Method and apparatus for suppressing sparks

a technology of suppressor and spark, which is applied in the direction of separation process, colloidal chemistry, dispersed particle separation, etc., can solve the problems of affecting the effect of spark extinguishing, sparks in this size range may travel relatively long distances, sparks may move, etc., to achieve the effect of effectively extinguishing sparks, reducing the number of sparks, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

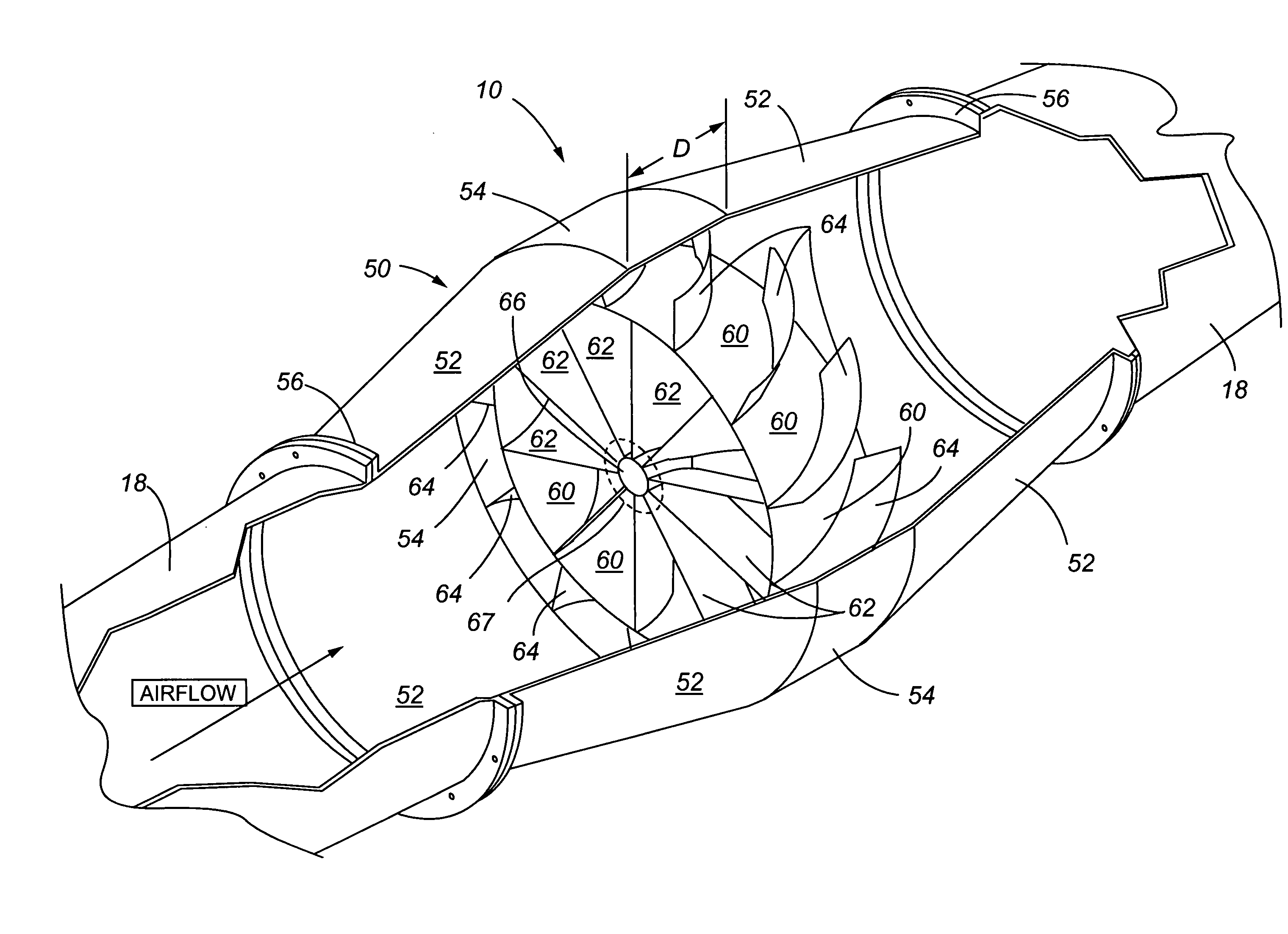

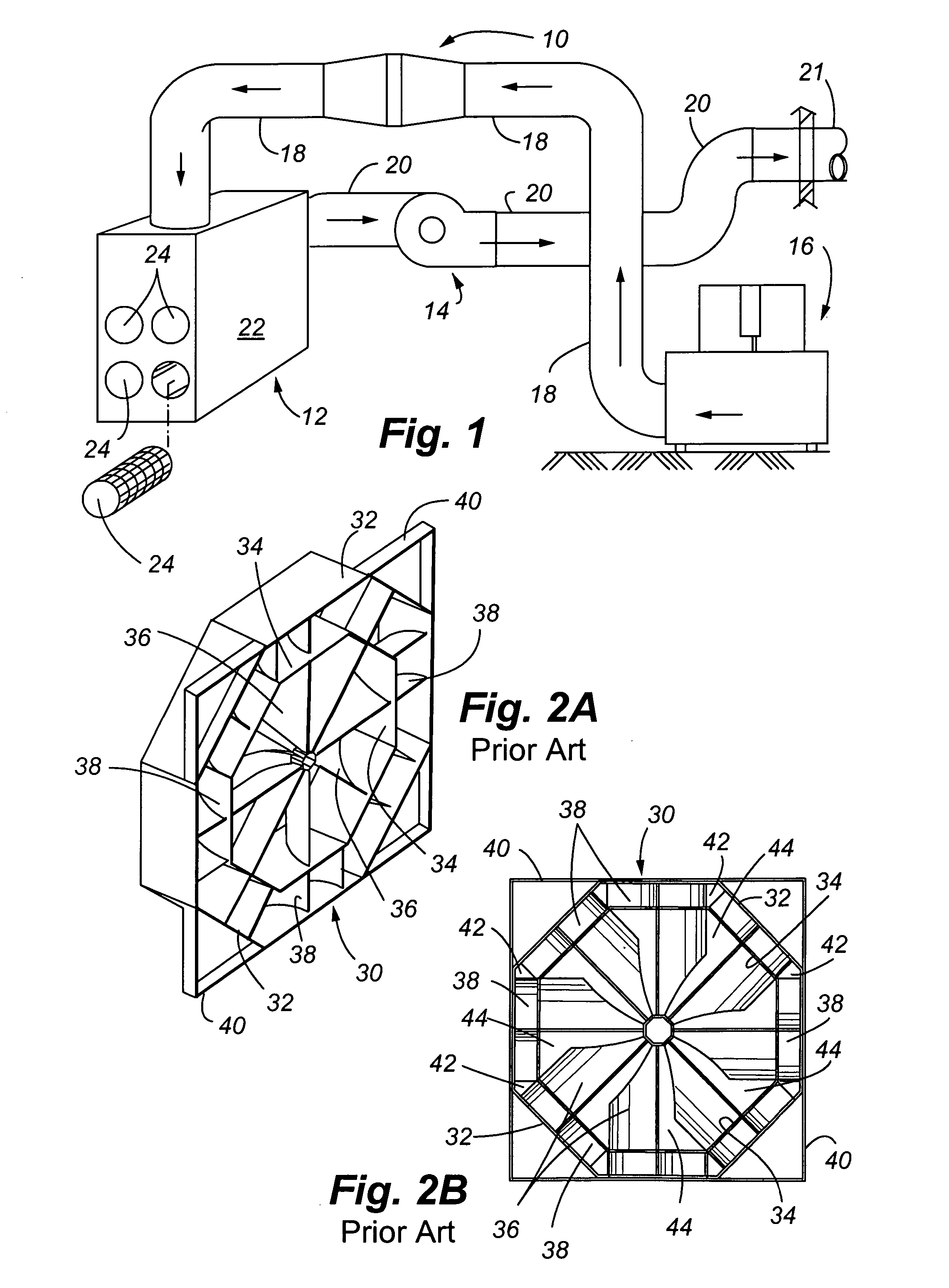

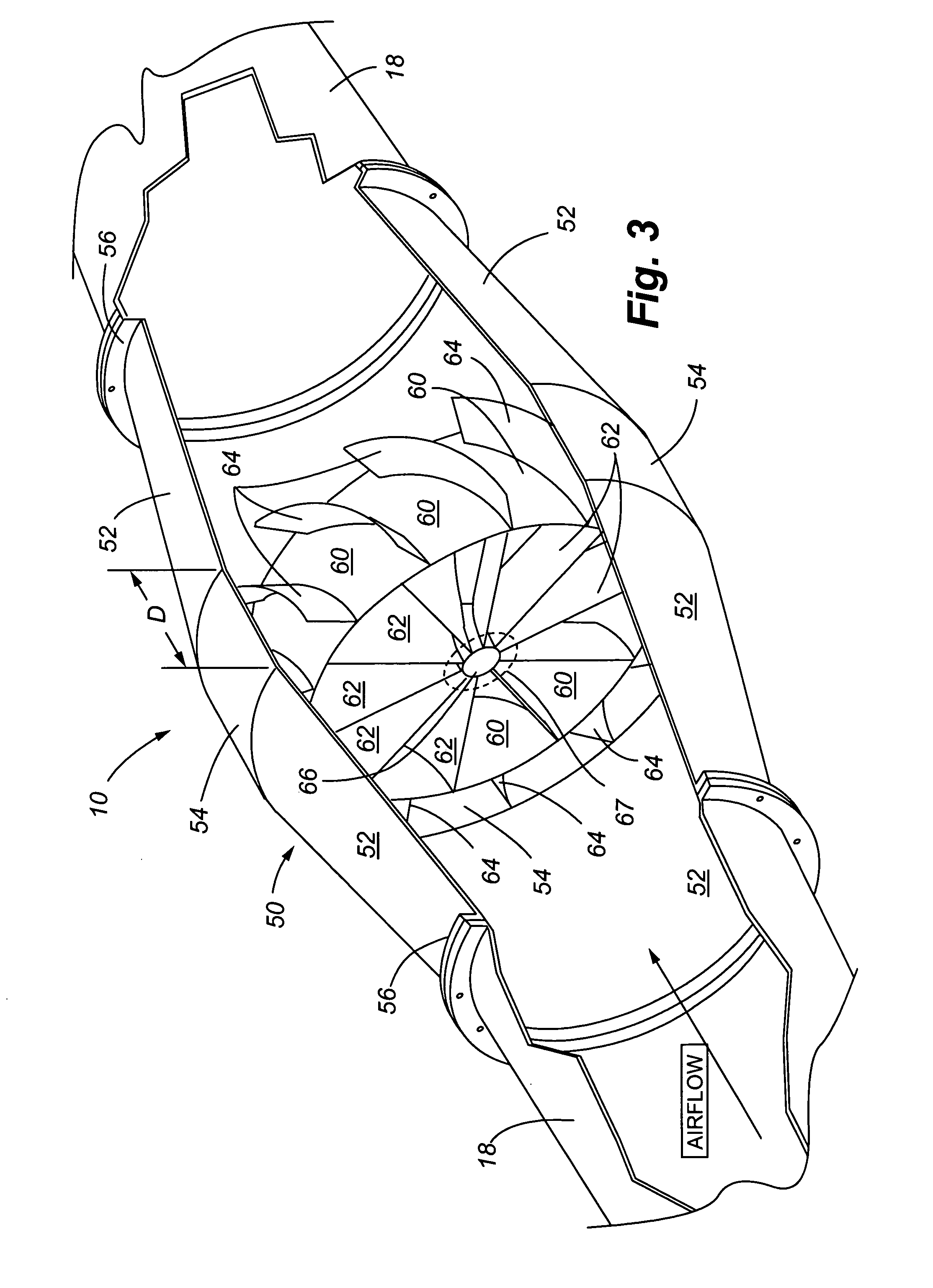

[0026]Referring to FIG. 1, the spark suppressor 10 of the present invention is illustrated as being installed within an air handling system. A typical air handling system includes the machine / process 16 which generates sparks, either actively, passively or accidentally, and a filtration inlet line / duct 18 which conveys contaminated air and sparks to a filtration unit 12. The filtration unit 12 includes a filter housing 22, and one or more filter elements 24. In this particular system, the filter elements 24 are shown as cartridge-type filters, which are replaced periodically over time as they become clogged / caked over with particulate. A filtration outlet line / duct 20 allows conveyance of filtered air back into the environment through discharge exit duct 21. A fan 14 draws the airstream through the filtration unit. The fan 14 is representative of any standard process fan providing enough power to draw air-flow through the system and to thereby draw particulate away from the machine / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com