Sling release mechanism

a release mechanism and sling technology, applied in emergency apparatus, parachutes, transportation and packaging, etc., can solve the problems of pyrotechnic cord cutters above moderate size that are too large and powerful for safe handling by personnel, and the parachute system to fail, so as to reduce the necessary size of the retainer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

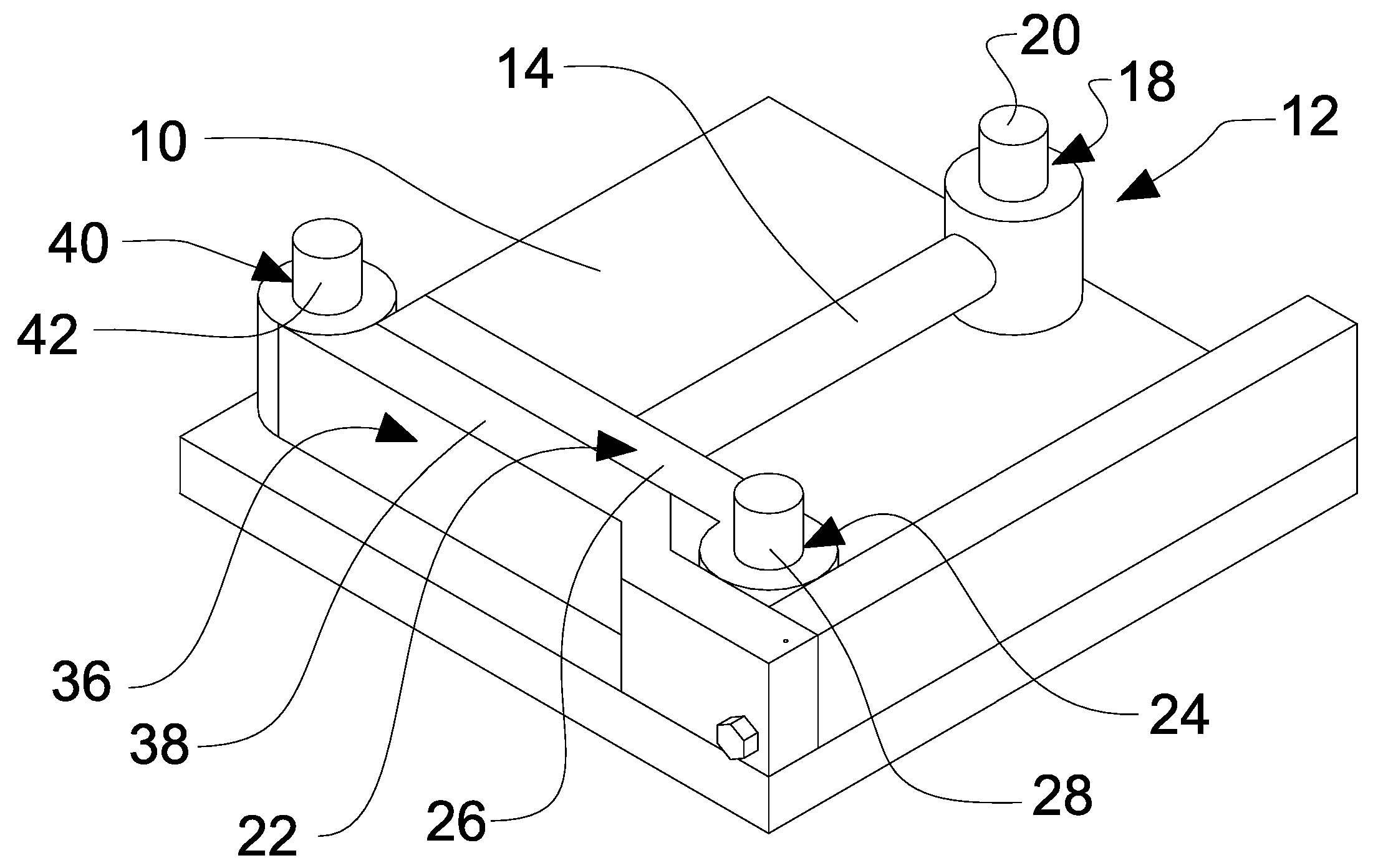

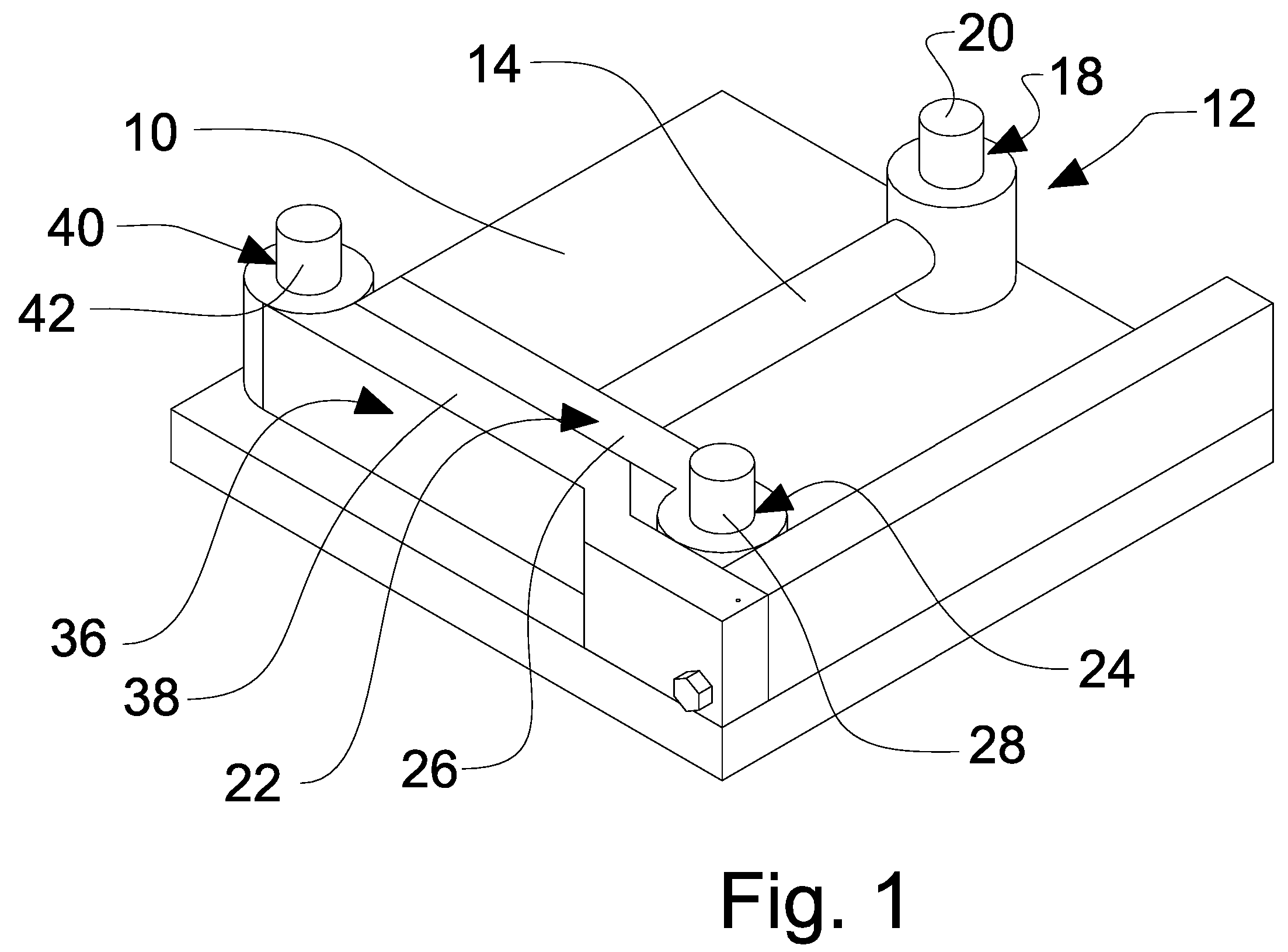

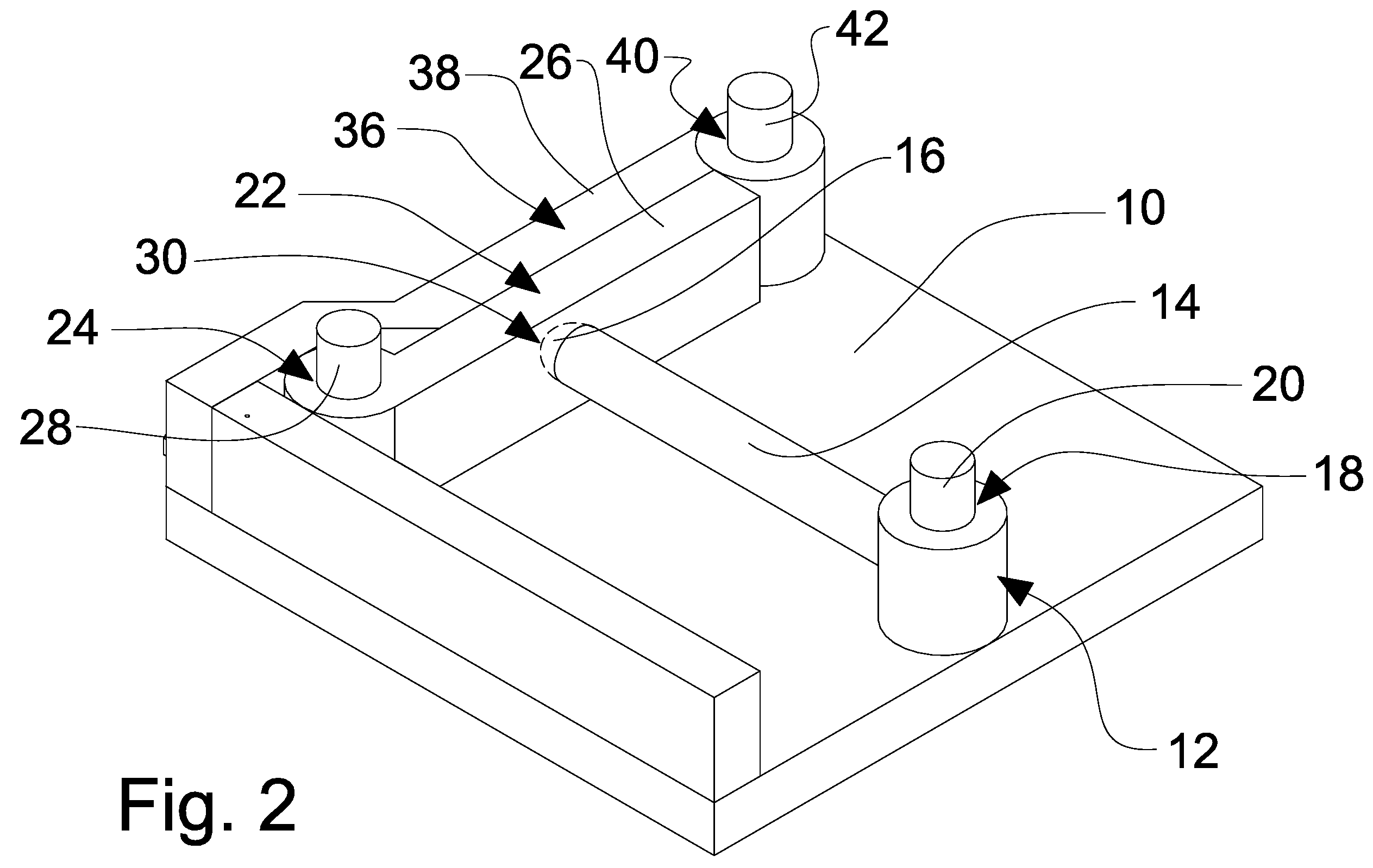

[0024]As shown in FIGS. 1 and 2, a preferred embodiment of a sling release mechanism is comprised, first, of a body 10, which serves as the base or foundation upon which all other components are assembled. The base can be fabricated of any commonly known, structurally strong material, such as metal, including but not limited to steel, stainless steel, cast iron, aluminum, aluminum alloys, titanium or titanium alloys.

[0025]Attached to the body is a pivot arm 12. The pivot arm 12 has an elongated section 14. At one end of the elongated section 14 is a shaped end section 16 and at the other, a means for articulating with the body 10. This means for articulating with the body 10 comprises, preferably, an aperture 18. A first pin 20 or the like passes through the aperture 18 with minimal clearance and conjoins at one or both of its ends with the body10. The pivot arm 12 can then freely articulate around the first pin 20. The shaped end section 16 is disposed at the opposite end of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com