Motor vehicle drivetrain having at least two CNT's and flywheels

a technology of motor vehicles and drivetrains, applied in the direction of gearing, mechanical control devices, instruments, etc., can solve the problems of reducing the overall efficiency, cost, weight of batteries and electric motors, overall thermal efficiency, etc., and achieve the effect of a simple and far more efficient motor vehicle drivetrain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

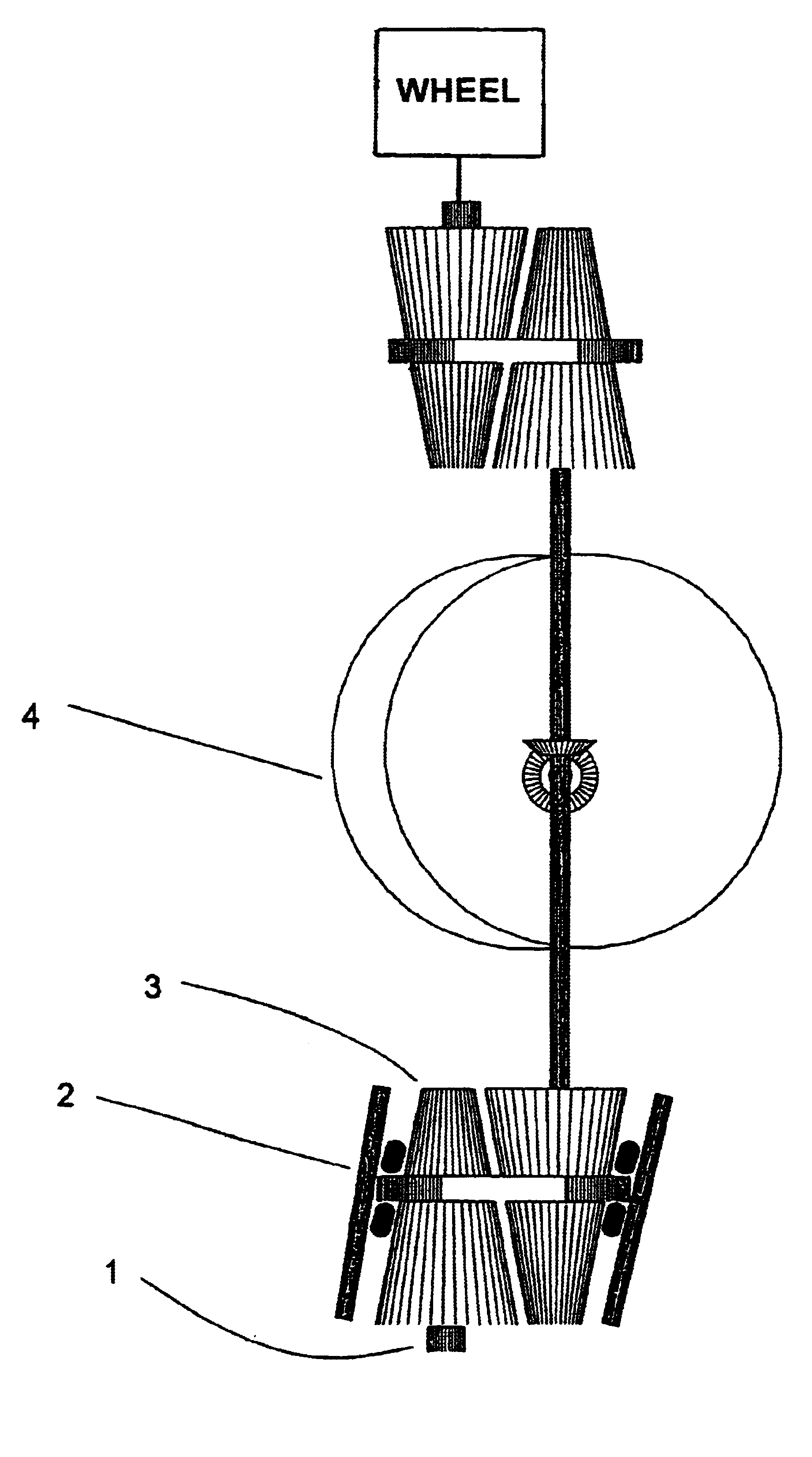

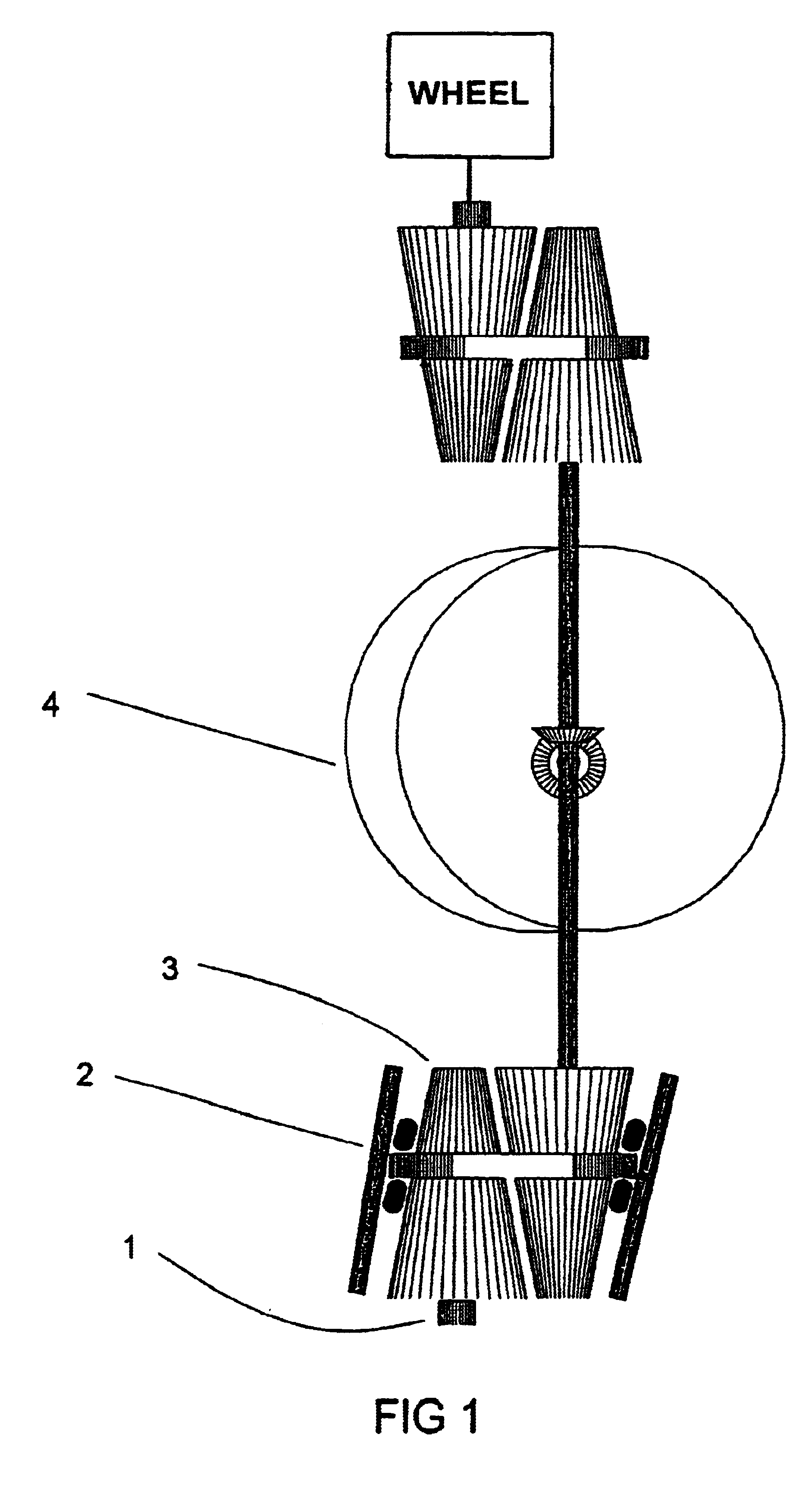

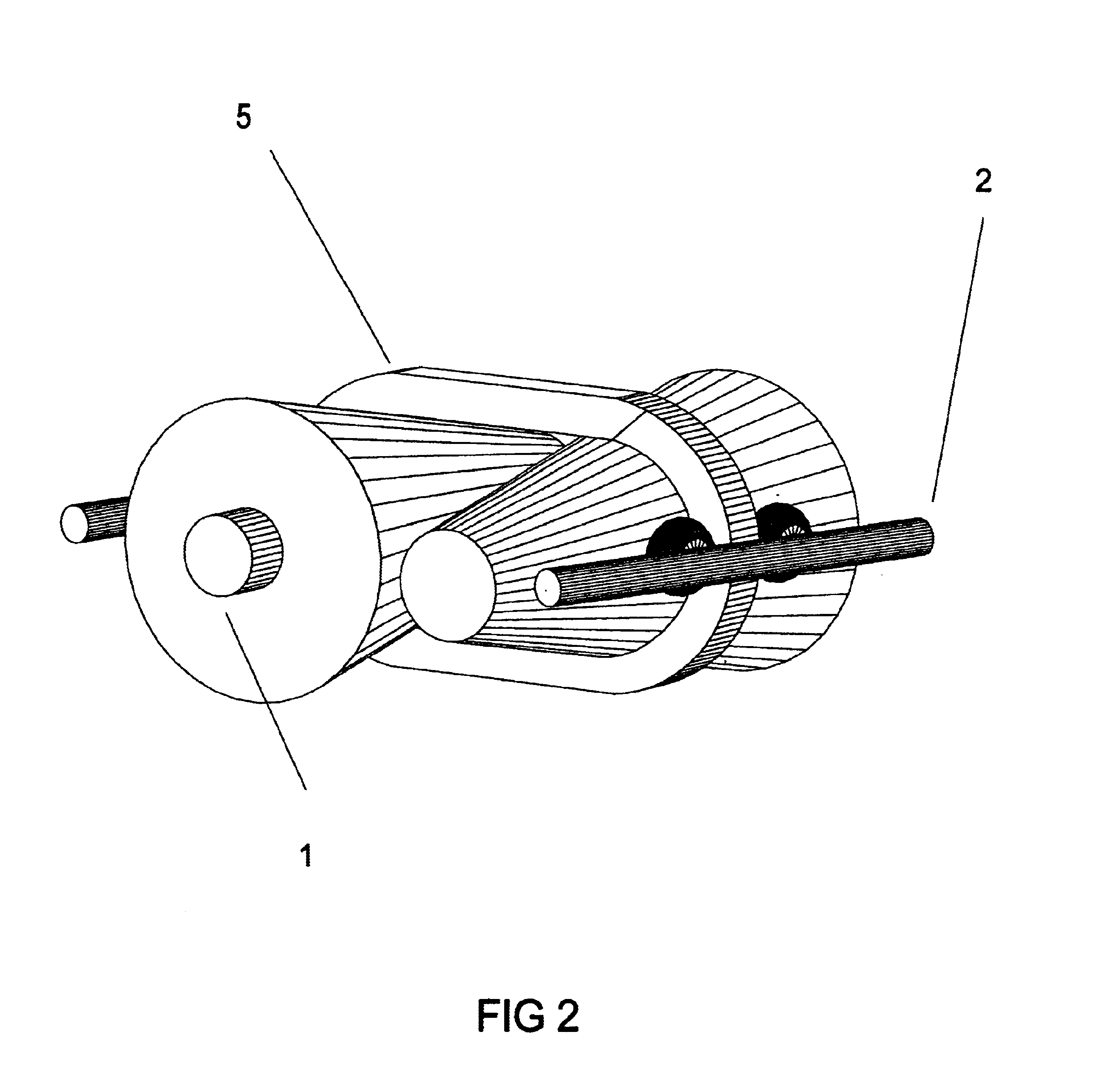

[0018]A continously variable ratio transmission 3 (CVRT), transfers power from the engine torque converter via the input shaft 1 (not part of this patent application) to the flywheel set 4, is controlled by an onboard programmable logic controller (PLC). This PLC receives inputs from the input shaft's RPM, the flywheel set's RPM, and torque on the input shaft I and adjusts the transmission by moving the shuttle control 2 which moves the drive belt. The program is set to a constant torque and a maximum flywheel RPM is specified. Initially, the flywheel set is accelerated at the maximum torque specified, until, and if, it reaches maximum RPM. The torque and RPM maximum are dependent on flywheel material and design, and the intended goal of the programmer (acceleration vs high mileage). Once the flywheel reaches maximum speed, the torque is reduced by changing the ratio of CVRT 3, allowing the flywheel to slow as demand for power is received from the second CVRT. At all times the engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com