Core-sheath composite fiber and method for producing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

[0023]Next, a core-sheath structured filament according to an embodiment of the present invention will be described.

[0024]It is to be noted that the present invention is not limited only to the following embodiment.

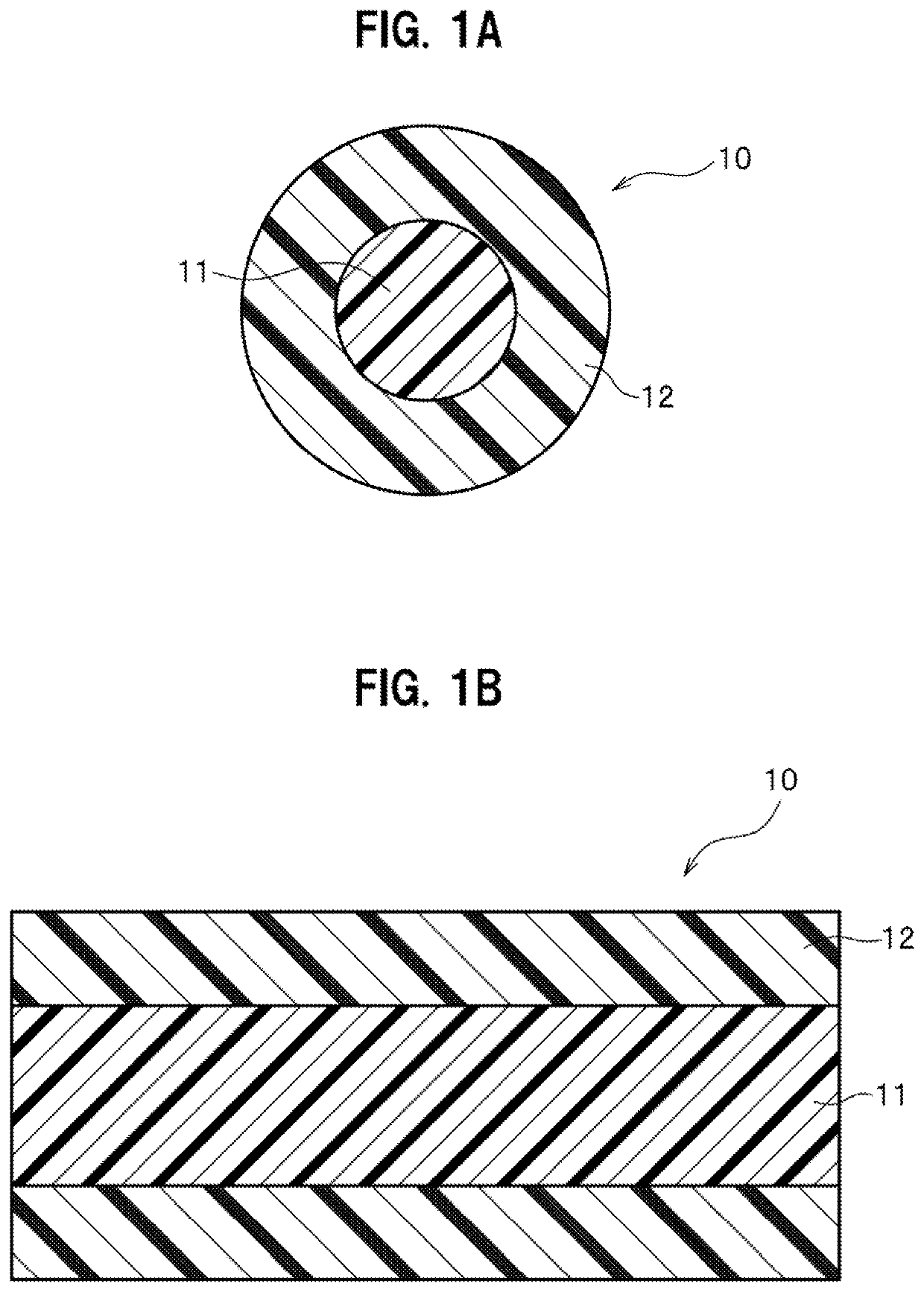

Core-Sheath Structure

[0025]FIG. 1A illustrates a transverse sectional view showing a round cross-section of a core-sheath composite fiber 10 of this embodiment, and FIG. 1B illustrates a vertical sectional view showing a cross-section in a long-side direction of the core-sheath composite fiber 10 of this embodiment.

[0026]The core-sheath composite fiber 10 of this embodiment includes a core member 11, and a sheath member 12 that is wrapped around the core member 11. The core-sheath composite fiber 10 is formed by extrusion. Each of the core member 11 and the sheath member 12 of this embodiment has an external shape with a round cross-section. Note that the external shape of the core member is not limited to such a round cross-section but may be an irregular cross-section p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com