Air filtering system

a filtering system and air technology, applied in the direction of filter regeneration, particle charging/ionising station, external electric electrostatic separator, etc., can solve the problem of increasing pressure drop, achieve the effect of accelerating the breaking down of organic substances in the air, cleaning the air, and increasing the energy level of oxygen in the air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

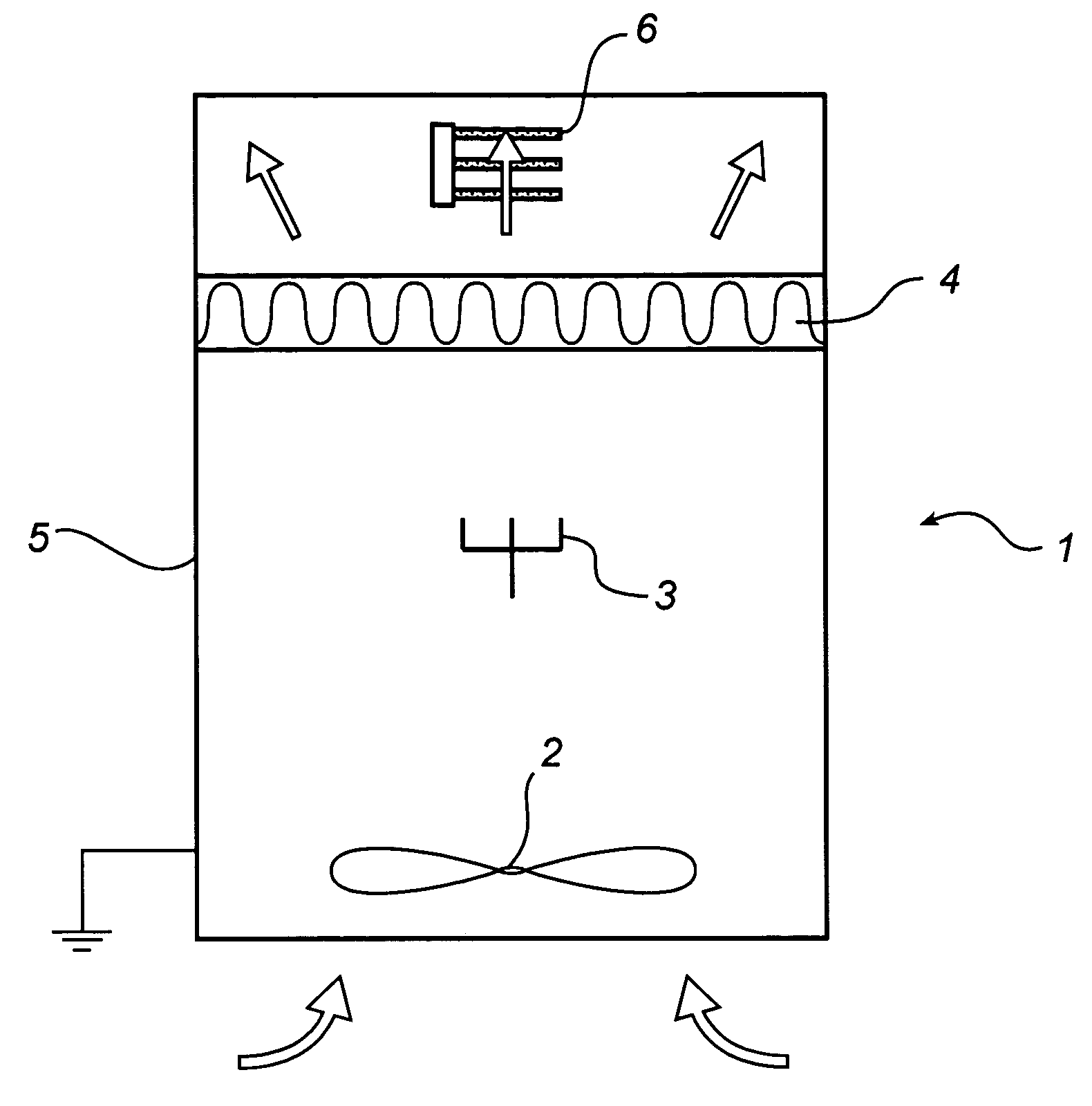

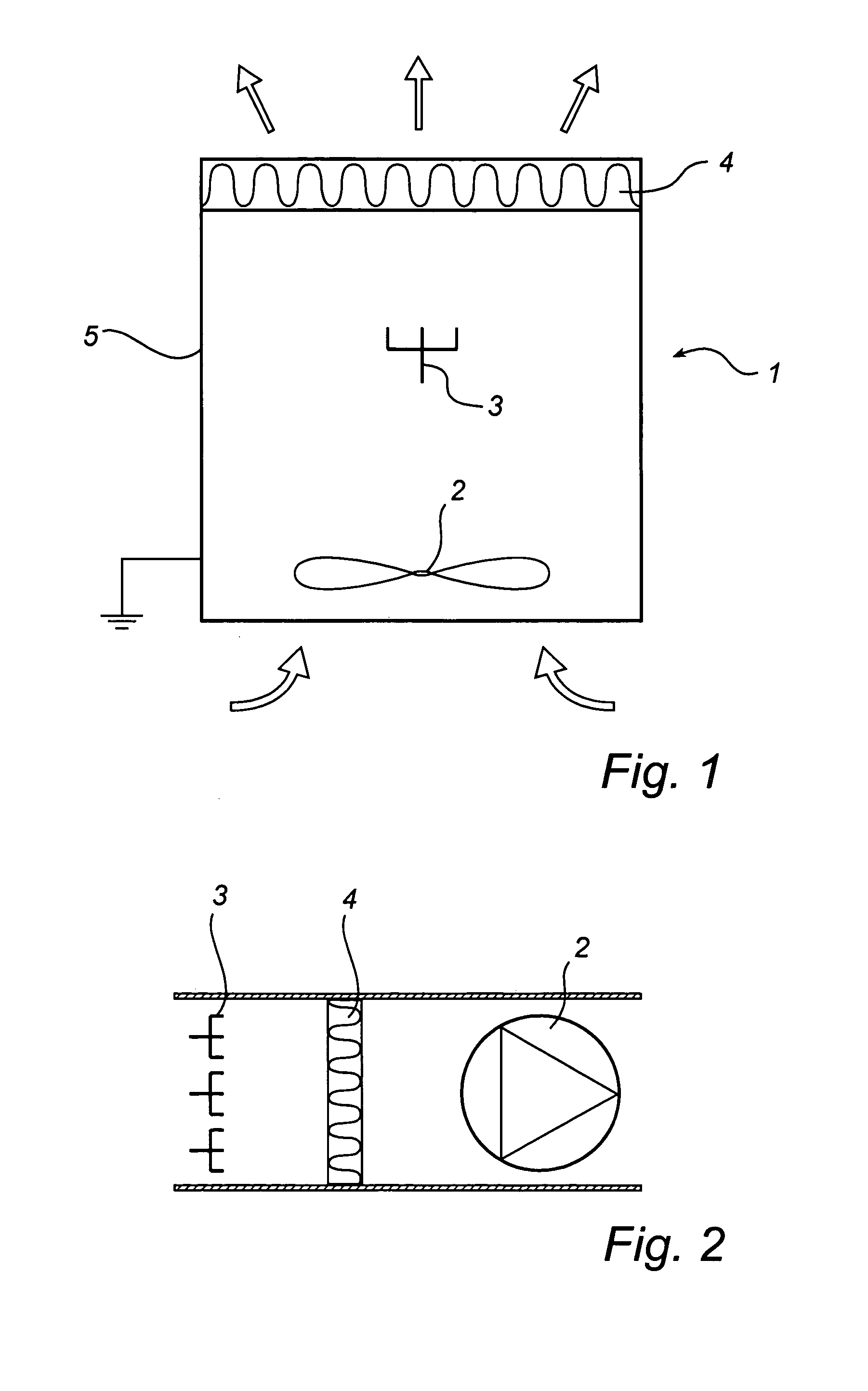

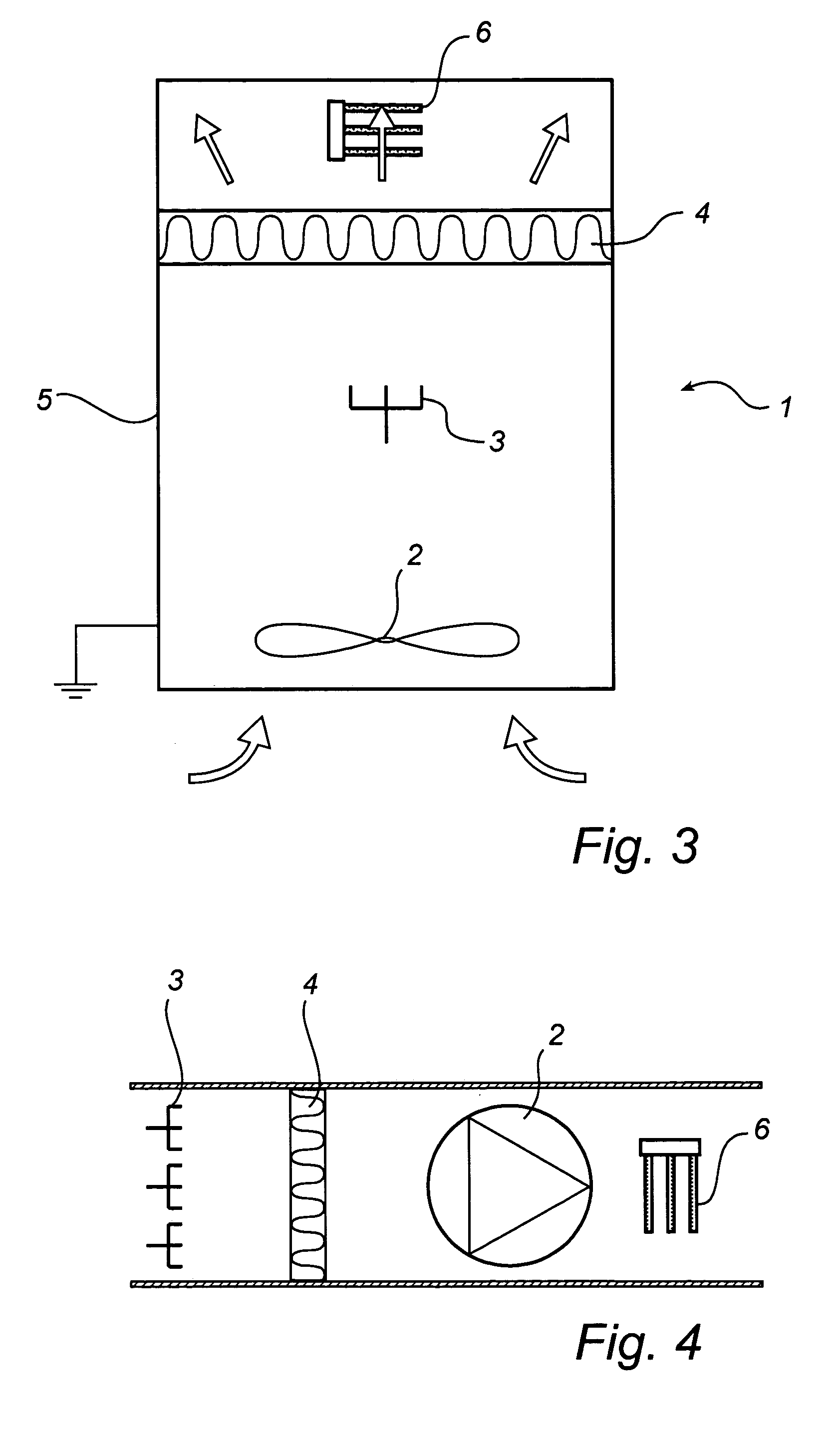

[0015]FIG. 1 shows an air cleaner 1 comprising a fan 2, an ionizing means 3, a filter 4 and an earthed casing 5. The air is delivered to the air cleaner 1 by means of the fan 2, after which the air flows past the ionizing means 3, whereby the air is ionized. After the air has been ionized, it thus flows through the filter 4. The filter 4 is preferably made of polypropylene mixed with modified acrylic, i.e. in this case polyvinyl chloride is grafted into the acrylic. The polypropylene fibers and the acrylic are processed in a carding process to produce filter material comprising portions which are negatively charged and other portions which are positively charged, an electric field arising in the filter material that helps to catch the particles in the ionized air. The effect of the ionization differs, depending on the properties of the particles, such as material, size and temperature. In some cases, the particles form lumps, which makes it easier for them to be absorbed by the filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure drop | aaaaa | aaaaa |

| energy level | aaaaa | aaaaa |

| electric field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com