols, breech mechanisms, weapons components, etc., can solve the problems of malfunctions, functional failures, and gaps between the assembled internal parts, and achieve the effect of preventing high-temperature heat, ensuring the structural soundness of firearms, and ensuring the accuracy rate of bullets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Hereinafter, preferred embodiments of the invention will be described in more detail with reference to the accompanying drawings.

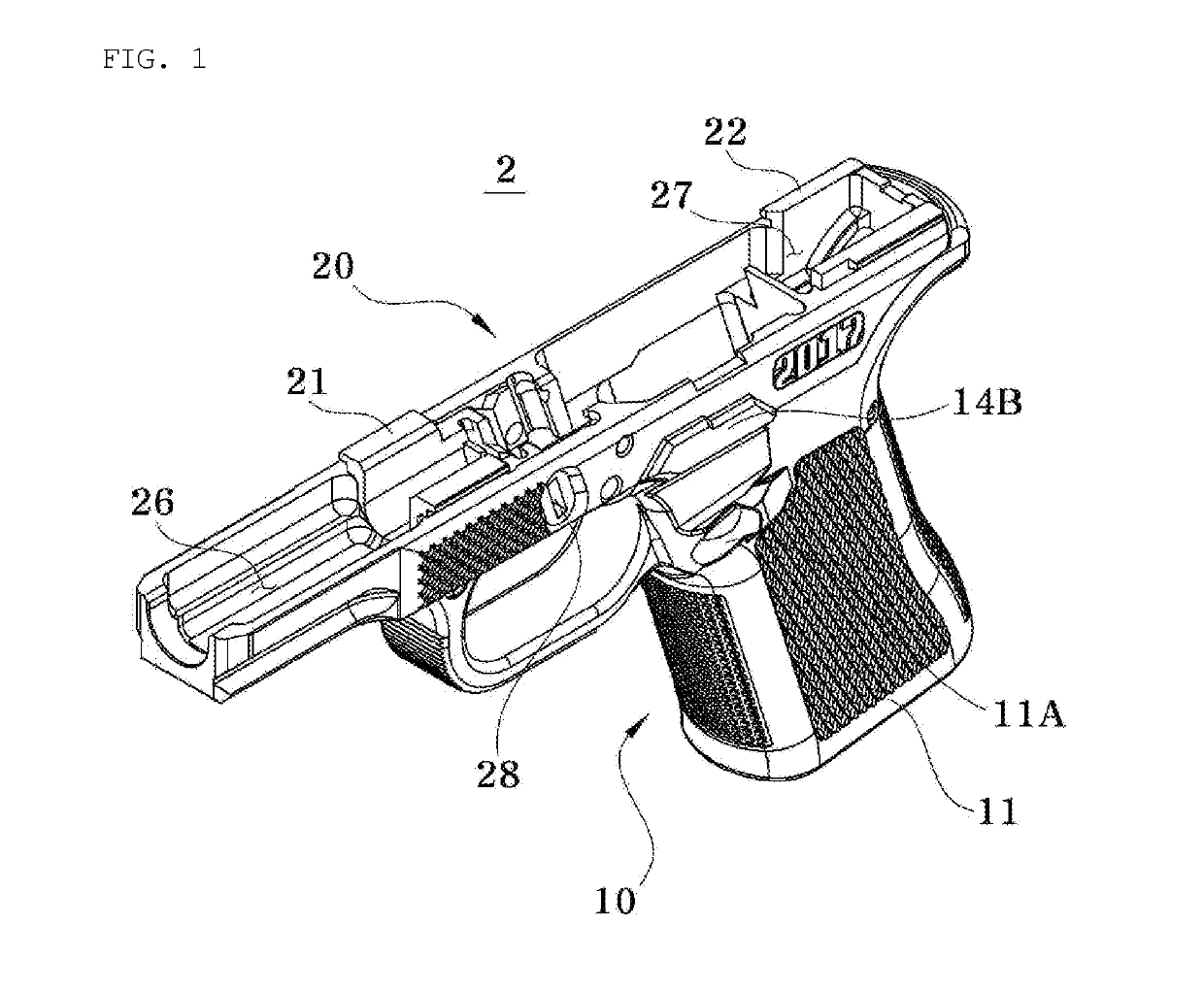

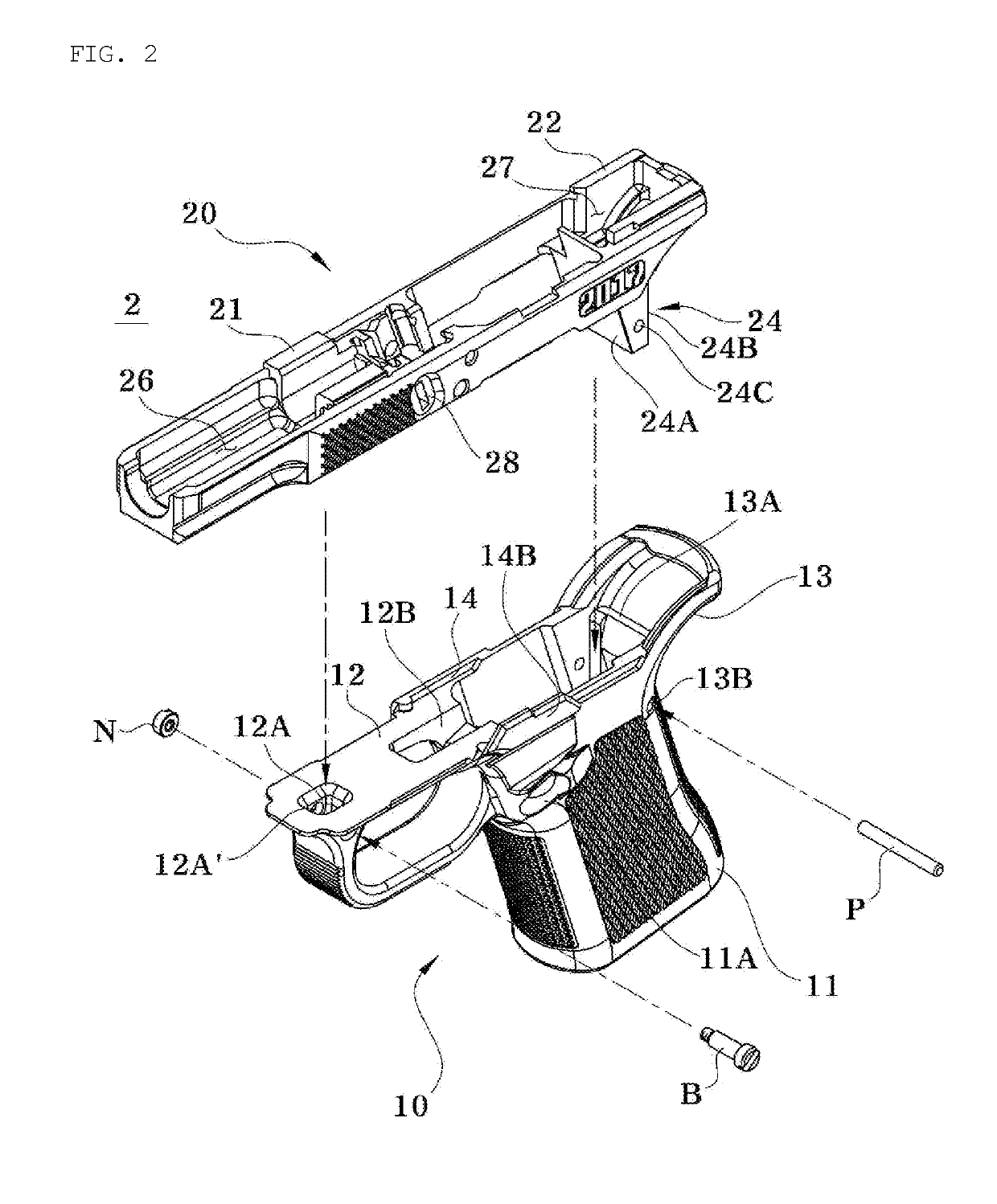

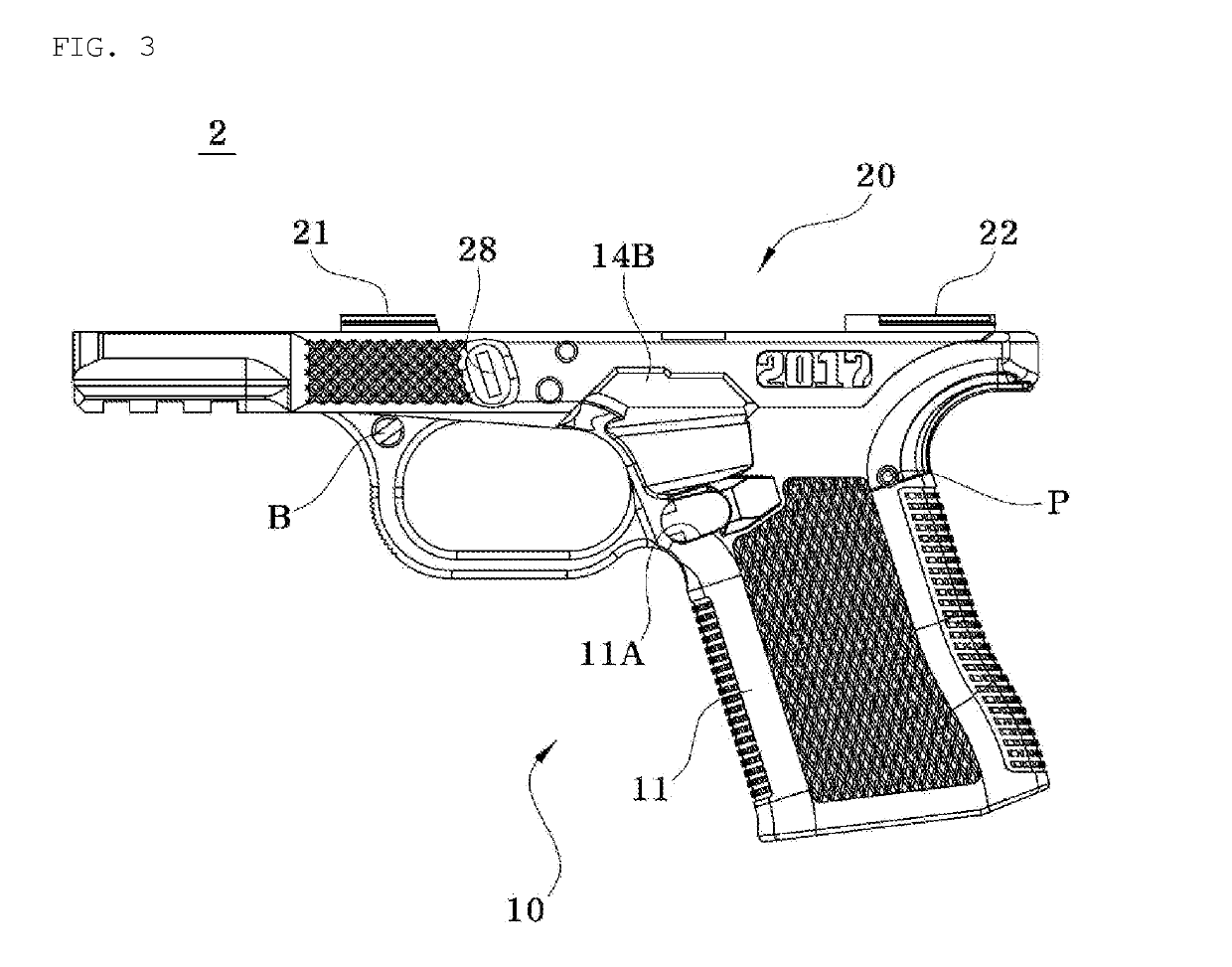

[0037]The present invention is to provide a frame for a polymeric pistol with a metal rail, capable of securing the structural soundness of firearms to secure an accuracy rate of bullet even in high-temperature environments, preventing the high-temperature heat generated in a barrel or the like from being transferred, as it is, to a handle of the frame, and disassembling and replacing components as occasion demands. As illustrated in FIGS. 1 and 2, a frame (2) according to an embodiment of the present invention includes a lower frame (10) and an upper frame (20).

[0038]The lower frame (10) is made of a reinforced plastic material by injection molding. As illustrated in FIGS. 3 and 4, the lower frame (10) has a handle (11) that allows a user to grip a pistol, and a magazine insertion hole (with no reference numeral) into which a magazine is inserted th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com