Takeout and transfer apparatus and method for a wheel blow molding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

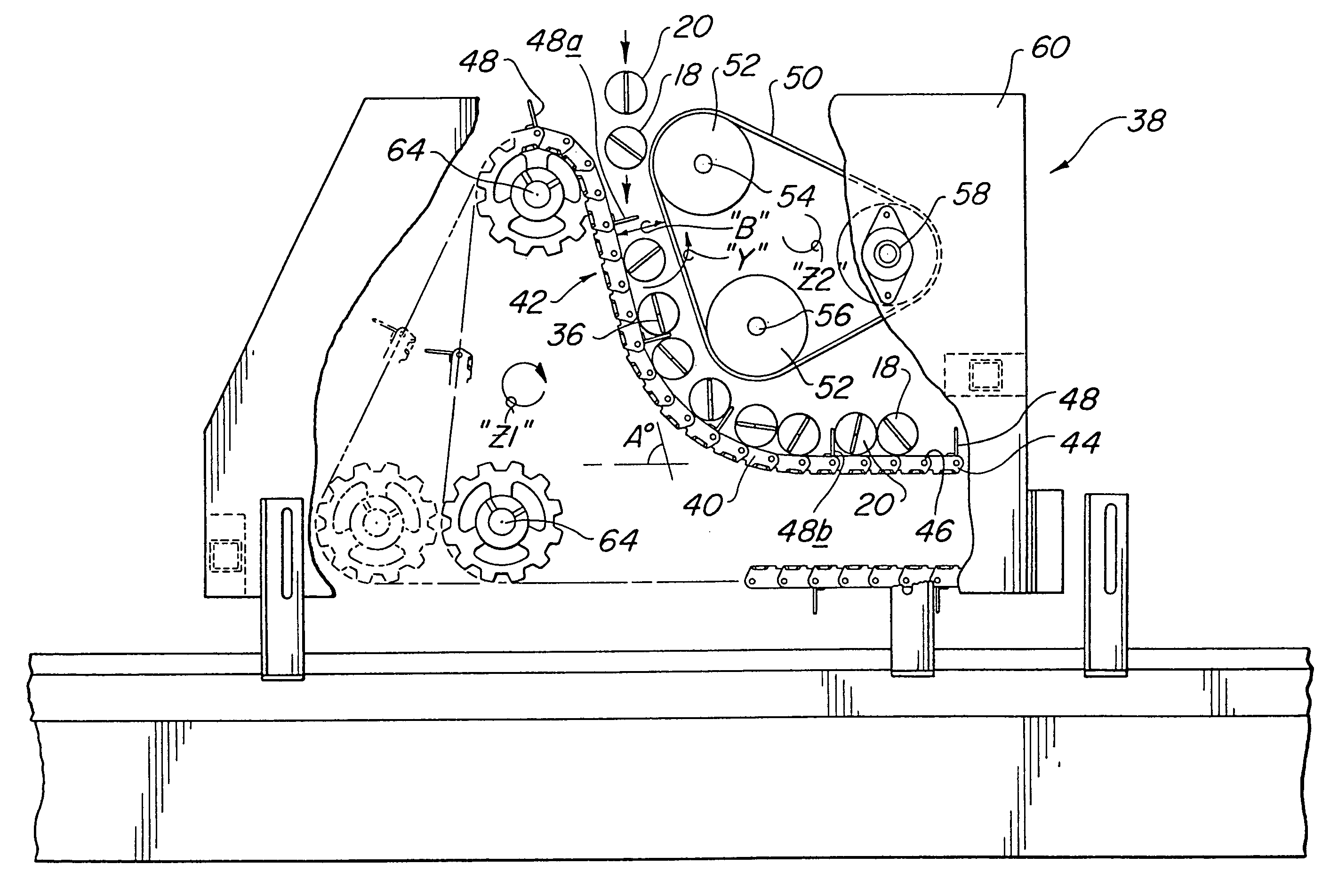

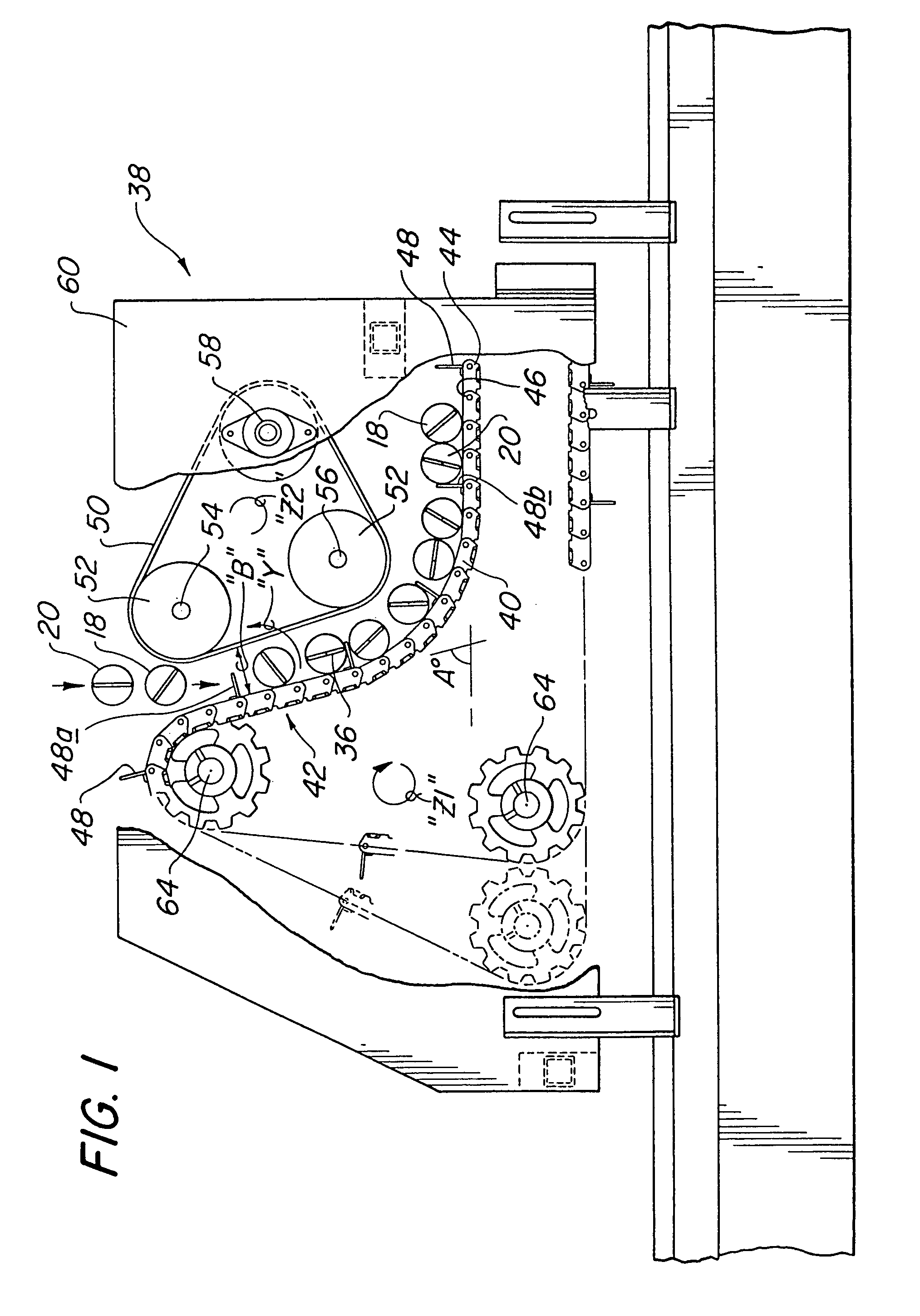

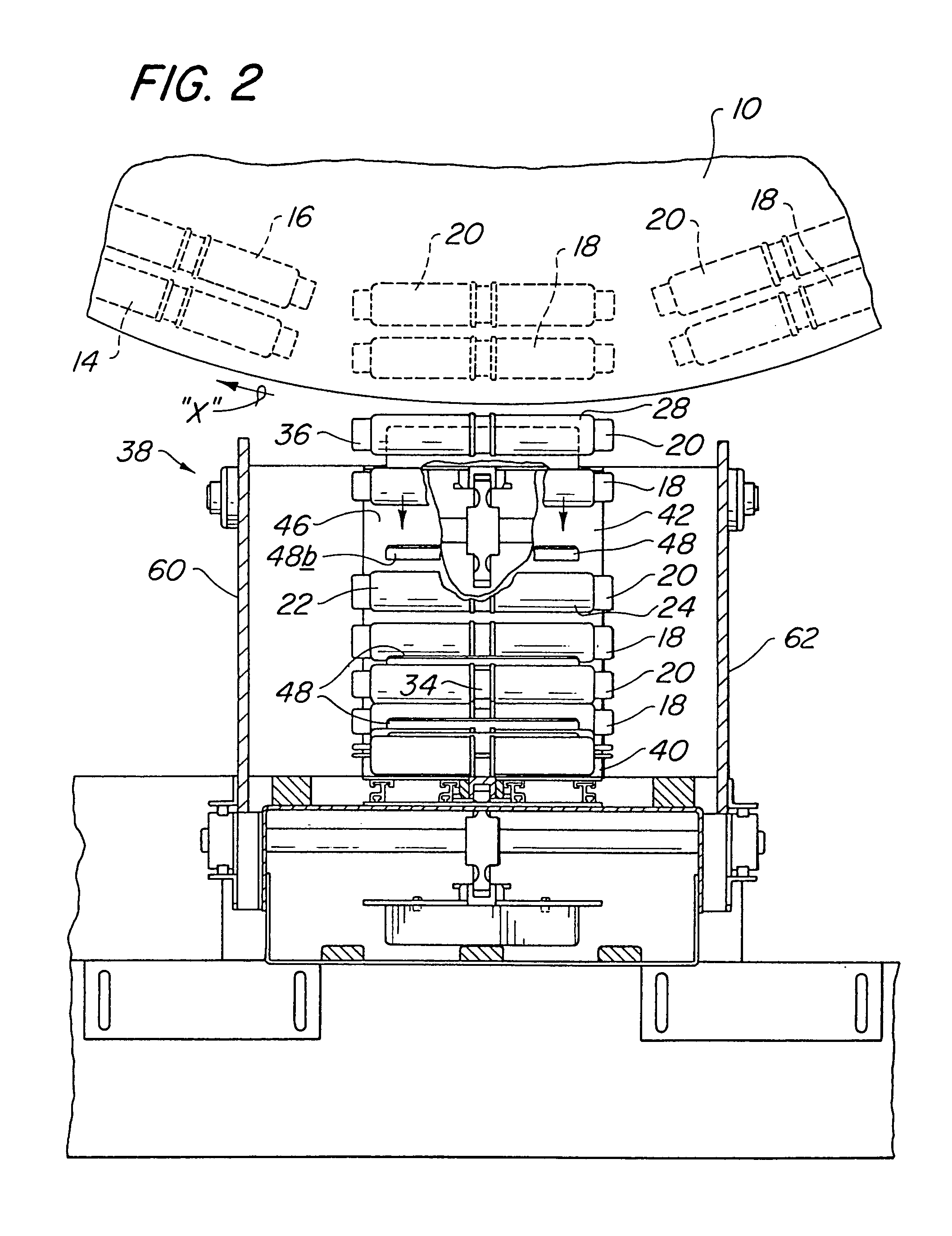

[0021]As referenced above, a vertically-disposed wheel blow molding machine includes an outer peripheral circular array of blow molds which follow a circular path of travel as the wheel blow molding machine continuously revolves at a constant speed. For purposes of example, a portion of a wheel blow molding machine 10 rotating in a clock-wise direction “X” is illustrated in FIG. 2, and a blow mold 12 is illustrated in FIG. 4. Each mold 12 is capable of opening to receive at least one molten tube of thermoplastic material, ie. a parison, and closing to confine the parison within a cavity formed by the inner walls of the mold. As the mold rotates, a blow pin is inserted into the parison to expand it into the cavity of the closed mold, and before one complete revolution, the mold opens to release the blown article. Thus, at the end of a full revolution, the mold is empty and open in a condition ready to receive another parison.

[0022]The takeout and transfer apparatus of the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com