Modeling of cell delay change for electronic design automation

a technology of electronic design automation and delay change, applied in the field of electronic design automation, can solve the problems of finer granularity, inconsistent results, and cost of adding cells to the library

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

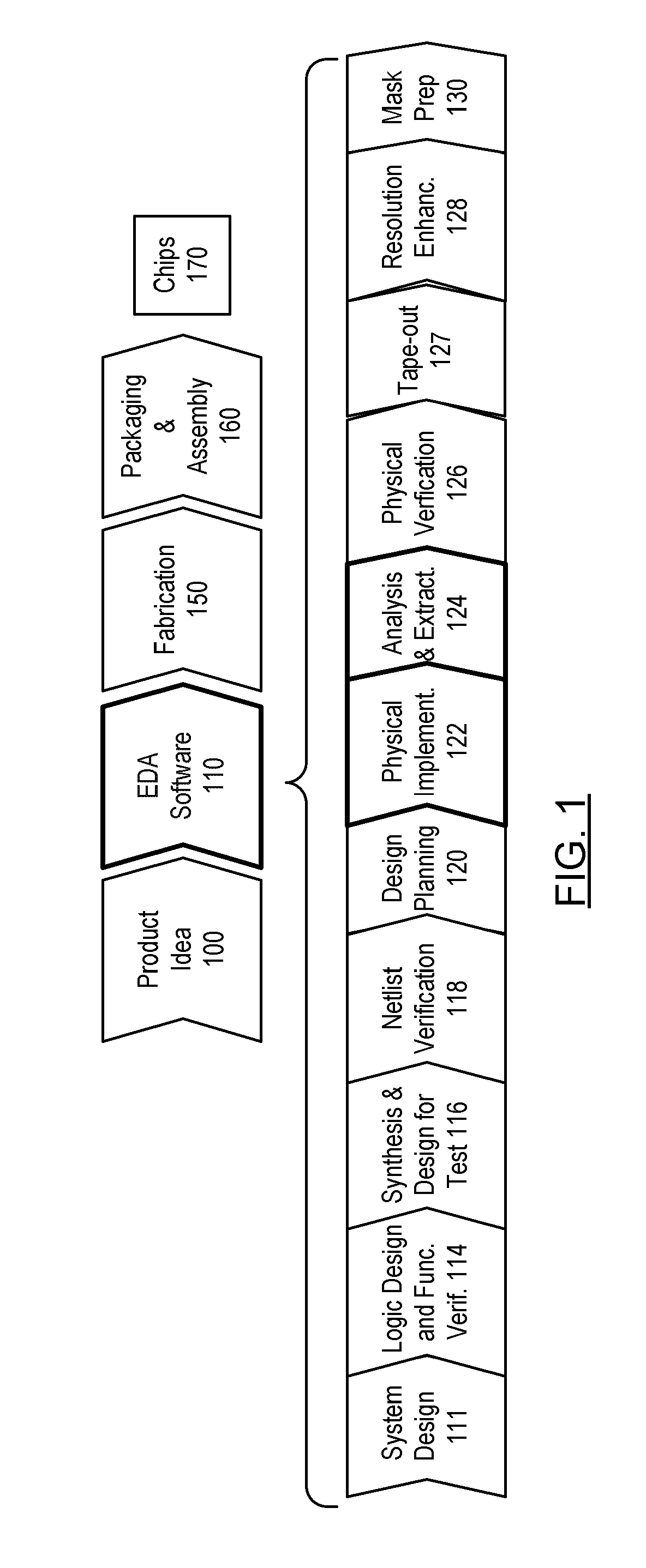

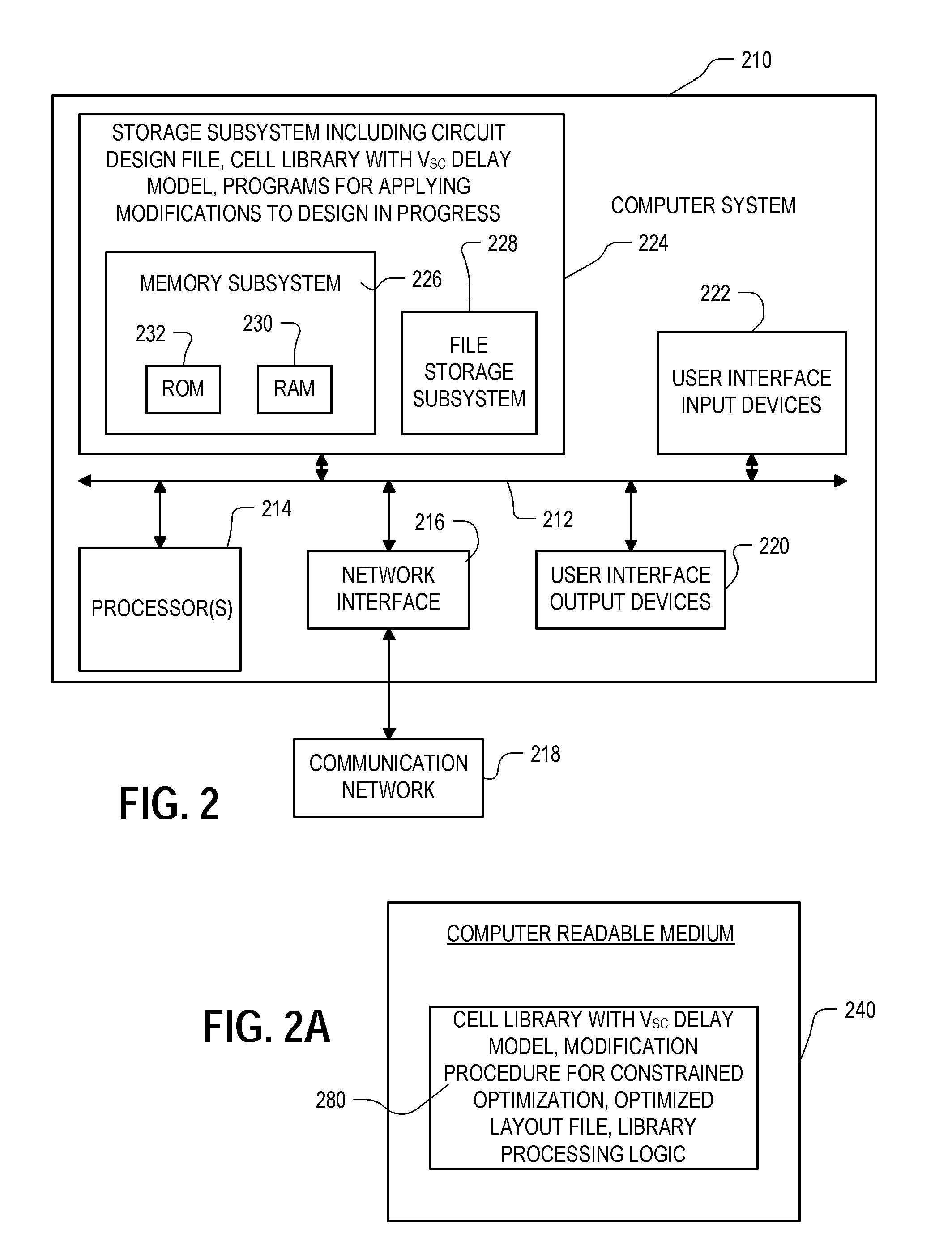

[0041]A detailed description of embodiments of the present invention is provided with reference to the FIGS. 1-15.

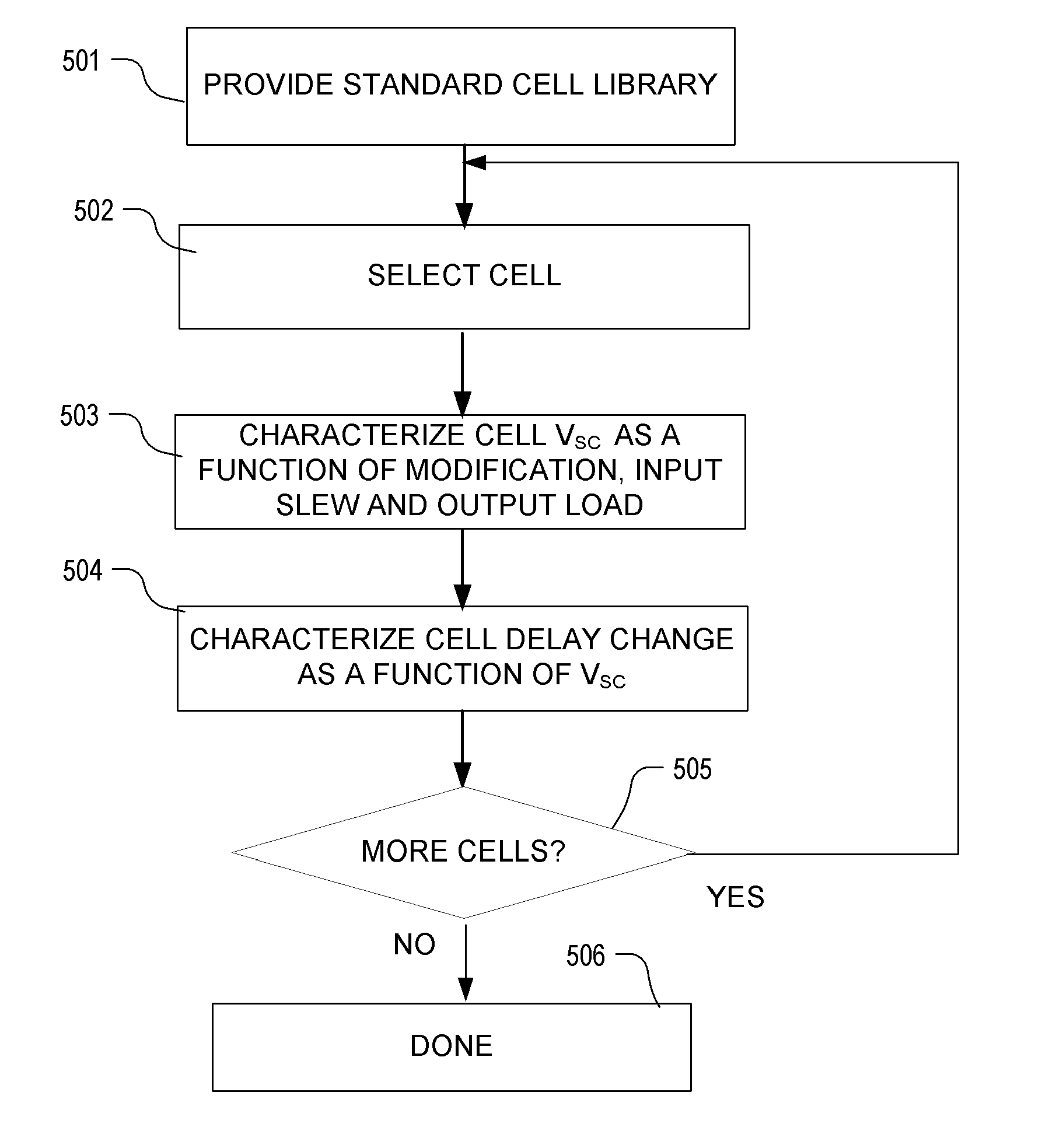

[0042]A phenomenological model derived from device equations with empirical fitting parameters to model percentage changes in delay as a result of gate length bias is described. The model can be extended to any type of cell modification, such as threshold voltage doping, gate shape changes, cell width changes, and so on, that can be used for optimizations constrained by delay. The model focuses on capturing the percentage delay change as a function of gate length change or other change (i.e., bias) over wide, practical ranges of input slews and output capacitances that are typically used in library characterization. The model can be derived based on physical device equations with empirical fitting parameters for improved accuracy. A physically based parameter is introduced that can be determined efficiently based on cell modifications and that correlates with delay chang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com