Homogenization apparatus for pepper raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

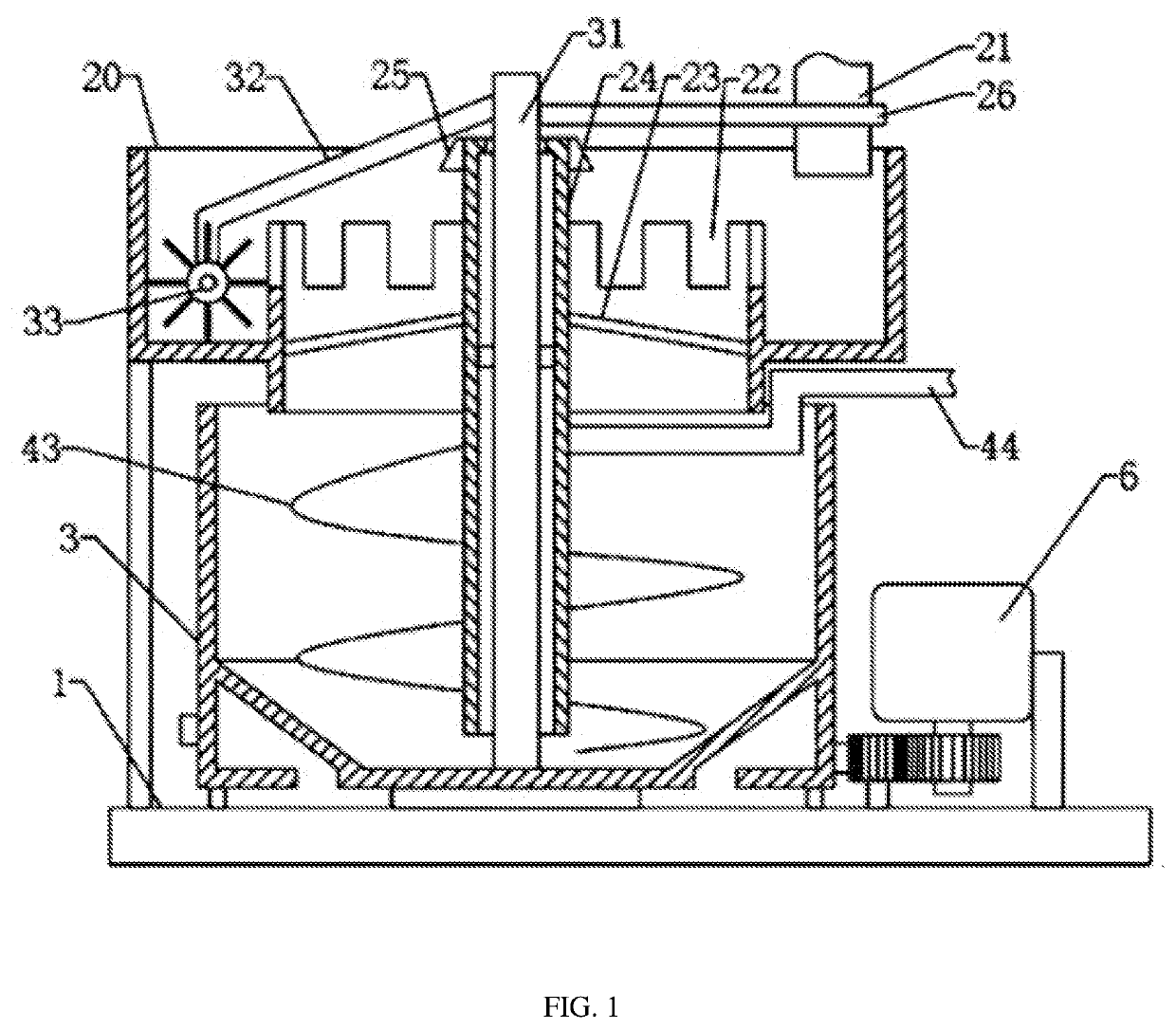

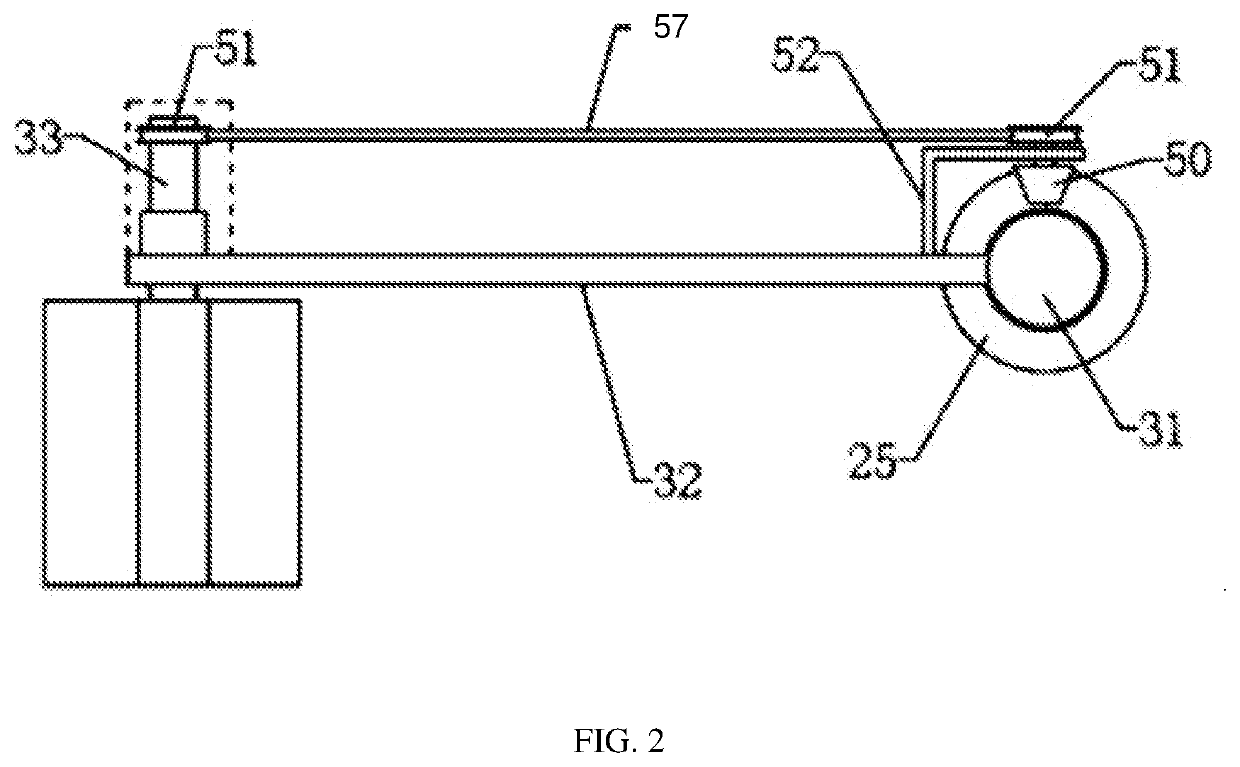

[0026]As shown in FIG. 1, disclosed is a homogenization apparatus for pepper raw materials with a specific pungency degree, in which a base 1 is included, a stirring barrel 3 and a storage tank 20 are arranged on the base 1, the storage tank 20 is positioned over the stirring barrel 3, the storage tank 20 and the stirring barrel 3 are coaxially arranged, and the storage tank 20 and the base 1 are fixed via a rack. The storage tank 20 is annular, the inner wall of the storage tank 20 is lower than the outer wall thereof, and a plurality of discharge chutes 22 are formed in the inner wall of the storage tank 20.

[0027]The center of the storage tank 20 is a through hole, the through hole is provided with a sleeve 24, the sleeve 24 and the storage tank 20 are coaxially arranged, and a plurality of connecting rods 23 are welded on the outer wall of the sleeve 24, and the connecting rods 23 are all welded and fixed to the inner wall of the storage tank 20. The lower end of the sleeve 24 ex...

embodiment 2

[0035]The difference from Embodiment 1 lies in that, as shown in FIG. 3, the discharge pipe 44 is fixed to the rack, the stationary shaft 31 is of a hollow structure, the lower end of the stationary shaft 31 is provided with a through hole communicating with the stirring barrel 3, and the feed pipe 21 communicates with the upper end of the stationary shaft 31 and is connected with a negative pressure pump. The feed pipe 21 is fixed to the rack, the storage tank 20 is rotatably connected to the rack, an annular rack is fixed on a circumferential surface of the storage tank 20, an intermediate gear, a power gear and a motor 6 are connected to the rack, the intermediate gear is rotatably connected to the rack, the power gear is fixed on an output shaft of the motor 6, and the motor 6 is fixed to the rack.

[0036]In this way, the motor 6 drives the storage tank 20 to rotate, the spiral blade 43 rotates relative to the stirring barrel 3. Compared with Embodiment 1, the motor 6 drives the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com