Structural vent assembly for a roof perimeter

a structure vent and perimeter technology, applied in ventilation systems, lighting and heating apparatus, heating types, etc., can solve the problems of affecting the quality of roof materials, and the design of venting eaves is not uniform, so as to improve field productivity and improve the quality of products. , the effect of less expensive and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

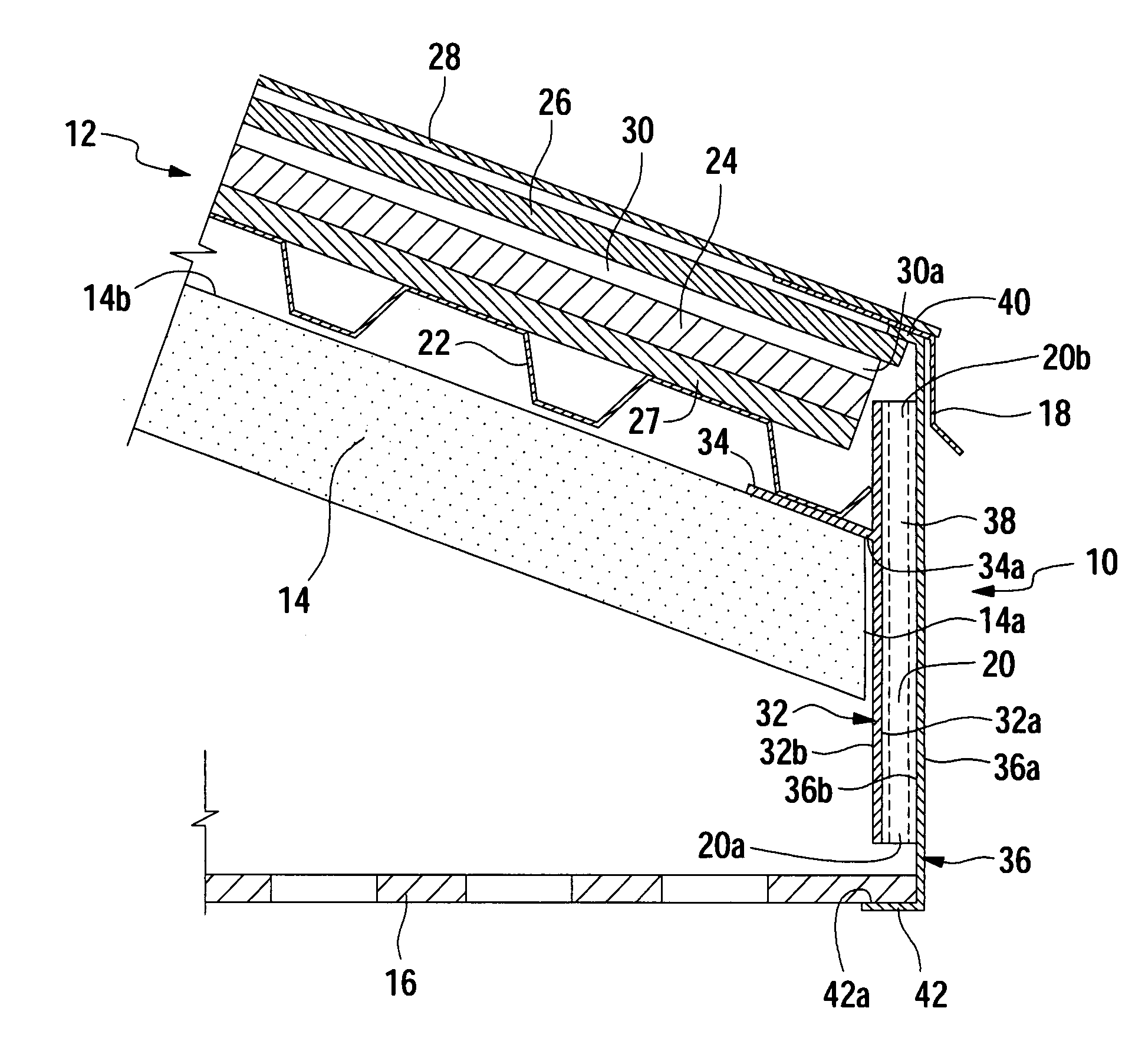

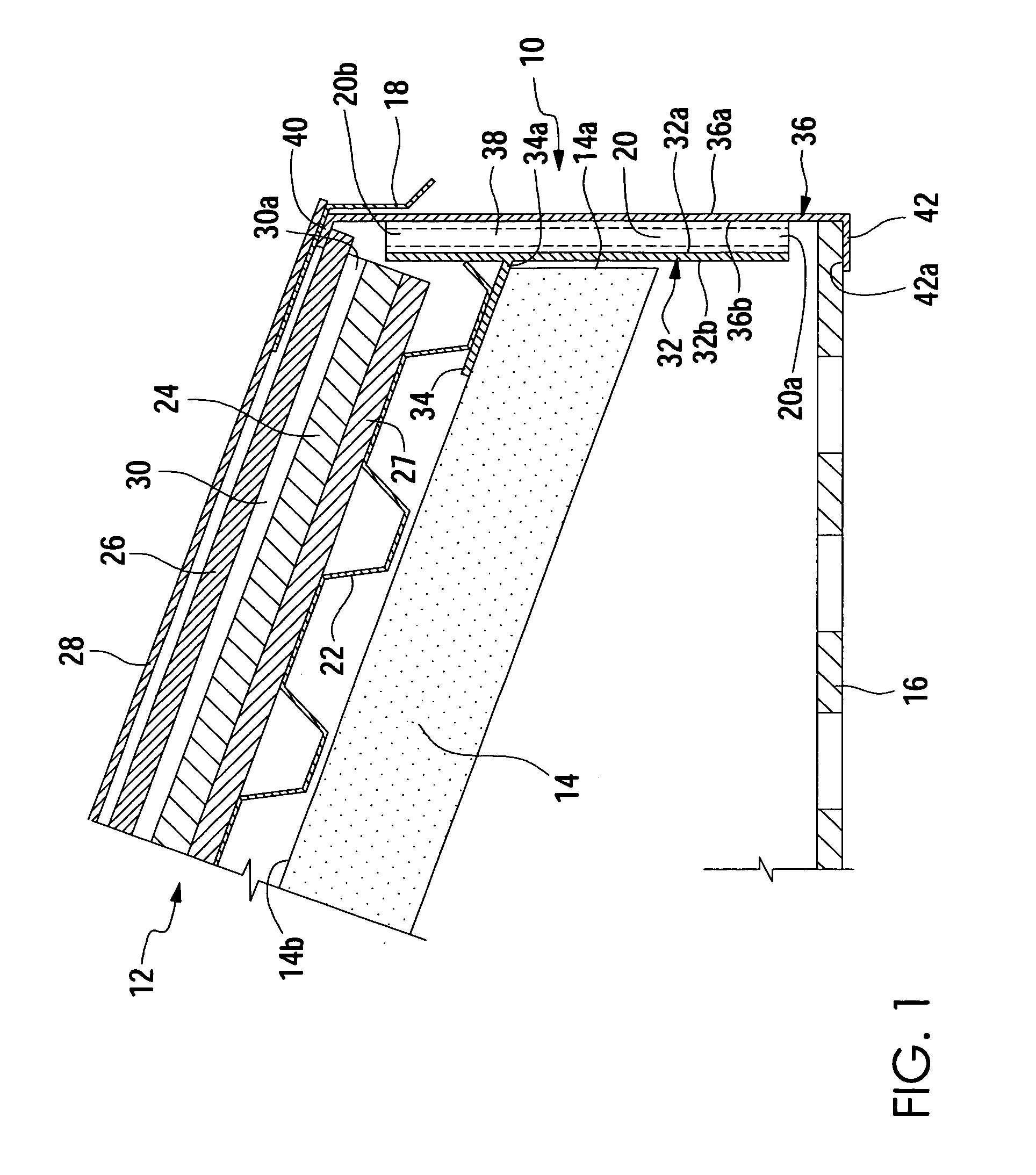

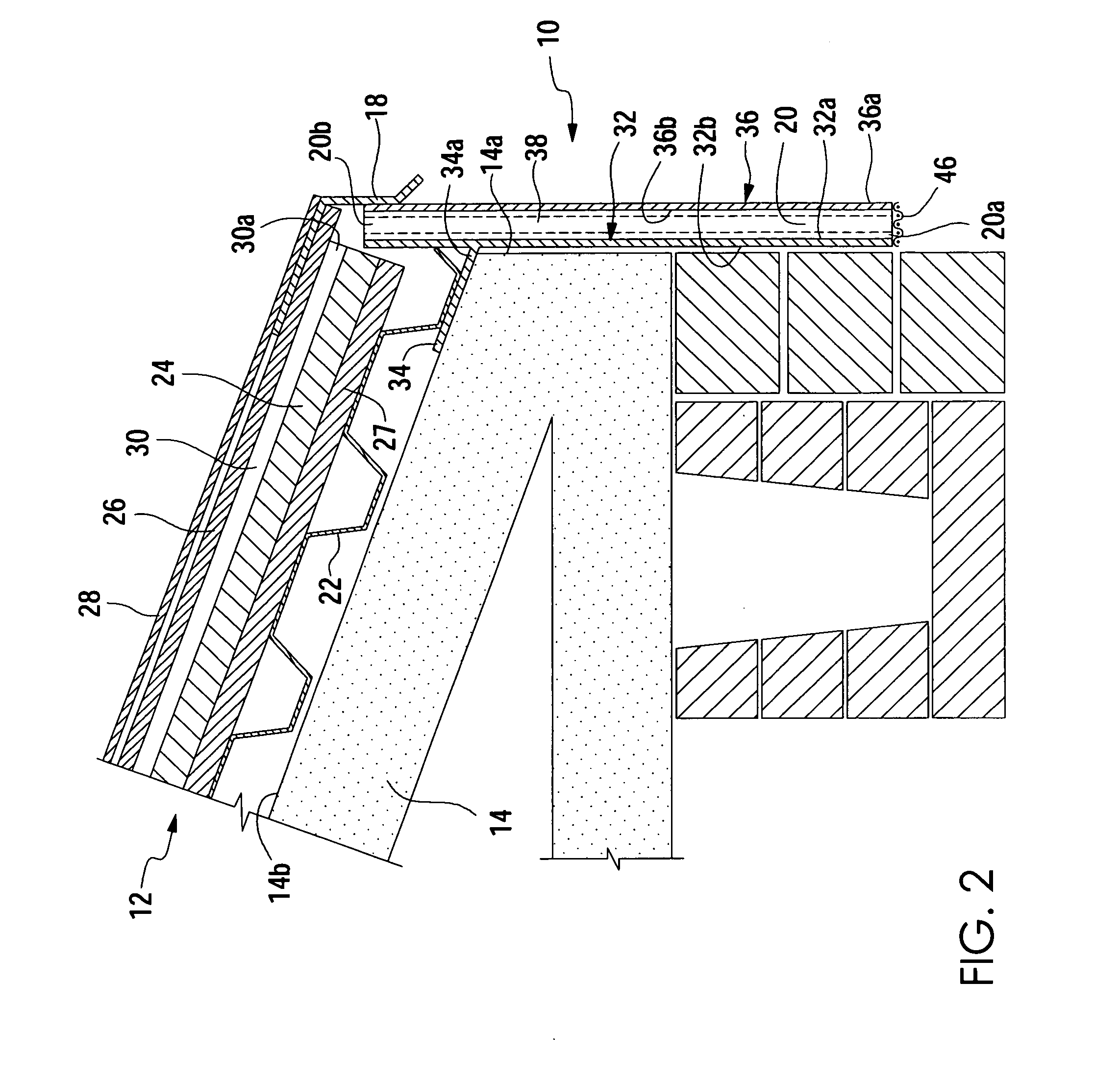

[0022]Referring to the FIGS. 1–5 for a clearer understanding of the invention, it may be seen that the invention contemplates a vented roof system having a structural vent assembly 10 for use along the perimeter of a roof comprising a vented roof deck 12 and a roof deck support structure 14. The structural vent assembly 10 of the present invention is preferably a single, prefabricated assembly ready for field installation during building construction in a one-step procedure. The preferred embodiment of the vent assembly 10 provides an air passage 20 which allows outside air to flow from a vented soffit 16 to a vented roof deck 12 as shown in FIG. 1. Alternatively, the vent assembly 10 of the present invention may be utilized for roof systems not having a soffit panel, such as the roof system shown in FIG. 2. As shown in FIGS. 1 and 2, the vent assembly 10 is shown providing structural support for metal flashing 18; however, the present invention may be utilized to provide structural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com