Opening/closing chuck and method of manufacturing fingers

a technology which is applied in the field of opening/closing chuck and manufacturing method of fingers, can solve the problems of insufficient development of the technique that takes into account the concentration of stress generated in the fingers and the body, and the damage of the fingers and the sliding surfaces of the body, so as to reduce the concentration of stress and alleviate the concentration of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

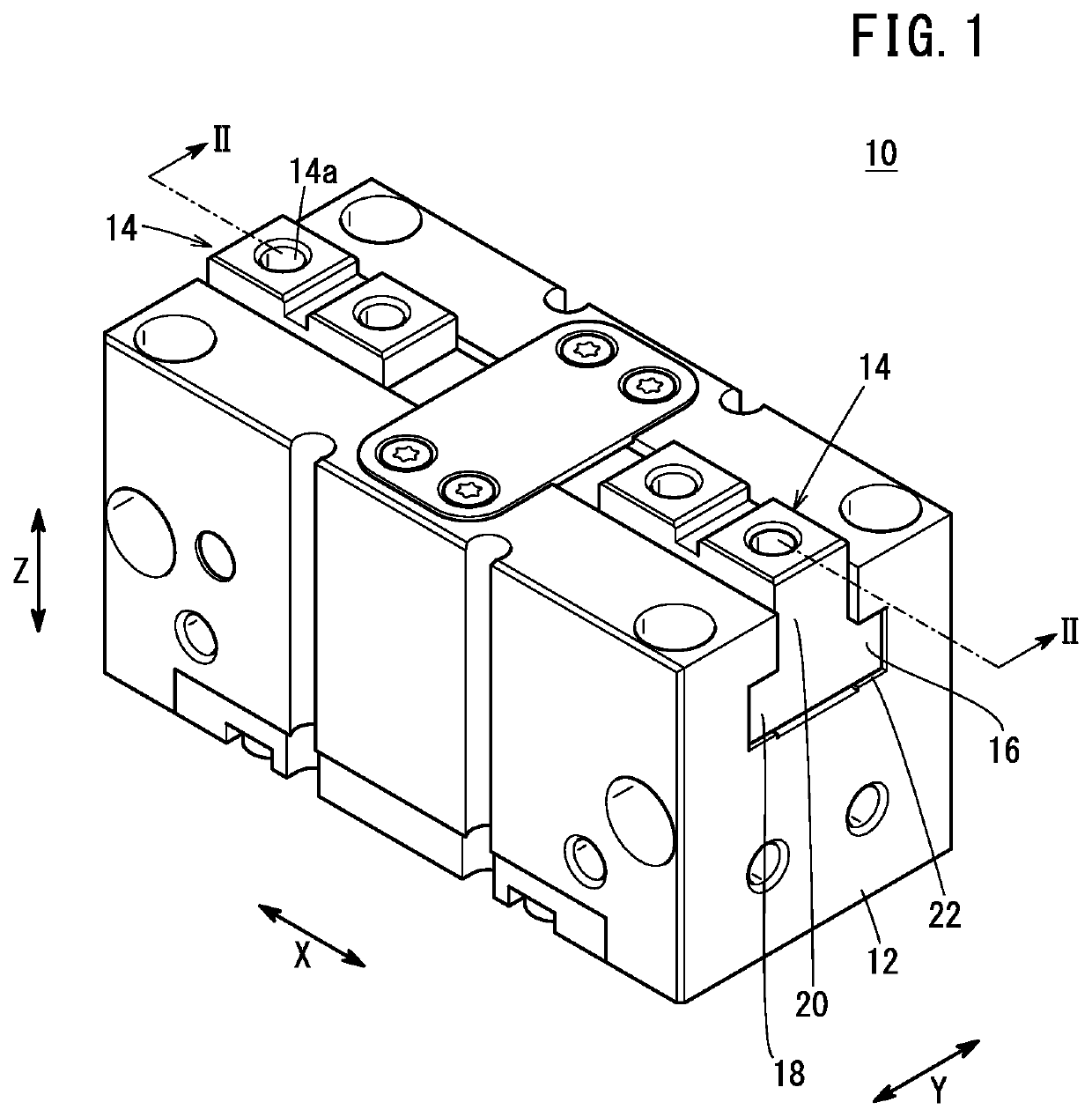

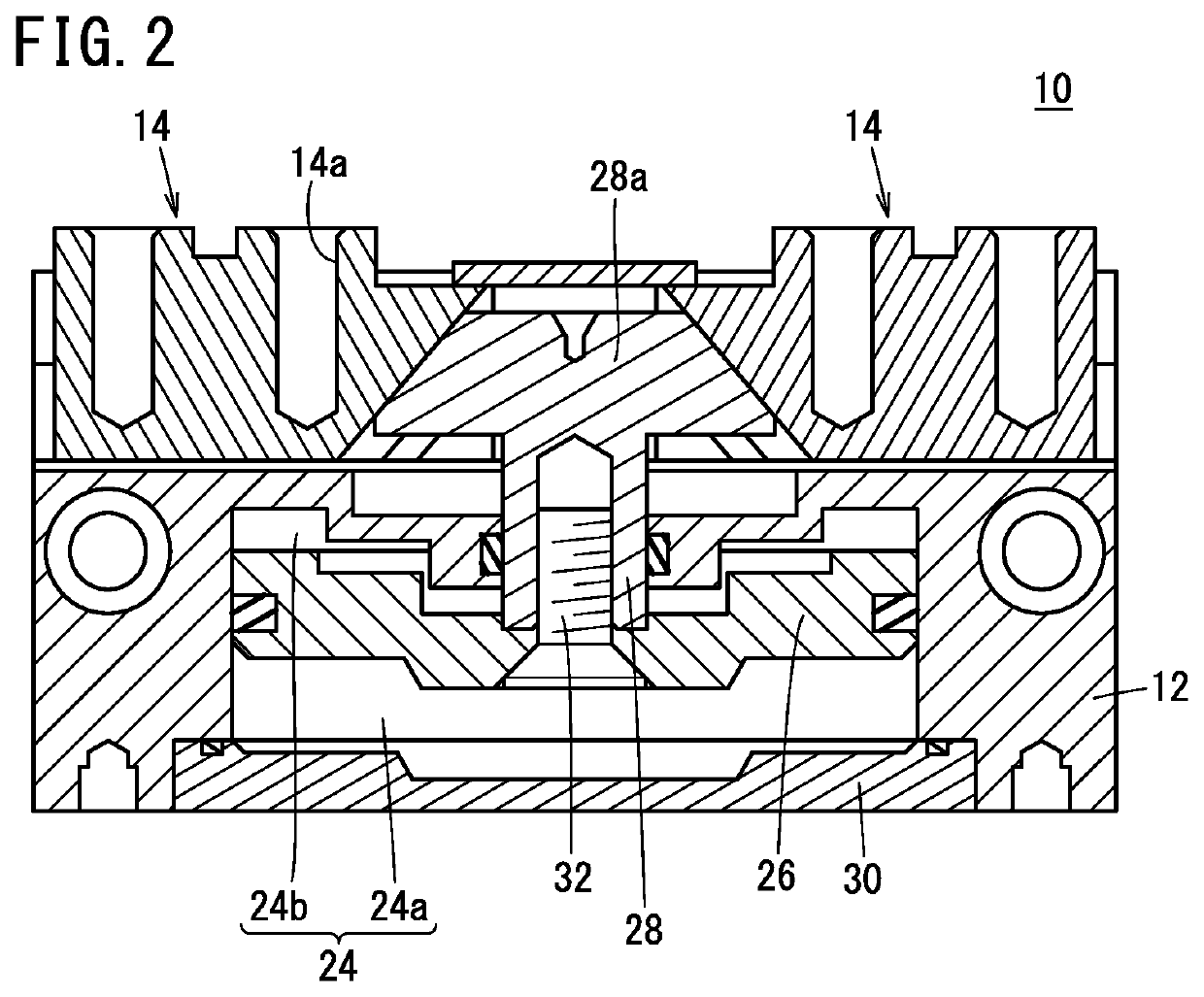

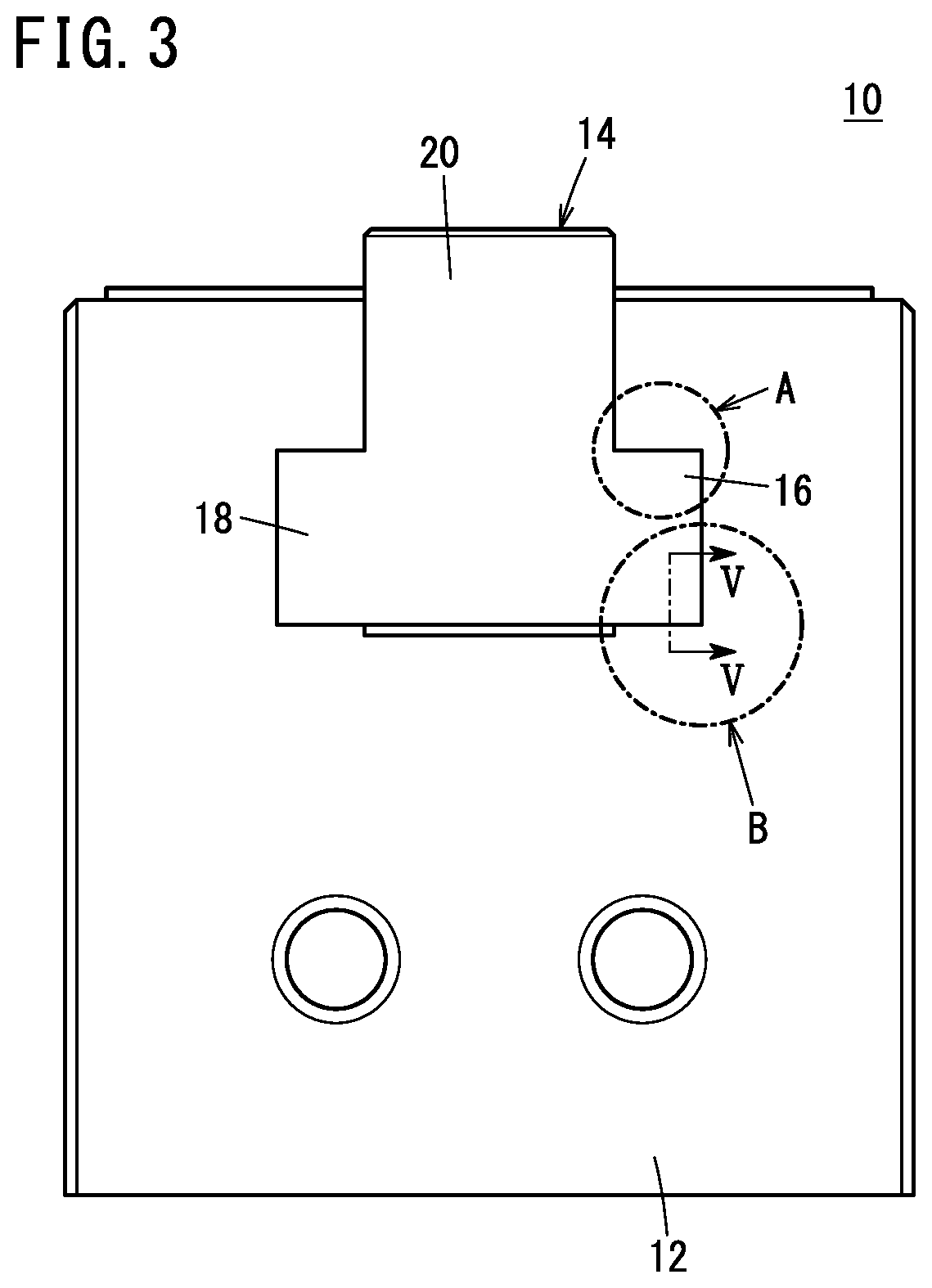

[0035]A description will be given with reference to FIGS. 1 to 6 concerning an opening / closing chuck 10 according to the first embodiment of the present invention. As shown in FIGS. 1 and 2, the opening / closing chuck 10 includes a rectangular parallelepiped shaped body 12, and a pair of fingers 14 that are slidably supported in a longitudinal direction (the X direction) of the body 12. The opening / closing chuck 10 is used by connecting non-illustrated attachments for gripping a workpiece to the fingers 14. That which is shown by reference numeral 14a are screw holes used for connecting the attachments.

[0036]The body 12 includes a cylinder chamber 24 at a lower central part in the longitudinal direction. Further, the body 12 has a guide groove 22 that extends in the longitudinal direction of the body 12, and both ends of which open on end surfaces of the body 12 at portions above the cylinder chamber 24. A piston 26 which is capable of sliding in a vertical direction (Z direction) is...

second embodiment

[0070]Next, a description will be given with reference to FIGS. 10 to 13 concerning a method of manufacturing an opening / closing chuck 40 and fingers 42 thereof according to a second embodiment of the present invention. In the opening / closing chuck 40 according to the second embodiment, the shape of the pair of overhanging portions of the fingers and the shape of the guide groove of the body differ from those of the opening / closing chuck 10 according to the first embodiment.

[0071]As shown in FIGS. 10 and 12, each of the fingers 42 includes a pair of trapezoidal overhanging portions 44 and 46 which project out laterally from a main body portion 48 over the entire length thereof in the longitudinal direction. Upper surfaces 44a and 46a and lower surfaces 44c and 46c of each of the overhanging portions 44 and 46 are formed as tapered surfaces, which are inclined so as to come into closer proximity to each other toward side surfaces 44b and 46b. A guide groove 50 of the body 12 includes...

third embodiment

[0086]Next, a description will be given with reference to FIGS. 14 and 15 concerning fingers 62 of an opening / closing chuck and a method of manufacturing the same according to a third embodiment of the present invention. The fingers 62 according to the third embodiment differ from the fingers 42 of the opening / closing chuck according to the second embodiment, in that each of the overhanging portions includes a recess and a grease reservoir.

[0087]As shown in FIG. 14, one of the overhanging portions 64 includes a recess 72 centrally in the longitudinal direction of the upper surface 64a, the side surface 64b, and the lower surface 64c, and includes crowning regions CR1 and CR2 at both ends of the recess 72. A grease reservoir 70 opens in a bottom surface of the recess 72 that is formed in the upper surface 64a. The other one of the overhanging portions 66 also includes a similar grease reservoir 70 therein. Grease that is stored in the grease reservoirs 70 is supplied to the sliding s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reaction force | aaaaa | aaaaa |

| gripping force | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com