High pressure quartz glass bubbler ampoule and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

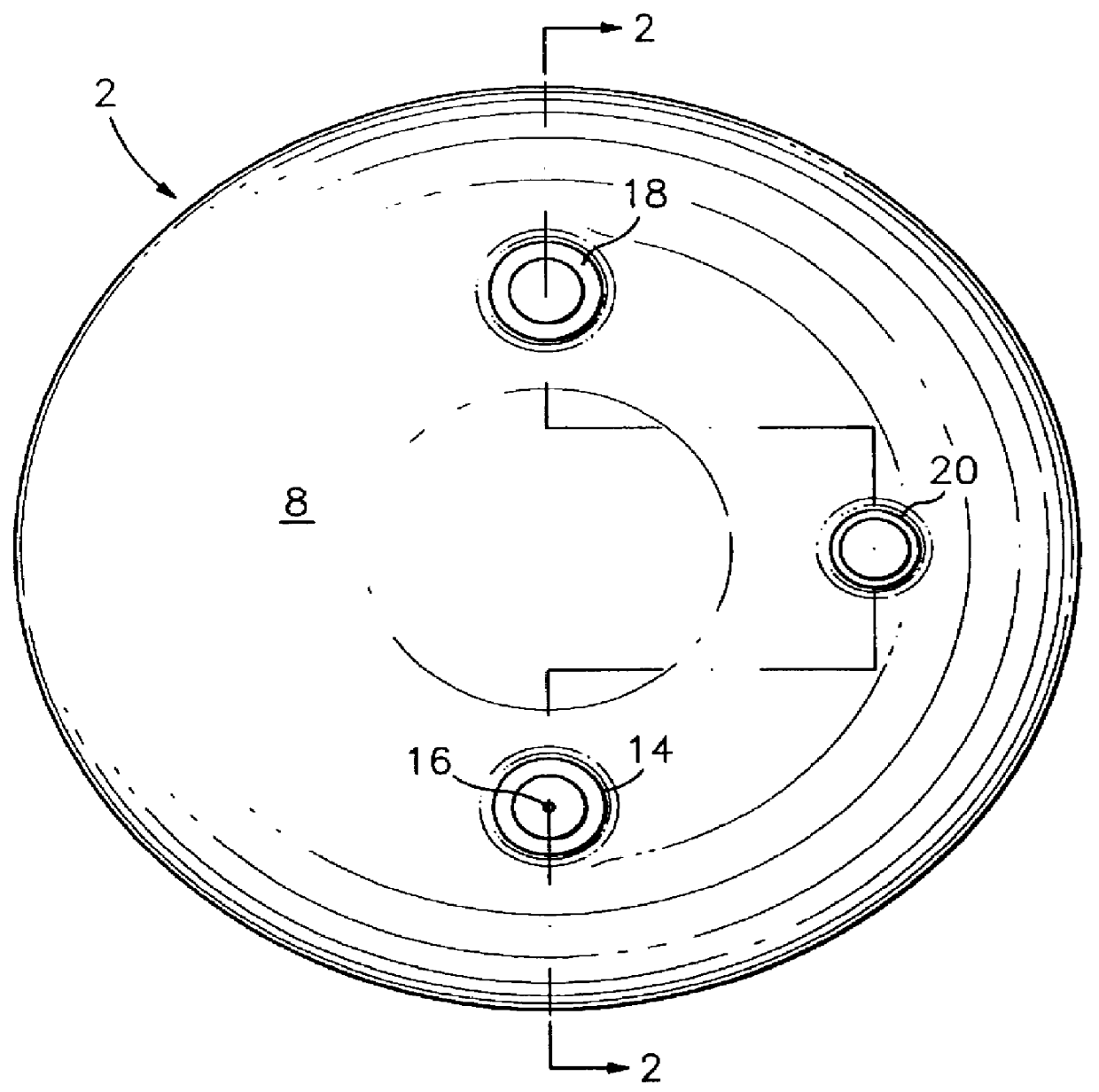

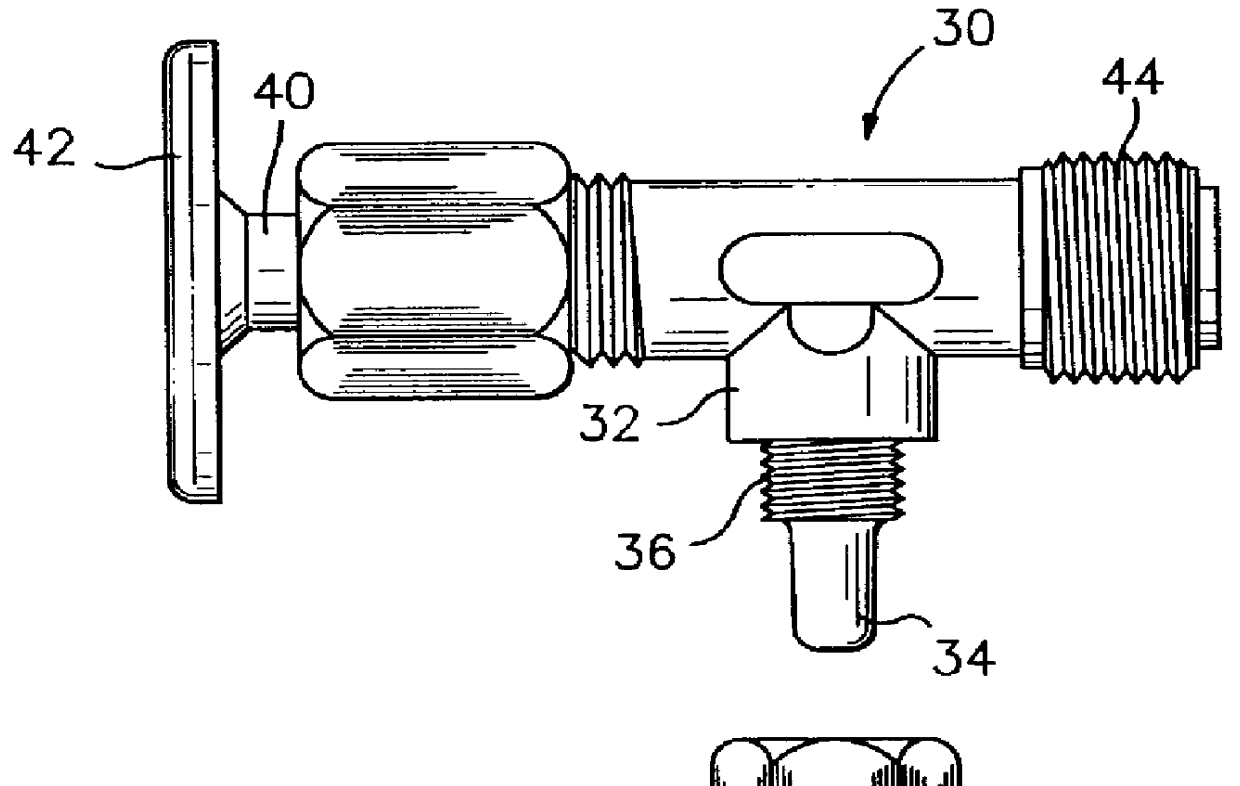

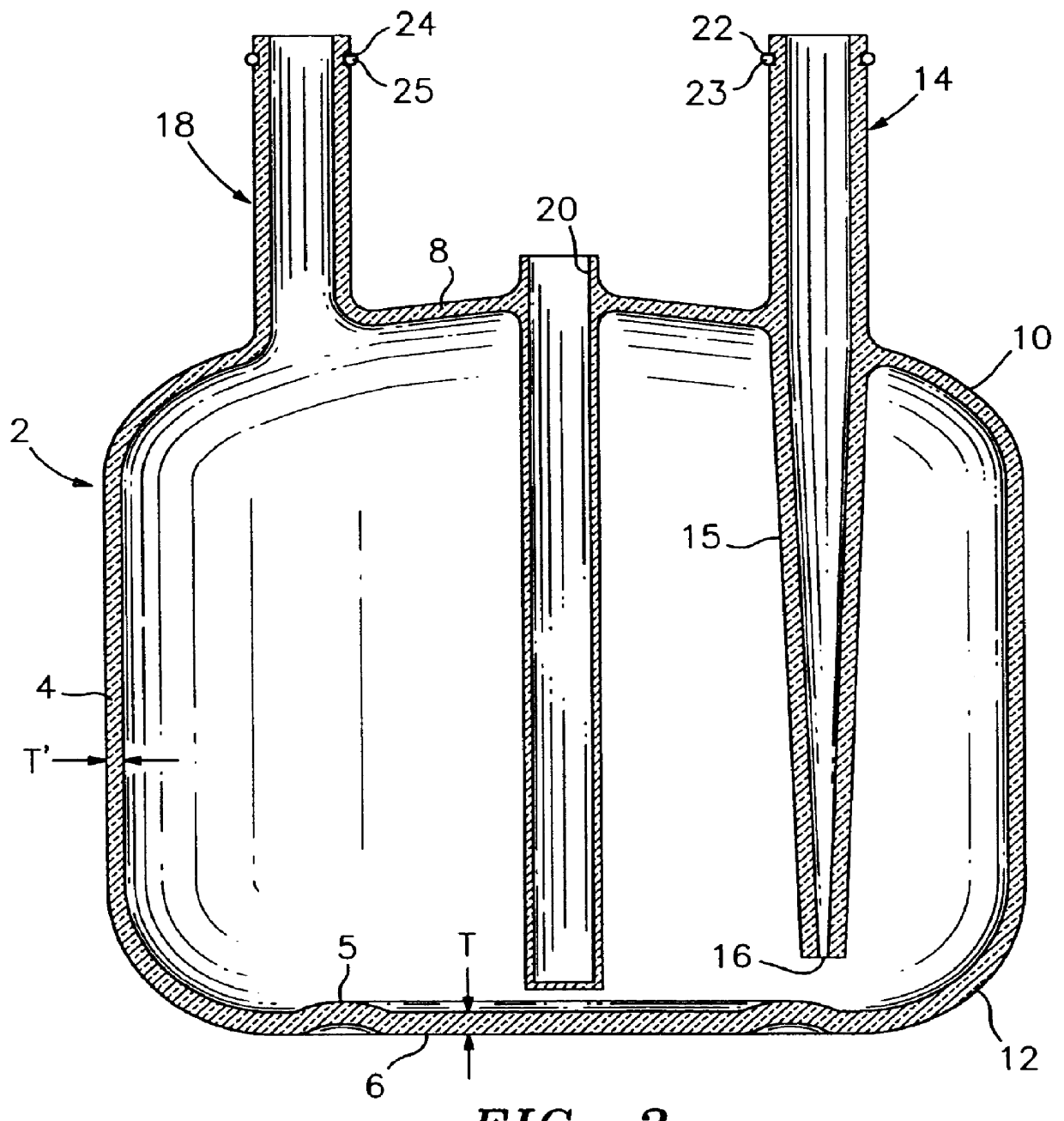

Referring now to the drawings, there is shown in FIGS. 1 and 2, an embodiment of an improved ampoule, which is denoted generally by the numeral 2, and which is formed in accordance with this invention. The ampoule 2 has a circular side wall 4, a bottom wall 6, and a top wall 8. The side wall 4 and the top wall 8 are interconnected by a curvilinear corner wall 10; and the side wall 4 and the bottom wall 6 are likewise interconnected by a curvilinear corner wall 12. The bottom wall 6 is essentially flat, and the top wall 8 is essentially curved upwardly and outwardly. The ampoule 2 includes an integral gas inlet neck 14 that connects with a gas inlet dip tube 15 which extends downwardly into the ampoule 2, and tapers to a terminal nozzle opening 16 through which the carrier gas stream is bubbled into the liquid chemical contained in the ampoule 2. The opening 16 is sized so as to accurately control the amount of carrier gas released into the liquid chemical, and the size of the carrie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap