Swing-out manhole cover

a manhole cover and swinging technology, applied in the field of swinging manhole covers, can solve the problems of not being suitable for pressurized applications, not being suitable for lifting manhole covers, and being more expensive than other systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

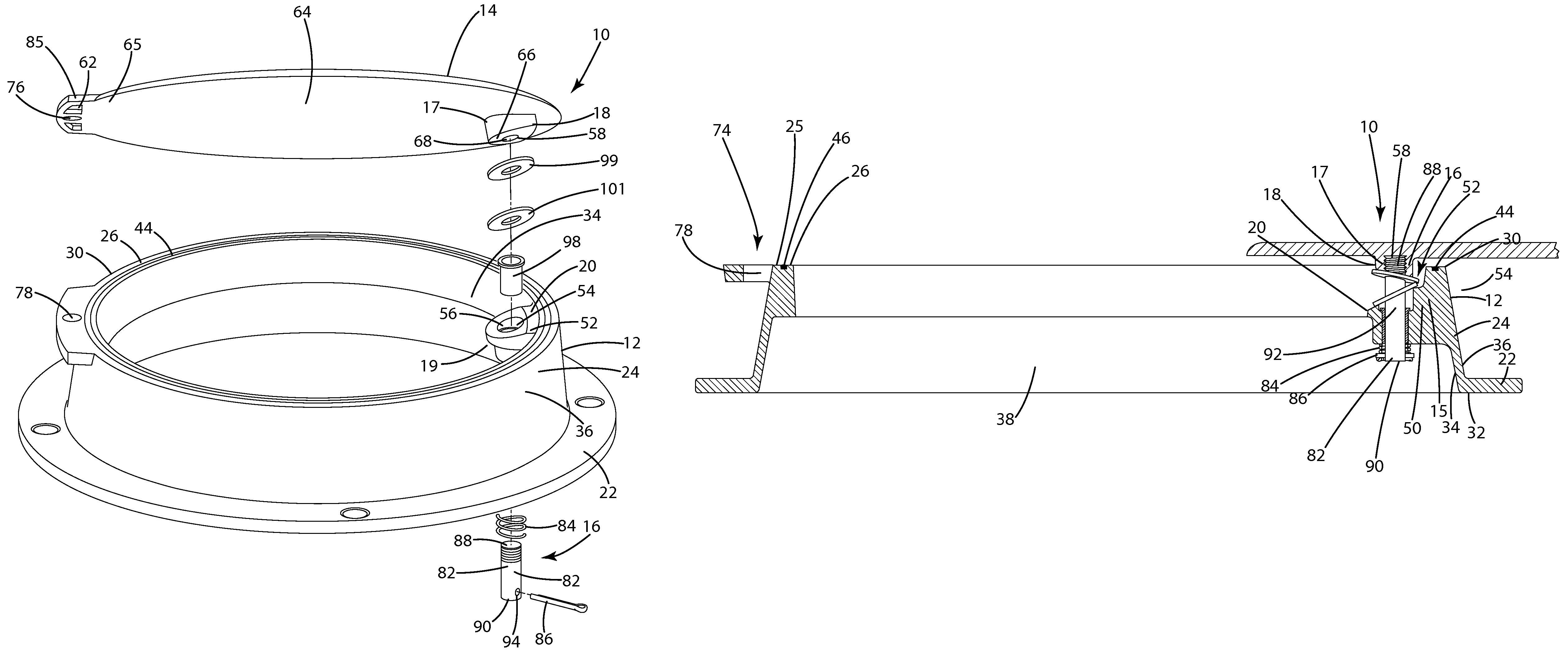

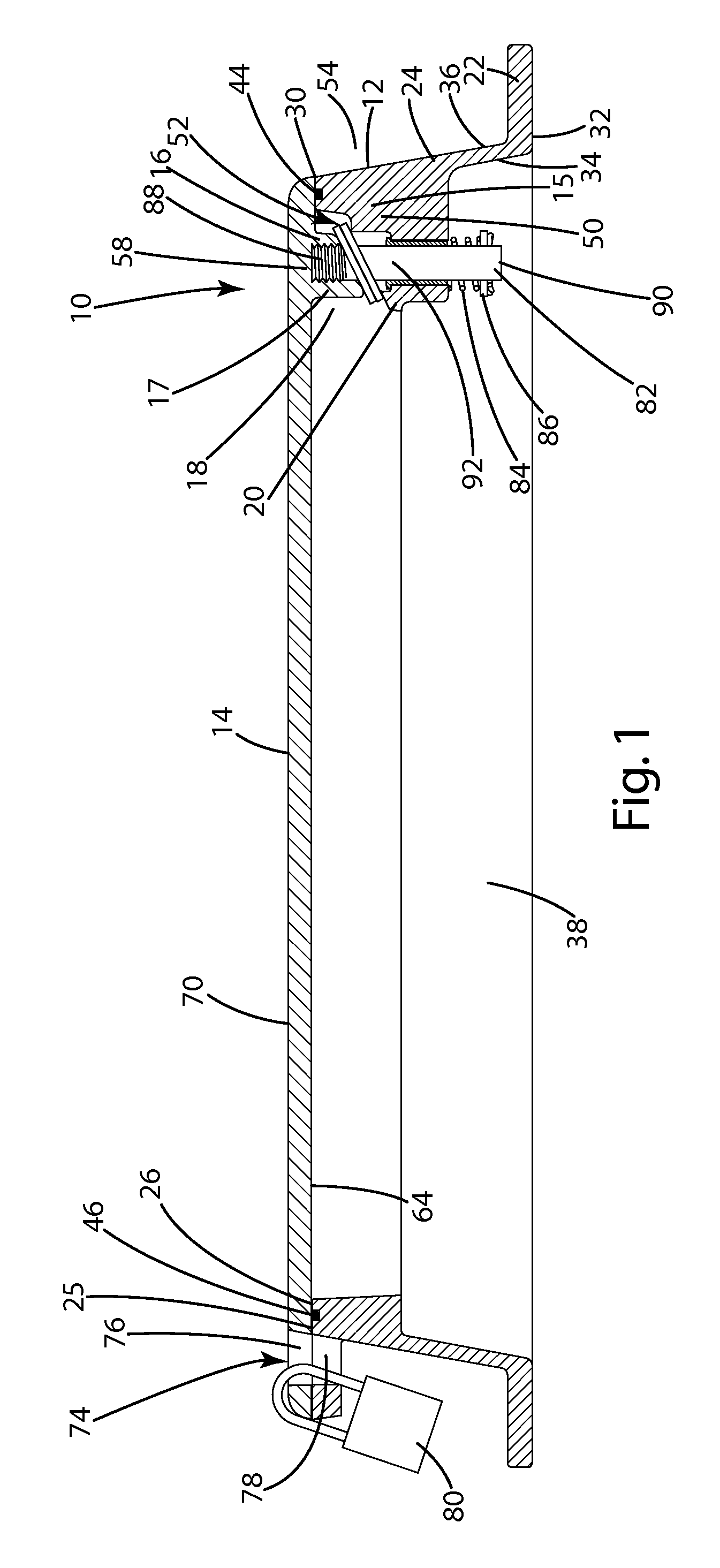

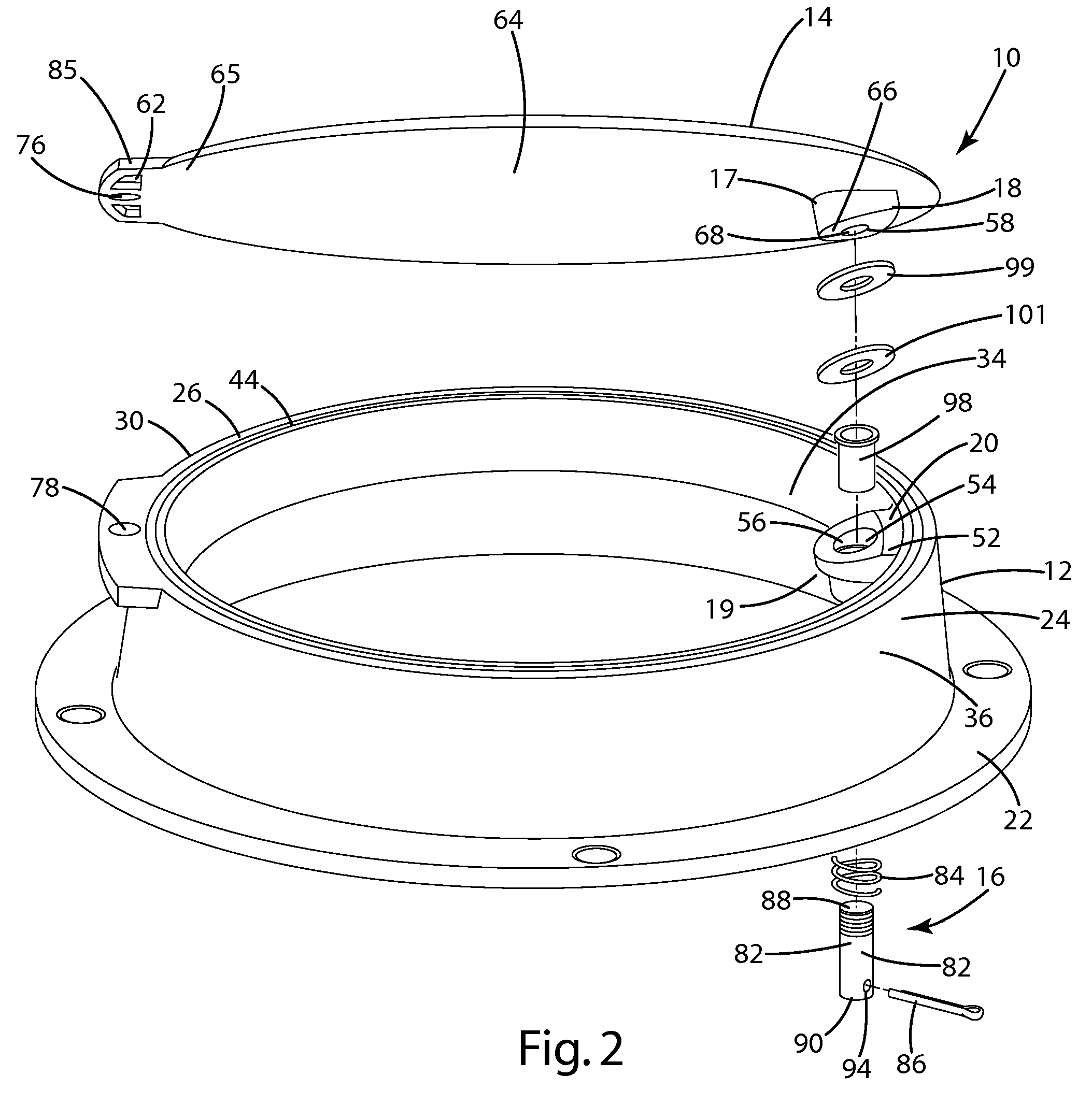

[0020]A swing-out manhole cover assembly in accordance with an embodiment of the present invention is illustrated in the drawings and generally designated 10. In the embodiment illustrated in the figures, the manhole cover assembly 10 includes a frame 12 defining an opening 38, a cover 14 of sufficient size to cover the opening 38, a cover ramp 18, a frame ramp 20 and a swing assembly 16. The swing assembly 16 rotatably connects the cover 14 to the frame 12 to permit the cover 14 to be selectively rotated out of the frame opening 38. As the cover 14 is rotated away from the opening 38 about the swing assembly 16, the cover ramp 18 and the frame ramp 20 interact to impart linear movement to the cover 14 slightly separating the cover 14 from the frame 12. This separation provides clearance between the cover 14 and the frame 12 to, among other things, ease movement of the cover 14.

[0021]The present invention is illustrated in connection with a specific circular manhole frame and circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com