Liquid crystal display device

A technology for liquid crystal display devices and substrates, which is applied to static indicators, instruments, nonlinear optics, etc., can solve the problems of prolonged film formation time of gate insulating layers, decreased glue coating efficiency, and affected production efficiency, and is conducive to miniaturization. And the effect of narrowing the frame, reducing the occupied area, and enhancing the antistatic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0043] In the following description, many specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways than those described here, so the present invention is not limited by the specific embodiments disclosed below.

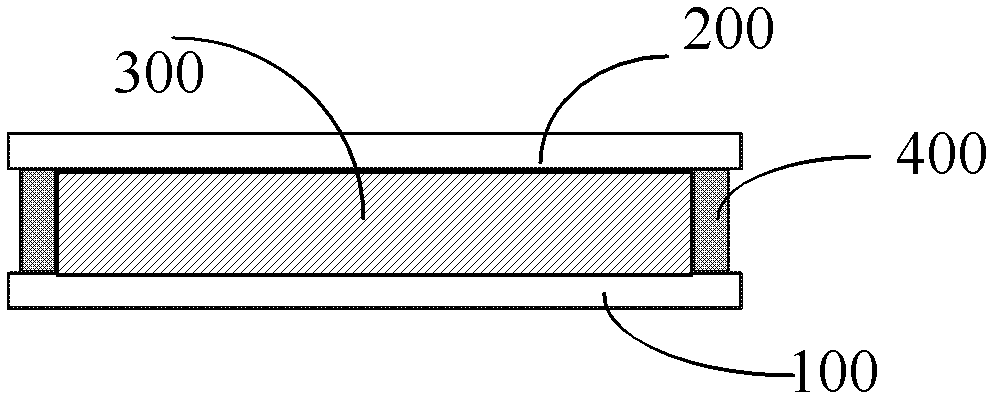

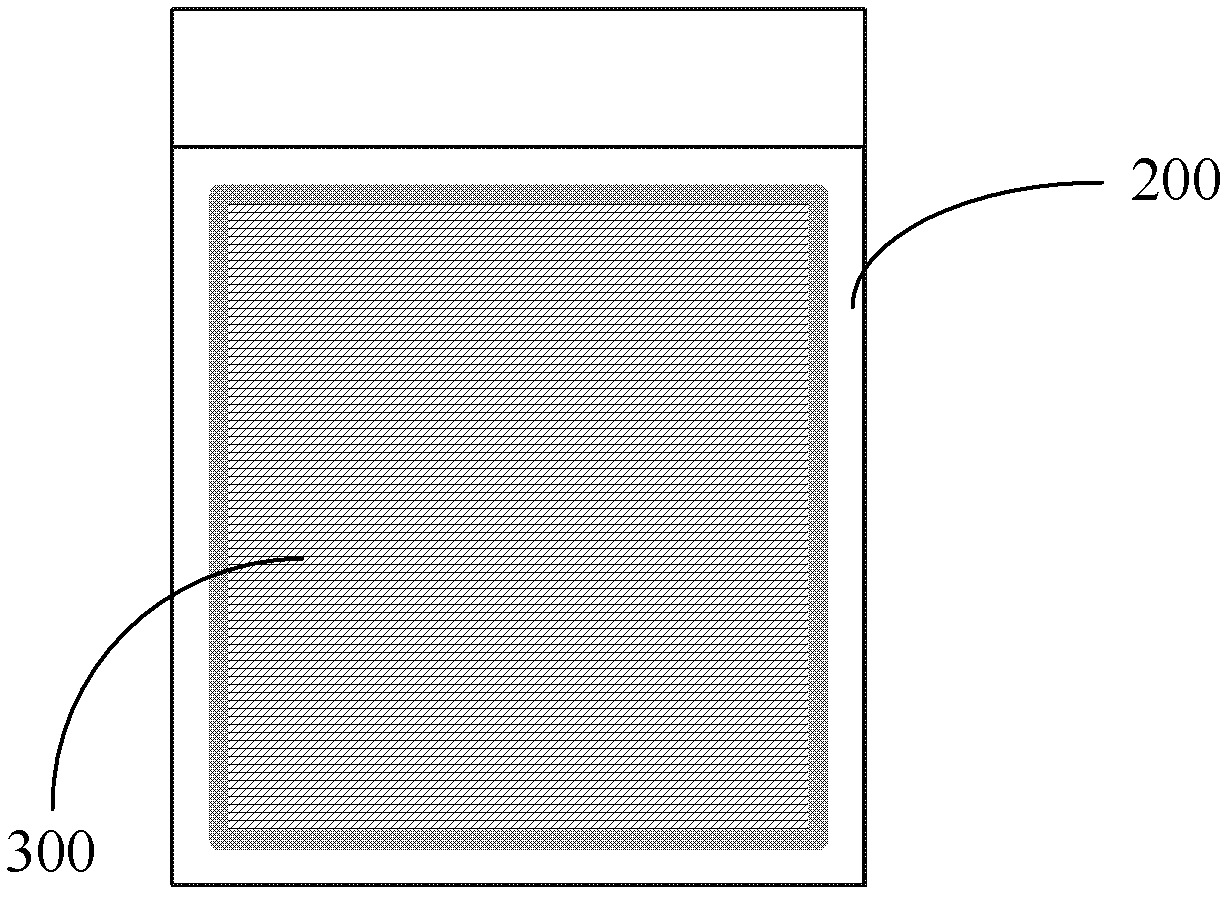

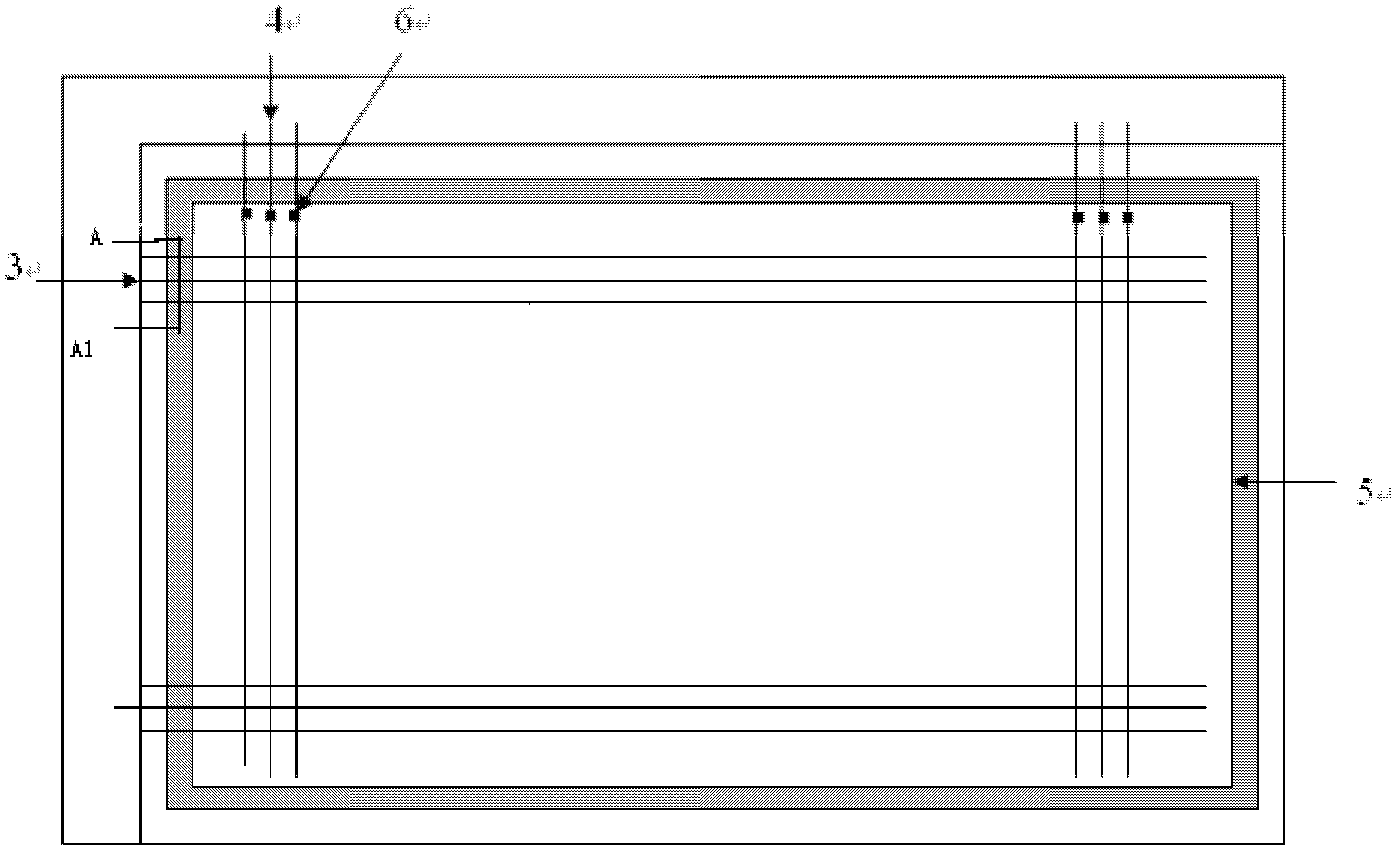

[0044]In order to solve the problems described in the background technology, the inventor provides a liquid crystal display device, comprising: a first substrate, a second substrate, arranged between the first substrate and the second substrate and used for bonding the first substrate and the second substrate Sealing of two substrates, the first substrate is provided with drive lines and first substrate common electrodes facing the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com