Thin film transistor substrate, liquid crystal display device including same, and method for producing thin film transistor substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

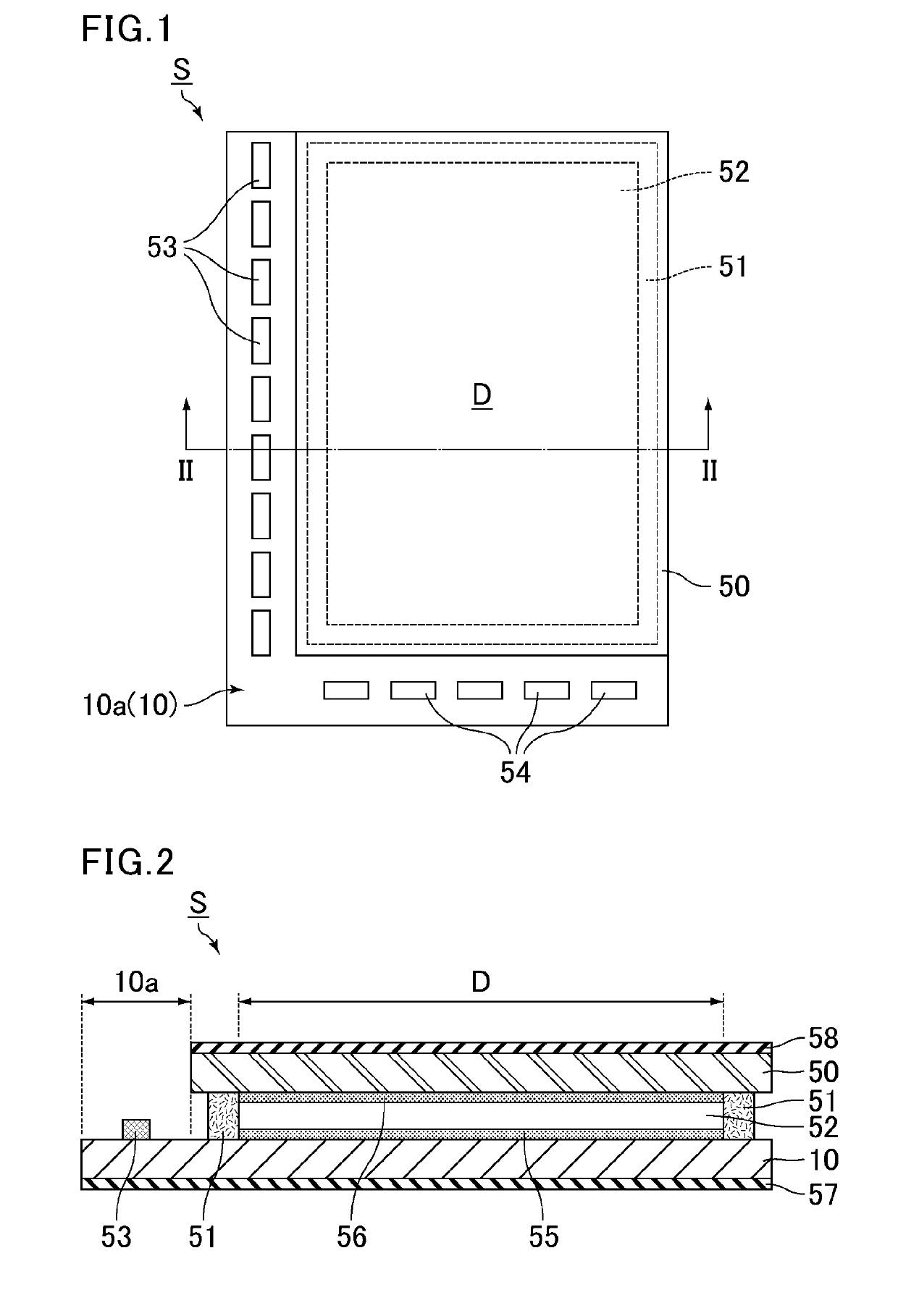

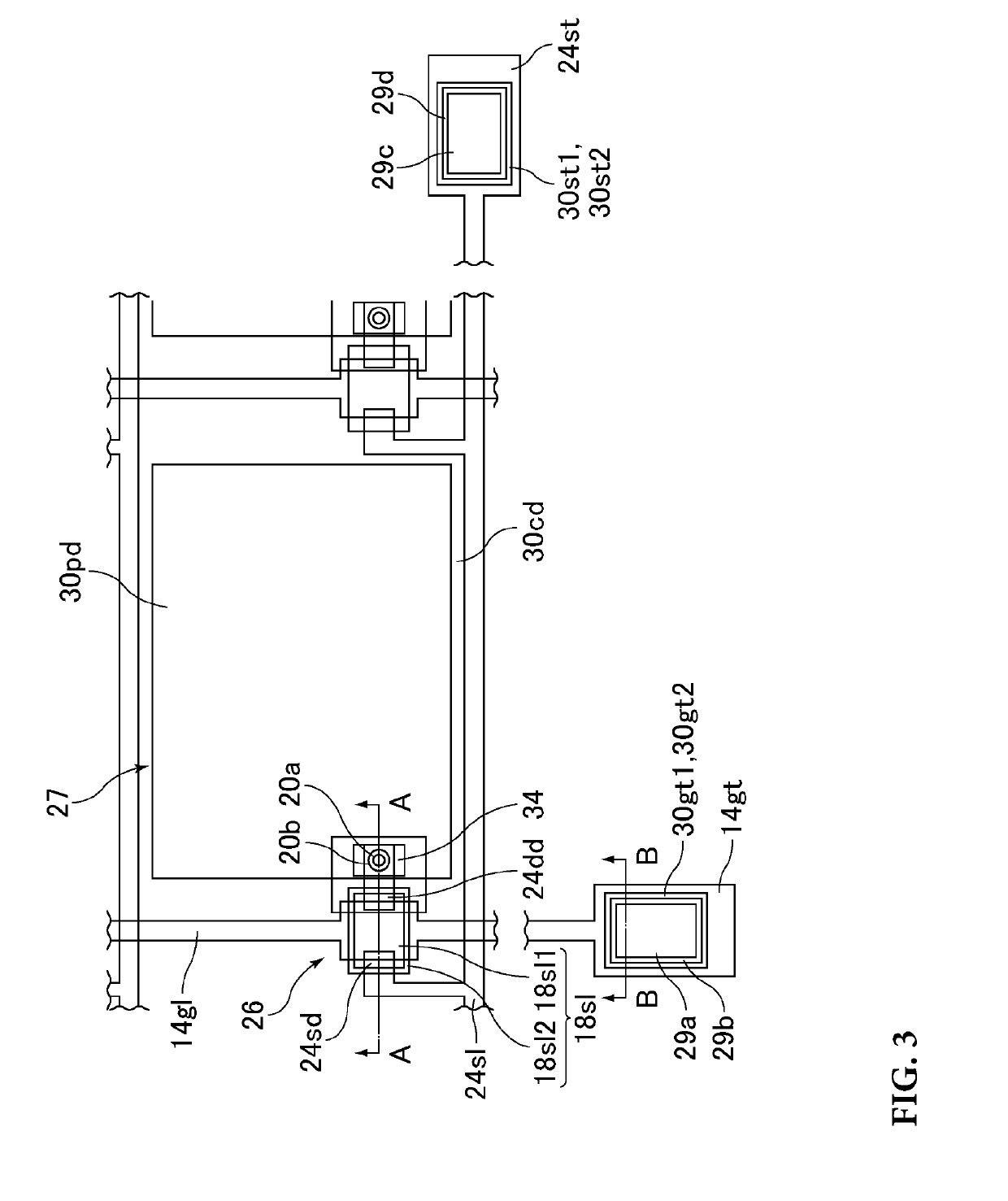

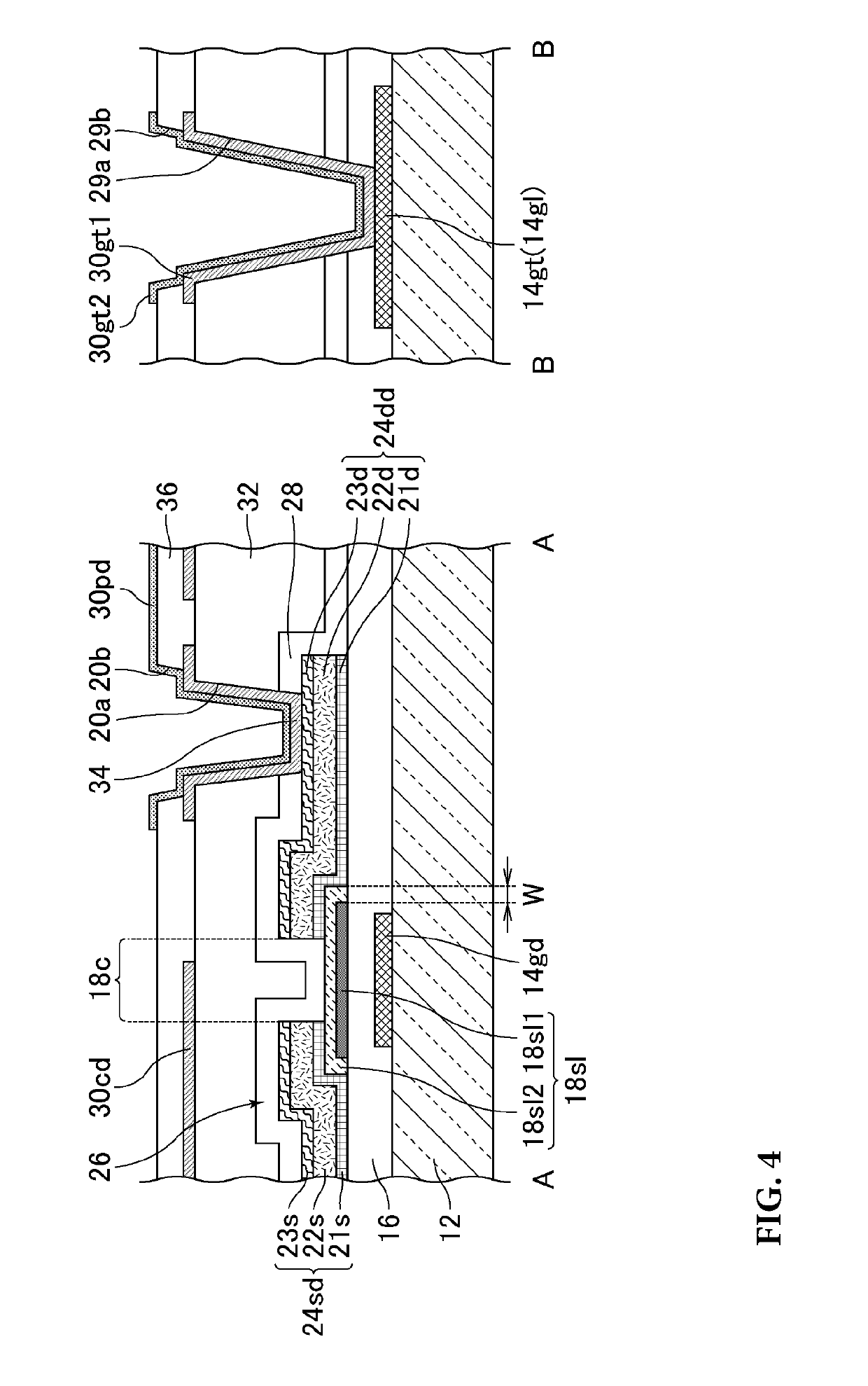

[0050]FIG. 1 is a schematic plan view of a liquid crystal display device S according to the present embodiment. FIG. 2 is a cross-sectional view illustrating a cross-sectional structure along the II-II line in FIG. 1. In FIG. 1, a polarizing plate 58 shown in FIG. 2 is omitted.

Structure of Liquid Crystal Display Device S

[0051]The liquid crystal display device S includes a TFT substrate 10 and a counter substrate 50 facing each other, a frame-shaped seal 51 bonding the peripheries of the TFT substrate 10 and the counter substrate 50, and a liquid crystal layer 52 sealed inside the seal 51 between the TFT substrate 10 and the counter substrate 50.

[0052]The liquid crystal display device S is a transmissive liquid crystal display device. The liquid crystal display device S has a display area D for image display in the region where the TFT substrate 10 and the counter substrate 50 overlap inside the seal 51, that is, the region where the liquid crystal layer 52 is formed. Outside the dis...

embodiment 2

[0105]The present embodiment mainly describes the characteristic features of the present embodiment, and omits the descriptions of the same features as those of Embodiment 1. In the present embodiment and Embodiment 1, members that exhibit the same or similar functions are donated by the same reference signs and the description of the members are omitted in the present embodiment. The present embodiment is substantially the same as Embodiment 1 except that the TFTs are etch stopper-type TFTs as described below.

Structure of TFT Substrate 10

[0106]FIG. 15 and FIG. 16 are schematic views illustrating the TFT substrate 10 according to the present embodiment. FIG. 15 is a schematic plan view illustrating one pixel and the terminal of each line. FIG. 16 includes cross-sectional views illustrating, from left to right in the figure, cross-sectional structures along the A-A line and the B-B line in FIG. 15.

[0107]In the present embodiment, as shown in FIG. 15, the TFT substrate 10 has the same...

embodiment 3

[0120]The present embodiment mainly describes the characteristic features of the present embodiment, and omits the descriptions of the same features as those of Embodiments 1 and 2. In the present embodiment and Embodiments 1 and 2, members that exhibit the same or similar functions are donated by the same reference signs and the description of the members are omitted in the present embodiment. The present embodiment is substantially the same as Embodiment 1 except that the oxide semiconductor layer is arranged inside the gate electrode.

Structure of TFT Substrate 10

[0121]FIG. 19 and FIG. 20 are schematic views illustrating the TFT substrate 10 according to the present embodiment.

[0122]FIG. 19 is a schematic plan view illustrating one pixel and the terminal of each line. FIG. 20 includes cross-sectional views illustrating, from left to right in the figure, cross-sectional structures along the A-A line and the B-B line in FIG. 19.

[0123]In the present embodiment, as shown in FIG. 19, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com