Solid-State Lighting With Dual Mode Operations

a solid-state lighting and dual-mode technology, applied in the direction of electroluminescent light sources, emergency power supply arrangements, transportation and packaging, etc., can solve the problems of high total cost of ownership, incompatibility between ballast identification and replacement, and large labor costs for both identification and replacemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

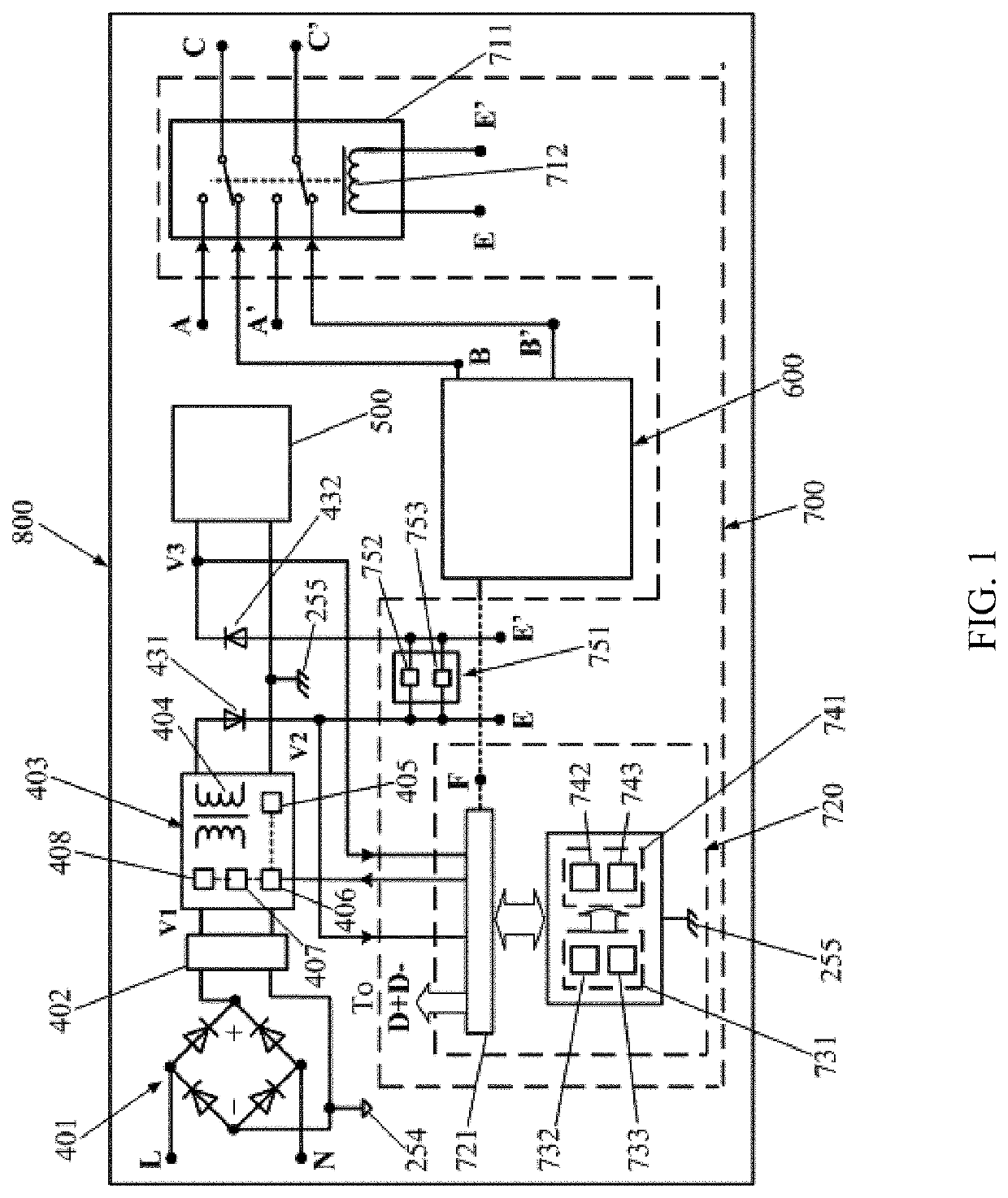

[0023]FIG. 1 is a block diagram of a luminaire power pack according to the present disclosure. The luminaire power pack 800 comprises at least two electrical conductors denoted as “L” and “N” configured to couple to alternate-current (AC) mains, a rechargeable battery 500, a full-wave rectifier 401, an input filter 402, a charging circuit 403, an LED driving circuit 600, and a line voltage detection and control circuit 700. In FIG. 1, the full-wave rectifier 401 is coupled to the AC mains and configured to convert the line voltage from the AC mains into a first DC voltage, V1, after the input filter 402. The charging circuit 403 is an isolated step-down converter and comprises a first ground reference 254, a second ground reference 255 electrically isolated from the first ground reference 254, a first transformer 404, a feedback control circuit 405, a control device 406, a first electronic switch 407, and a diode 408. The charging circuit 403 is coupled to the full-wave rectifier 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com