Natural fiber coated artificial turf infill

a technology of artificial turf and natural fibers, applied in the field of artificial turf, can solve the problems of reducing the heating small surface defects, and achieve the effects of improving the wear and longevity of artificial turf infill, and superior optical appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086]Like numbered elements in these figures are either equivalent elements or perform the same function. Elements which have been discussed previously will not necessarily be discussed in later figures if the function is equivalent.

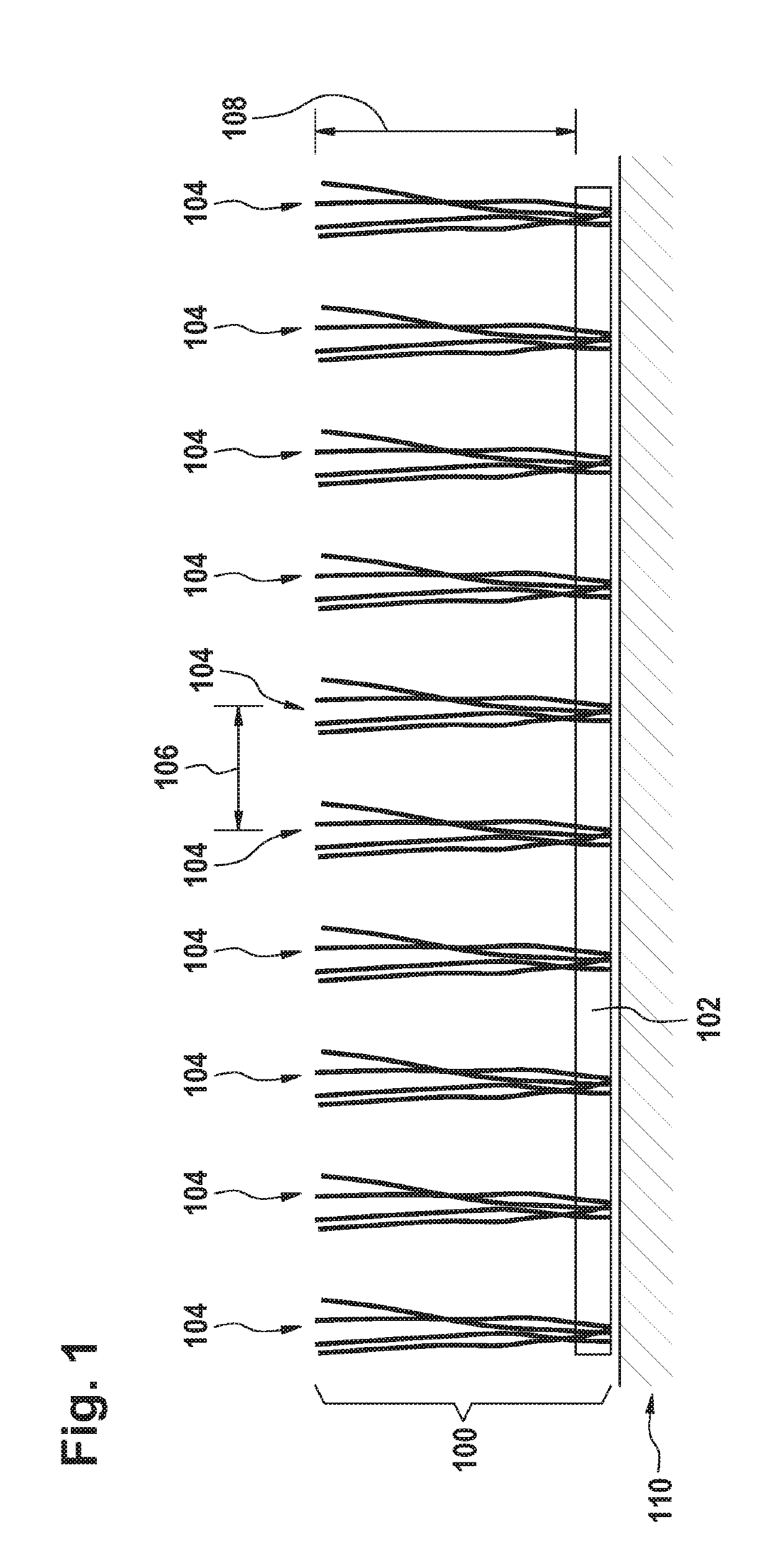

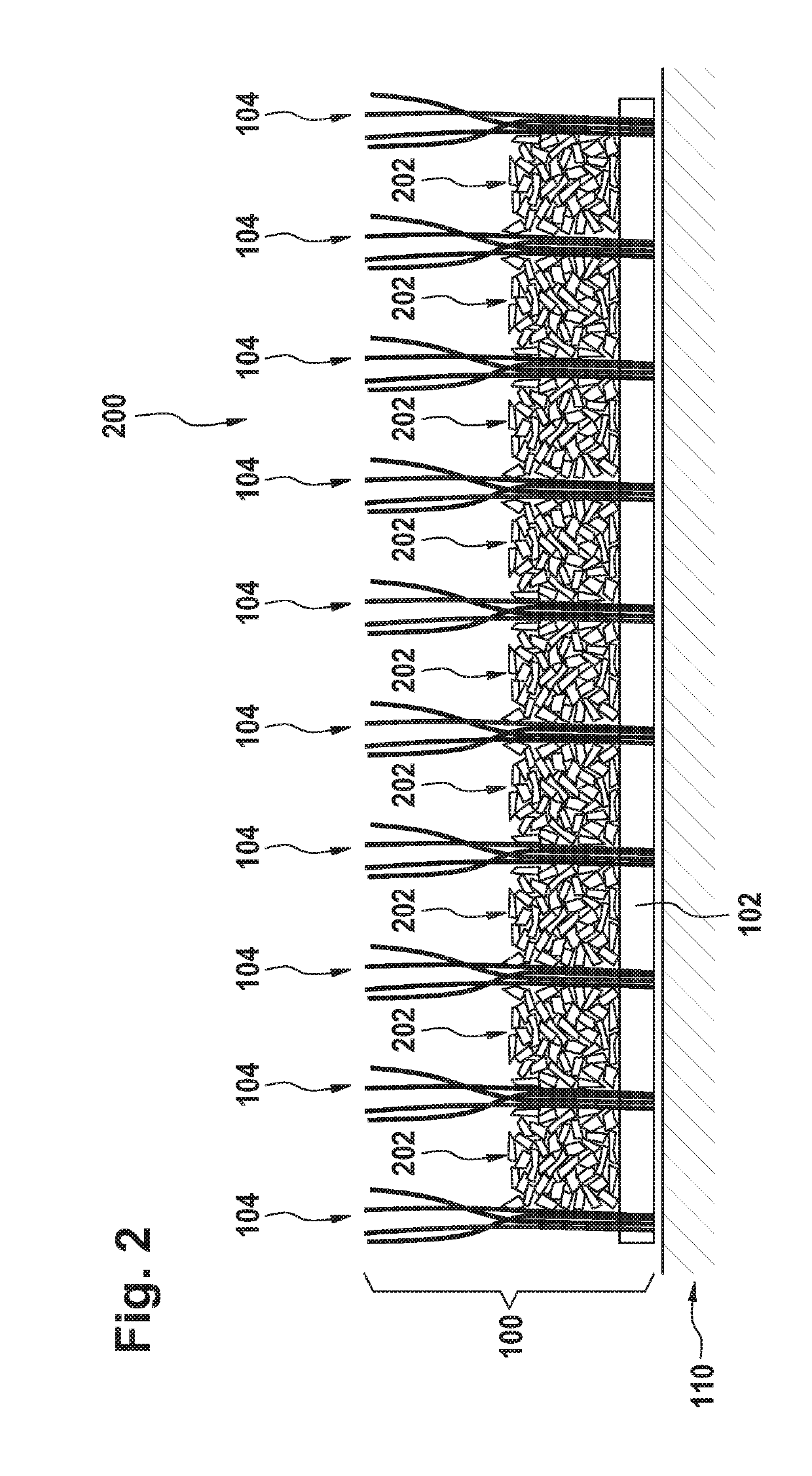

[0087]FIGS. 1 and 2 illustrate the manufacture of an artificial turf using an artificial turf carpet and artificial turf infill. In FIG. 1 an artificial turf carpet 100 can be seen. The artificial turf carpet 100 comprises a backing 102. The artificial turf carpet 100 shown in FIG. 1 is a tufted artificial turf carpet in this example. The artificial turf carpet is formed by artificial turf fiber tufts 104 that are tufted into the backing 102. The artificial turf fiber tufts 104 are tufted in rows. There is row spacing 106 between adjacent rows of tufts. The artificial turf fiber tufts 104 also extent a distance above the backing 102. The distance that the fibers 104 extend above the backing 102 is the pile height 108. In FIG. 1 it can be seen that the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com