Light emitting diode and method of the same

a technology of light-emitting diodes and diodes, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical apparatus, etc., can solve the problems of poor thermal dissipation and unsuitability for high-power applications, and achieve the effect of preventing static discharg

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

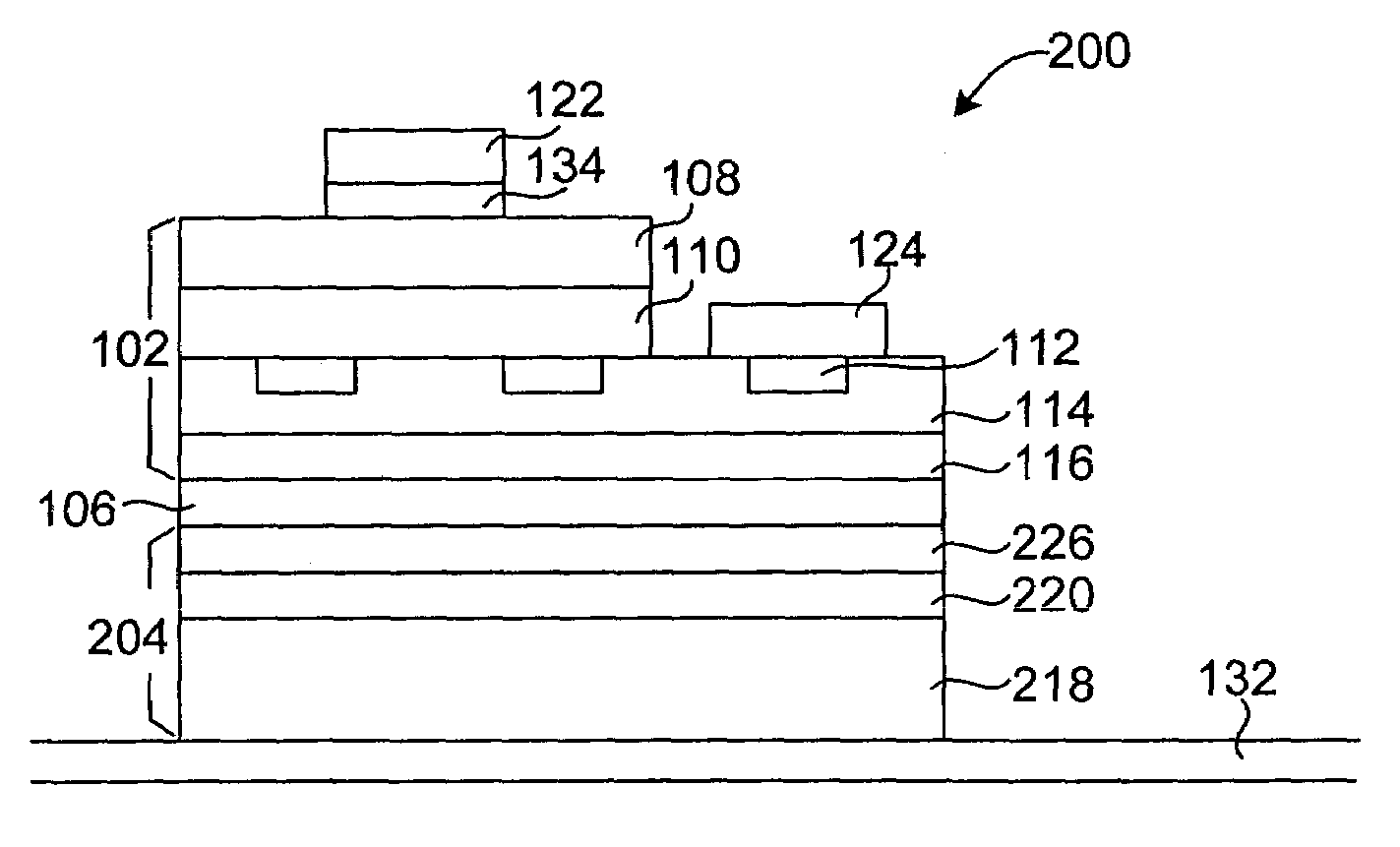

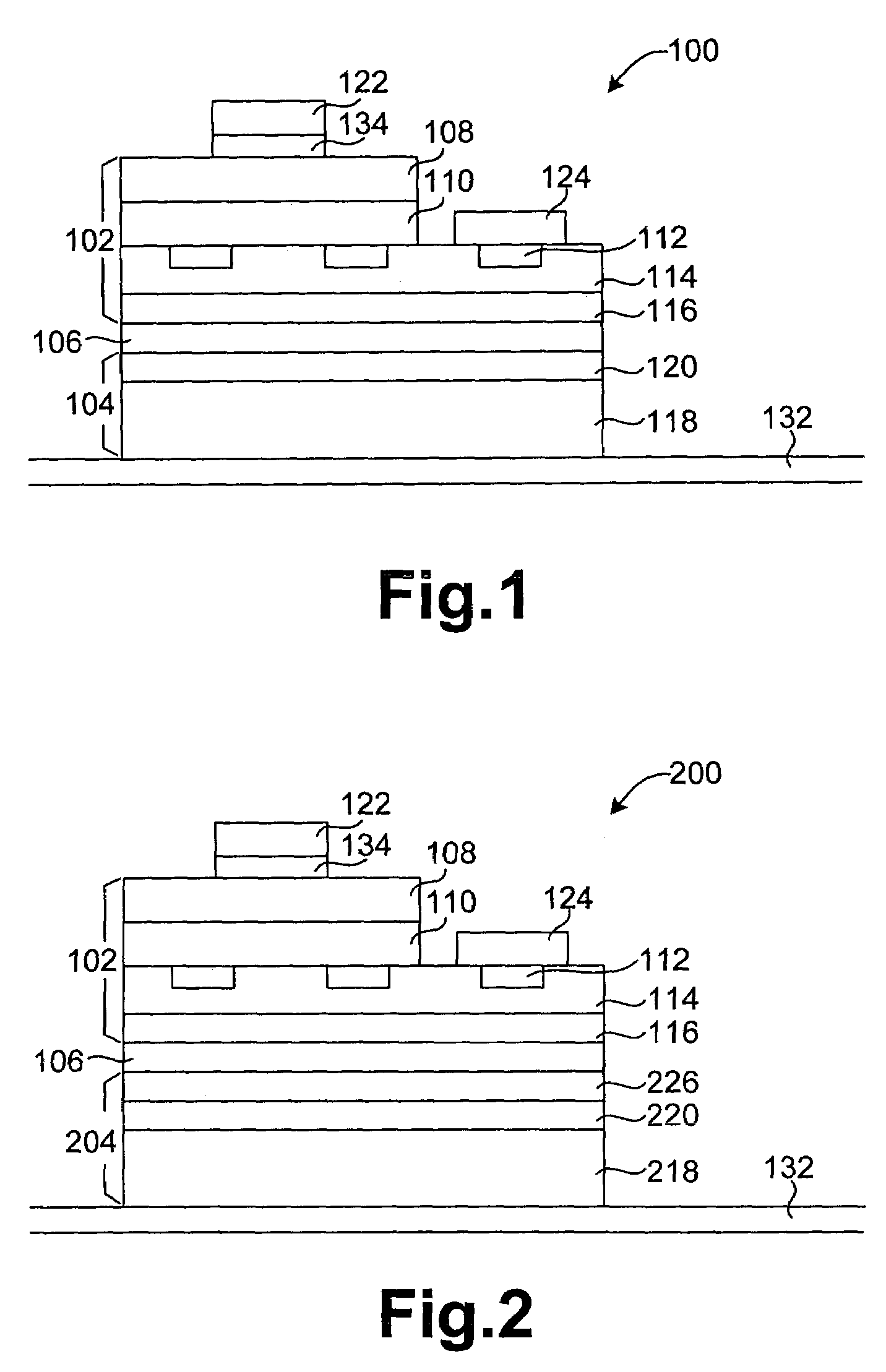

[0025]The present invention provides a light emitting diode, which is suitable for high current operation. FIGS. 1–7 illustrate preferred embodiments of the present invention. FIG. 1 illustrates a cross-sectional view of a light emitting diode 100 bonded to a base 132 in accordance with a first embodiment of the present invention. The light emitting diode 100 includes a light emitting structure 102, a silicon substrate 104, and a bonding layer 106. The light emitting structure 102 includes two semiconductor layers of different doped types, 108 and 110. The light emitting structure 102 is capable of emitting light when a current passes through. The silicon substrate 104 has two zones of different doped types, 118 and 120. The bonding layer 106 is interposed between the light emitting structure 102 and the silicon substrate 104 so that the semiconductor layer 110 and the zone 120 closest to the bonding layer 106 are of different doped types. It is noted that the bonding layer 106 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com