Metal bottle interior processed to stop nickel leaching and taste altering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]FIG. 1 shows plan view of a metal bottle exterior (100) indicating that FIG. 2 and FIG. 3 are section drawings of FIG. 1 As shown in FIG. 1, the metal bottle is sectioned for FIG. 2 and FIG. 3 to show vertical section view of the metal bottle interior.

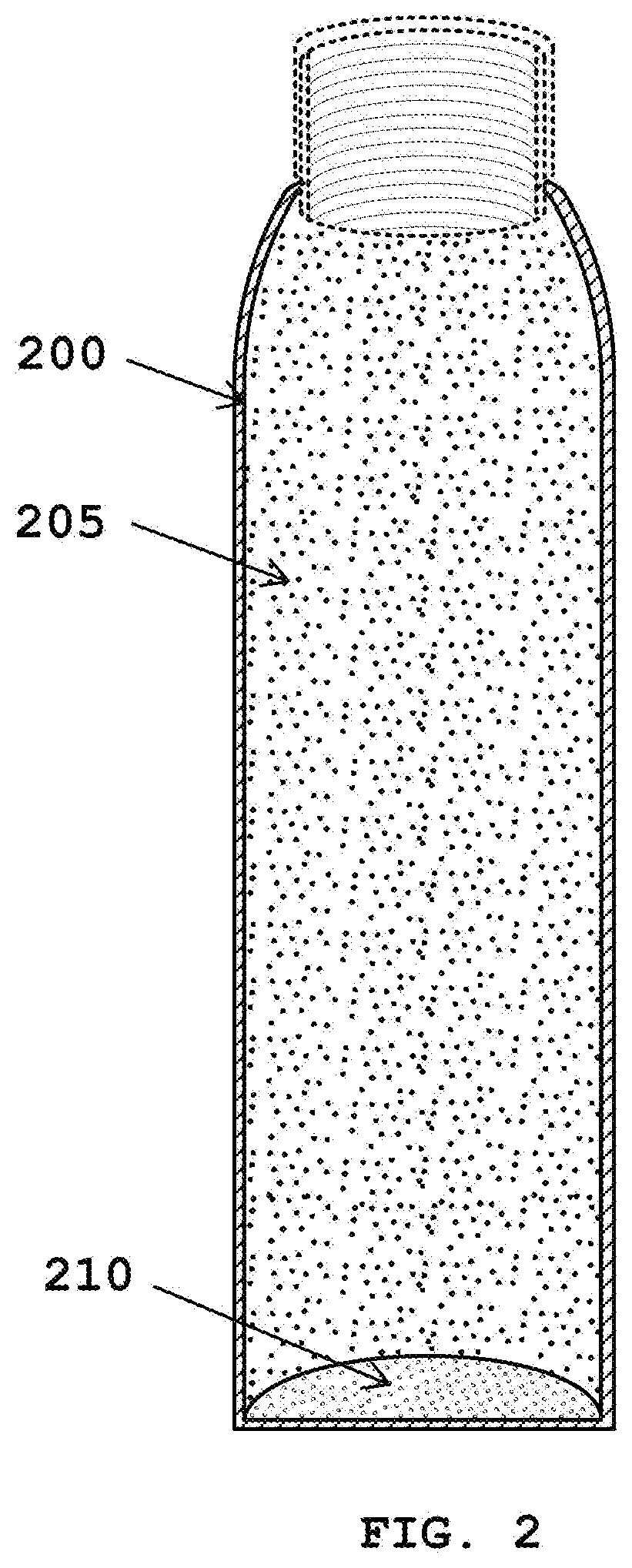

[0014]FIG. 2 shows a section view of a metal bottle interior prior to processing to stop nickel leaching and taste altering effects. Shown in FIG. 2 is a vertical section view of an unprocessed metal bottle interior (200). Shown in the vertical section view are the unprocessed circular lateral interior (205) of the metal bottle interior, and the unprocessed circular bottom interior (210) of the metal bottle interior.

[0015]The metal bottle interior, including the circular lateral interior (205) and the circular bottom interior (210) may be made of stainless steel, including SS304, SS316, or other stainless steels.

[0016]As shown in FIG. 2, the interior surface (200) of the metal bottle prior to processing to stop nickel leaching an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com