Singlehandedly operated dispenser for rolled sheets of paper

a dispenser and single-handed technology, applied in domestic applications, thin material handling, transportation and packaging, etc., can solve the problems of inconvenient and impractical applications utilizing electronically controlled dispensing operations, failure to solve whole problems, and failure to separate materials in unperturbed ways, so as to improve the interaction of paper surfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

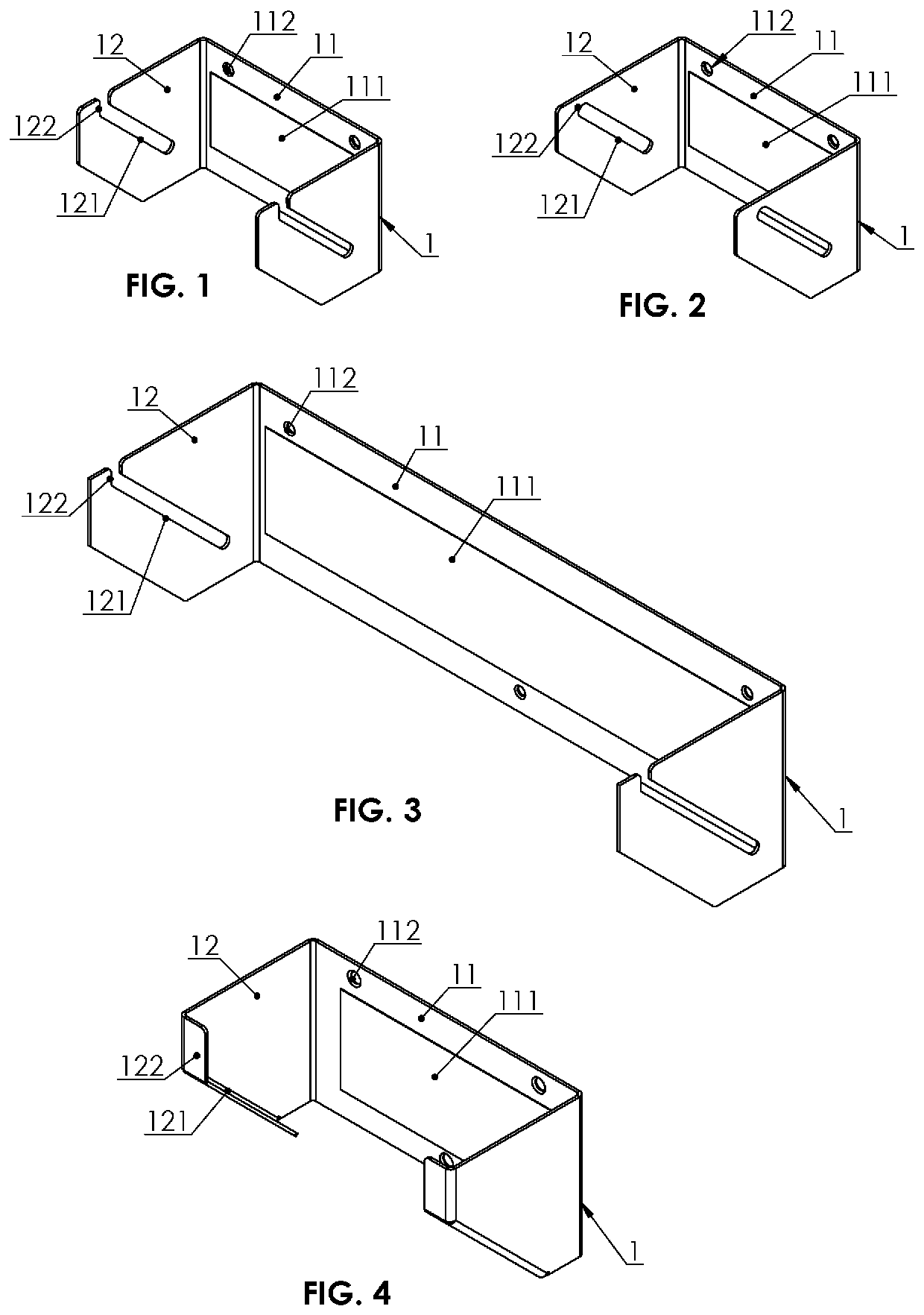

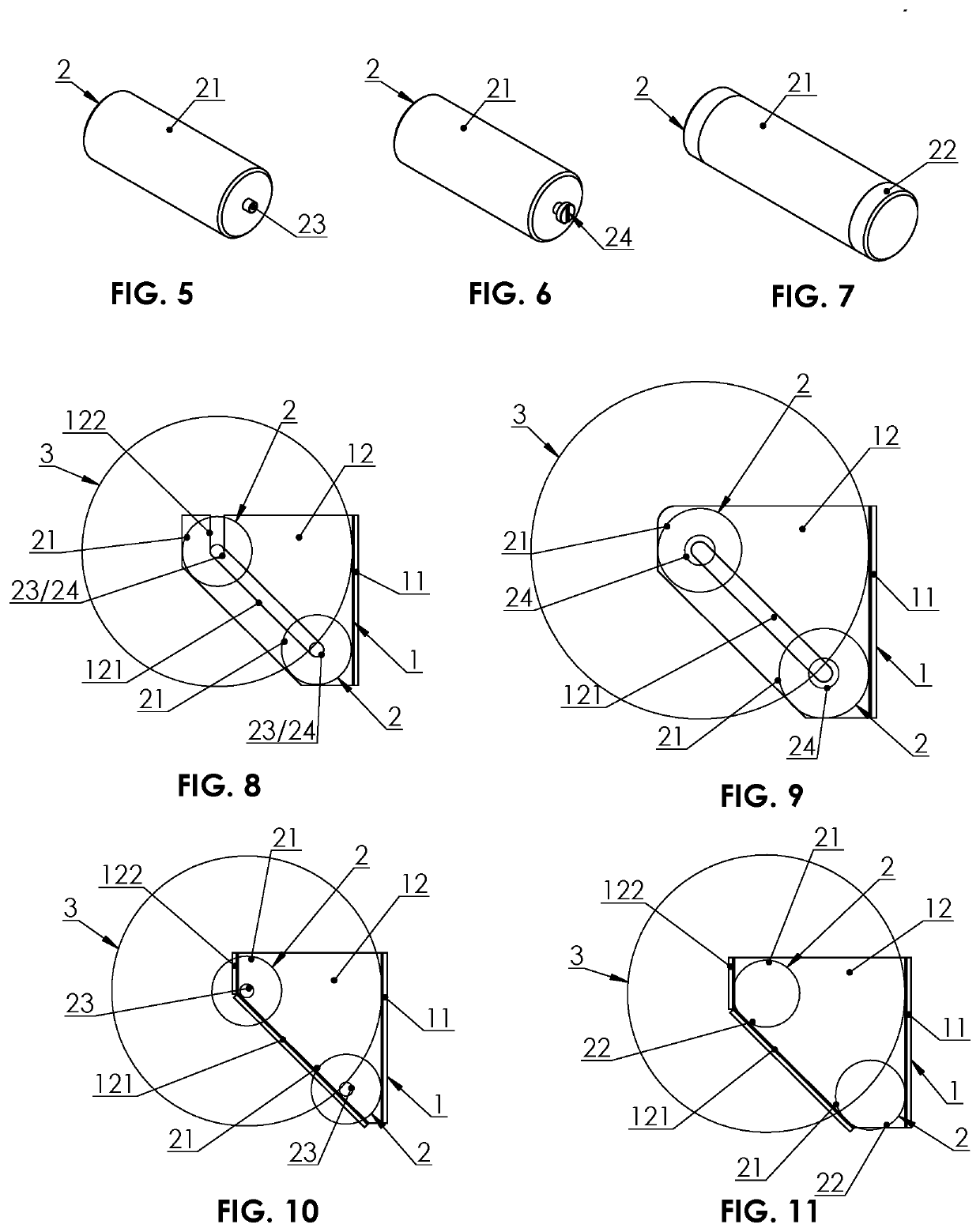

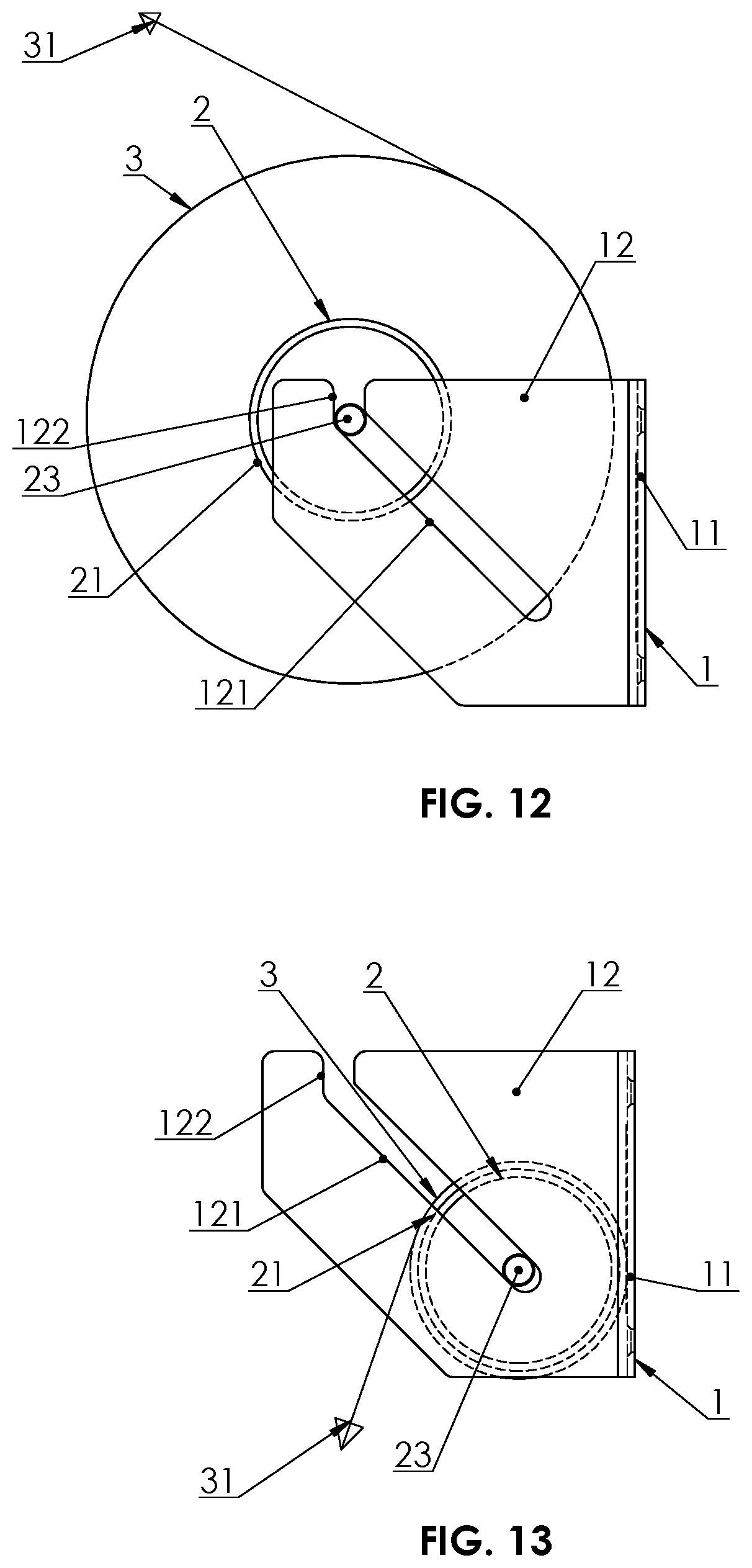

[0041]Use of actual terminology to describe exemplary and preferable embodiment of the dispenser in present disclosure as illustrated in FIGS. 1-20 is not intended to exclude any or other technical terminology or limit processes or shapes to describe similar products which may lead to the accomplishment of similar function and is limited only by the listed claims.

[0042]Referring to FIG. 1, example embodiment of toilet paper dispenser base 1 in isometric view illustrates parts common for all disclosed dispensers. Dispenser base 1 consists of rectangular back wall 11 with two side extensions 12 that protrude in the same direction in right angle from shorter edges of the back wall 11, and where peripheral lower corners of side extensions 12 have substantial chamfering in 45 degrees angle, while leaving the remaining upper lengths of peripheral edges untouched. Inner cutouts in side extensions 12 are opened at the top edges and follow the shape of peripheral edges in a distance to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com