Bogie Wheelset Radial Mechanism with Structure of Adjustable Rigidity

a radial mechanism and bogie technology, which is applied in the direction of bogies, transportation and packaging, railway components, etc., can solve the problems that the operation performance cannot reach the optimal state, the characteristics of the radial bogie have not been fully brought into play, etc., and achieve the effect of increasing the adaptation range of the rigidity improving linear and curvilinear runnability of the bogie, and effective adjustment of the radial mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]The present invention will be described in detail below by way of embodiments, which are only used to further illustrate the present invention, but should not be construed as limiting the scope of protection of the present invention. Some non-essential improvements and adjustments made by those skilled in the art in accordance with the above-mentioned contents of the present invention also fall within the scope of protection of the present invention.

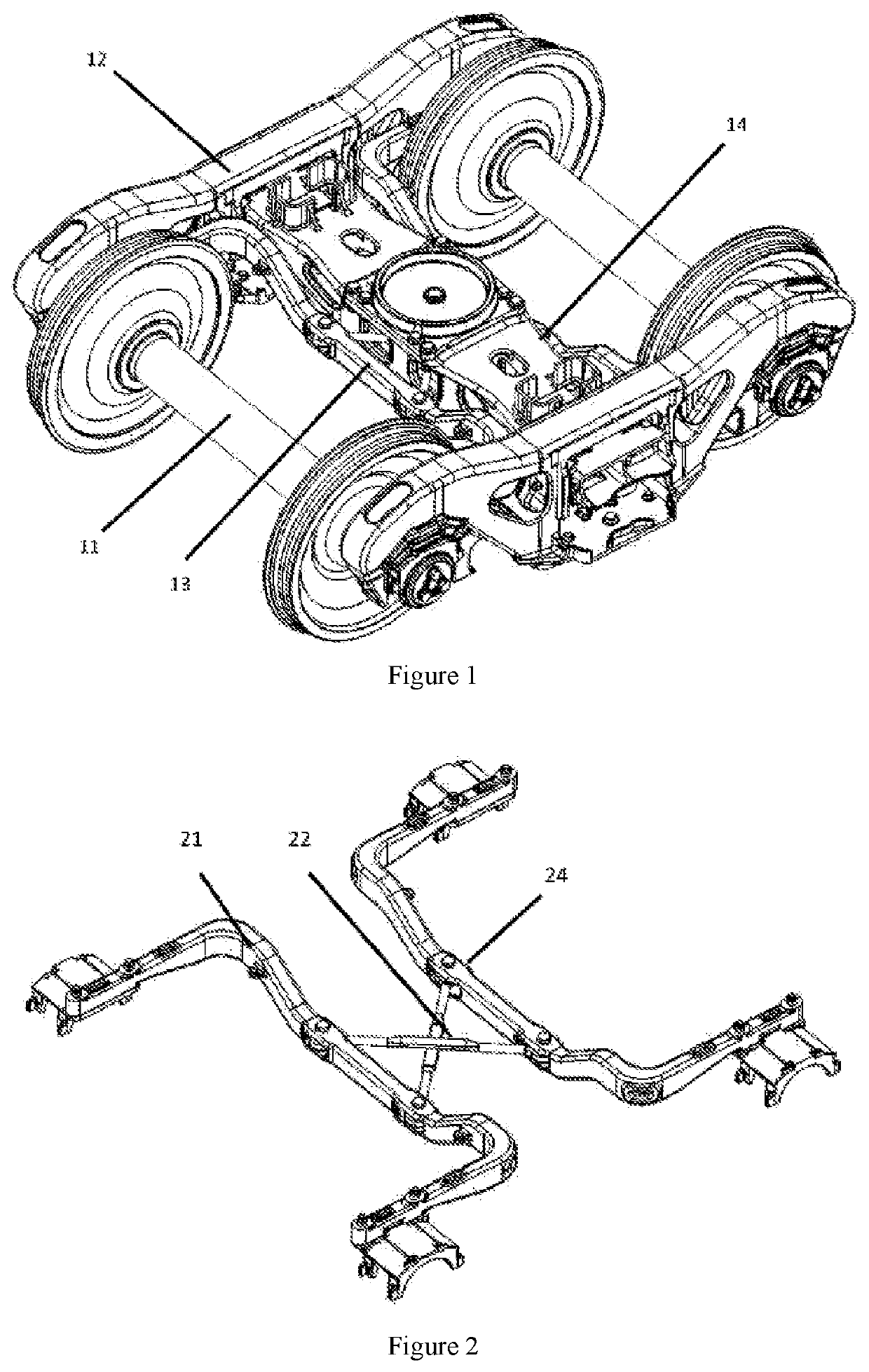

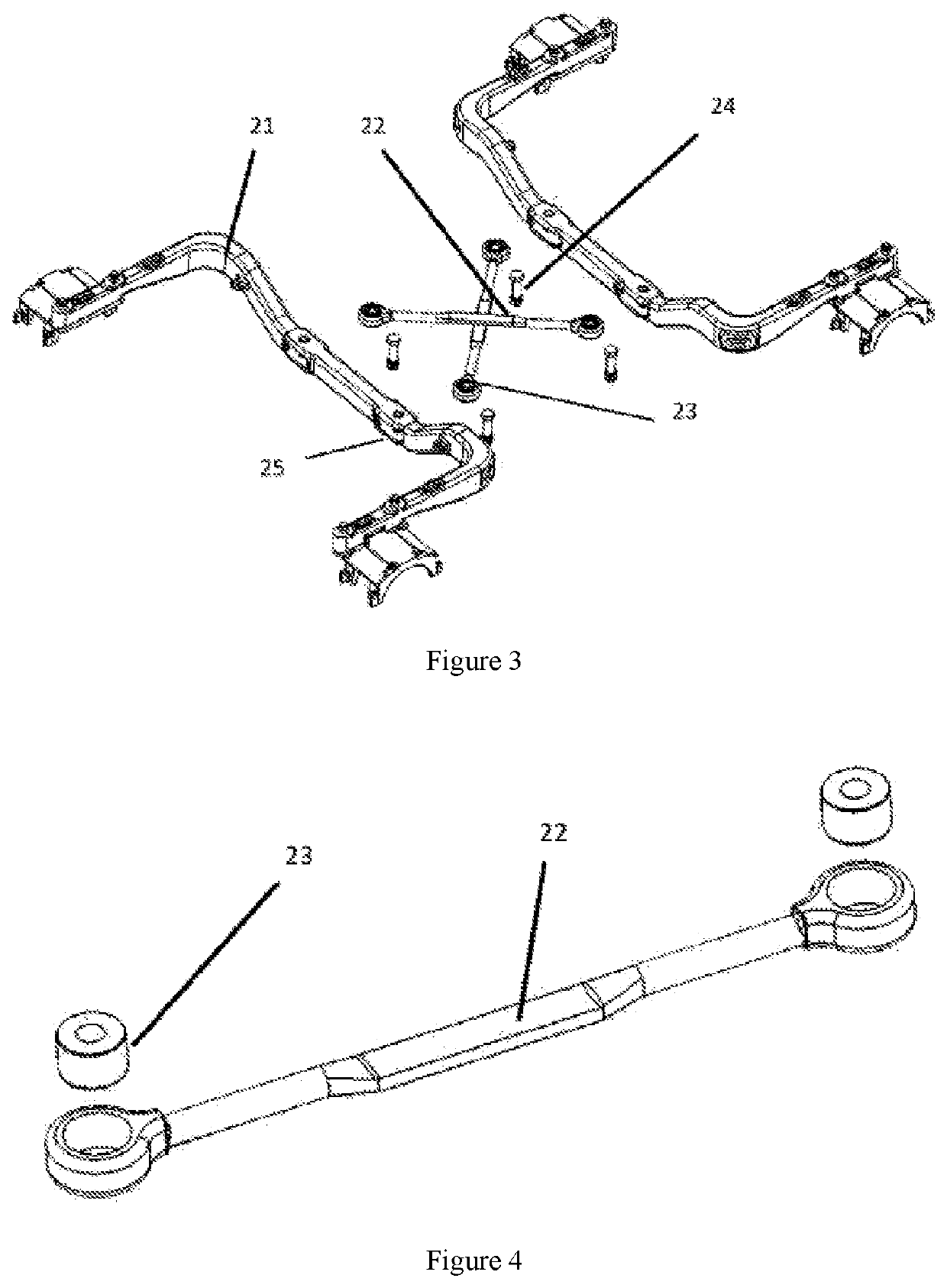

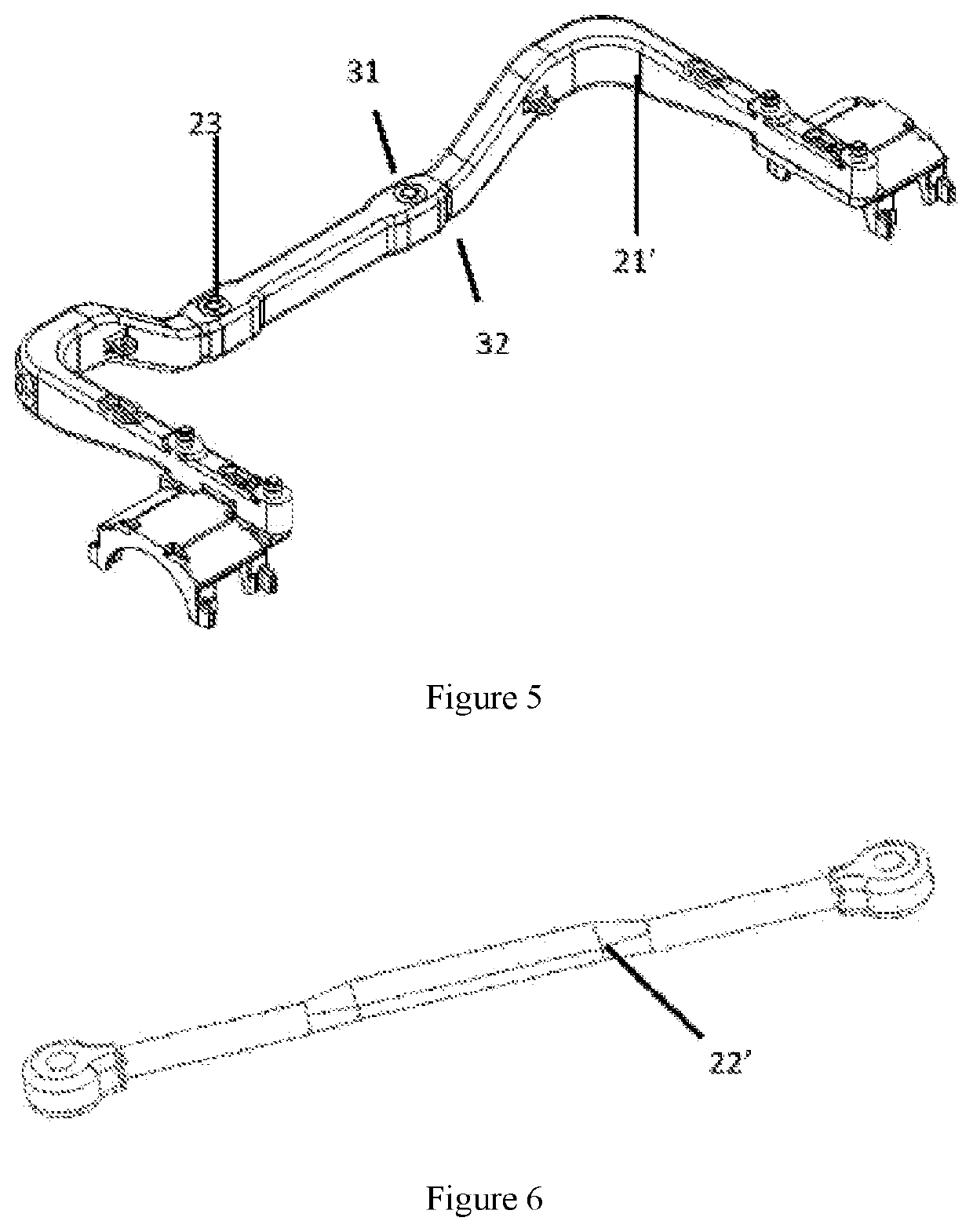

[0023]With reference to attached drawings,

[0024]a bogie wheelset radial mechanism with a structure which is of adjustable rigidity is provided, the wheelset radial mechanism 13 is composed of front and rear secondary frames 21 which are pin-connected via two connecting rods 22 arranged in a crosswise manner, the connecting rods 22 are pin-connected to the secondary frames 21 via round pins 24, and joints between the round pins 24 and the connecting rods 22 and / or joints between the round pins and the secondary frames 21 are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com