Modular basal thumb joint implant

a moduled, basal technology, applied in the field of modules, can solve the problems of one-piece construction or non-modularity of implants, unstable joints, disfunctionalities,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

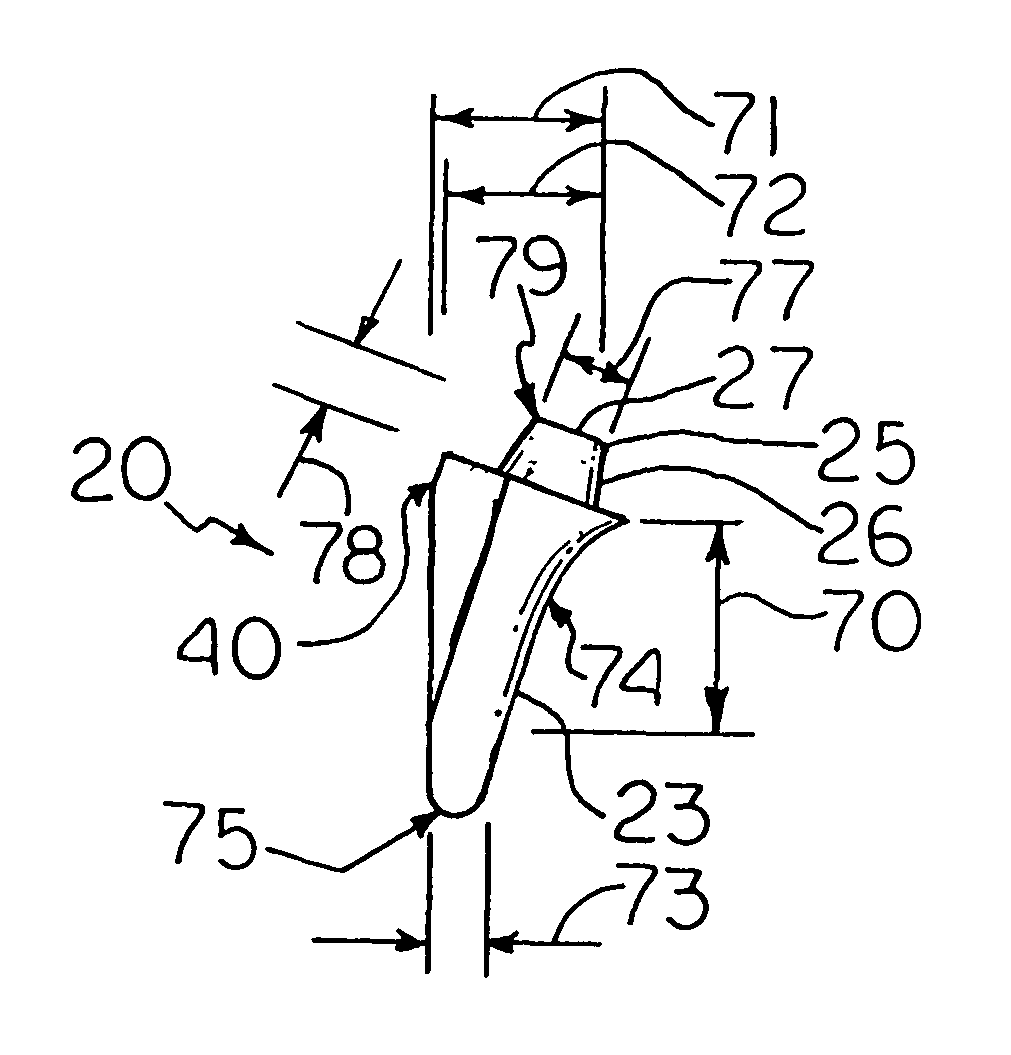

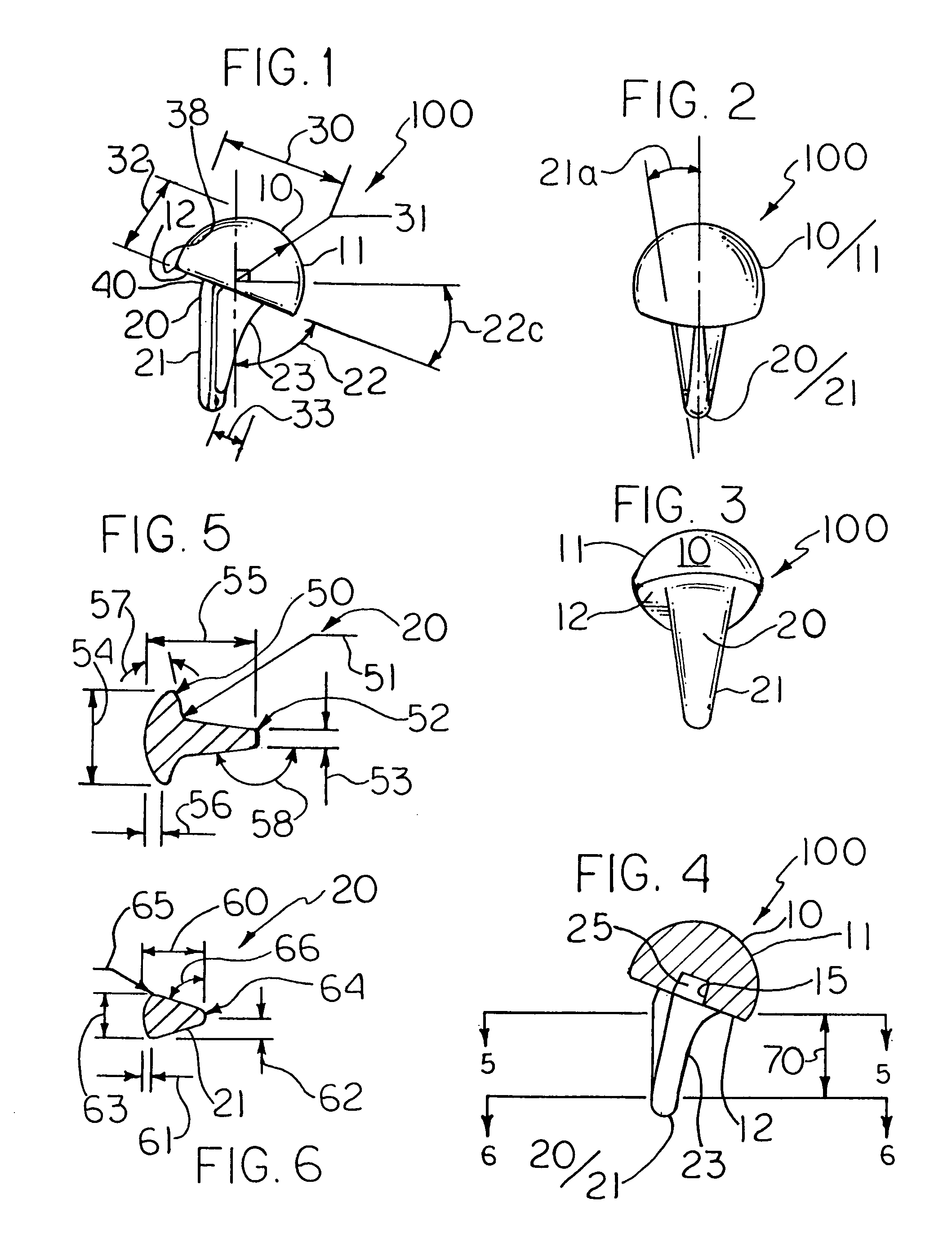

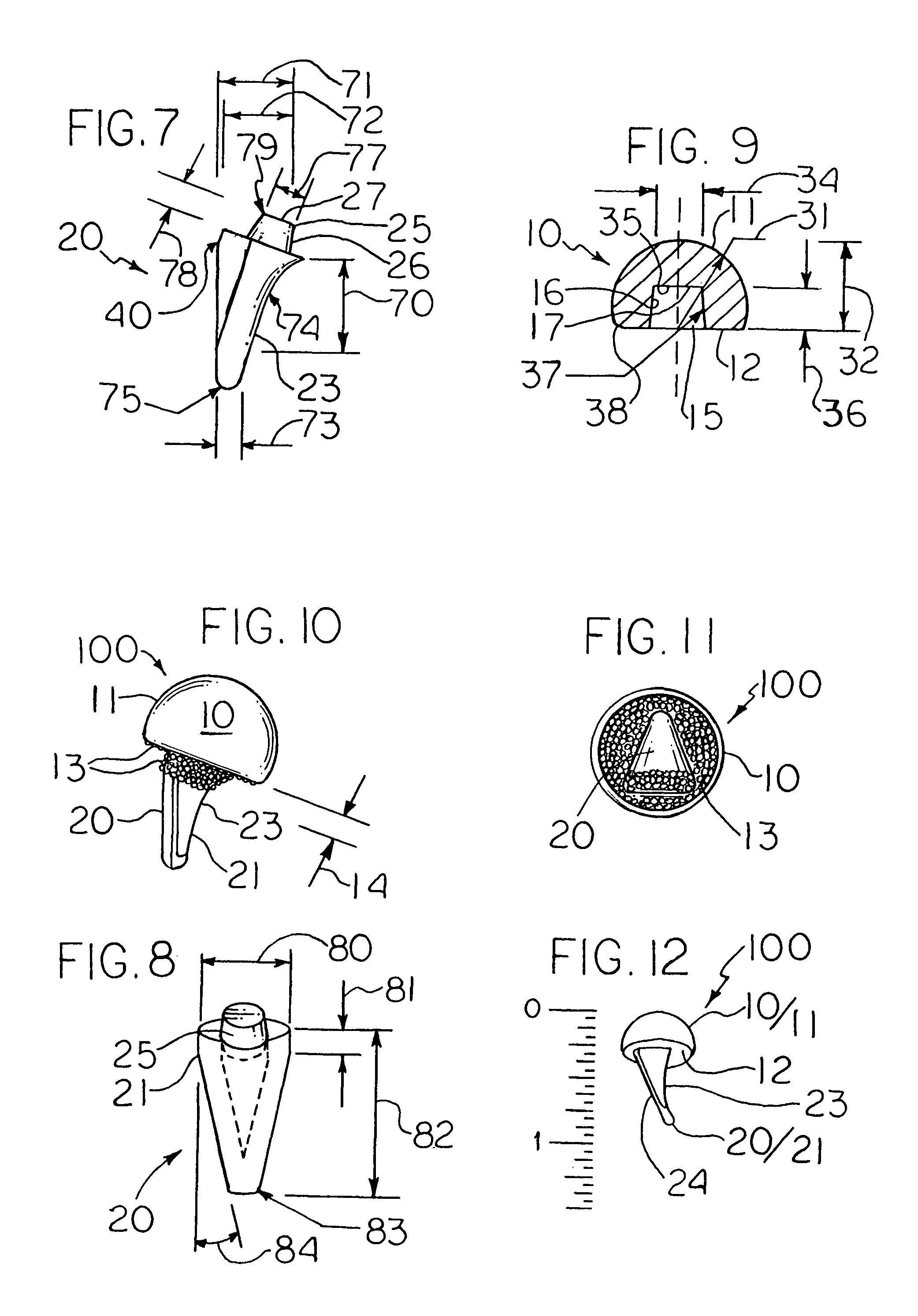

[0030]The invention can be further understood by the present detail, which may be read in view of the drawings. Such is to be taken in an illustrative, and not necessarily limiting, sense.

[0031]In general, the joint implant of the invention includes a head and a stem. It may be one-piece or modular in construction.

[0032]The implant can be made of any suitable material to include biocompatible ceramics, metals, plastics or other suitable material. However, manufacture from a cobalt-containing alloy is beneficially employed since, among other considerations, not the least of which is relative ease of manufacture, a better, more triboligically efficient articular surface can be provided than from the softer titanium, particularly when the implant is of one-piece construction. In modular digital joint implants, the cobalt-containing alloy may be employed for both head and stem components, or, preferably, the cobalt-containing, or other, alloy is employed to make the stem component, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| general angle | aaaaa | aaaaa |

| sphericity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com