Disk motor with bearing prestressing feature

a technology of prestressing and bearings, applied in the direction of magnetic circuit rotating parts, magnetic circuit shapes/forms/construction, instruments, etc., can solve the problems of two ball bearings with the associated additional assembly/installation costs, not contributing to the whole generation of torque, and the arrangement of ball bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

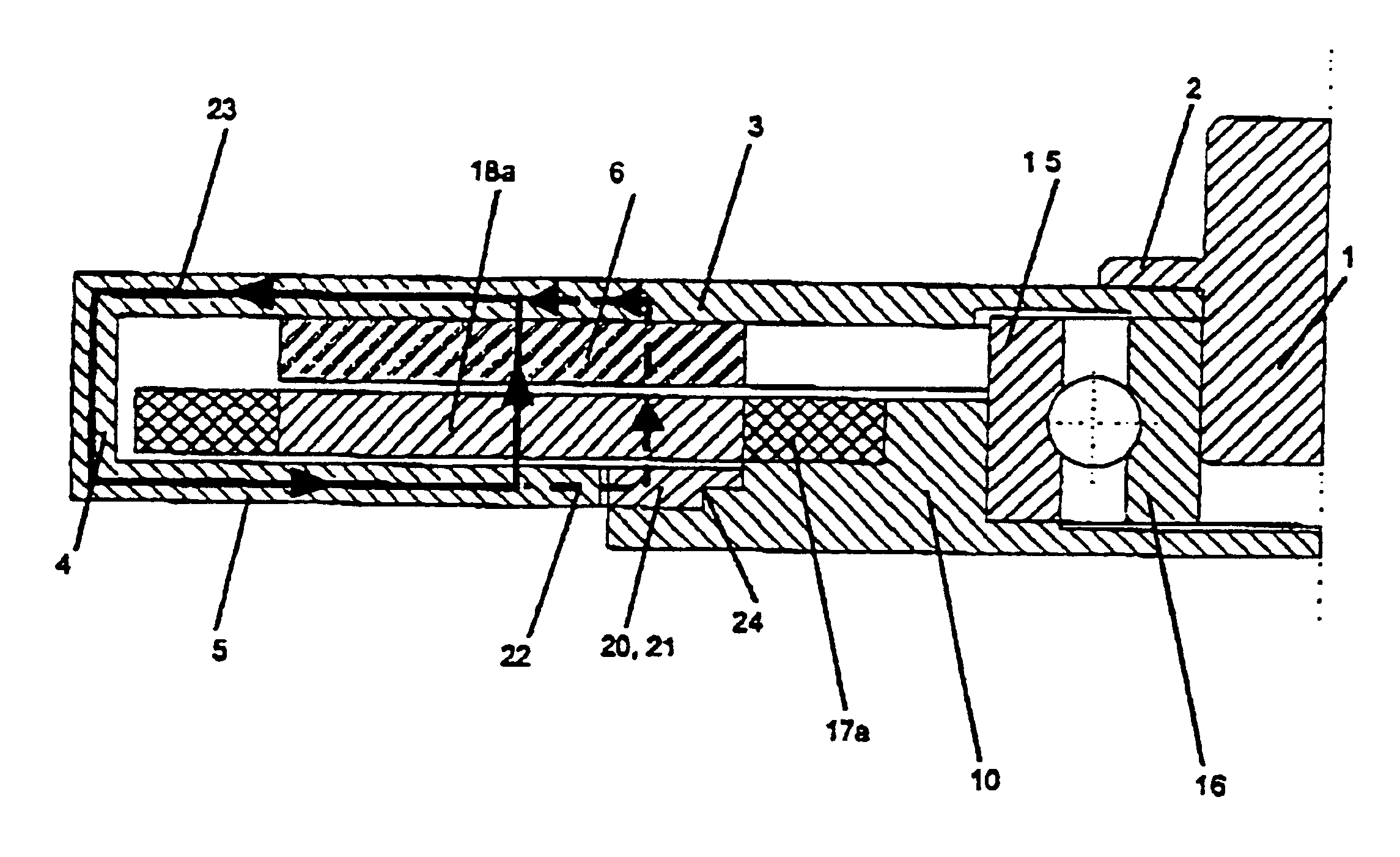

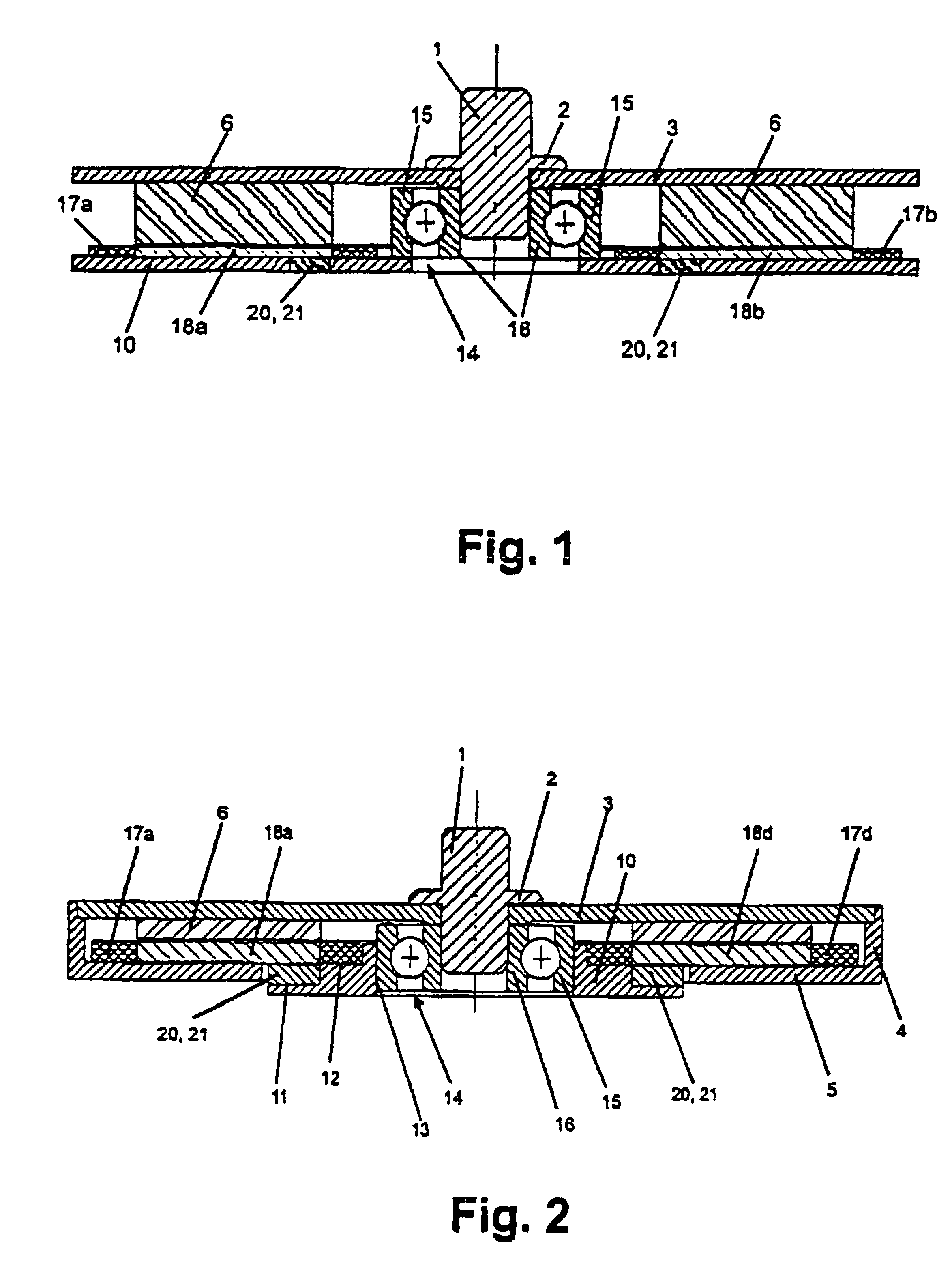

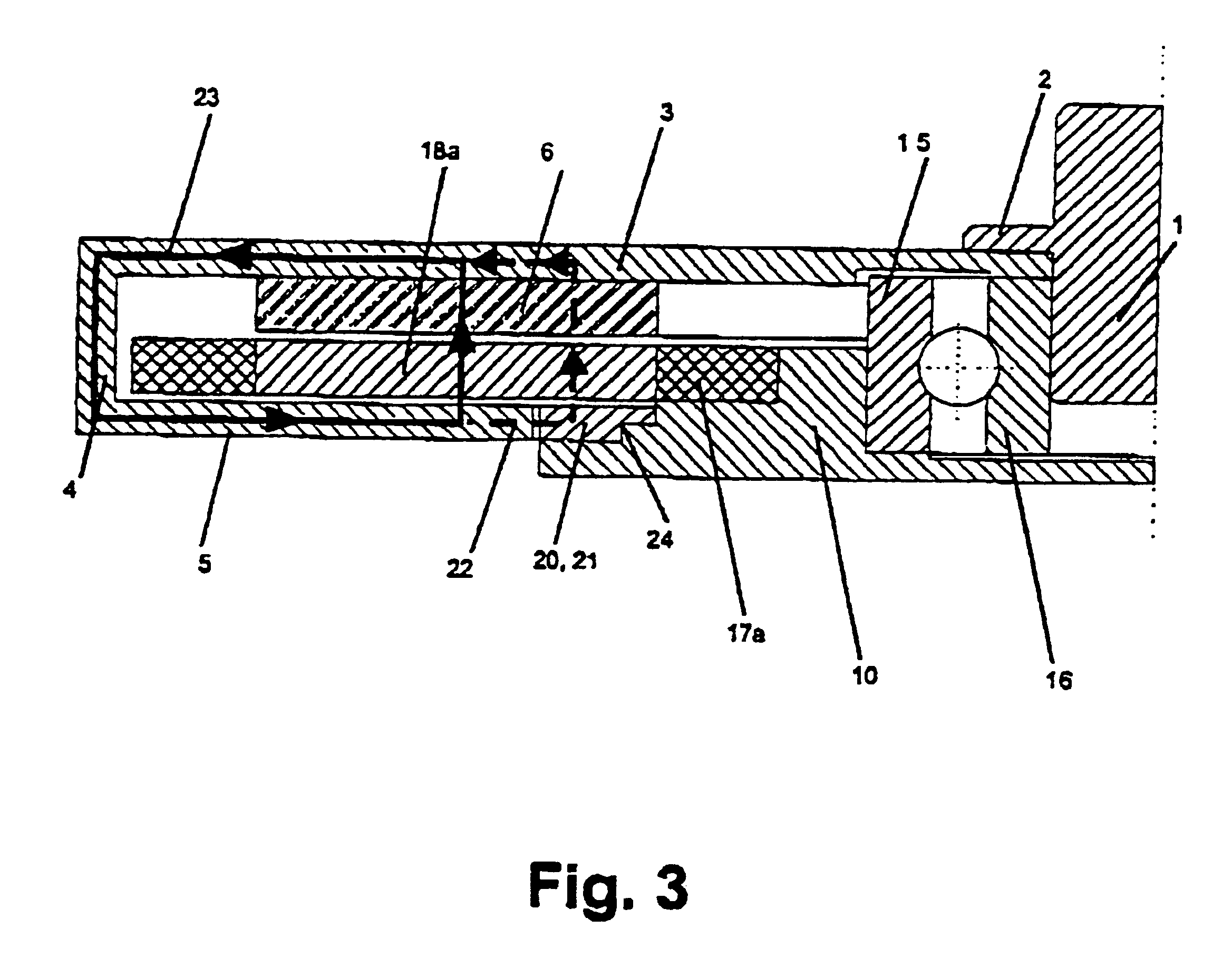

The embodiment relates to a design as shown schematically in FIGS. 2 and 3. The disk motor has an outside diameter of 12.8 mm and is 1.4 mm high.

The motor has a torque constant of 0.40 .mu.Nm / Ma. The motor can easily be used for rotational speeds of up to 20,000 rpm while exhibiting good running characteristics.

Due to the design, the ball bearing is not influenced by the magnetic field. An attractive force in the Mn range is exerted by the magnetic prestressing.

The annular permanent magnet is manufactured by means of micro injection molding or sizing of an NdFeB powder containing a plastic as binder. The annular magnet is approximately 300 .mu.m thick. The annular magnet is axially magnetized such that it has eight poles (four pole pairs) on the end face.

Miniaturized flat coils are manufactured by means of UV-deep lithography and subsequent galvanic precipitation.

The flat coils comprise two superimposed printed conductors separated by a polyimide film as a carrier. There are six coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com