Method for grinding and/or polishing a defect and device for carrying out the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016]The grinding movement and the movement type of a grinding tool are stored as an automatic grinding path in the computer as a work program.

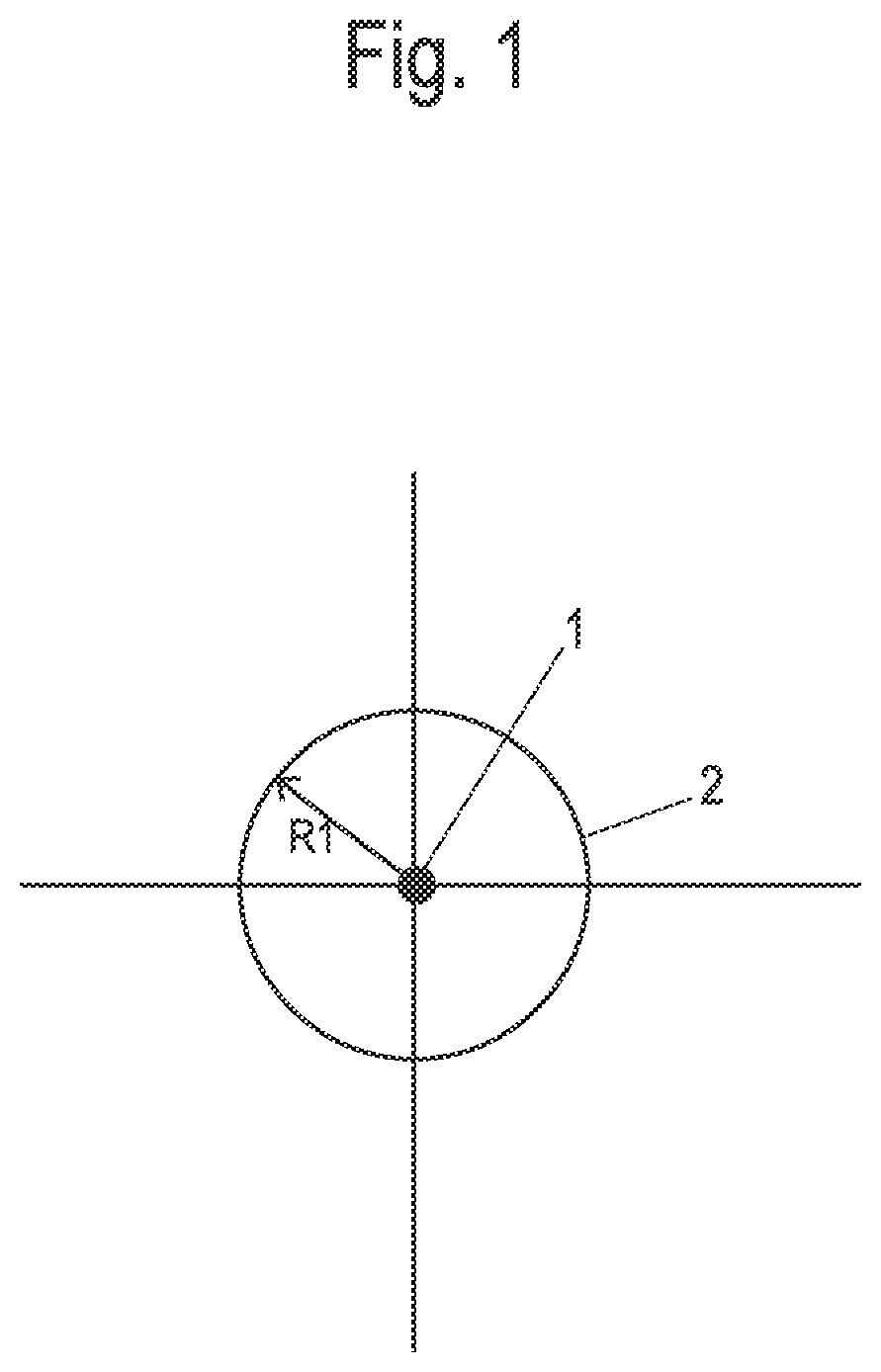

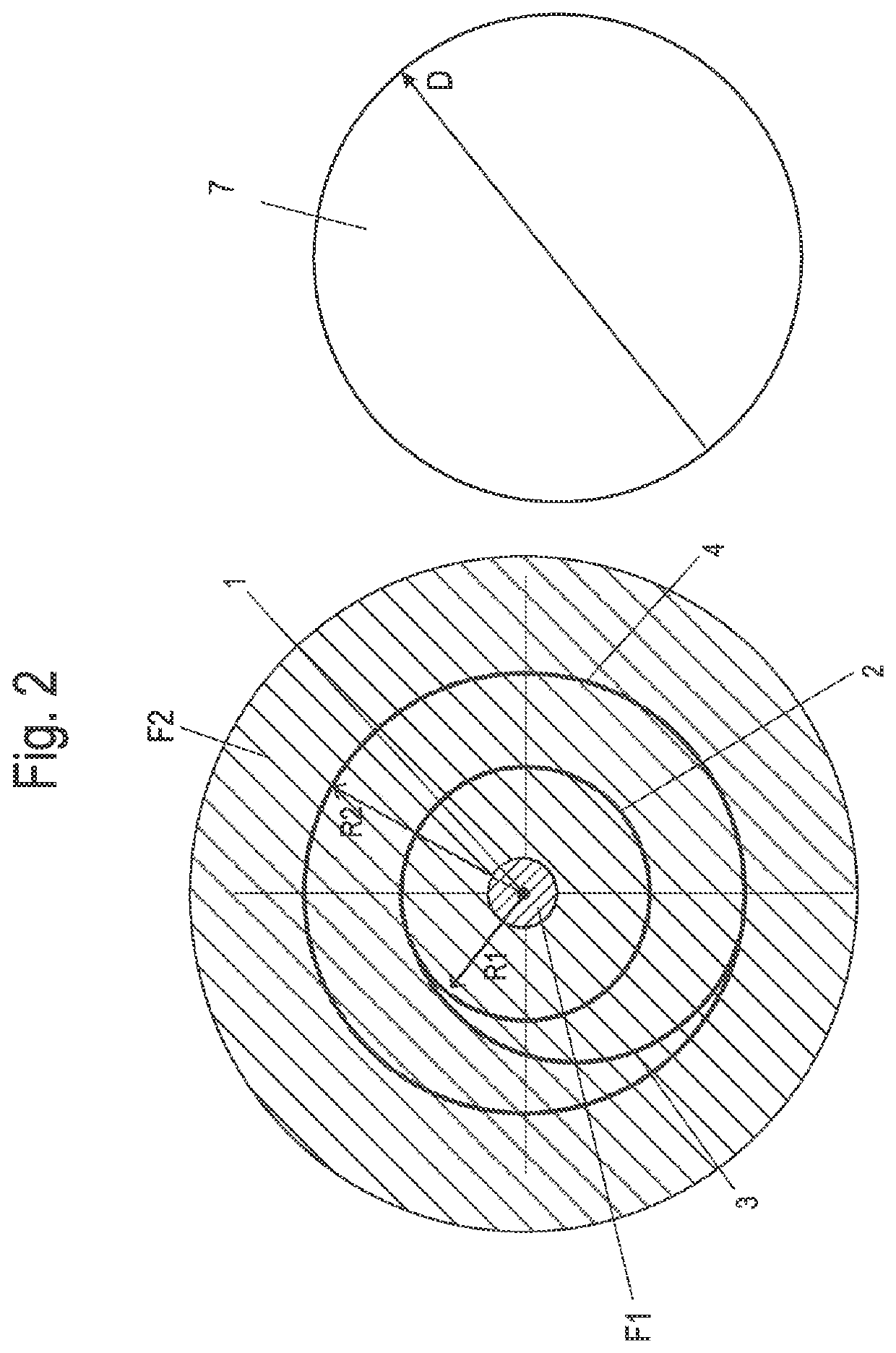

[0017]At the start of the grinding movement, the center of the grinding disc or backing pad is aligned with the defect 1 to be ground, wherein the grinding path starts in an inner circle 2. During the grinding movement in the grinding path 2, the center of the grinding disc is tilted inwards by a predetermined angle relative to the perpendicular to the defect 1, with a taper angle.

[0018]As mentioned, when grinding contours, the grinding tool and the workpiece to be machined are usually aligned orthogonally to each other.

[0019]Adjusting the grinding disc at a taper angle increases the grinding power at the center of the grinding disc, which makes it easier and quicker to grind the defect.

[0020]Depending on requirements, the grinding disc can be guided along the grinding path 2 once or several times.

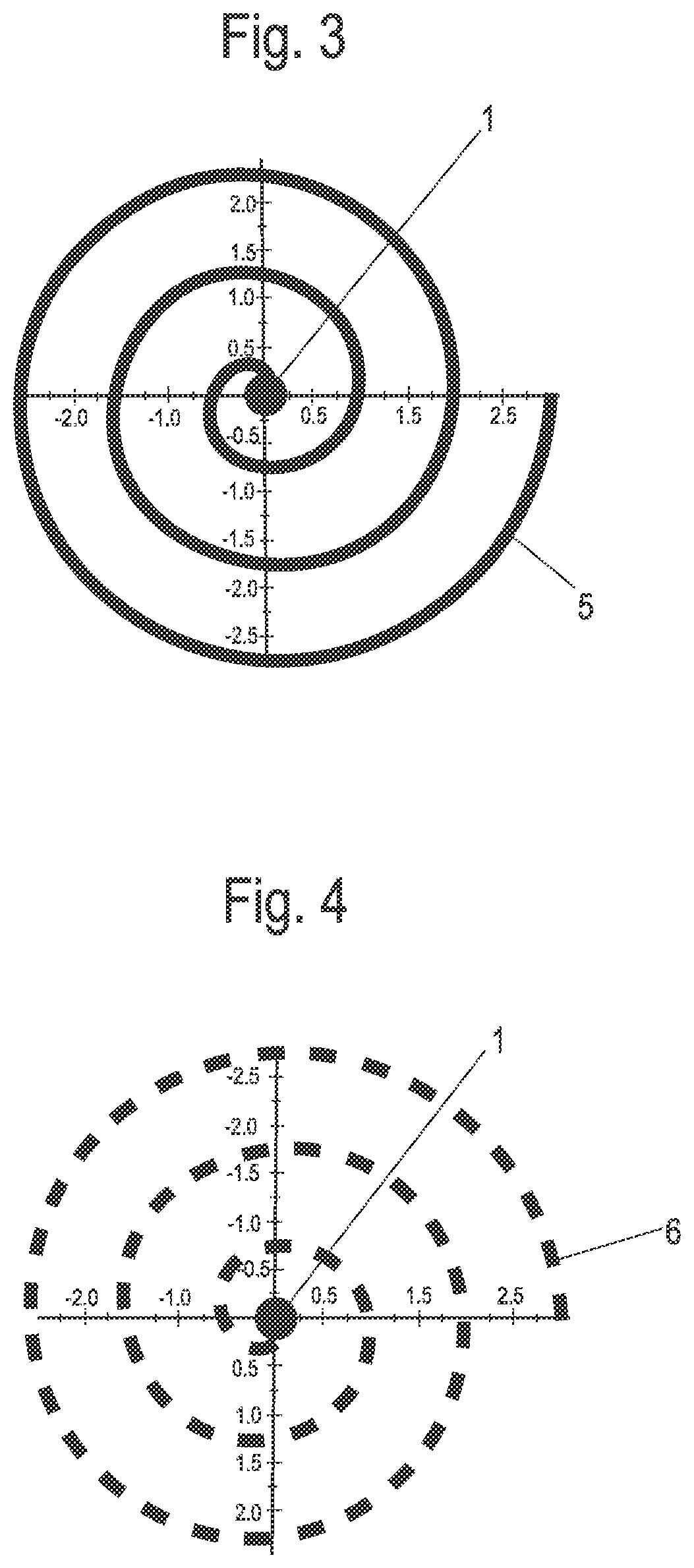

[0021]Along a spiral path 3, the grinding di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com