Method of making an article bearing a relief image using a removable film

a technology of relief image and removable film, which is applied in the direction of diffusion transfer process, photosensitive materials, instruments, etc., can solve the problems of difficult construction, long image creation time, and difficult image creation, so as to achieve less time, greater image sensitivity, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

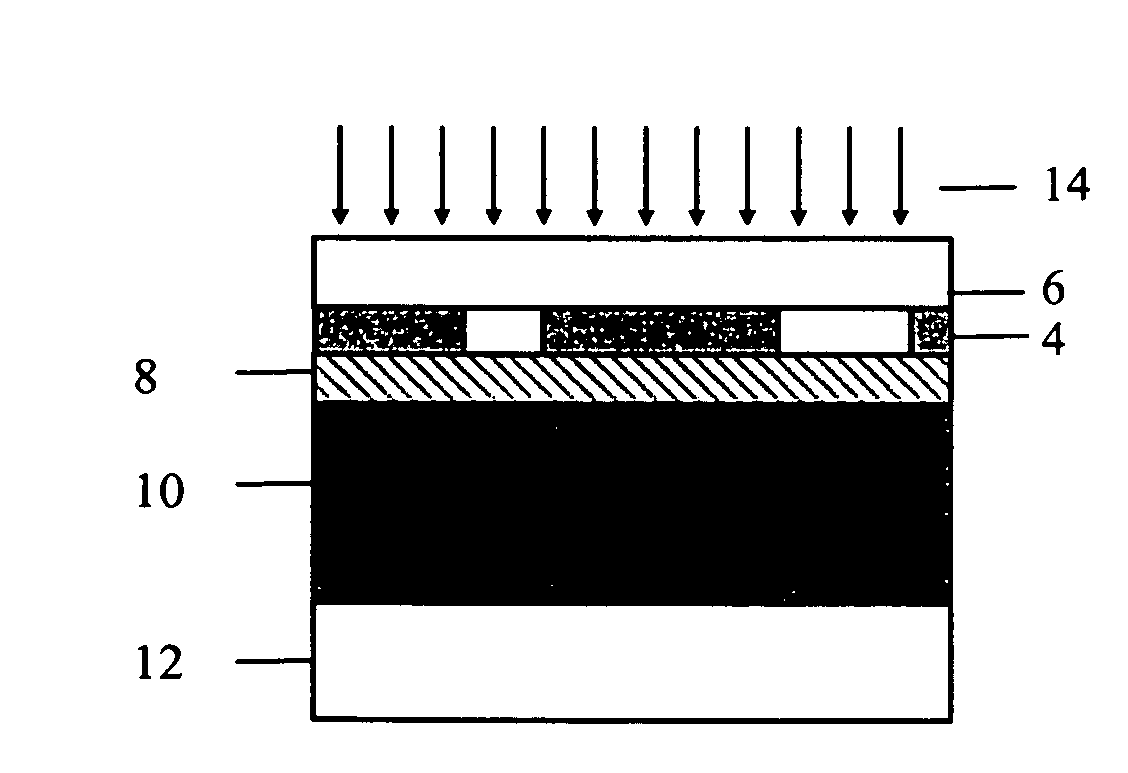

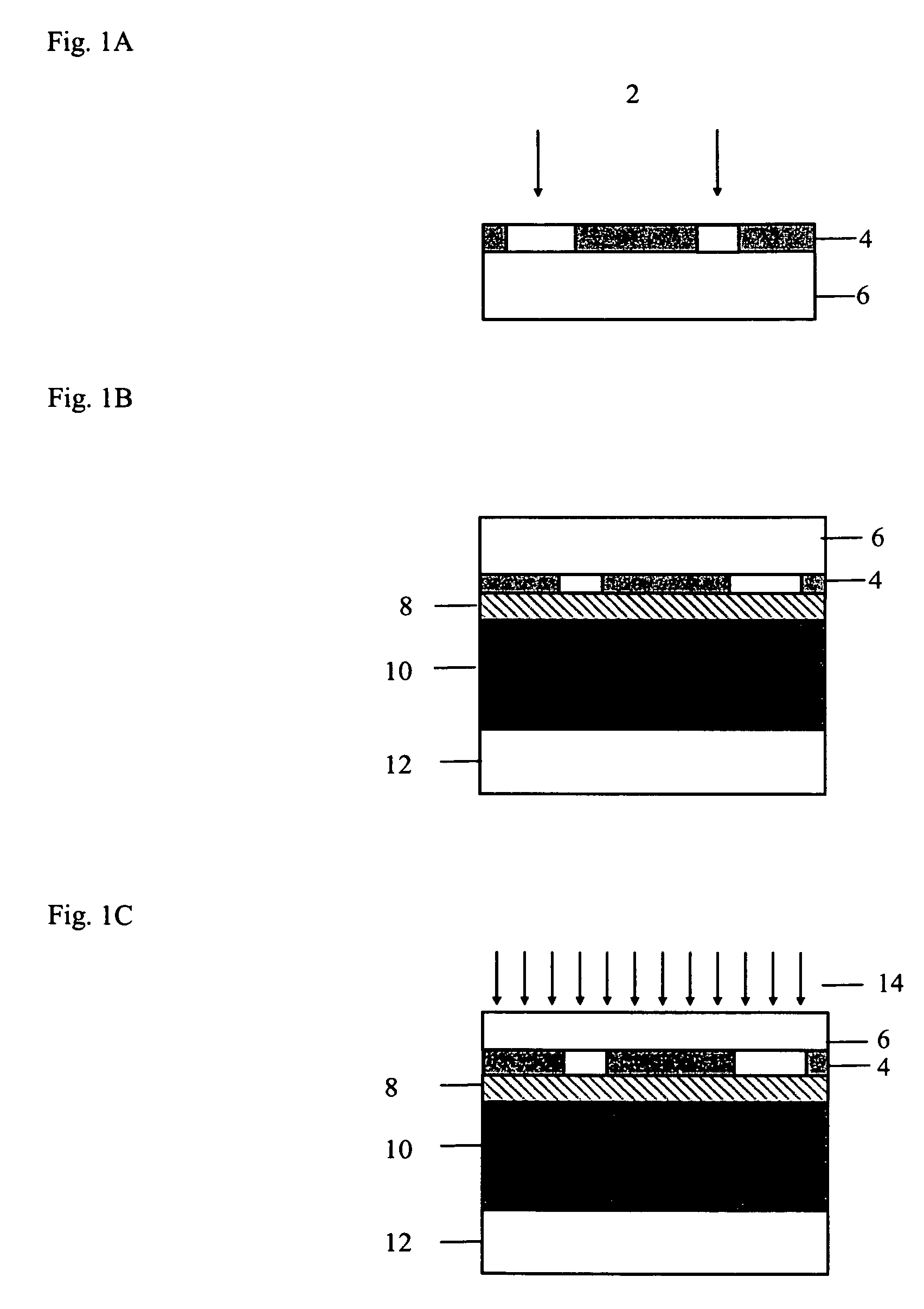

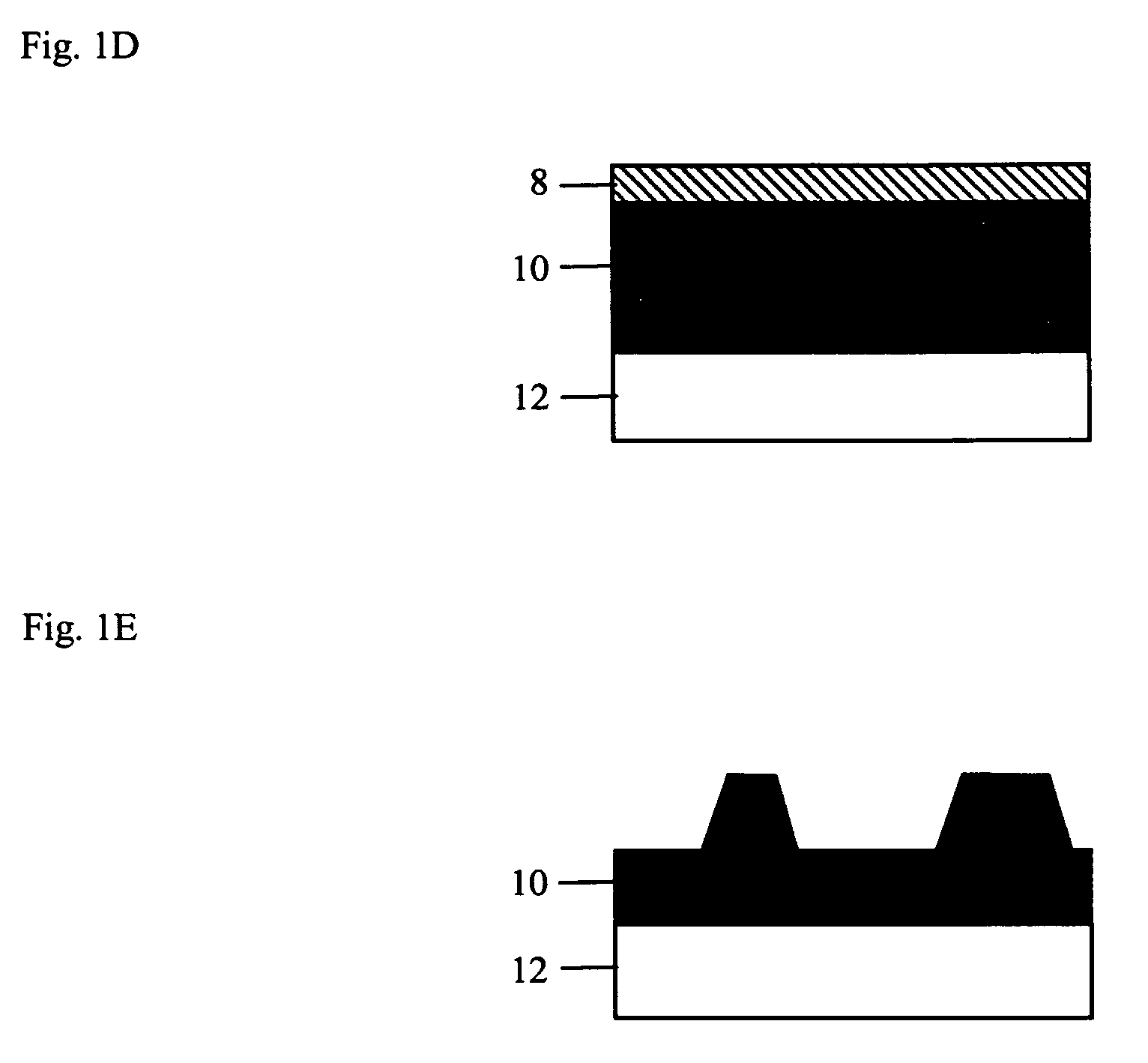

Method used

Image

Examples

example 1

[0186]A 7 mil thick polyester photosensitive substrate coated with a scratch resistant hardcoat, available from Courtaulds Performance Films (Martinsville, Va.), was coated with an ablatable layer solution containing the components listed in Table 1 as a 5% total solids solution in a 4.5:1 solvent mix of acetone and cyclohexanone using a #7 coating rod. The ablatable layer solution was dried for 5 minutes at 190° F. to form an ablatable layer having a coating weight of 50 mg / ft2 on the hardcoat.

[0187]

TABLE 1Components of the ablatable layer solution in Example 1ComponentPercent of total solidspolycyanoacrylate80.5%EPOLIGHT 117816.5%PC 3643.0%

[0188]An imageable material solution of the components listed in Table 2 was mixed as a 7.5% total solids solution in a 2:1 solvent mix of methyl isobutyl ketone and ethyl alcohol and applied to the ablatable layer using a #20 coating rod. The imageable material solution was heated in an 180° F. oven for 3 minutes to form a layer of imageable ma...

example 2

[0195]A sheet of Kodak Direct Image Thermal Recording Film 1401, available from Eastman Kodak (Rochester, N.Y.) was imaged with a halftone test pattern at 150 linescreen using round dots at 2400 dpi [above film was at 2540 dpi] using a DESERTCAT DC88 laser thermal imager, available from ECRM (Tewksbury, Mass.) emitting 830 nm radiation in the ablation mode at an energy level of 0.5 J / cm2 to form an imaged film.

[0196]A first FLEXCEL-SRH flexographic precursor (the “precursor”), available from Kodak Polychrome Graphics (Norwalk, Conn.), containing a photosensitive substrate, a photosensitive material, a releasing layer, and a cover sheet, was back-exposed with UV radiation through the photosensitive substrate on a KELLEIGH MODEL 310 PLATEMAKER available from the Kelleigh Corporation (Trenton, N.J.) for 31 seconds, and the cover sheet was peeled from the precursor. The imaged film was laminated to the precursor by placing the precursor in the entrance to an AGL hot roll laminator, avai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com