Vapor deposition source and vapor deposition apparatus, and method for manufacturing vapor deposition film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

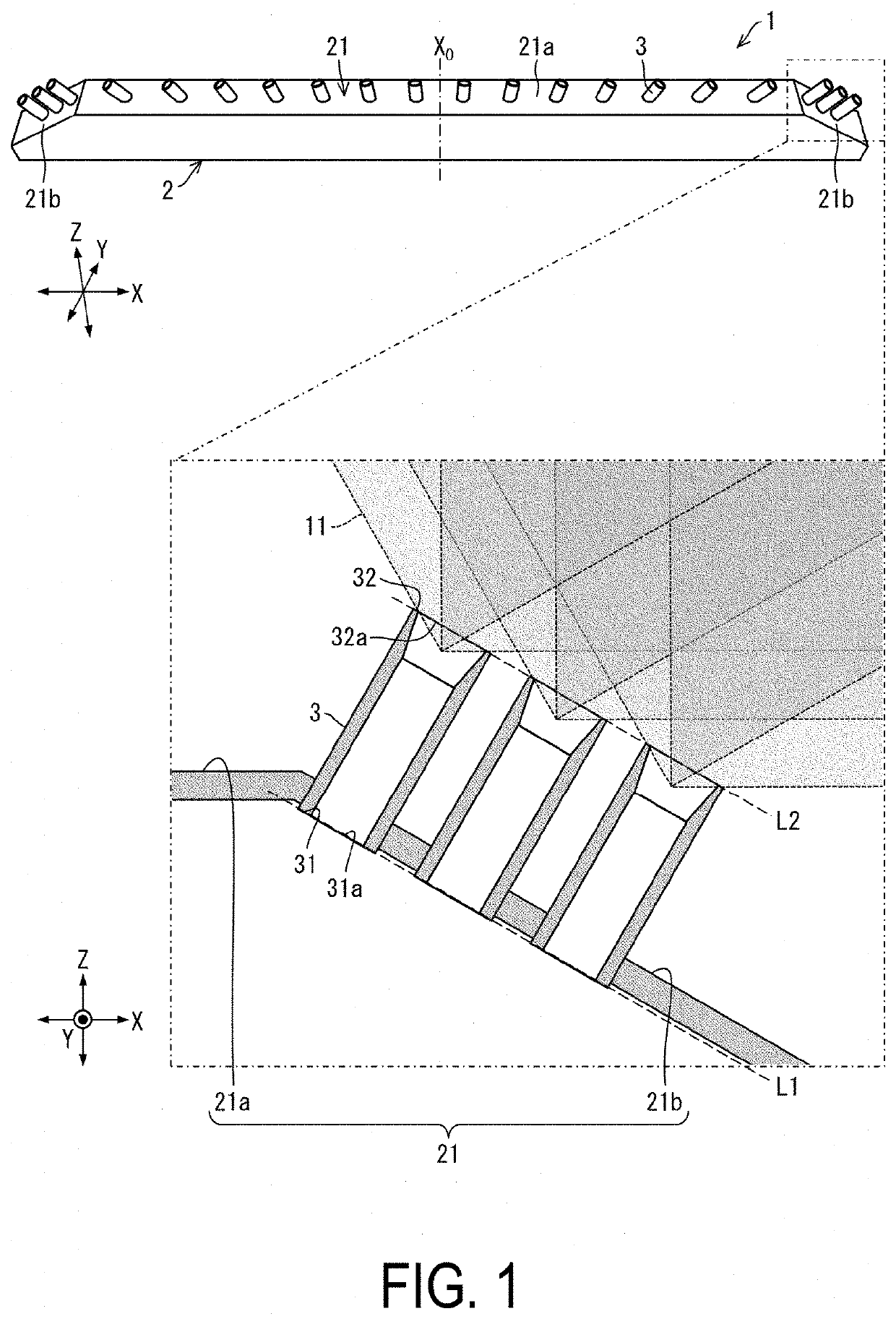

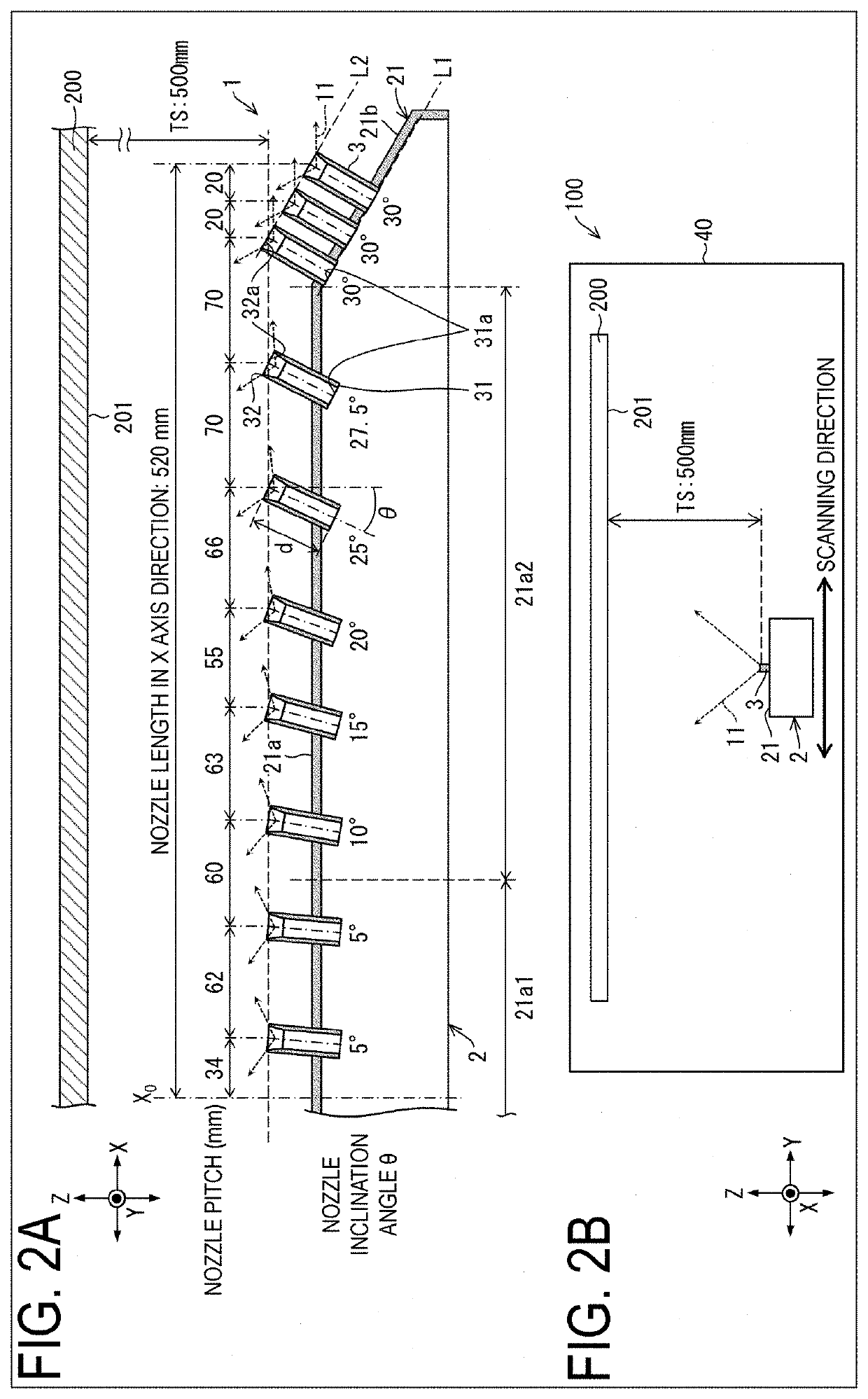

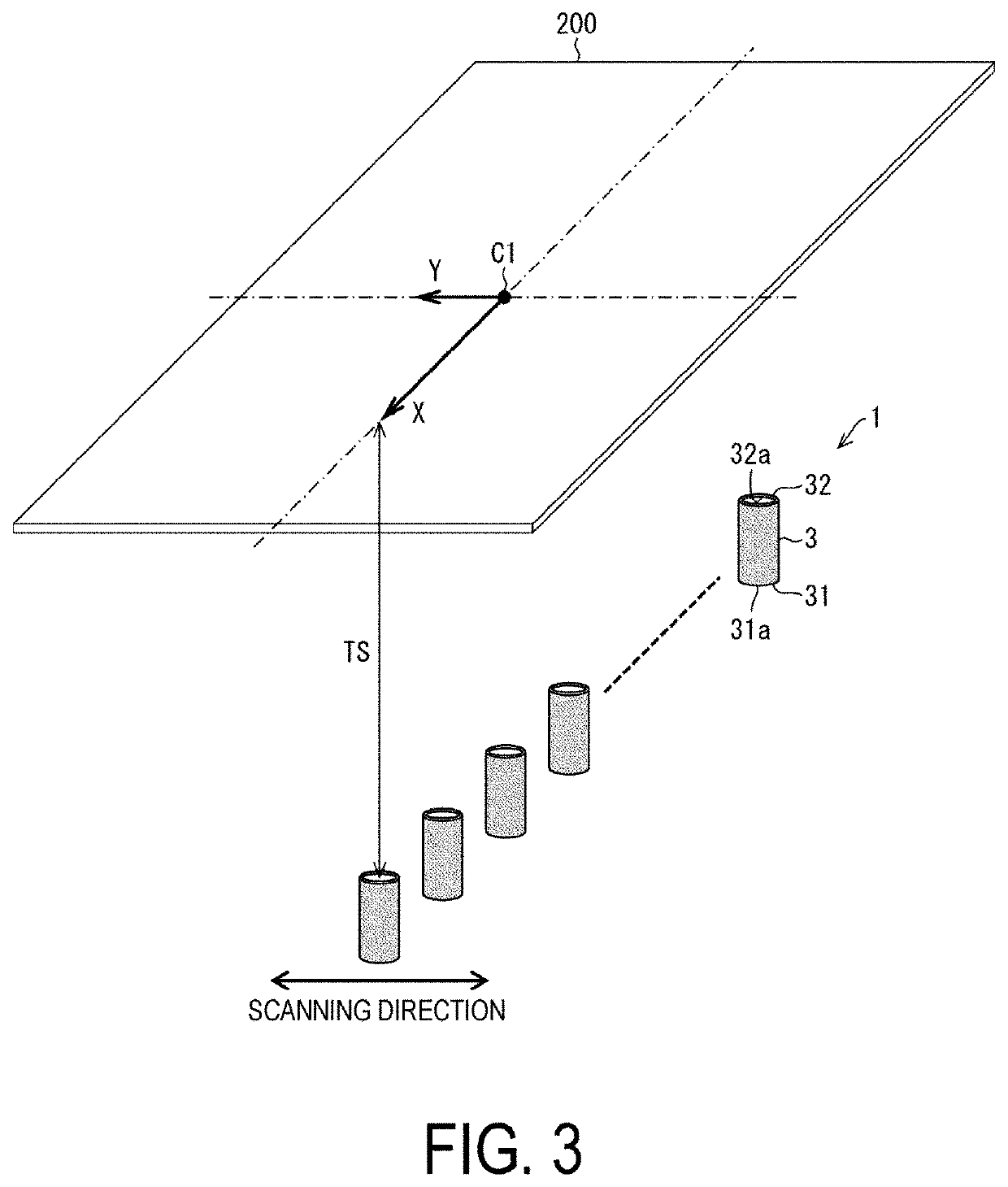

[0025]An embodiment of the disclosure will be described below with reference to FIGS. 1 to 5.

[0026]FIG. 1 is a perspective view illustrating in a partially enlarged manner, an outline configuration of a vapor deposition source 1 according to the first embodiment in conjunction with spread of vapor deposition particles ejected from the vapor deposition source 1. FIG. 2A is a cross-sectional view illustrating an outline configuration of a main portion of the vapor deposition source 1 according to the first embodiment in conjunction with an example of dimensions of the main portion and a film formed substrate 200, and FIG. 2B is a cross-sectional view illustrating an outline configuration of a main portion of a vapor deposition apparatus 100 including the vapor deposition source 1 according to the first embodiment.

[0027]Hereinafter, description will be given, assuming that a horizontal axis direction being an arrangement direction of nozzles 3 in the vapor deposition source 1 and exten...

first modified example

[0067]Note that in the first embodiment, the case where the nozzles 3 are provided in a row in a line form (that is, on an identical axis) on the upper face 21 of the containing unit 2 is describe as an example. However, the first embodiment is not limited to this case. The nozzles 3 may be provided in multiple rows in a line form.

second modified example

[0068]In addition, in the first embodiment, the case where the vapor deposition film serves as, for example, a function film in an organic EL element (Organic Light-Emitting Diode: OLED) is describe as an example. However, the first embodiment is not limited to this case. The vapor deposition film may serve as, for example, a function film in an inorganic light-emitting diode element (inorganic EL element) or a Quantum-dot Light Emitting Diode (QLED) element. The vapor deposition source 1 may be used generally for film formation (manufacturing) of a vapor deposition film.

[0069]The vapor deposition source 1 and the vapor deposition apparatus 100 can be used suitably, for example, as a manufacturing apparatus of an EL display device such as an organic EL display device including an Organic Light-Emitting Diode (OLED) element, and an inorganic EL display device including an inorganic light-emitting diode element, and a QLED display device including a QLED element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com