Child resistant tablet package

a tablet and packaging technology, applied in the field of child-resistant tablet packaging, can solve the problems of easy damage to the tablet packaging, easy breakage of the foil, and difficulty in packaging, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

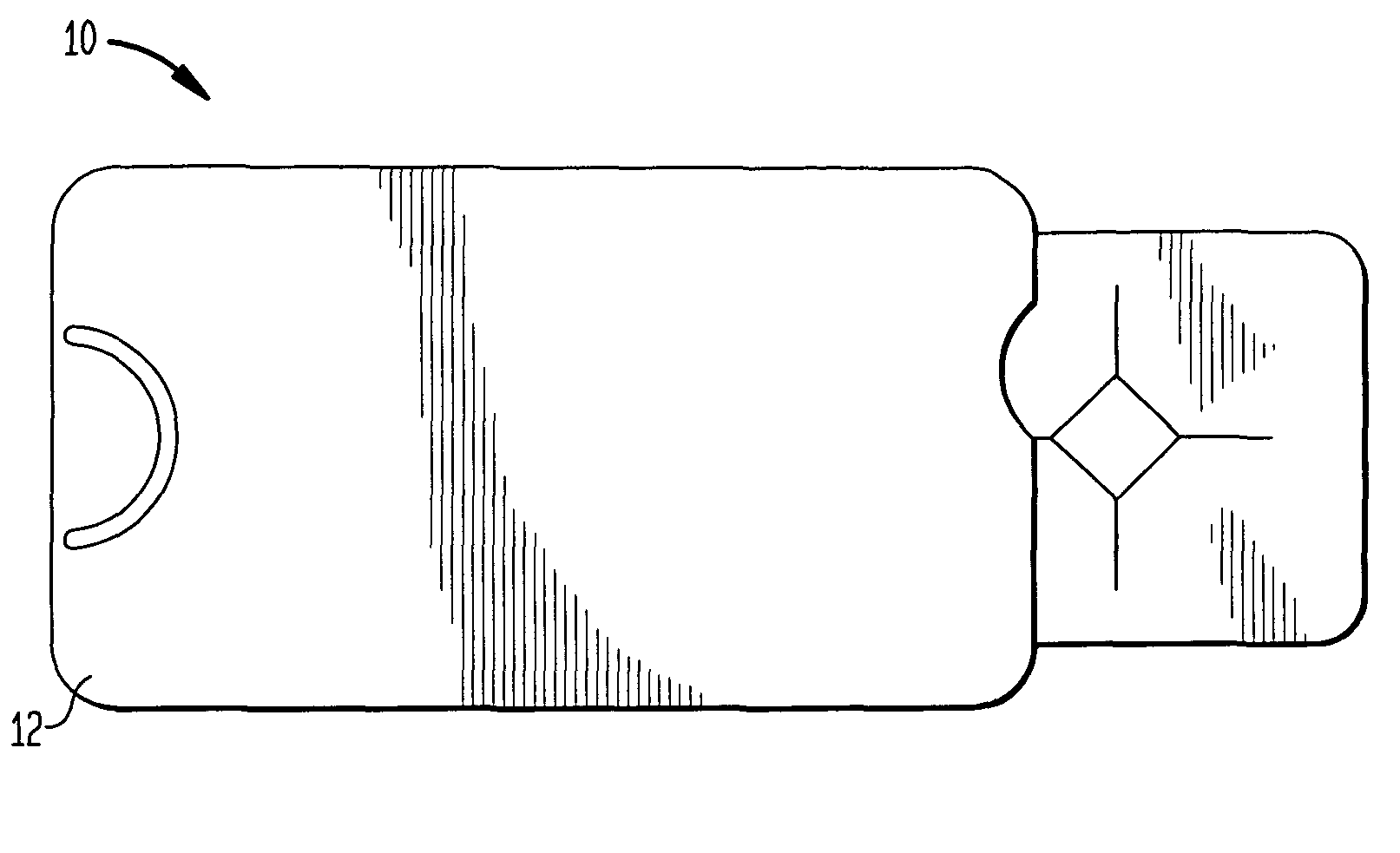

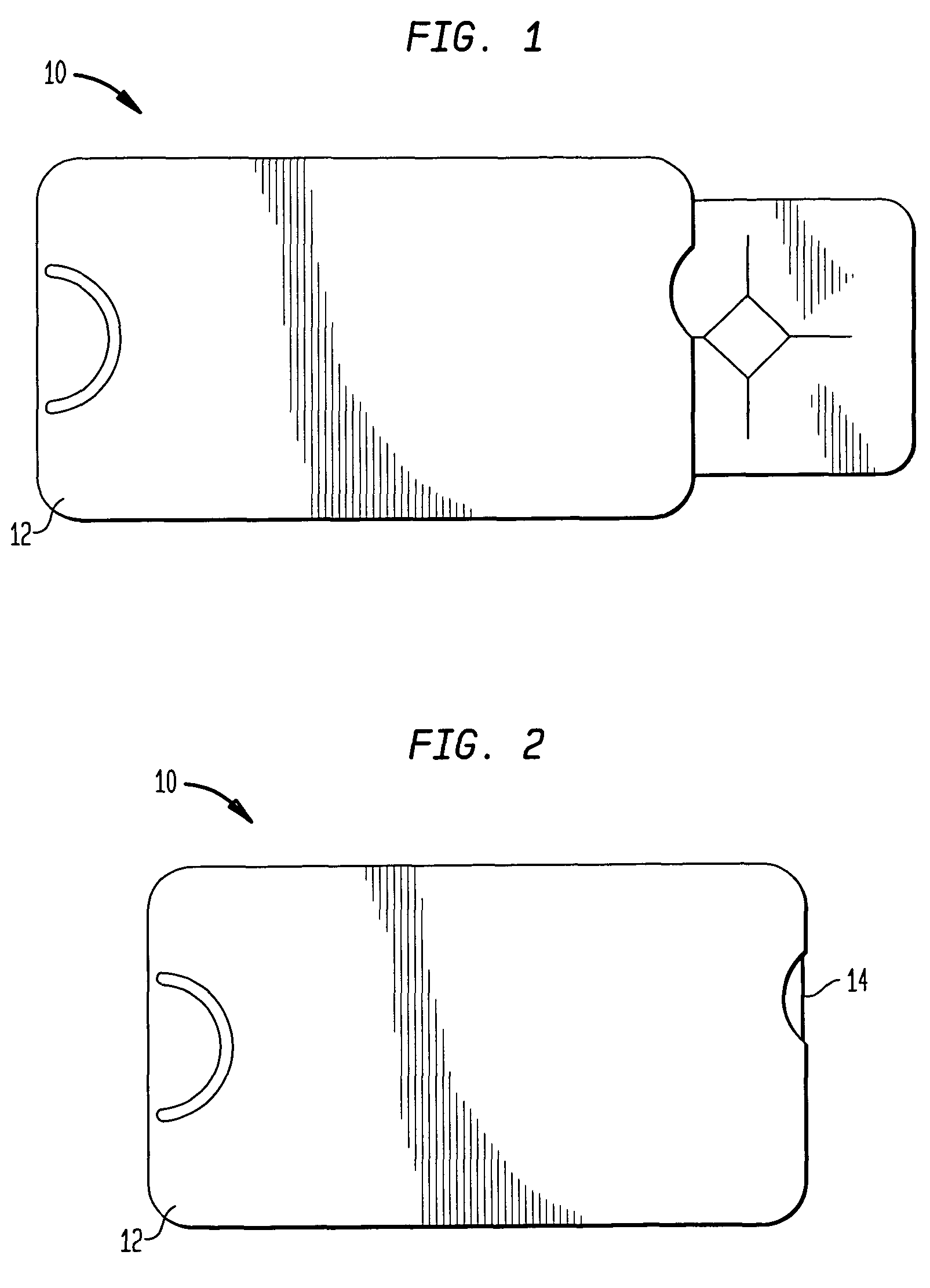

[0025]A child resistant tablet package 10 in accordance with an embodiment of the present invention is shown in FIGS. 1 and 2. Tablet package 10 is a child resistant container for non-frangible and frangible tablets that is also easily accessible. Tablet package 10 includes outer sleeve 12 and blister package 14. Outer sleeve 12 is preferably molded from a polymeric material, but can be made of any material suitable for providing a rigid outer covering. Package 10, on the other hand, is configured so that each tablet is packaged separately from each other in blister package 14. Blister package 14 may be moved within sleeve 12 from a position substantially extended from outer sleeve 12 (as shown in FIG. 1) to a position substantially disposed within outer sleeve 12 (as shown in FIG. 2). However, outer sleeve 12 preferably prevents blister package 14 from being completely removed from the outer sleeve.

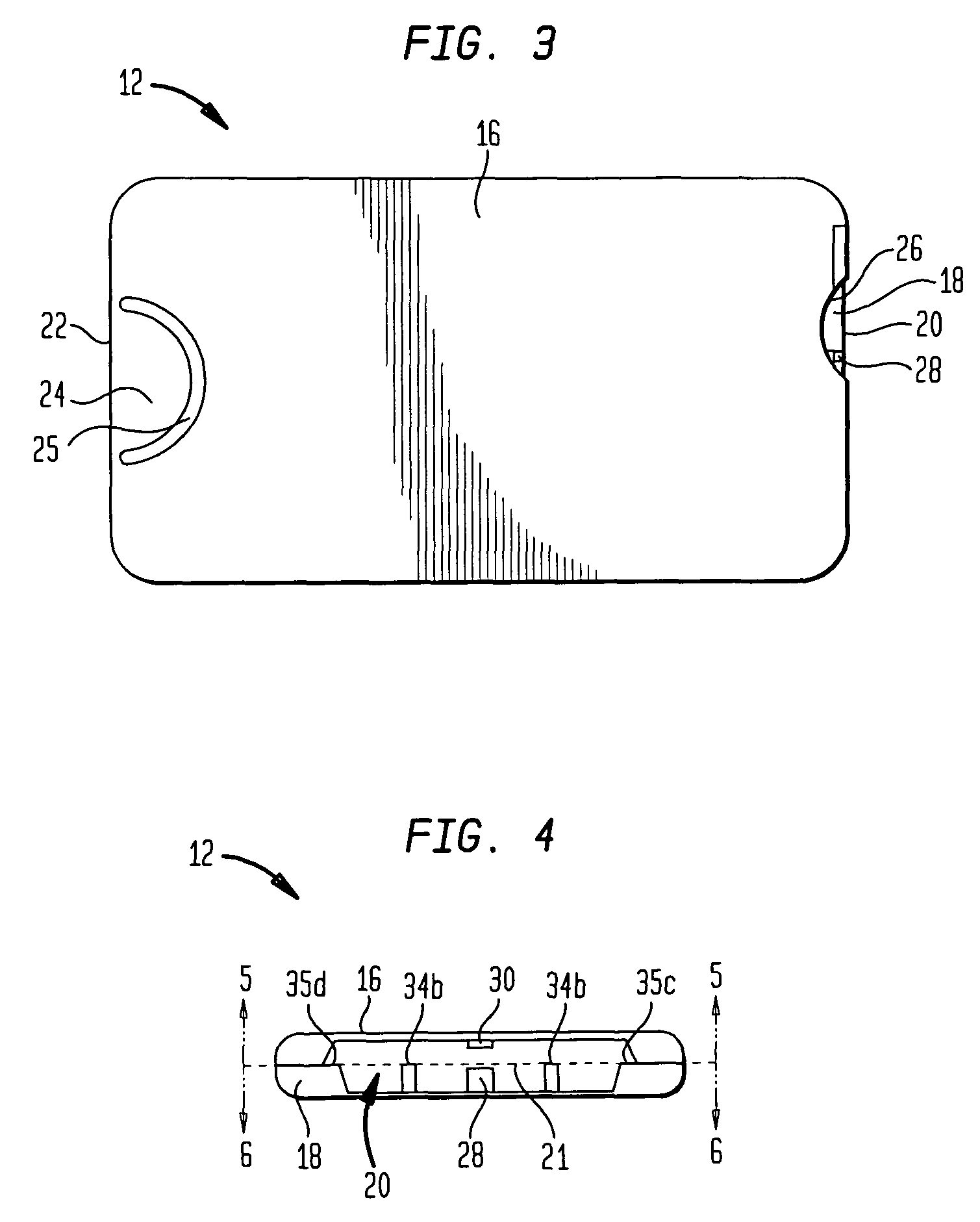

[0026]FIGS. 3-6 illustrate outer sleeve 12. This sleeve includes top portion 16 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com