Filtration apparatus

a technology of filtration apparatus and filtration device, which is applied in the direction of gravity filter, sedimentation settling tank, loose filtering material filter, etc., can solve the problems of limiting the effectiveness of current filtration device, limiting the space and weight requirements, and further waste disposal problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

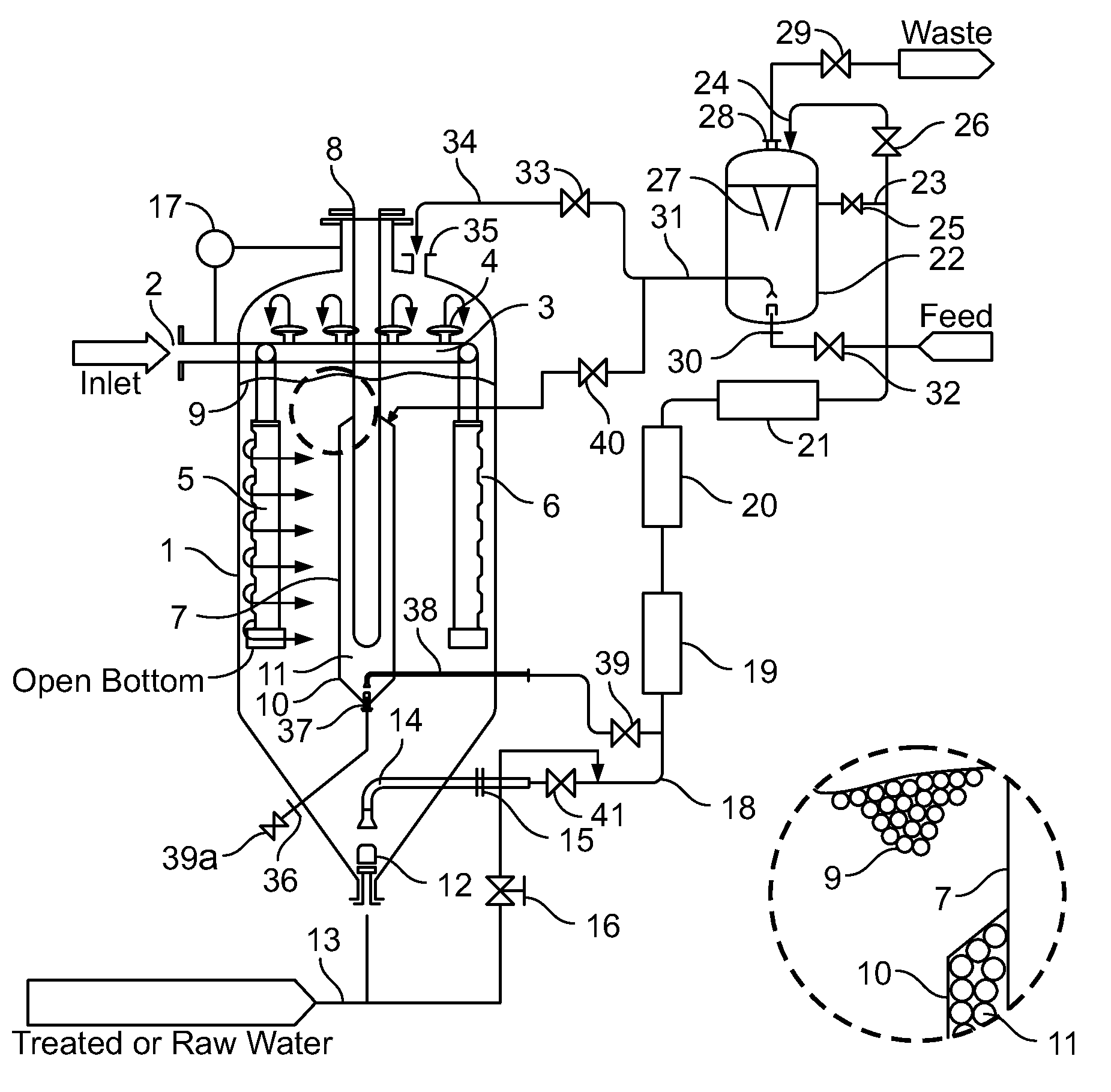

[0041]From the plot of FIG. 1 it can be seen that a lower number of larger particles account for the bulk of the volume of contaminants. In a conventional filtration process, it would be normal to attempt to remove the vast majority of these large particles at some cut off point, in this example around 80 microns and above with a coarse filter, so that any fine filtration would only need to remove smaller particles. The present invention seeks to achieve this degree of filtration with one filtration step.

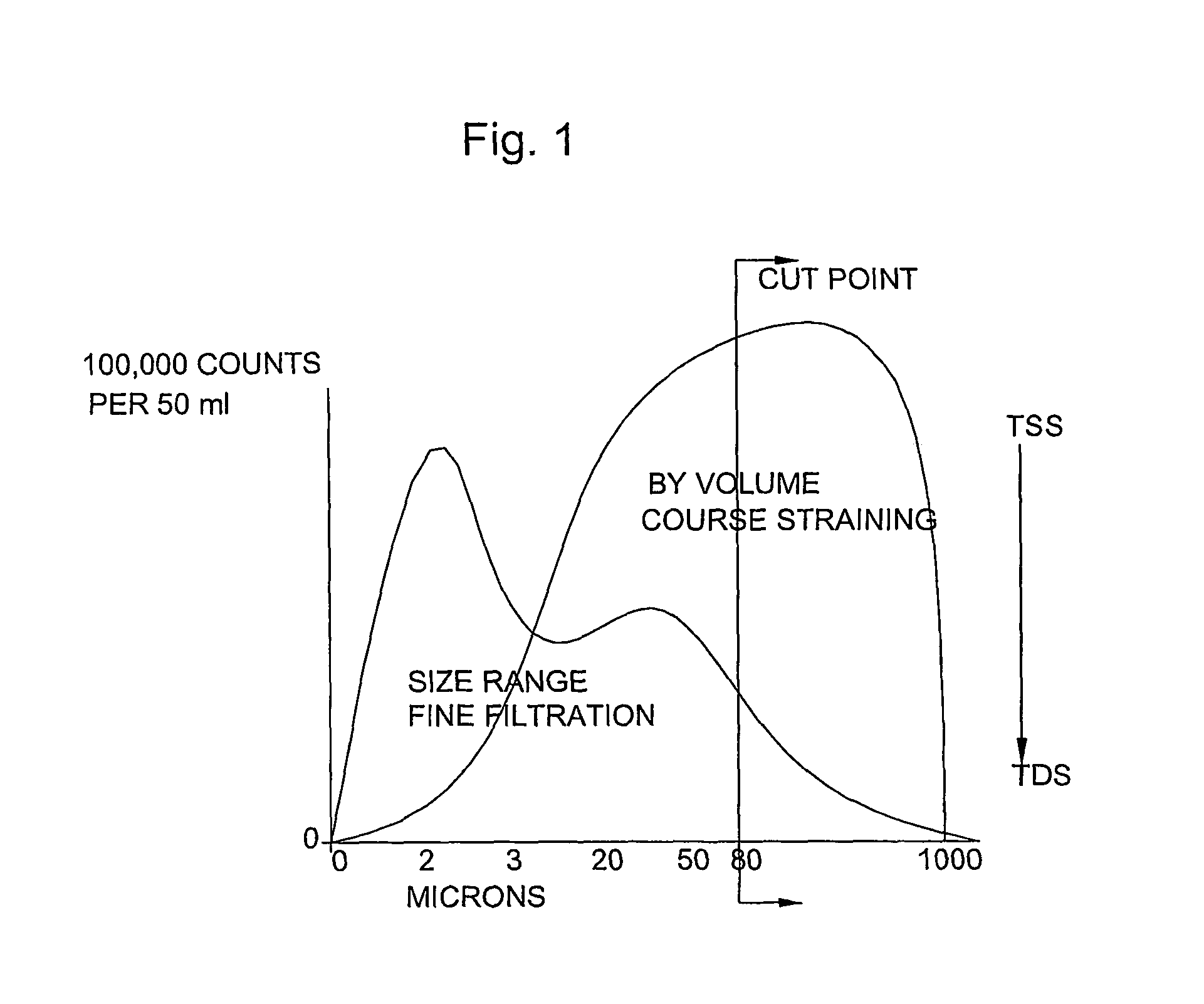

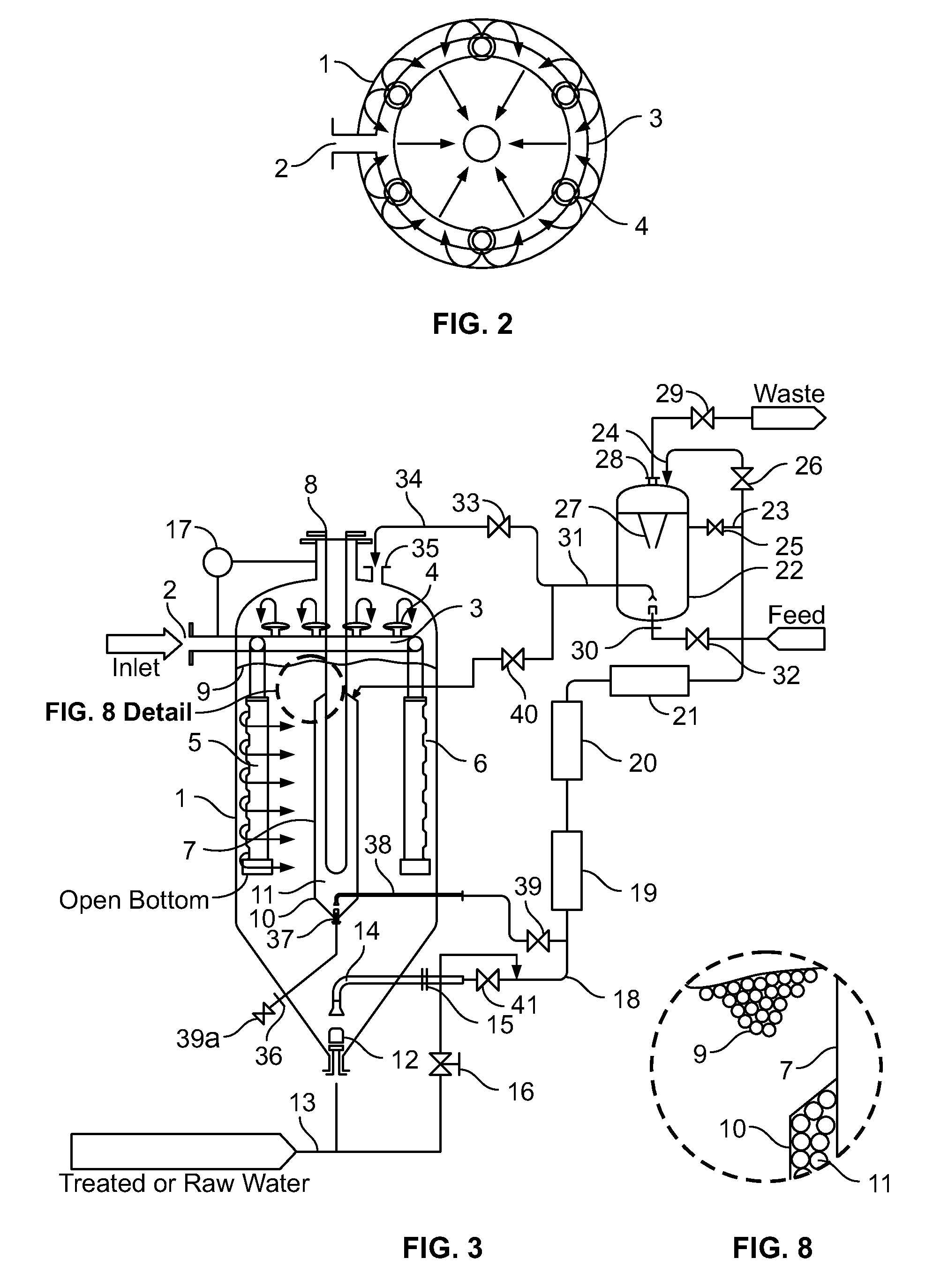

[0042]Referring to FIGS. 2 and 3, a pressure vessel or tank 1 has an inlet means 2 for raw water to be treated which connects with a distribution ring 3. The distribution ring 3 has a plurality of flow distribution heads 4, to distribute a portion of the inlet flow upwards to the top of the vessel 1, and a plurality of substantially vertical flow distribution tubes 5 which have distribution holes or slots 6 designed such that the flow of raw water is equally distributed and directed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com