Position adjustable load support mechanism

a technology of load support and position adjustment, which is applied in the direction of machine supports, building scaffolds, other domestic objects, etc., can solve the problems of limiting the materials available for the heavily stressed components, and difficulty in adjusting the counterbalancing for

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

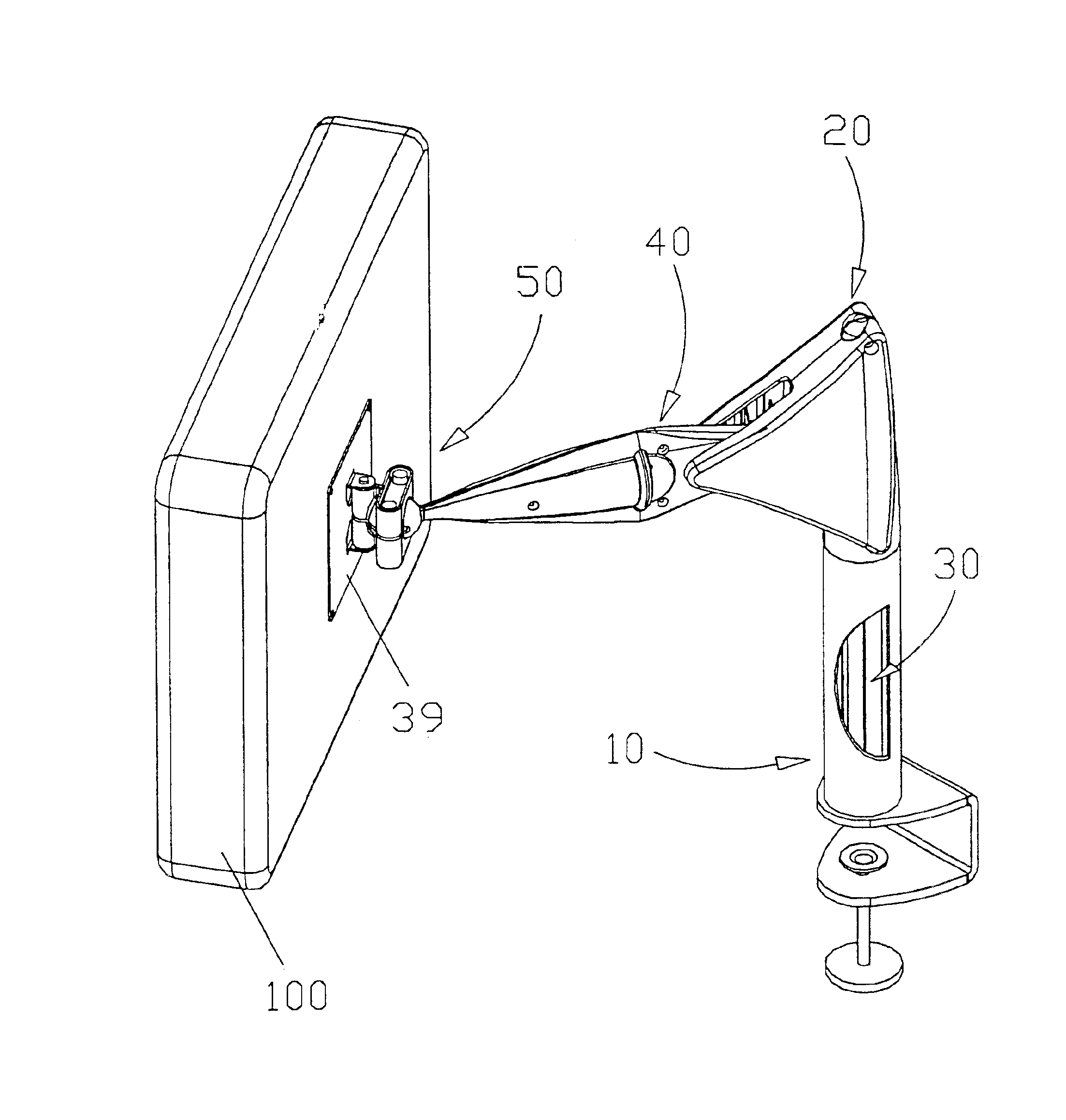

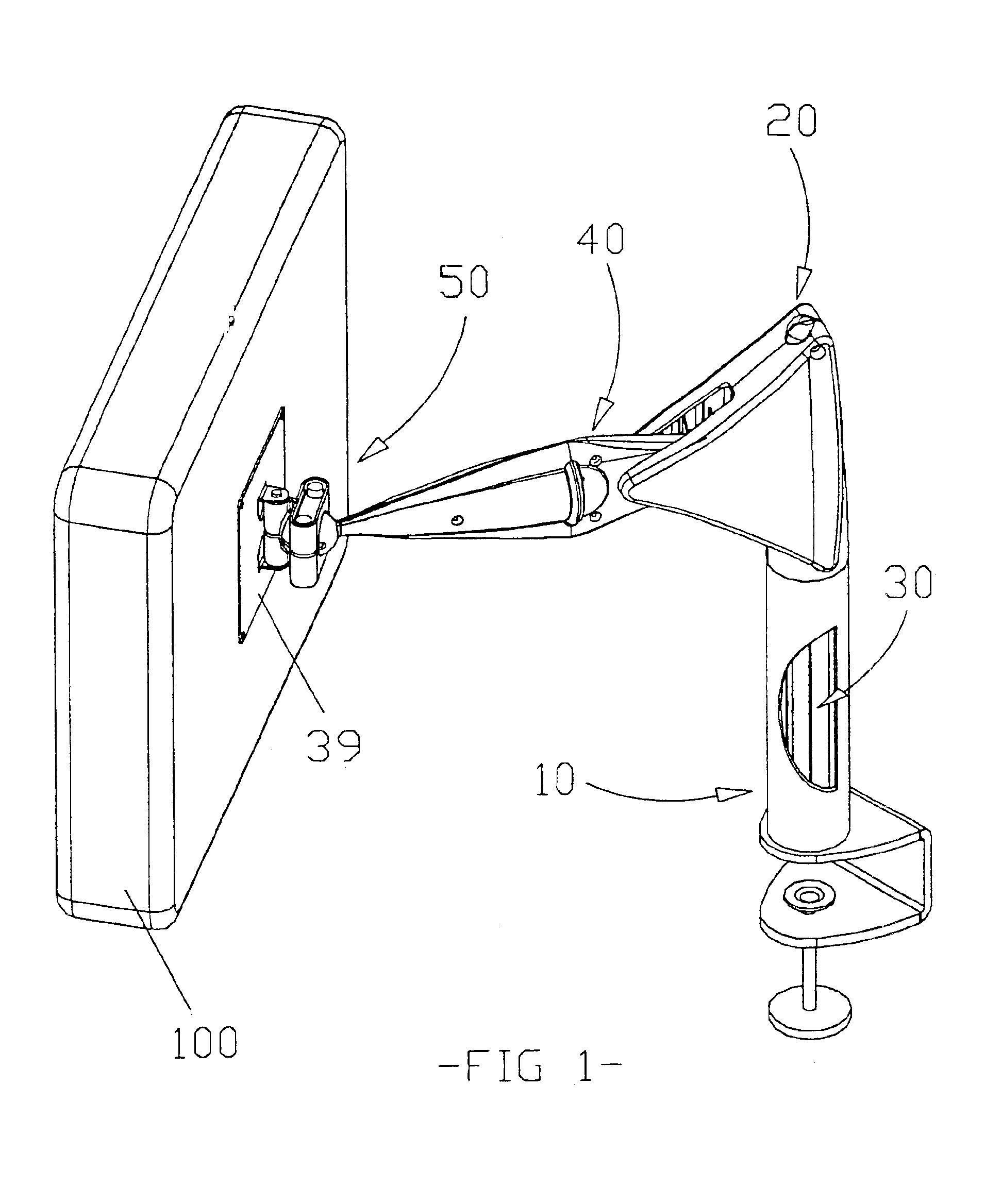

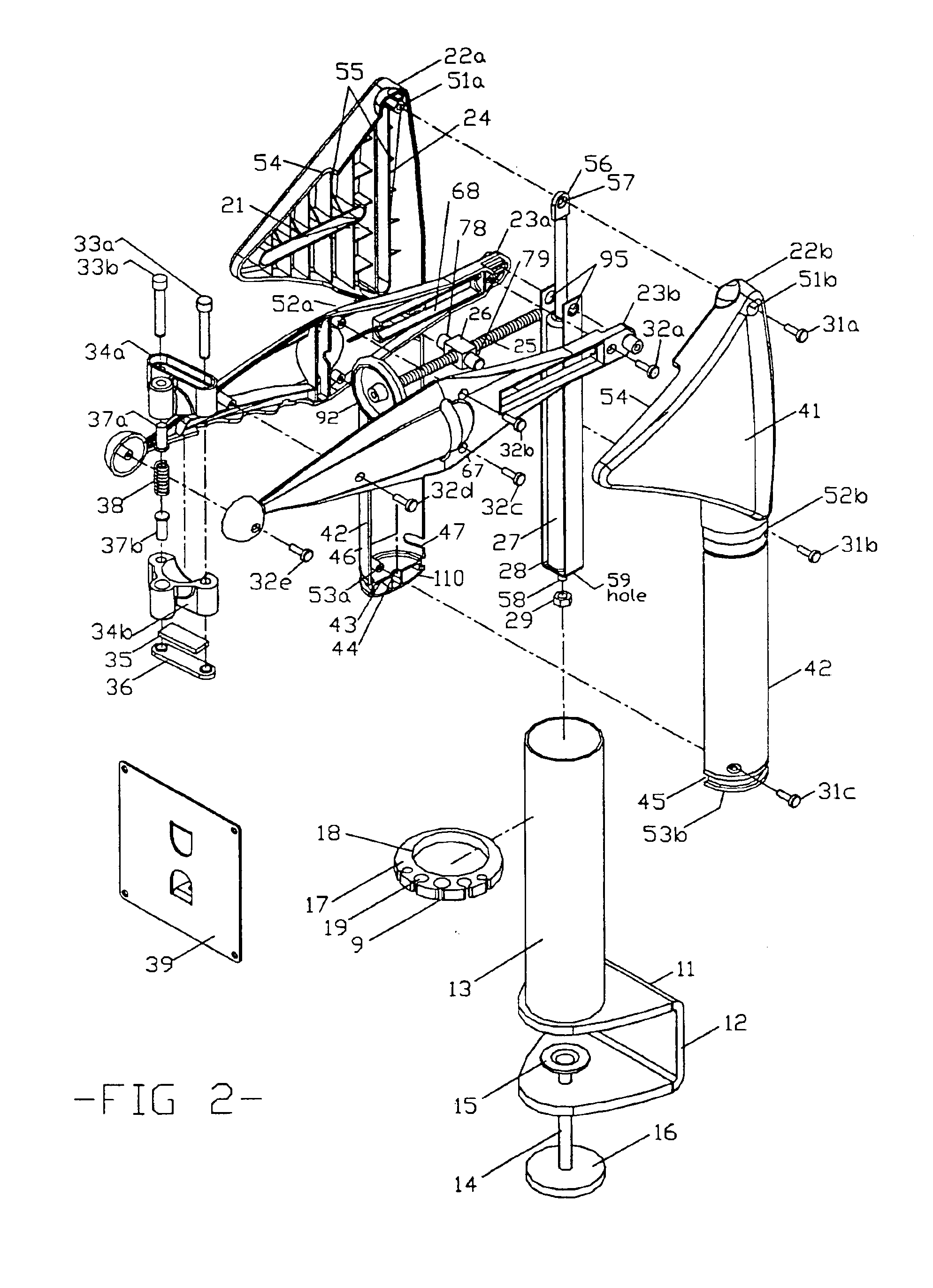

For purposes of description herein, the terms forward, rearward, upward, and downward relate to the load support mechanism as oriented in FIG. 2 where the viewer's left side is considered the forward direction. As shown in FIGS. 1 & 2 the adjustable position load support mechanism includes an anchoring arrangement 10, a load counterbalancing arrangement 30, a housing assembly 20, an arm assembly 40, and a ball and socket friction producing arrangement 50 that includes a mounting plate 39 for the attachment of a load 100, which is in this case a typical video display device.

The anchoring arrangement 10 is comprised of a channel shaped member 12. To one of the channel flange surfaces 1 is rigidly attached a hollow cylinder 13. On the same axis as the cylinder and extending through the opposite flange is a threadable member 14 and a disk shaped pad 15 which engages against the bottom surface of a desk overhang to enable a clamping operation to be effected when a clamping handle 16 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com