Stator with asymmetric poles and sensor oriented to more accurately determine position of rotor

a technology of asymmetric poles and sensors, applied in the field of electric machines, can solve the problems of more than compensating withdrawal, and achieve the effects of accurate synchronisation, small slot opening, and reducing stator inductance without lowering saturation poin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

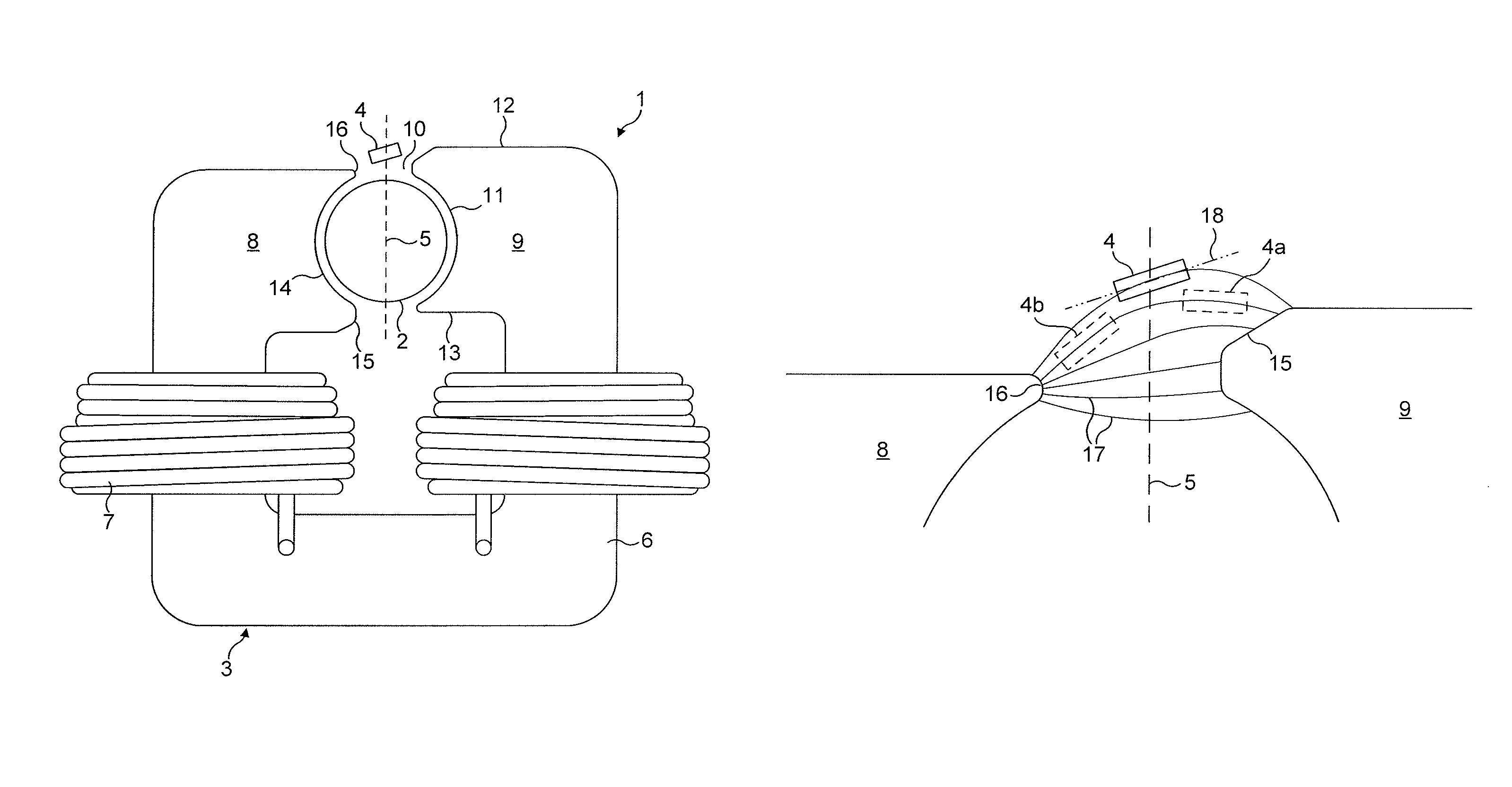

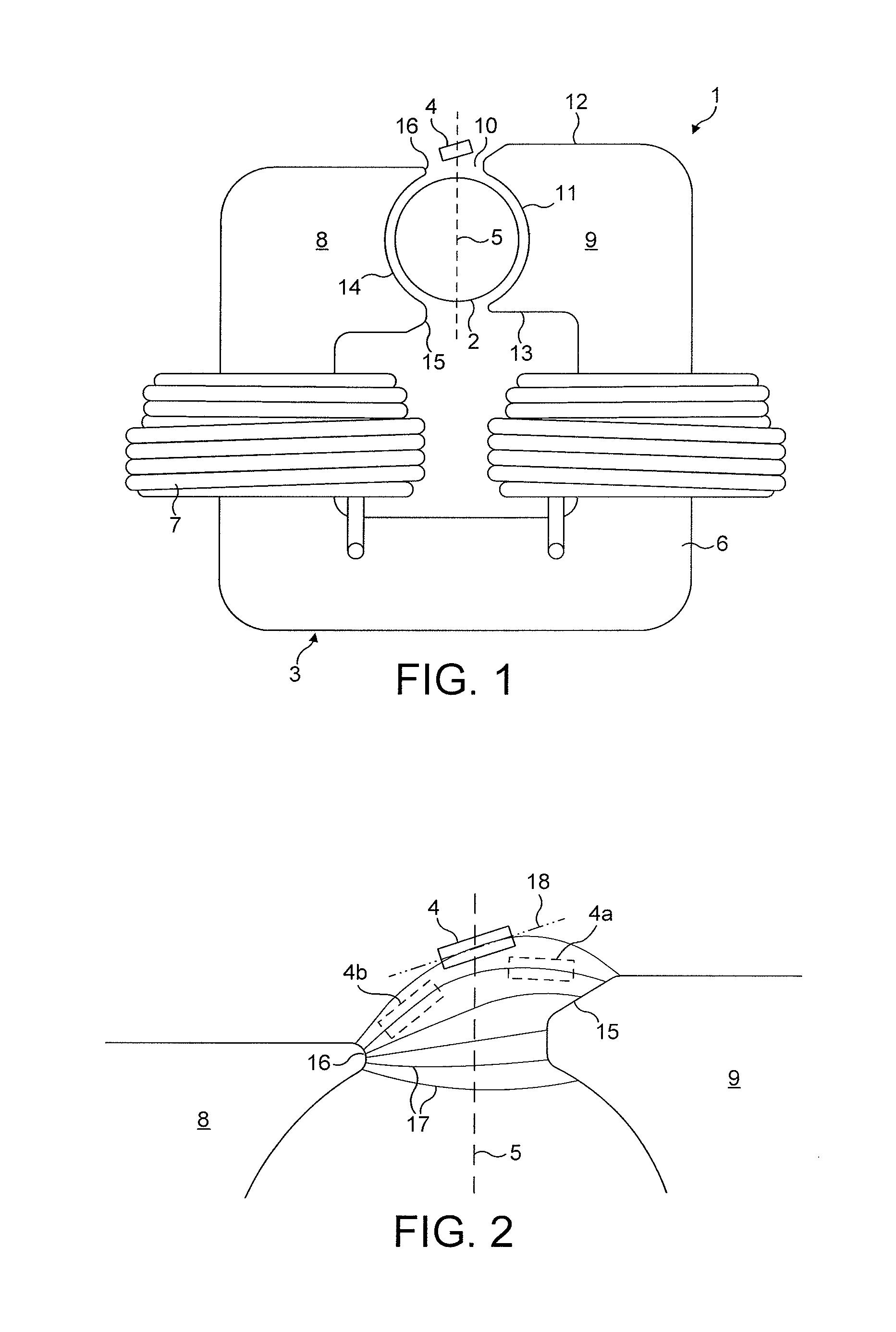

[0015]The motor 1 of FIG. 1 comprises a rotor 2, a stator 3 and a Hall-effect sensor 4.

[0016]The rotor 2 comprises a two-pole permanent magnet having an interpole axis 5.

[0017]The stator 3 comprises a stator core 6 about which a single-phase winding 7 is wound. The stator core 6 is c-shaped and comprises a pair of asymmetric poles 8,9 separated by a slot opening 10. Each pole 8,9 has a pole face 11, a first side 12 and an opposite second side 13 that extend from the pole face 11. Each pole face 11 includes an arcuate recess or pole arc 14, a leading edge 15 and a trailing edge 16 relative to the direction of rotation of the rotor 2. The leading edge 15 extends between the pole arc 14 and the first side 12 of each pole 8,9, and the trailing edge 16 extends between the pole arc 14 and the second side 13 of each pole 8,9. The pole arc 14 thus extends between the leading and trailing edges 15,16.

[0018]The leading edge 15 of each pole 8,9 is thicker than that of the trailing edge 16 in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com