Vacuum stirring process for ultra-high-performance concrete

An ultra-high performance, vacuum mixing technology, applied in cement mixing equipment, clay preparation equipment, chemical instruments and methods, etc., can solve problems such as unpredictable effects, achieve improved density, uniform dispersion, and improved mechanical properties and durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

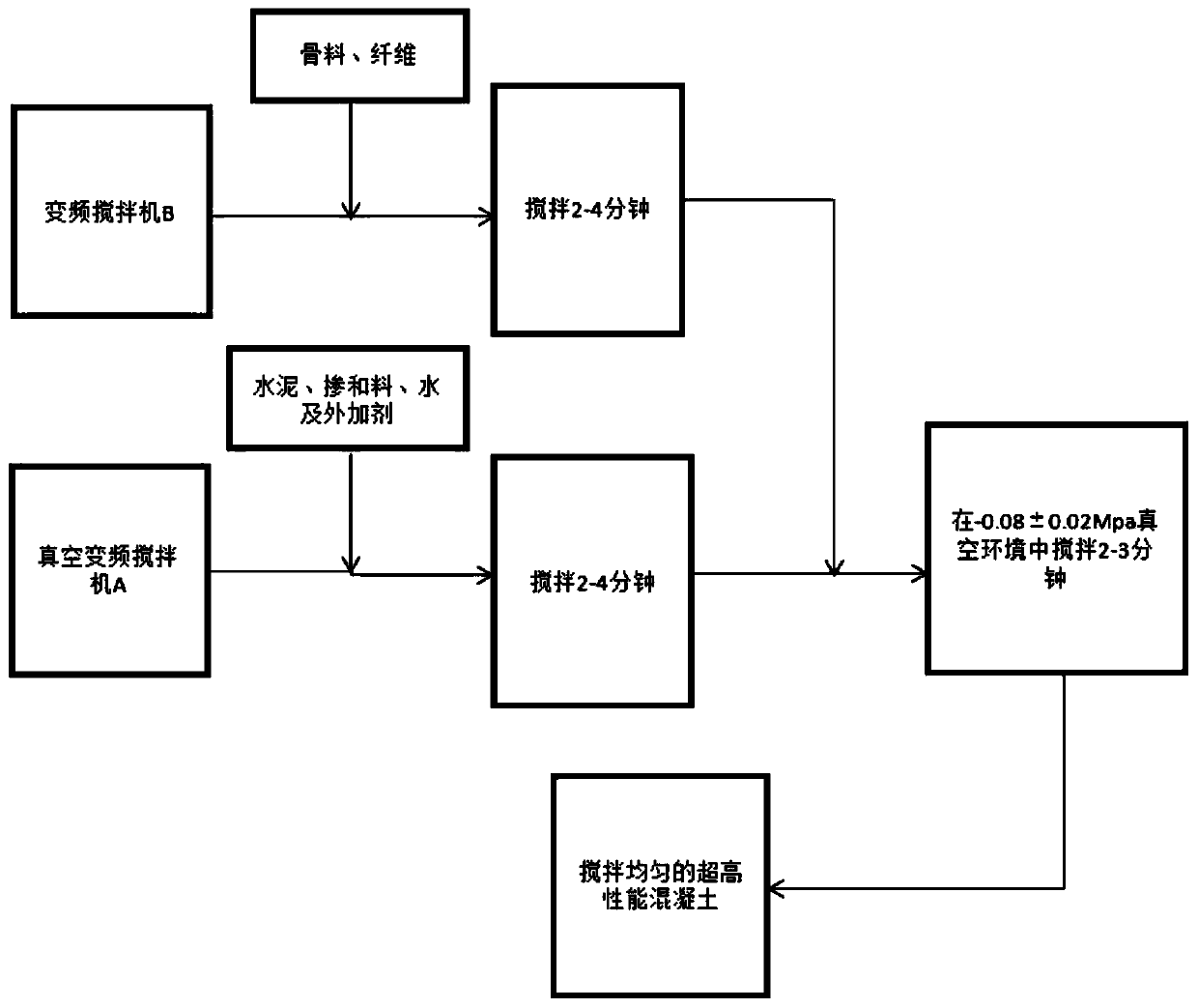

Method used

Image

Examples

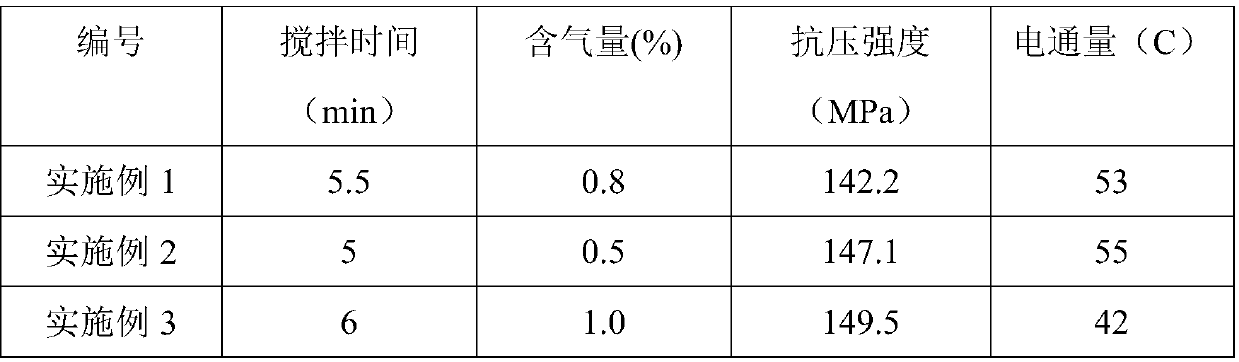

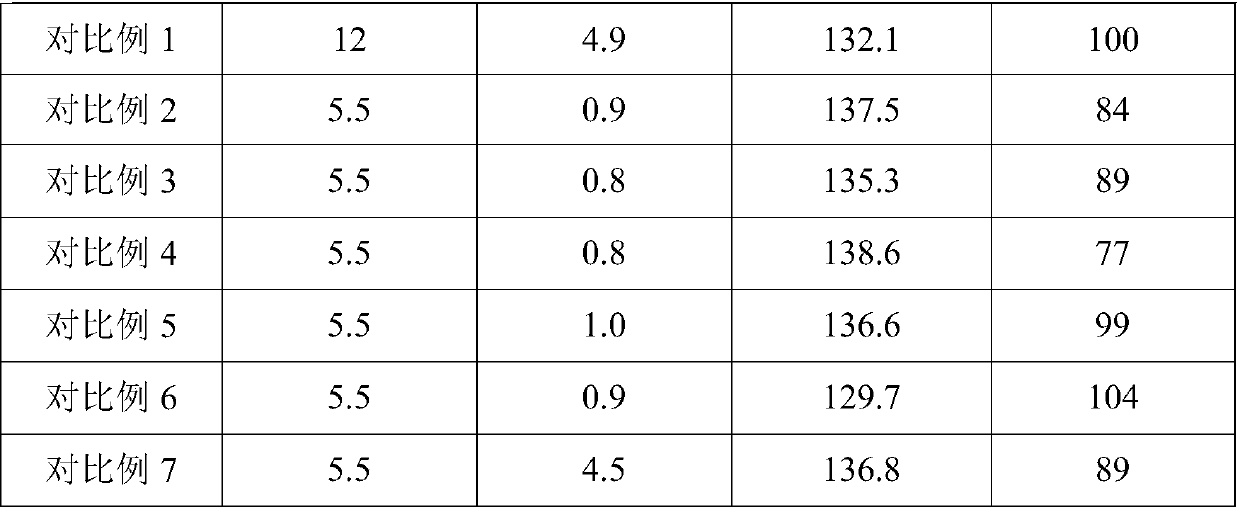

Embodiment 1

[0023] S1 prepares mixer A and mixer B;

[0024] S2 Put 2.6kg of Portland cement (P.O 52.5), 1.5kg of silica fume, 0.8kg of water and 0.13kg of polycarboxylate superplasticizer into mixer A and stir for 3 minutes to obtain a uniformly stirred cementitious material slurry;

[0025] S3 Put 4.0kg of quartz sand (about 0.5mm) and 0.8kg of steel fiber (about 0.3×12mm) into the mixer B and stir for 3 minutes to obtain a uniformly stirred mixture;

[0026] S4 puts the mixture obtained in step S3 into the uniformly stirred cementitious material slurry in step S2, and continues to stir for 2.5 minutes under the vacuum condition of 0.08±0.02Mpa to obtain uniformly stirred ultra-high performance concrete.

Embodiment 2

[0028] S1 prepares mixer A and mixer B;

[0029] S2 Put 3.0kg of Portland cement (P.O 52.5), 1.0kg of silica fume, 0.6kg of water and 0.15kg of polycarboxylate superplasticizer into mixer A for stirring, and stir for 2 minutes to obtain a uniformly stirred cementitious material slurry;

[0030] S3 Put 3.5kg of quartz sand (about 0.5mm) and 1.2kg of steel fiber (about 0.3×12mm) into the mixer B and stir for 2 minutes to obtain a uniformly stirred mixture;

[0031] S4 puts the mixture obtained in step S3 into the uniformly stirred cementitious material slurry in step S2, and continues to stir for 3 minutes under the vacuum condition of 0.08±0.02Mpa to obtain uniformly stirred ultra-high performance concrete.

Embodiment 3

[0033] S1 prepares mixer A and mixer B;

[0034] S2 Put 2.3kg of Portland cement (P.O 52.5), 2.0kg of silica fume, 1.0kg of water and 0.11kg of polycarboxylate superplasticizer into mixer A and stir for 4 minutes to obtain a uniformly stirred cementitious material slurry;

[0035] S3 Put 4.5kg of quartz sand (about 0.5mm) and 0.4kg of steel fiber (about 0.3×12mm) into the mixer B and stir for 4 minutes to obtain a uniformly stirred mixture;

[0036] S4 puts the mixture obtained in step S3 into the uniformly stirred cementitious material slurry in step S2, and continues to stir for 2 minutes under the vacuum condition of 0.08±0.02Mpa to obtain uniformly stirred ultra-high performance concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com