Planetary carrier and method for manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Modes for carrying out the various aspects of the disclosure will be described below with reference to the drawings.

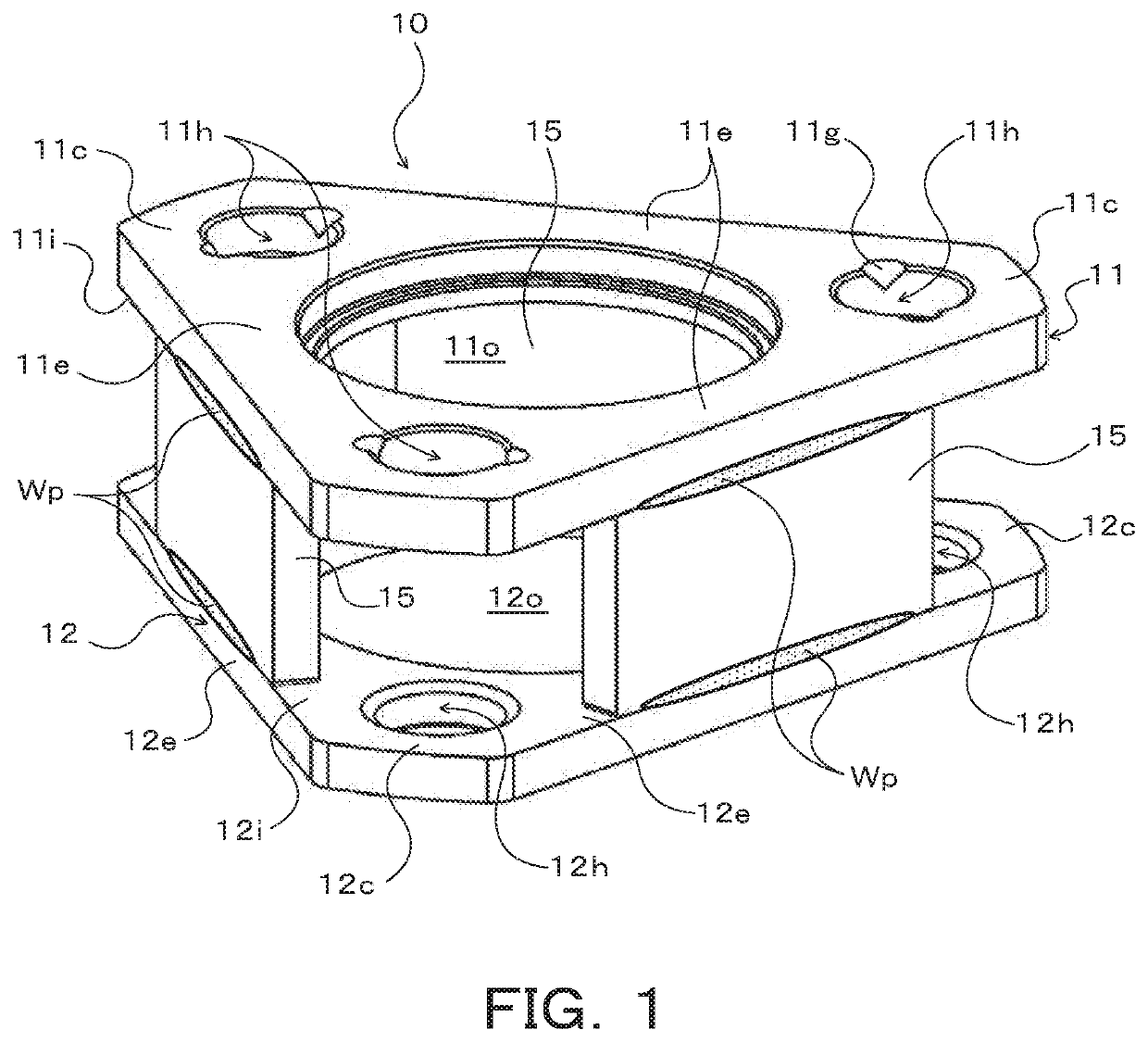

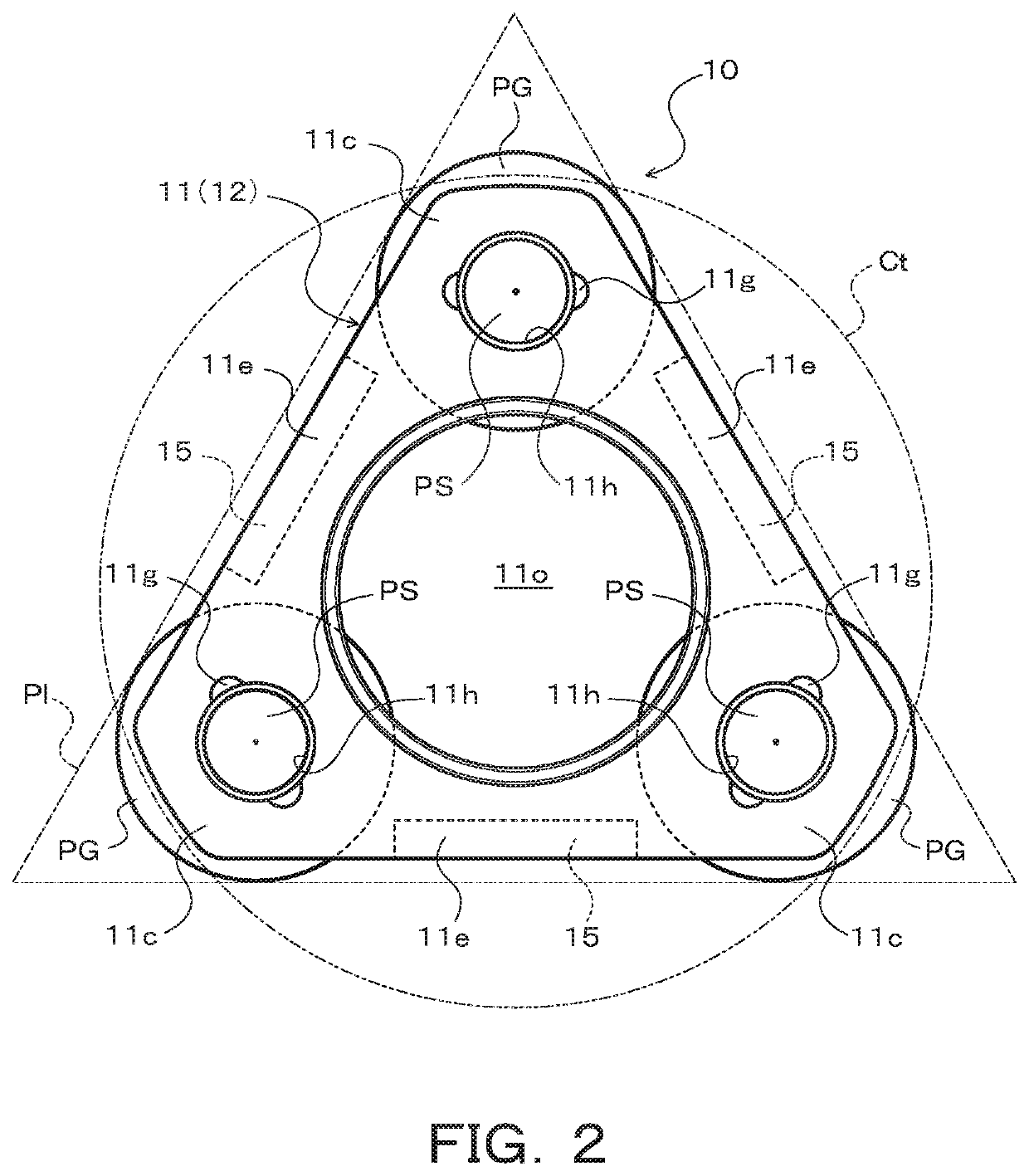

[0023]FIG. 1 is a perspective view of a planetary carrier 10 of the disclosure. FIG. 2 is a plan view of the planetary carrier 10. The planetary carrier 10 illustrated in the drawings are included in a single-pinion type planetary gear that is applied to a transmission. The planetary carrier 10 includes a plurality of (three in the embodiment, for example) pinion gears PG and a plurality of (three in the embodiment, for example) pinion shafts PS that are each inserted in the corresponding pinion gear PG (in FIG. 1, both are not shown). The planetary carrier 10 also includes a first supporting plate 11 that supports one end of each pinion shaft PS, a second supporting plate 12 that supports the other end of each pinion shaft PS, and a plurality of (three in the embodiment, for example) bridge plates 15 that connect the first and second supporting plates 11, 12.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com