Drop-Shaped Brush Head Assembly

a brush head and drop-shaped technology, applied in the field of brushes, can solve the problems of difficulty in controlling the operating angle of the brush, the amount of paint required, and the need to clean the paint left in the bristles frequently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

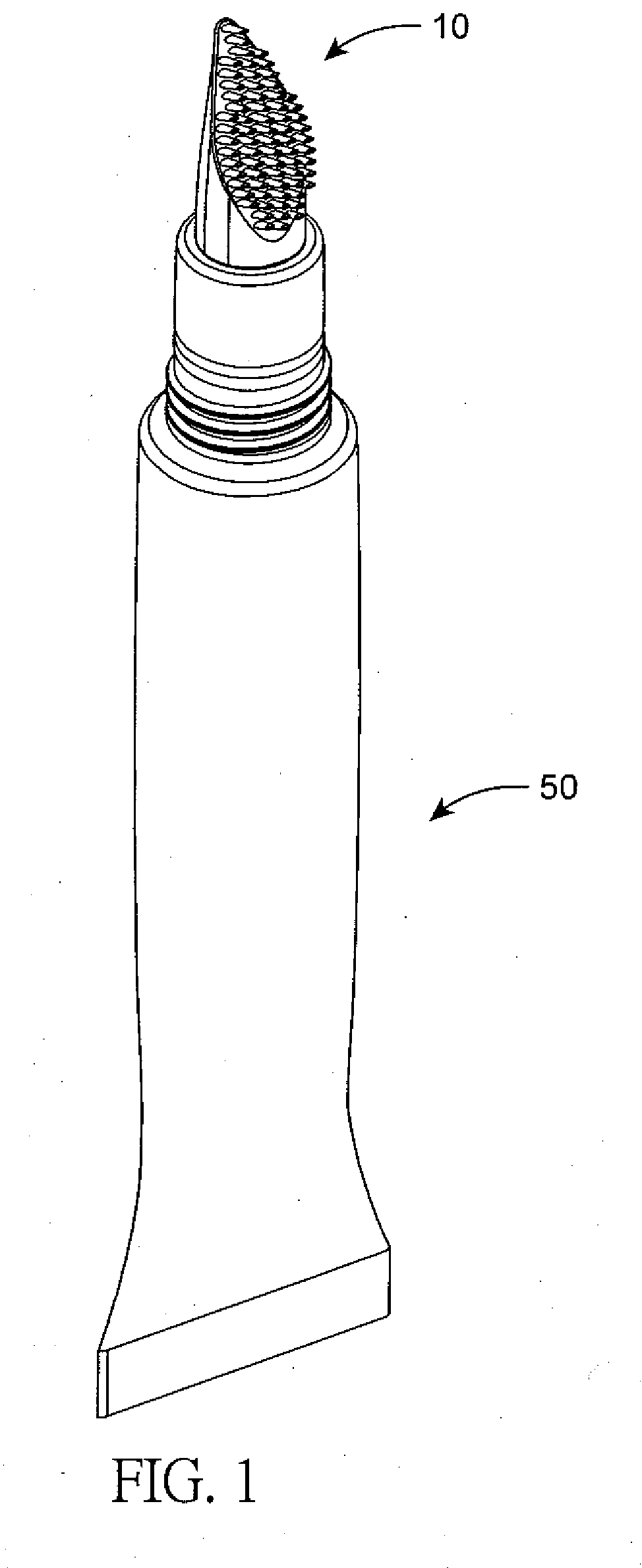

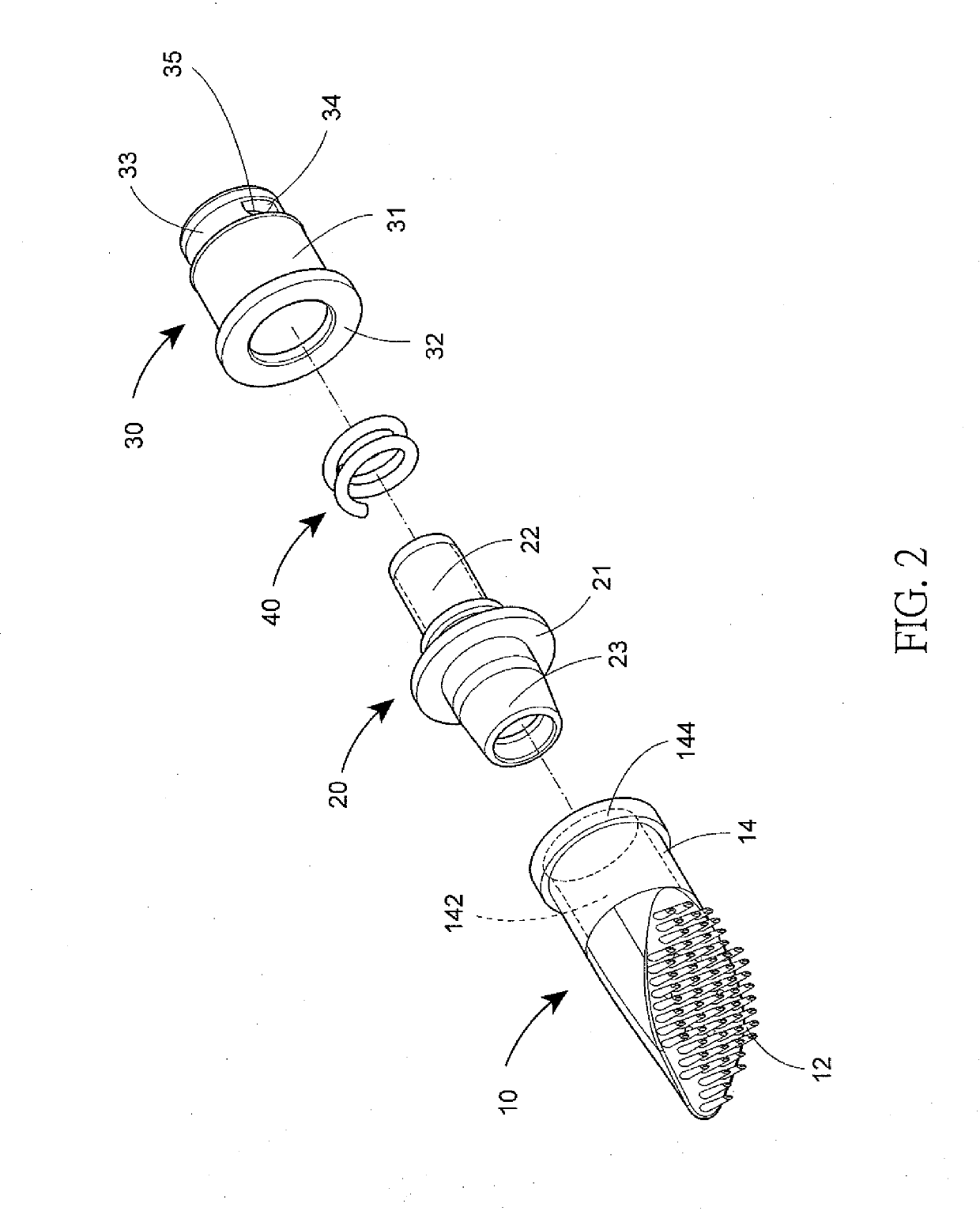

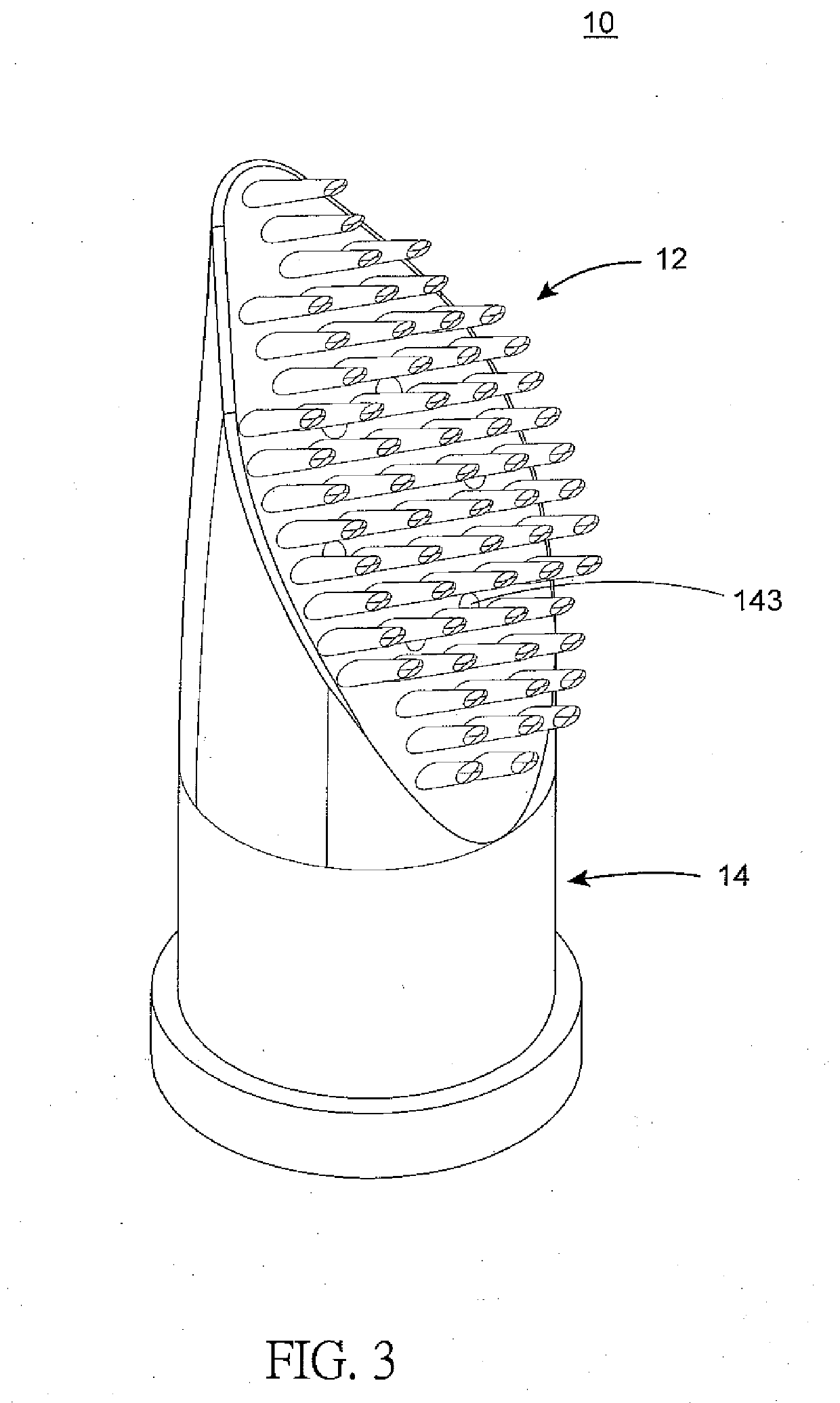

[0021]Refer to FIG. 1 and FIG. 2; a drop-shaped brush head assembly with an inclined cutting plane (oblique section plane) is revealed. The drop-shaped brush head assembly includes a drop-shaped brush head 10, a hollow piston rod 20, and a hollow sleeve 30. A mounting space 142 is arranged at the drop-shaped brush head 10 and the hollow piston rod 20 is mounted in the mounting space 142. The piston rod 20 includes a leaning portion 21, a rod body 22 extended from one end of the leaning portion 21 and a fixing portion 23 extended from and arranged at the other end of the leaning portion 21. The hollow sleeve 30 is mounted on the rod body 22 of the piston rod 20 and an elastic member 40 is disposed between the piston rod 20 and the sleeve 30. The sleeve 30 consists of a shaft body 31, a conical bottom portion 33 tapered from one end of the shaft body 31, a circular flange 32 extended outward and arranged at the other end of the shaft body 31, at least one discharge opening 34 radially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com