Furnace blower housing with integrally formed exhaust transition

a blower housing and exhaust transition technology, applied in the field of blower housings, can solve the problems of increasing and the labor to attach the transition piece to the blower assembly, so as to reduce the cost of the blower assembly and the associated, the effect of less labor intensive, and less expensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The use of the terms substantially and generally in the specification are meant to convey approximate shapes and orientations. The terms are not meant to limit the invention to precisely the shapes and orientations recited.

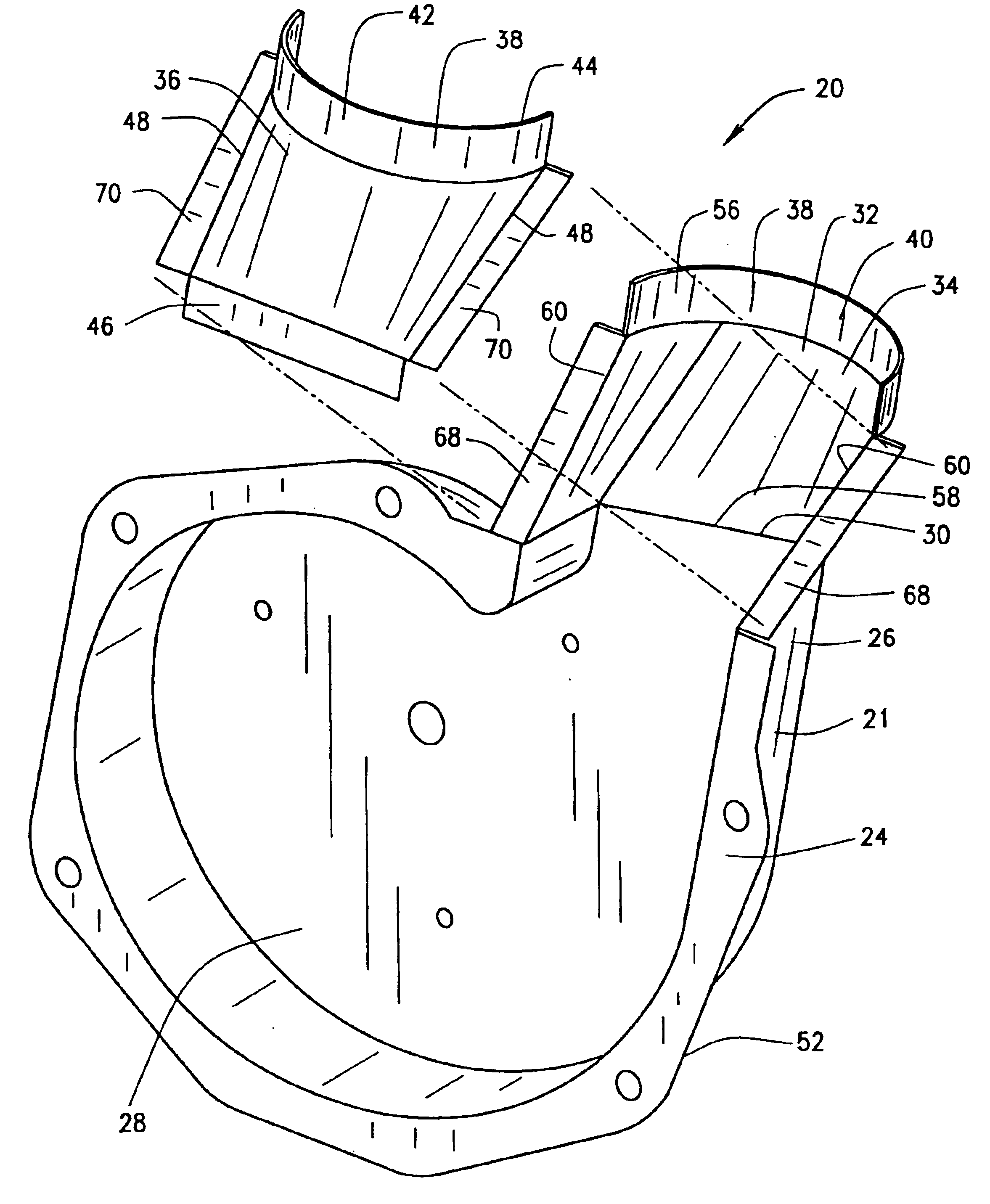

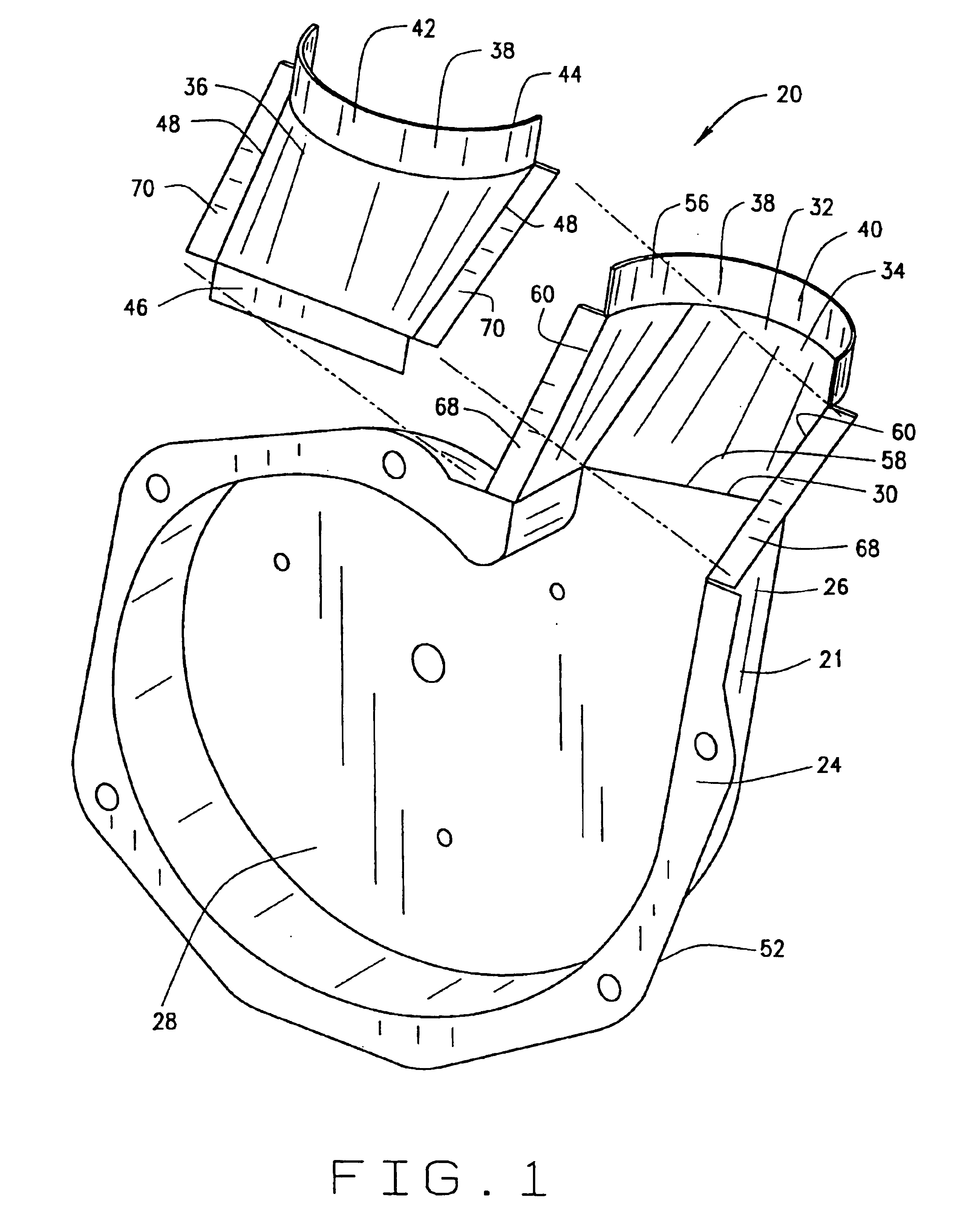

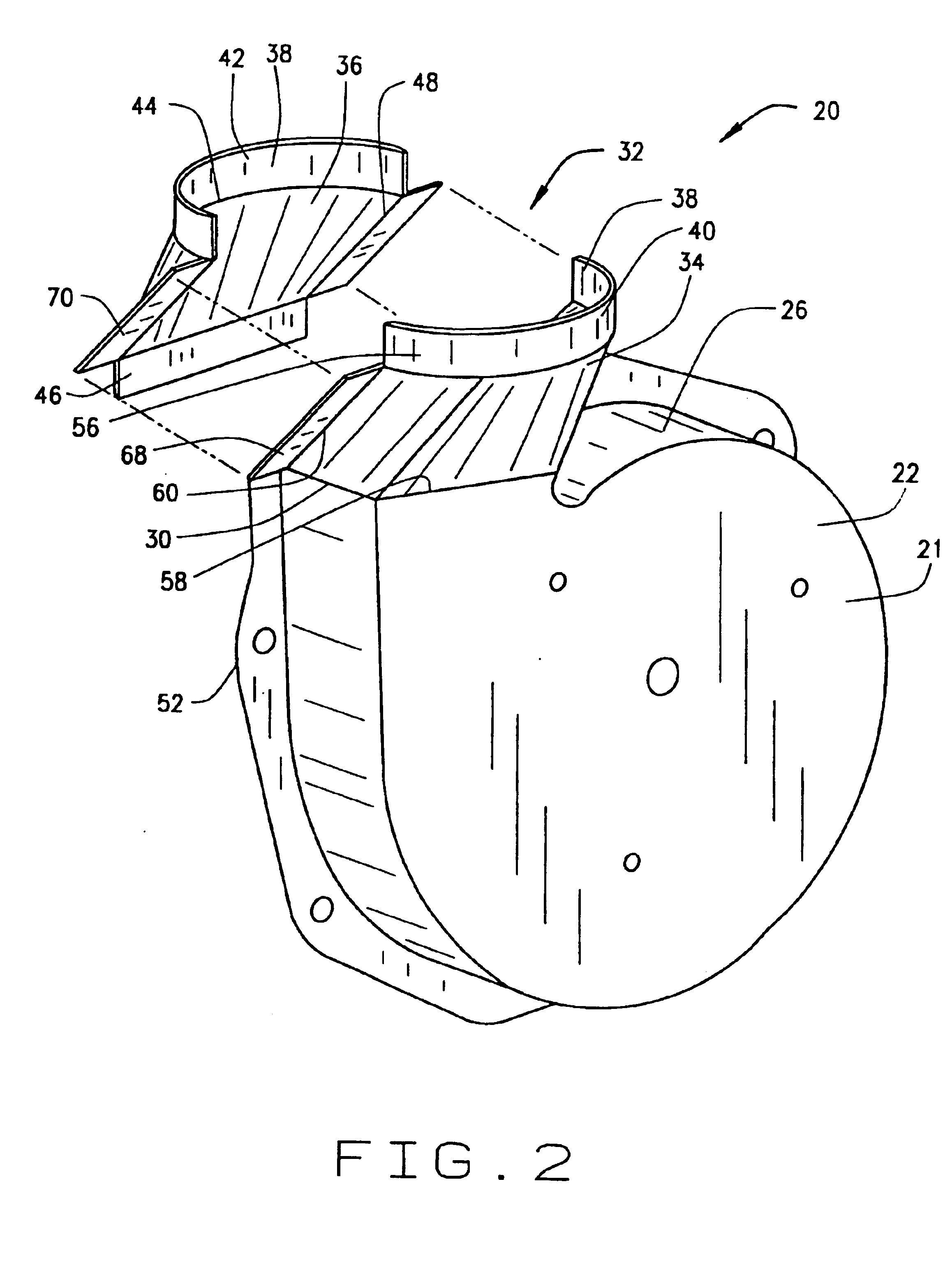

[0024]FIG. 1 shows the blower housing of the invention with the integrally formed portion of the exhaust transition generally indicated as 20. The housing 20 has a body 21 having a front wall 22 and a back wall or flange 24. A sidewall 26 extends between the front and back walls 22, 24. The sidewall 26 has a volute shape, which is typical of furnace blower housings and well known in the industry. The body 21 has a interior cavity 28 that is defined by the front and back walls 22, 24 and the sidewall 26. The cavity 28 is configured and adapted to house a fan (not shown) that rotates within the cavity 28 to generate a flow of air through the blower housing 20. The body 21 has a throat 30 that leads to an exhaust transition which is generally indicated as 32. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com