Patents

Literature

37results about How to "Good portion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

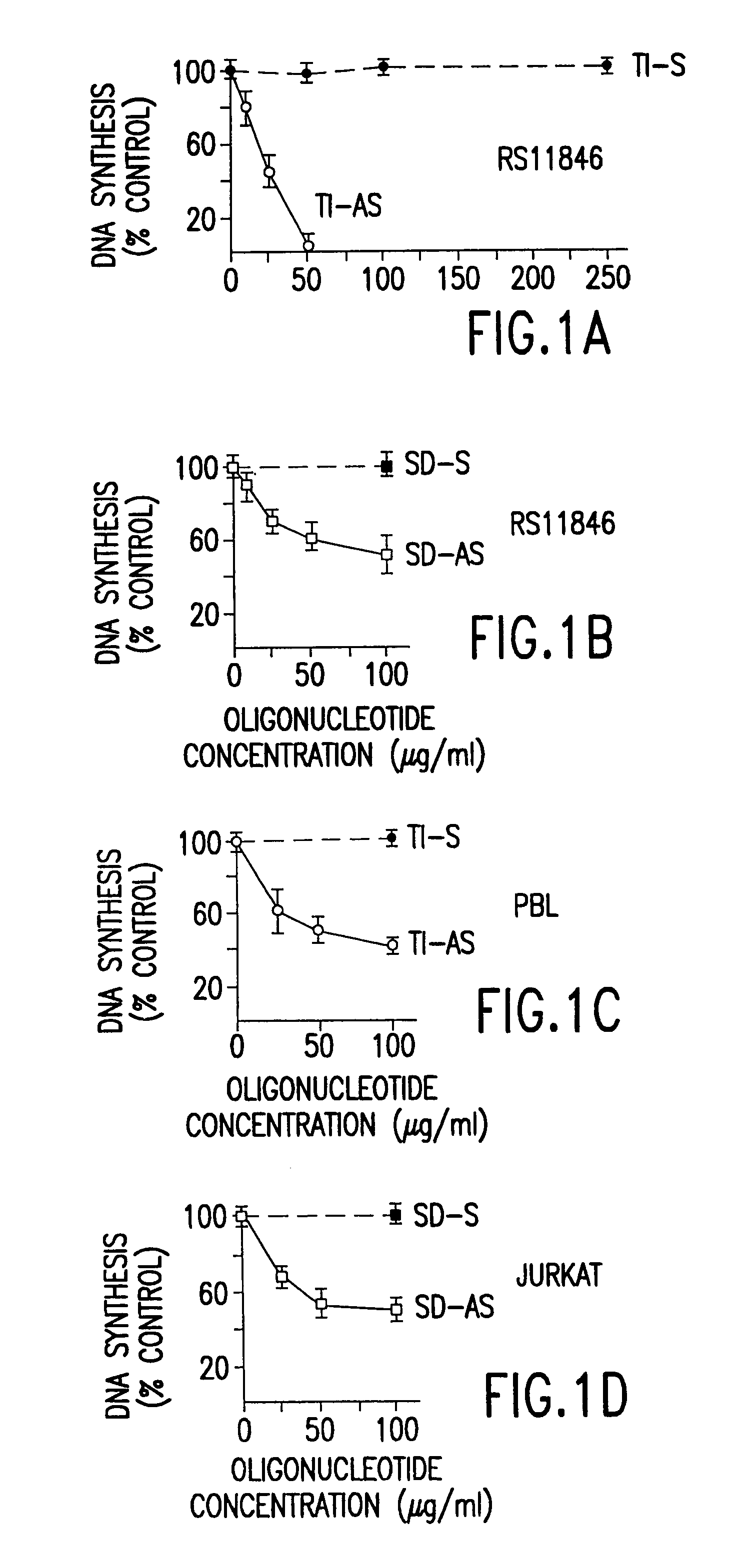

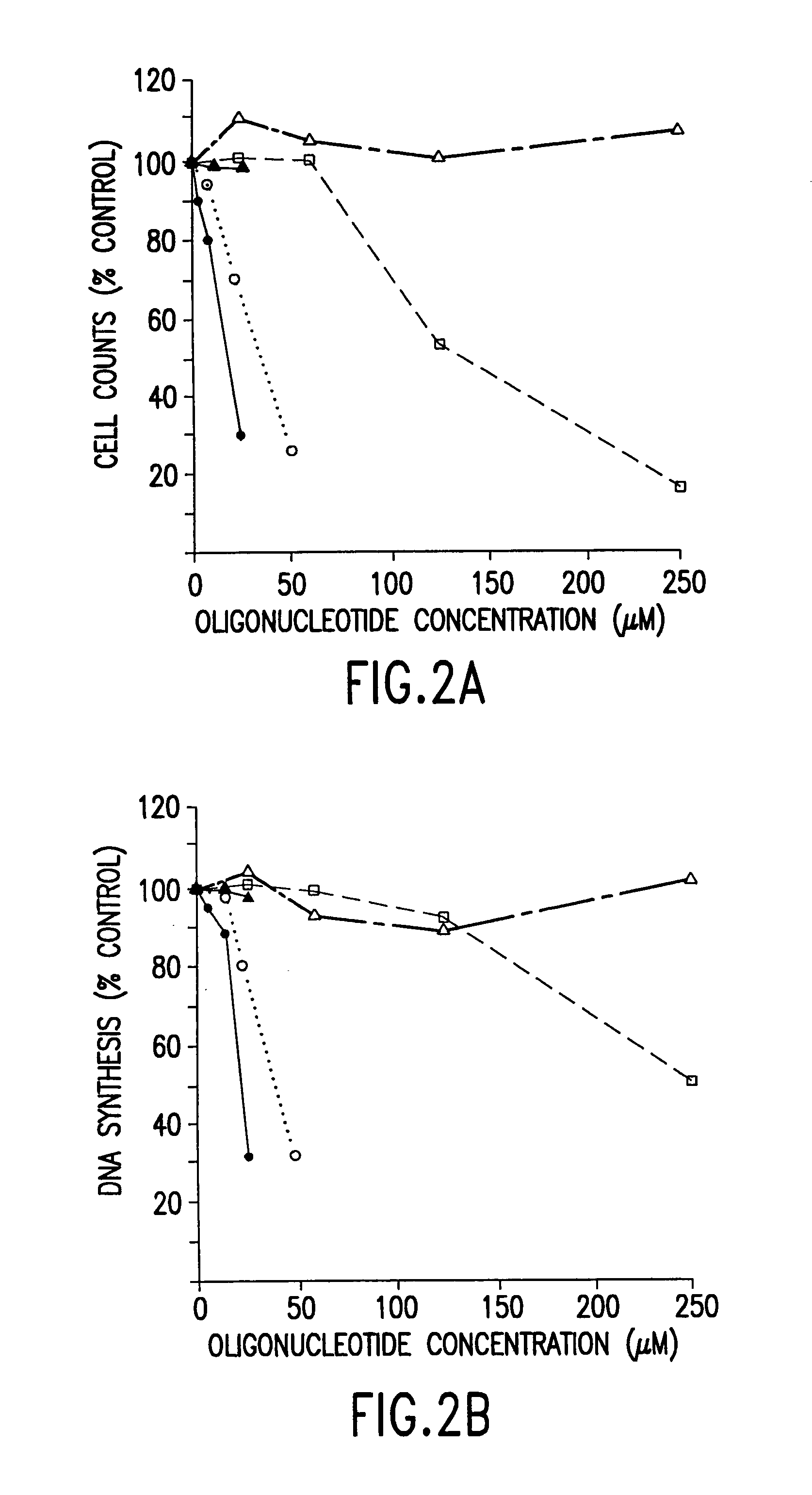

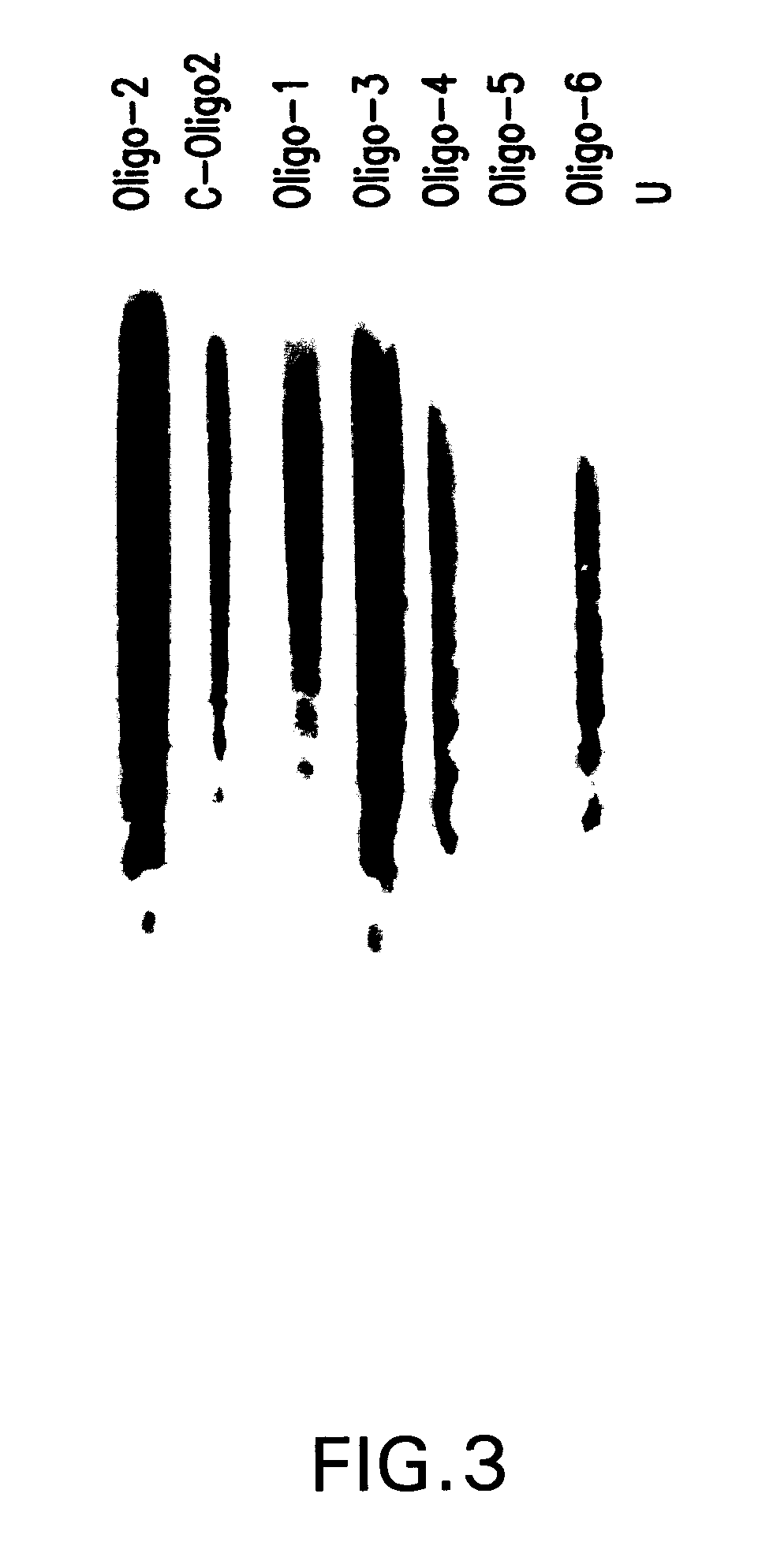

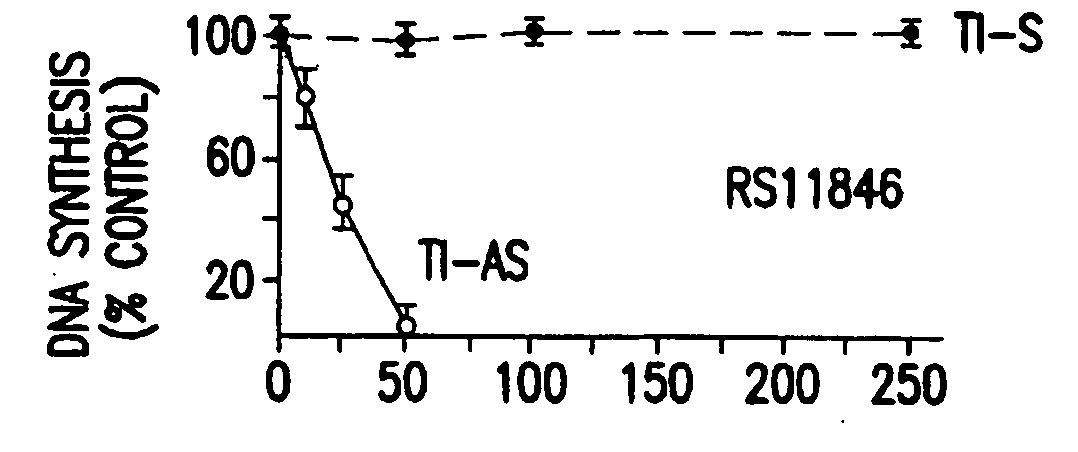

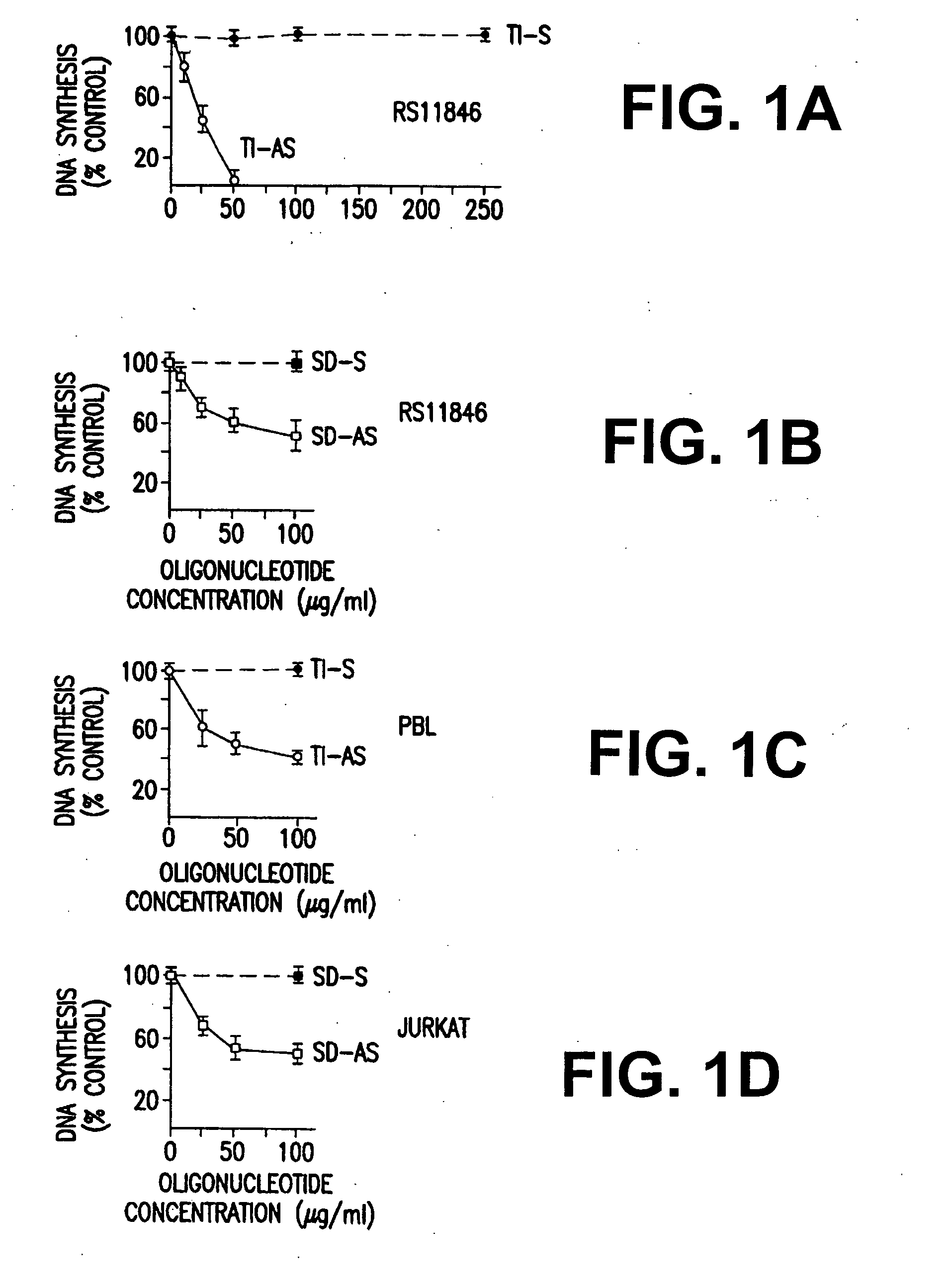

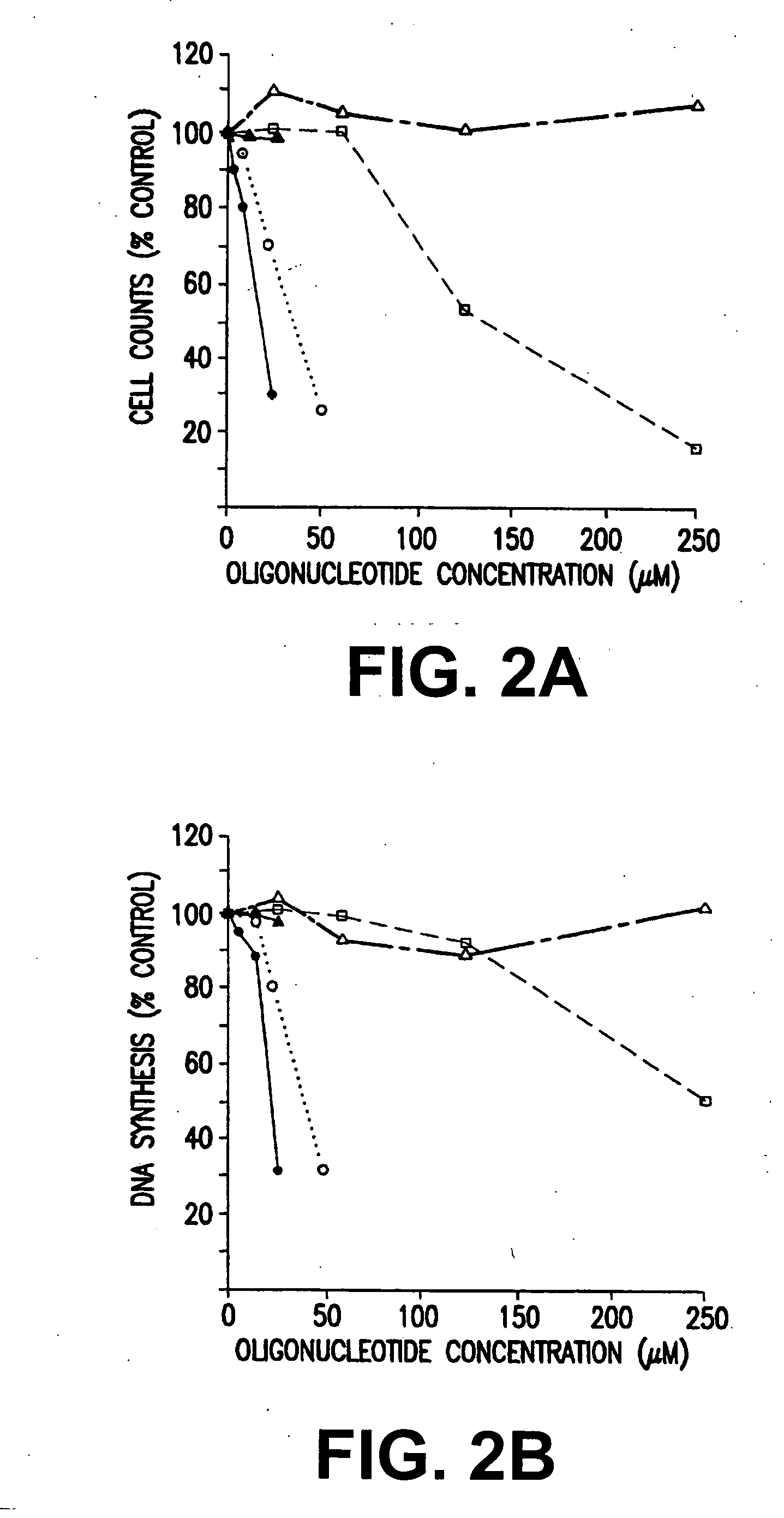

Regulation of BCL-2 gene expression

InactiveUS7022831B1High sensitivityIncreased chemosensitivitySugar derivativesPeptide/protein ingredientsOligomerCancer cell

Owner:UCB SA

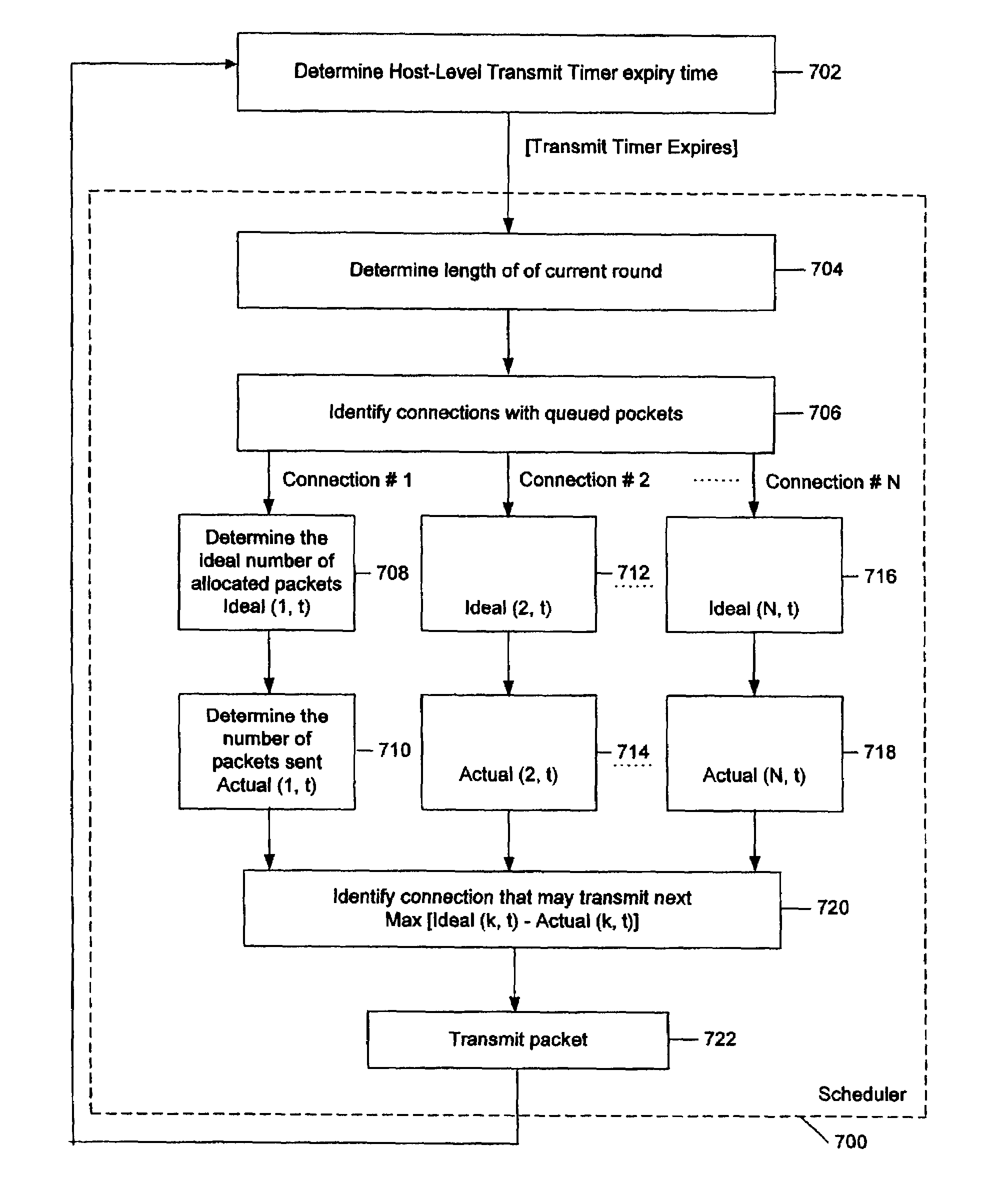

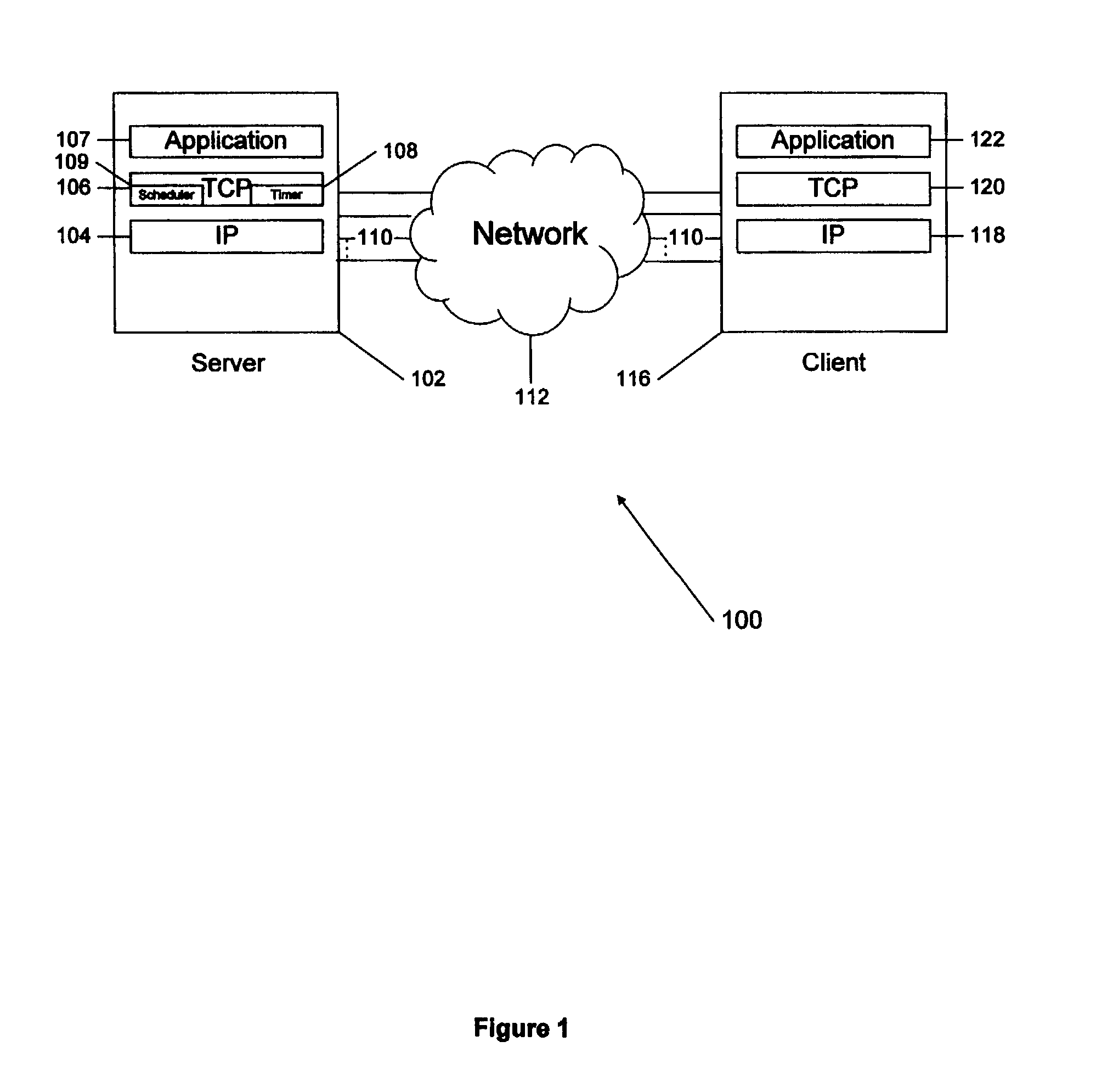

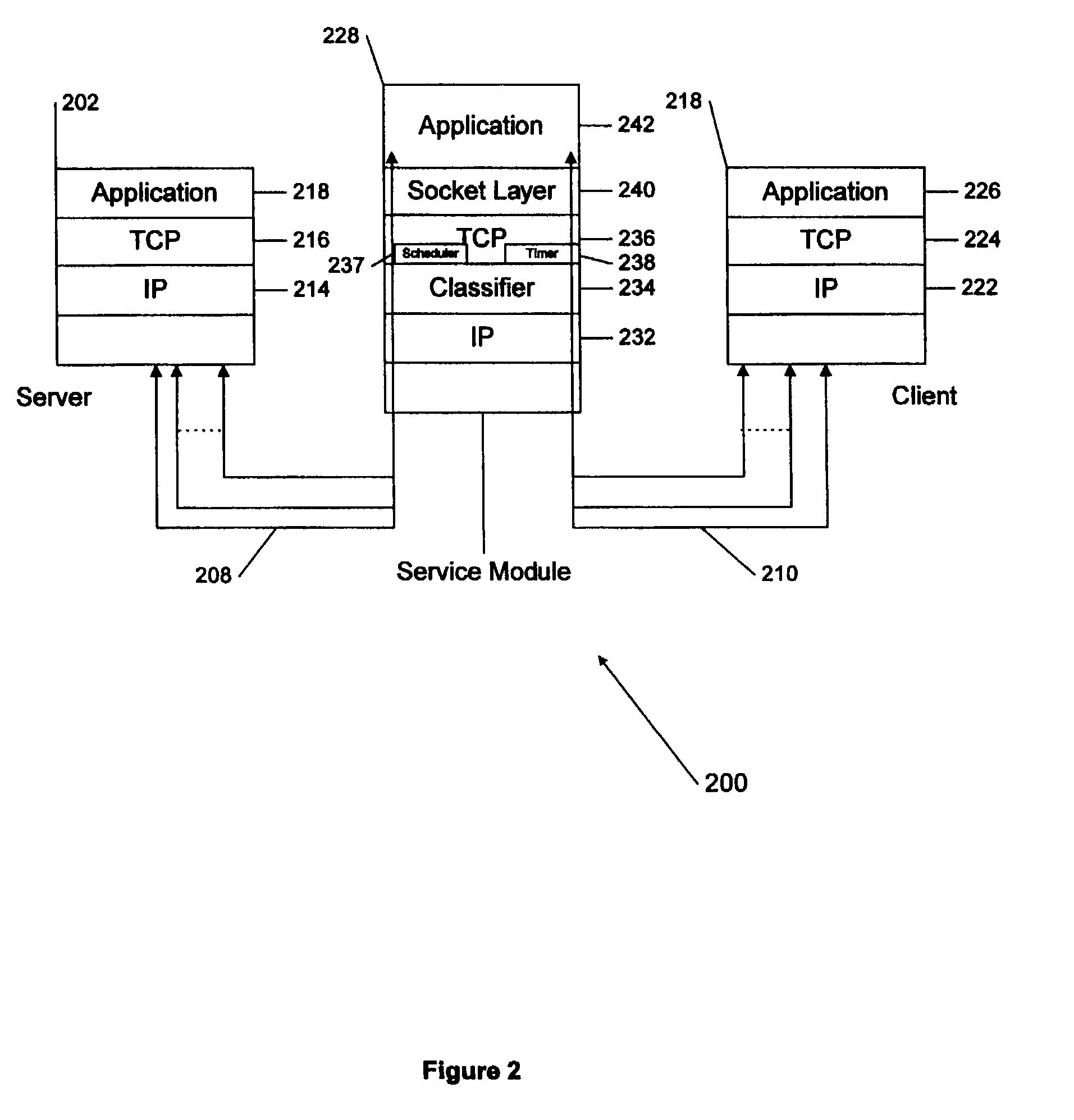

Quality of service management for multiple connections within a network communication system

ActiveUS7136353B2Reduce or avoid potentially destructive competitionReduce and eliminate bursty data transmissionError preventionTransmission systemsQuality of serviceCommunications system

Improved quality of service management for multiple connections between a sender and a receiver may be achieved by allocating a host-level transmission rate among the multiple connections based on a ratio of a weight associated with each connection and a sum of the weights associated the connections. Data packets associated with the connections may then be selectively transmitted to the receiver such that data packets having a highest difference between the allocated transmission rate and an actual transmission rate are transmitted first. The data packets transmitted to the sender may also be clocked using a transmission timer having period corresponding to the host-level transmission rate.

Owner:OPTIMORPHIX INC

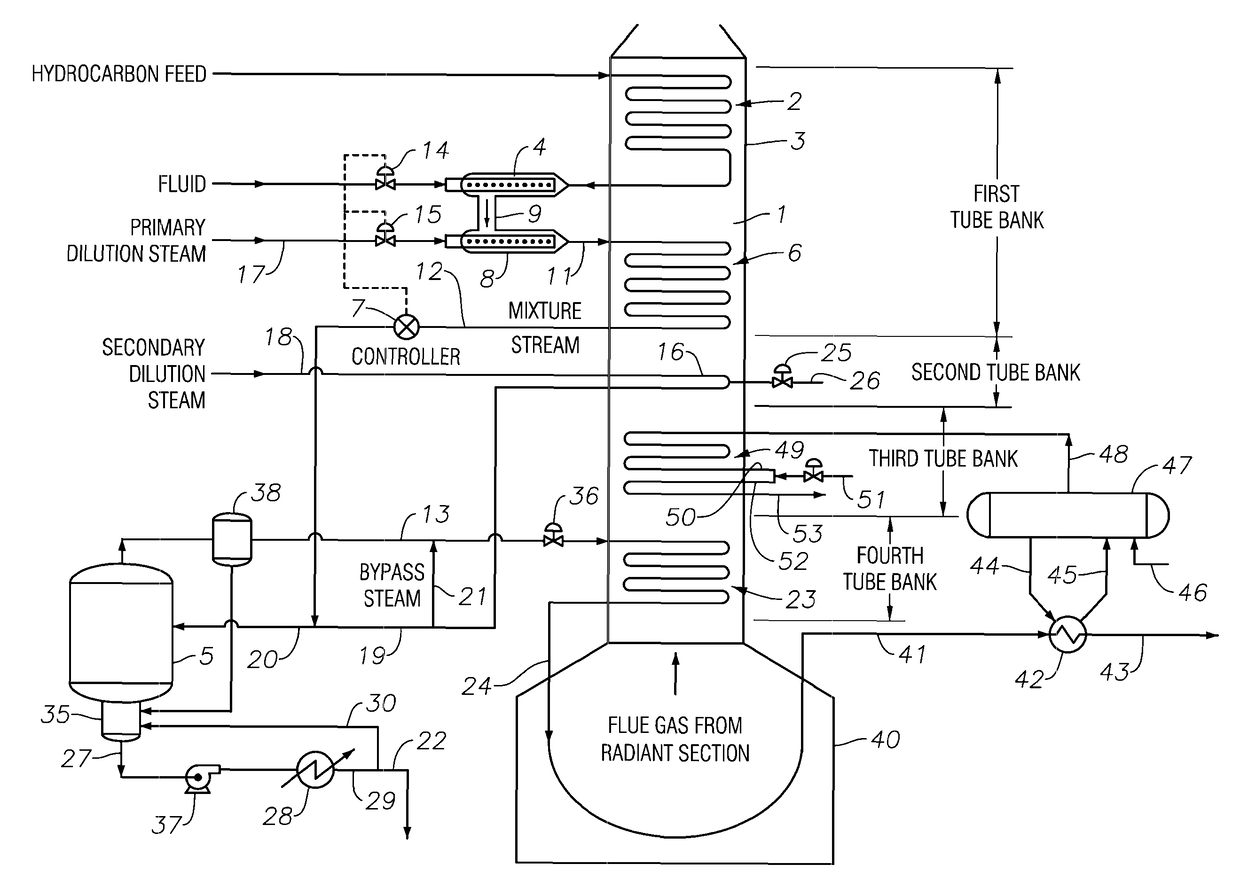

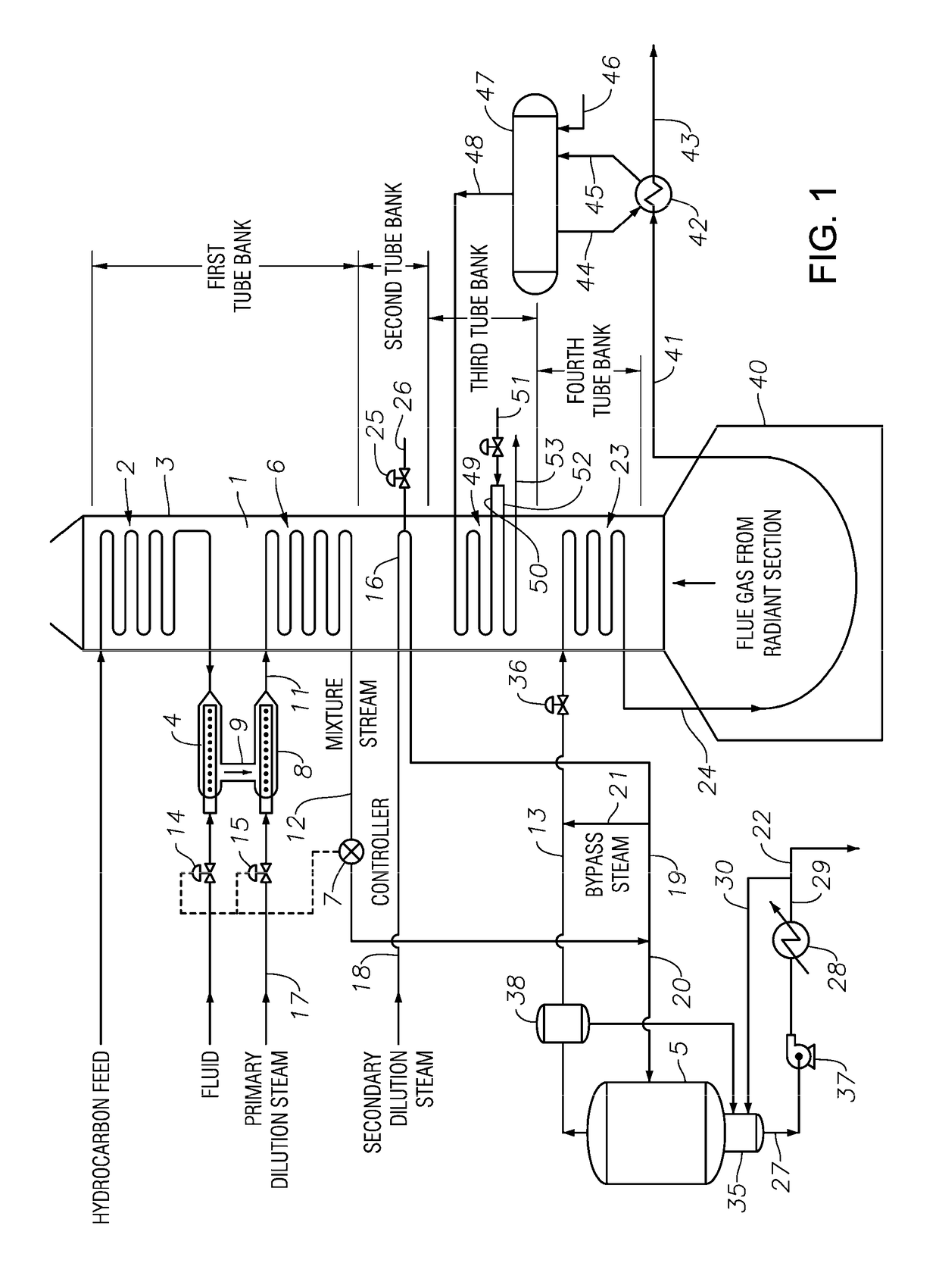

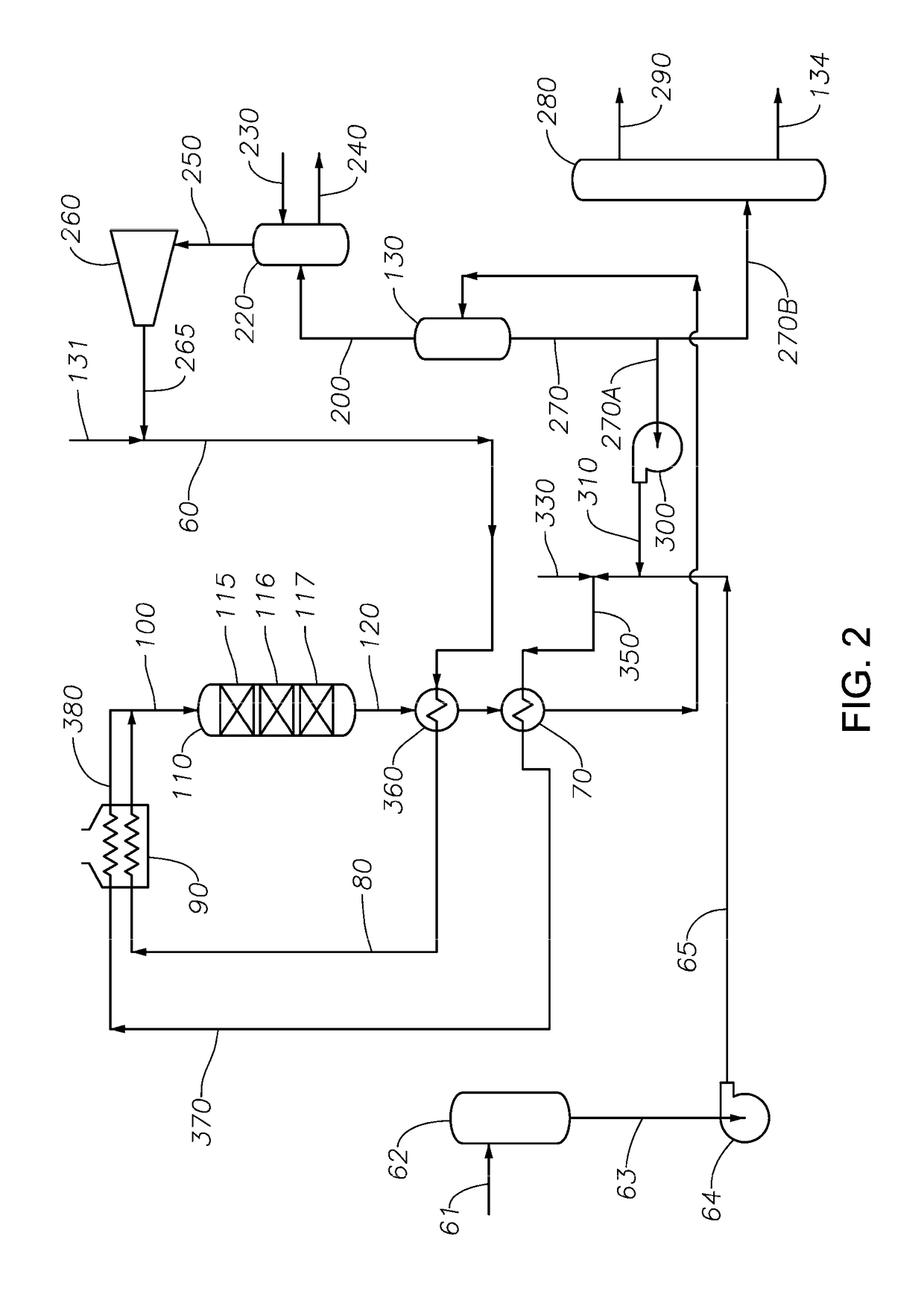

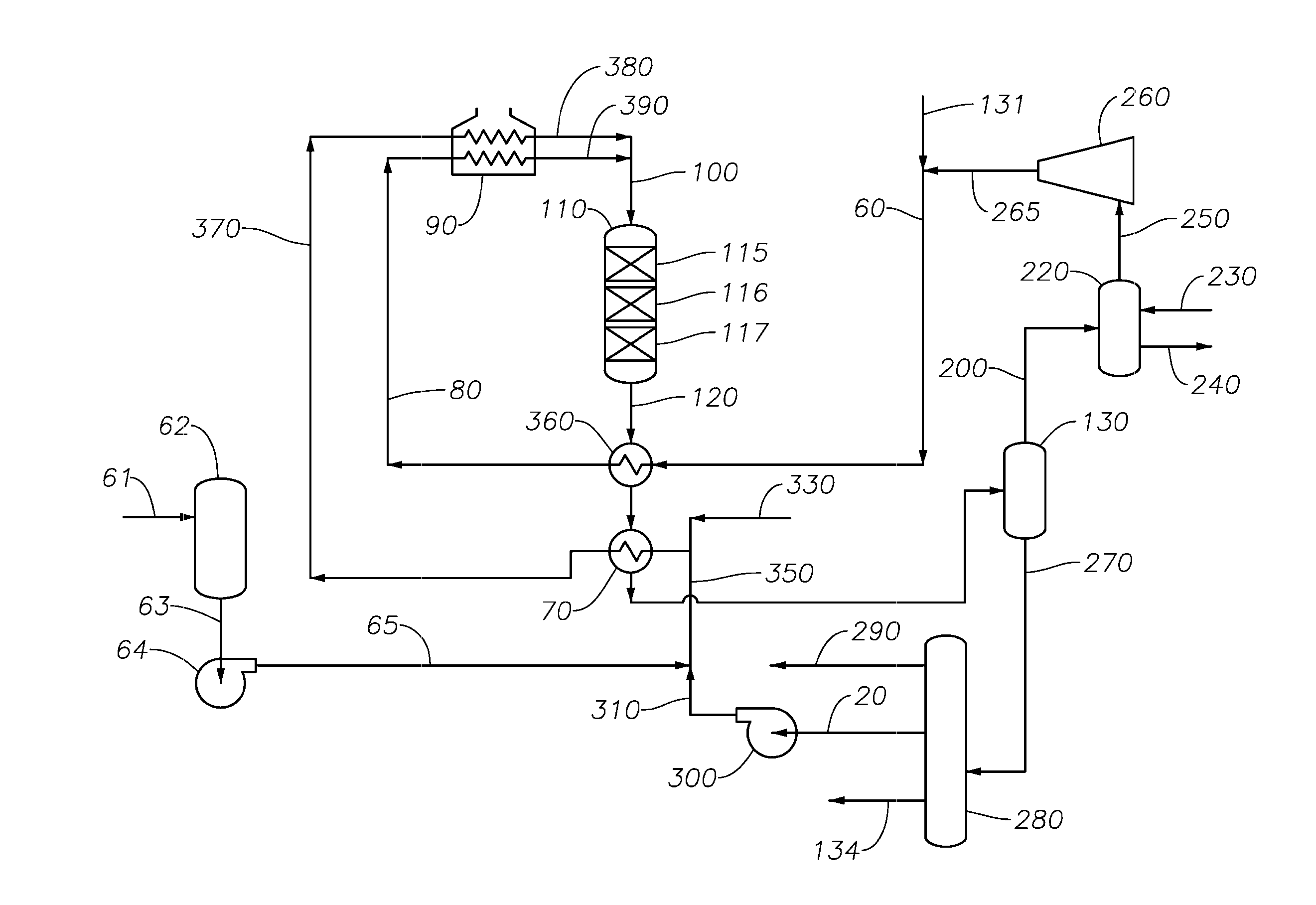

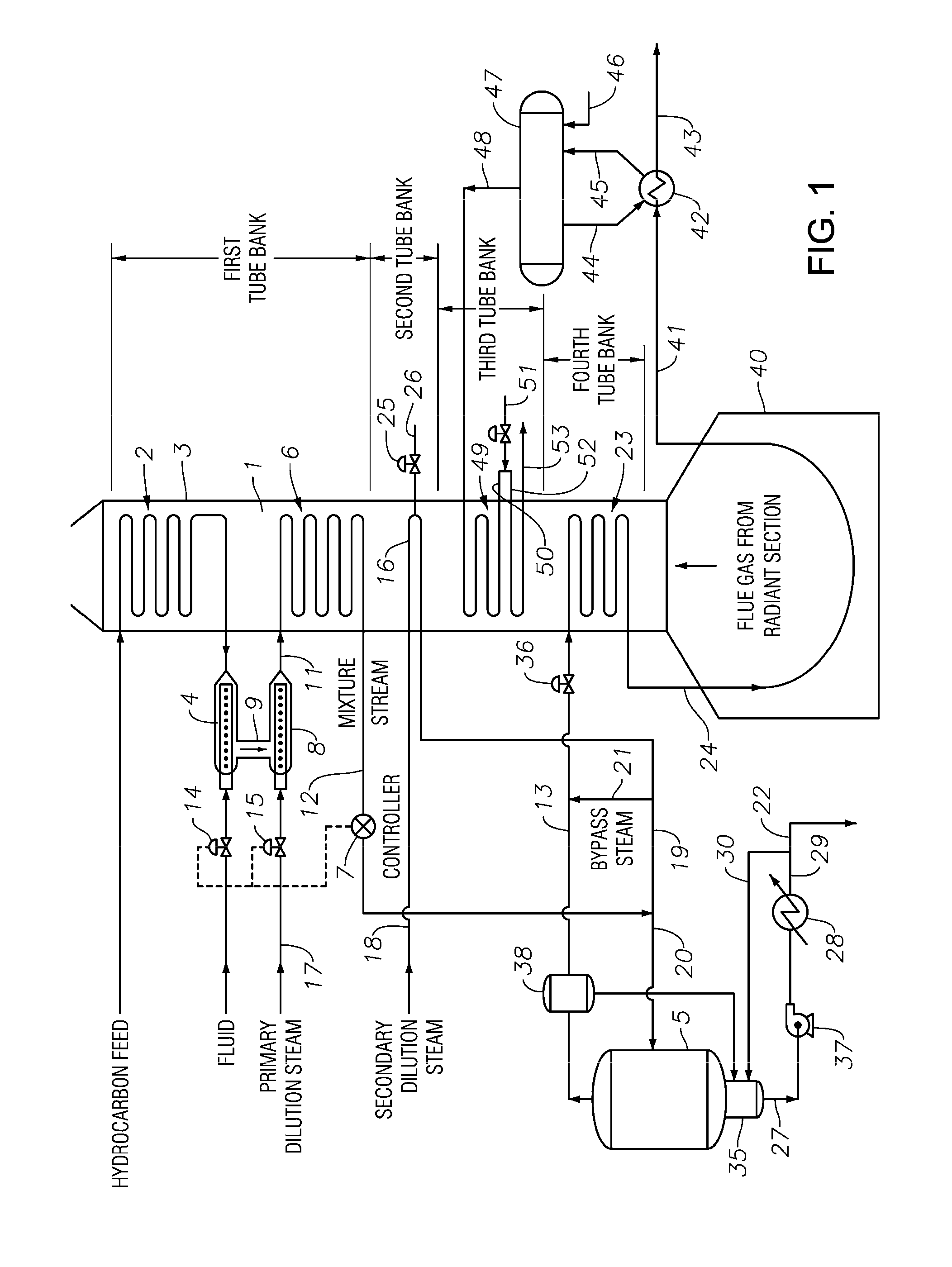

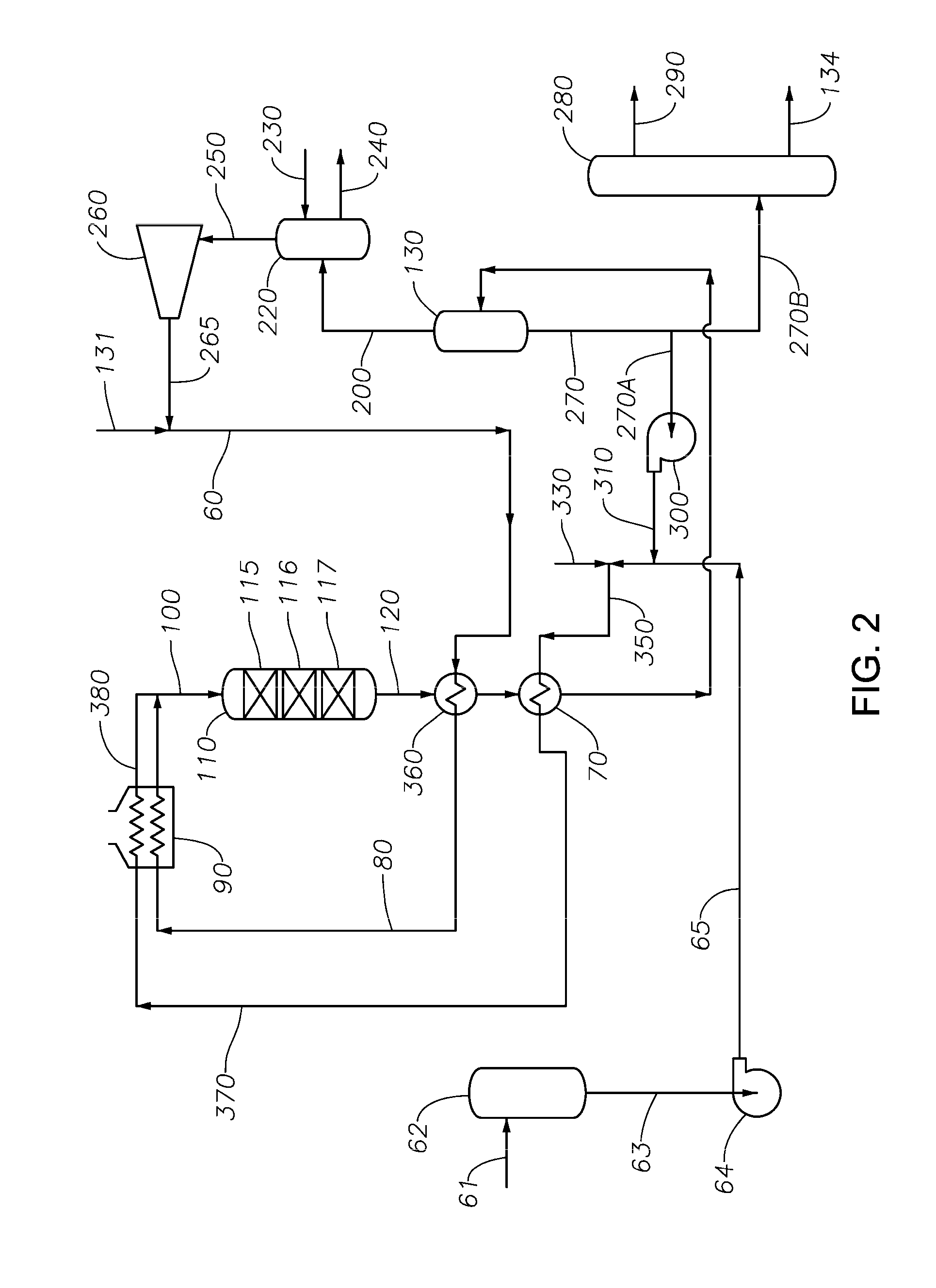

Pyrolysis tar upgrading using recycled product

ActiveUS9657239B2Pyrolysis tar hydroprocessing is improvedLesser rateHydrotreatment operations starting-upRefining to change hydrocarbon structural skeletonProcess engineeringFuel oil

The invention relates to a process for upgrading pyrolysis tar in the presence of a utility fluid. The utility fluid contains 1-ring and / or 2-ring aromatics and has a final boiling point ≦430° C. The invention also relates to the upgraded pyrolysis tar, and to the use of the upgraded pyrolysis tar, e.g., for fuel oil blending.

Owner:EXXONMOBIL CHEM PAT INC

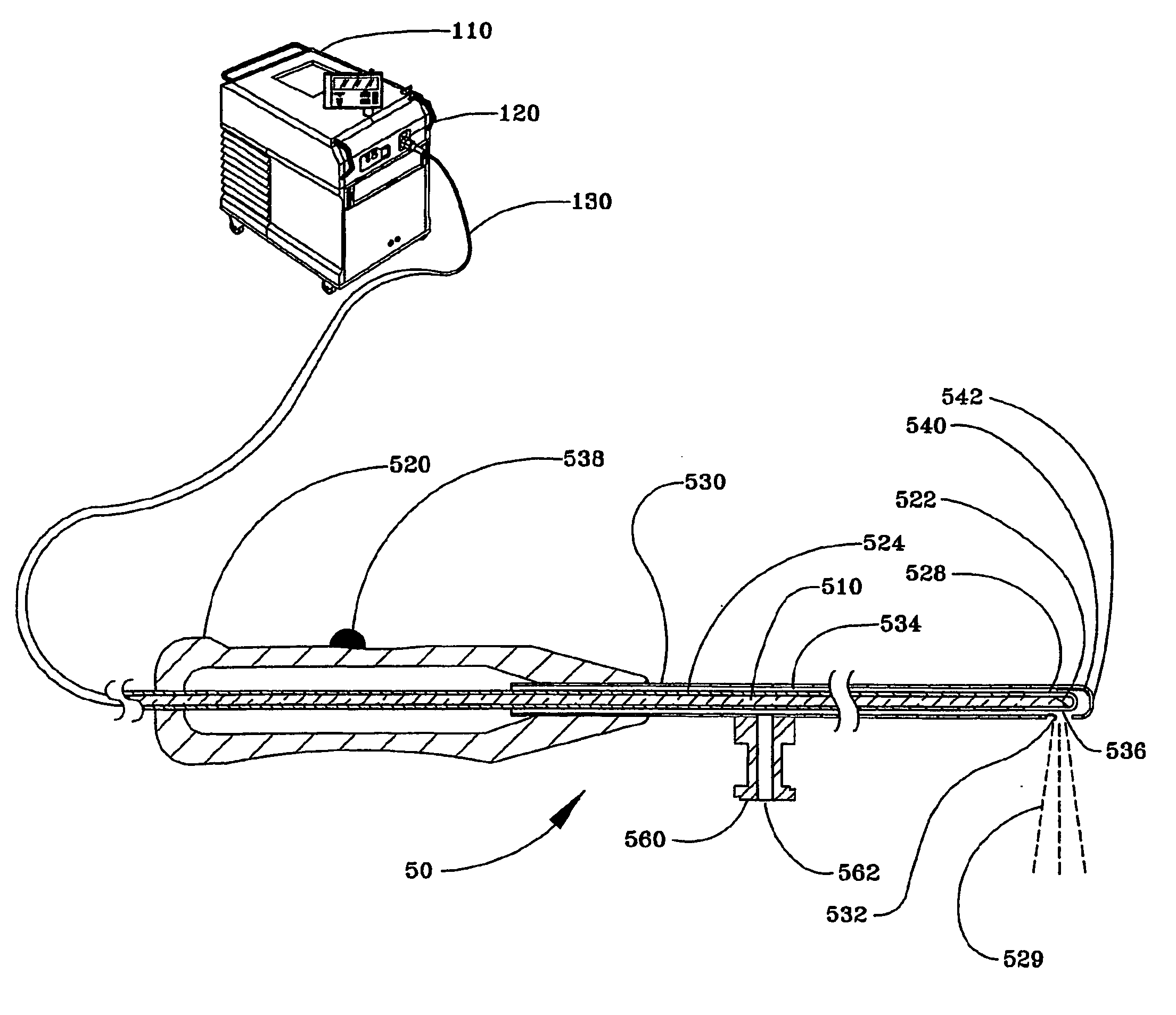

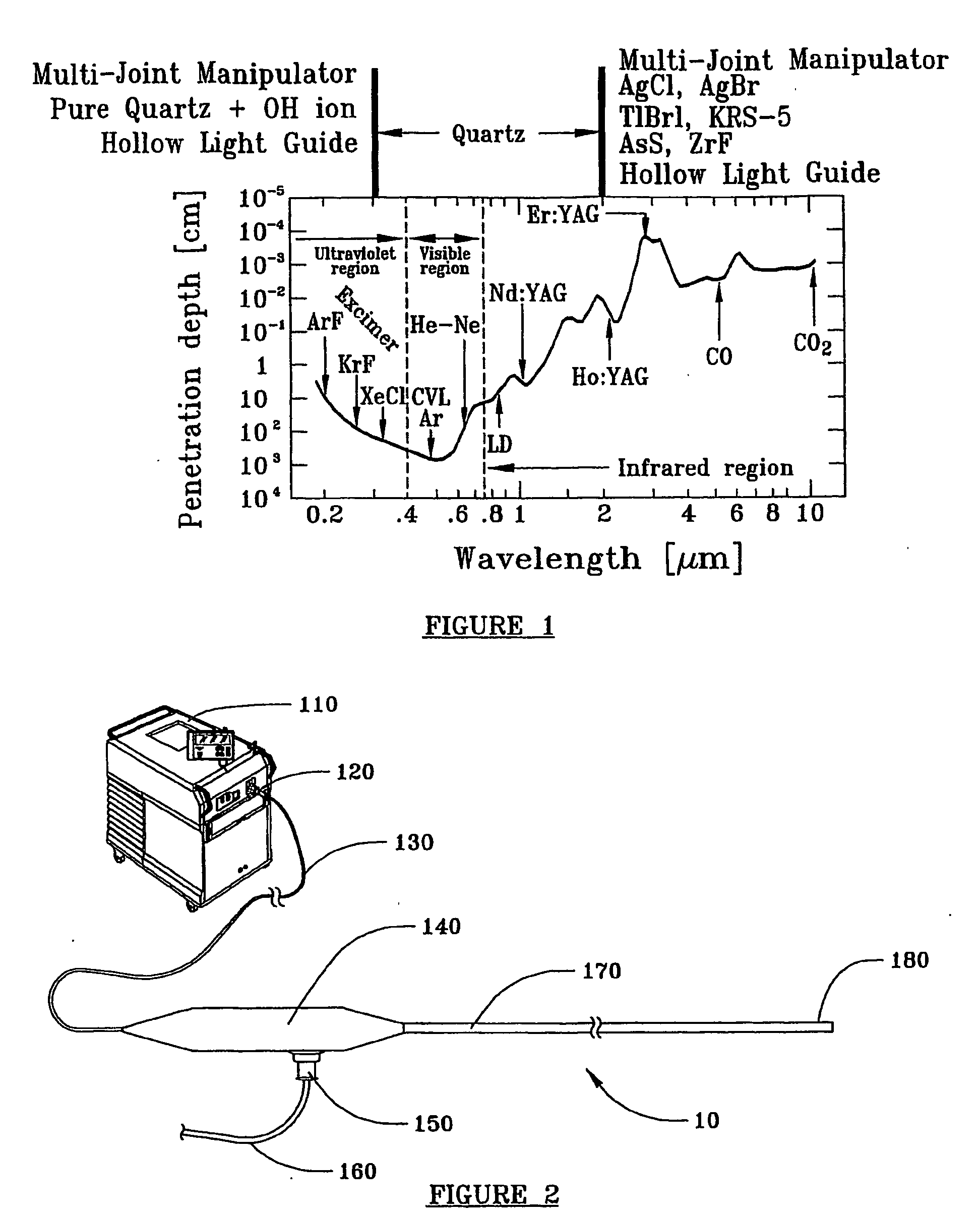

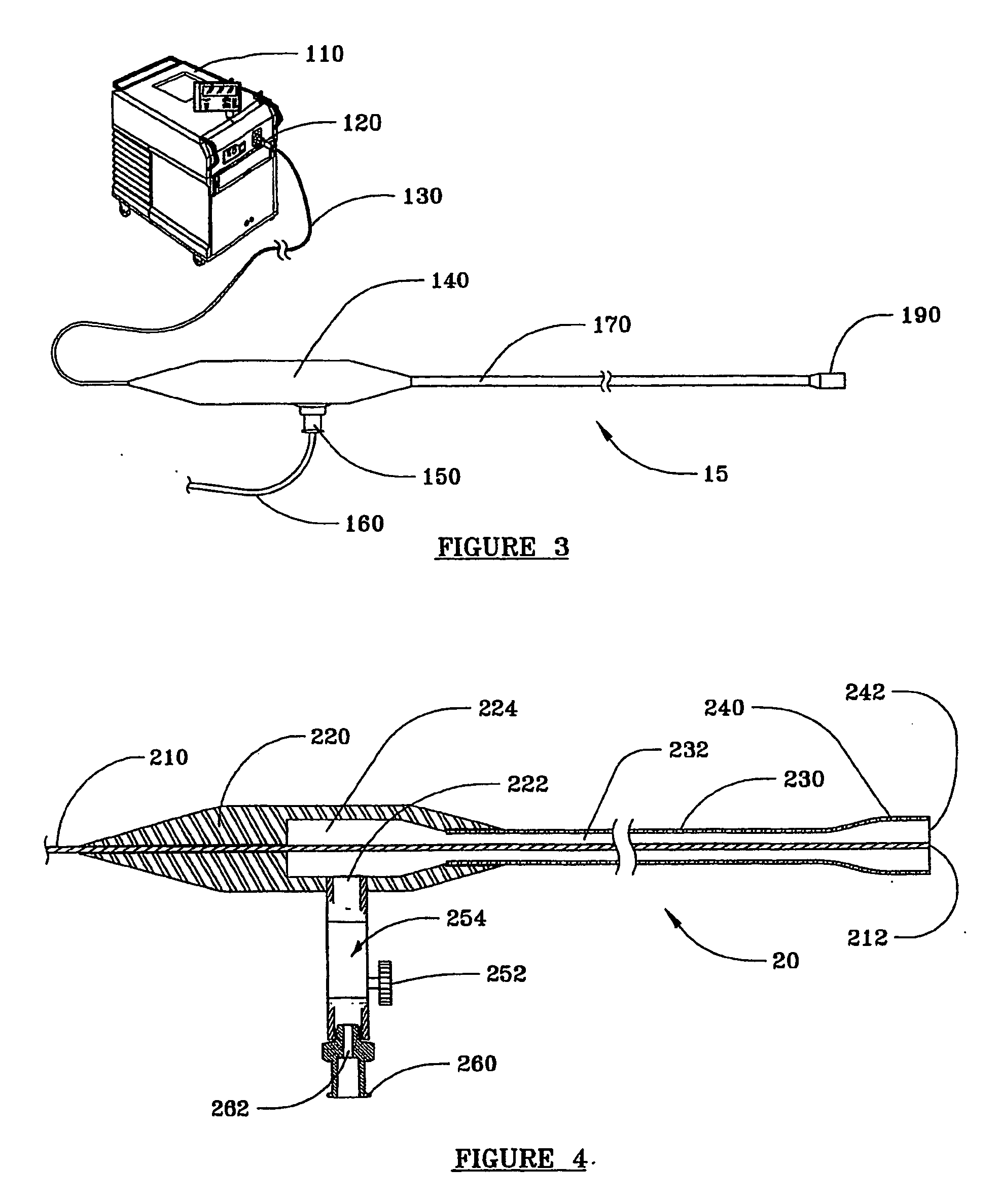

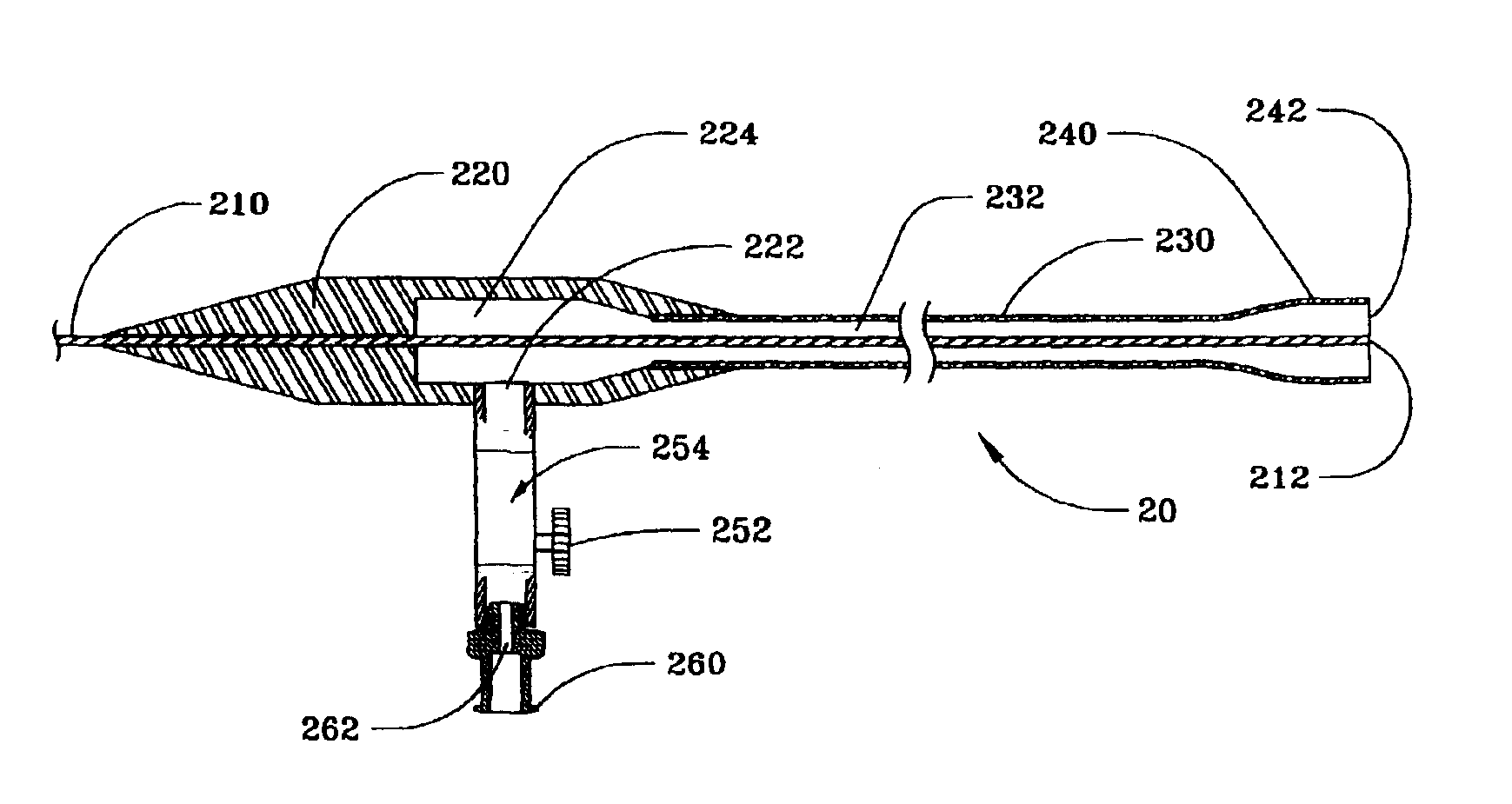

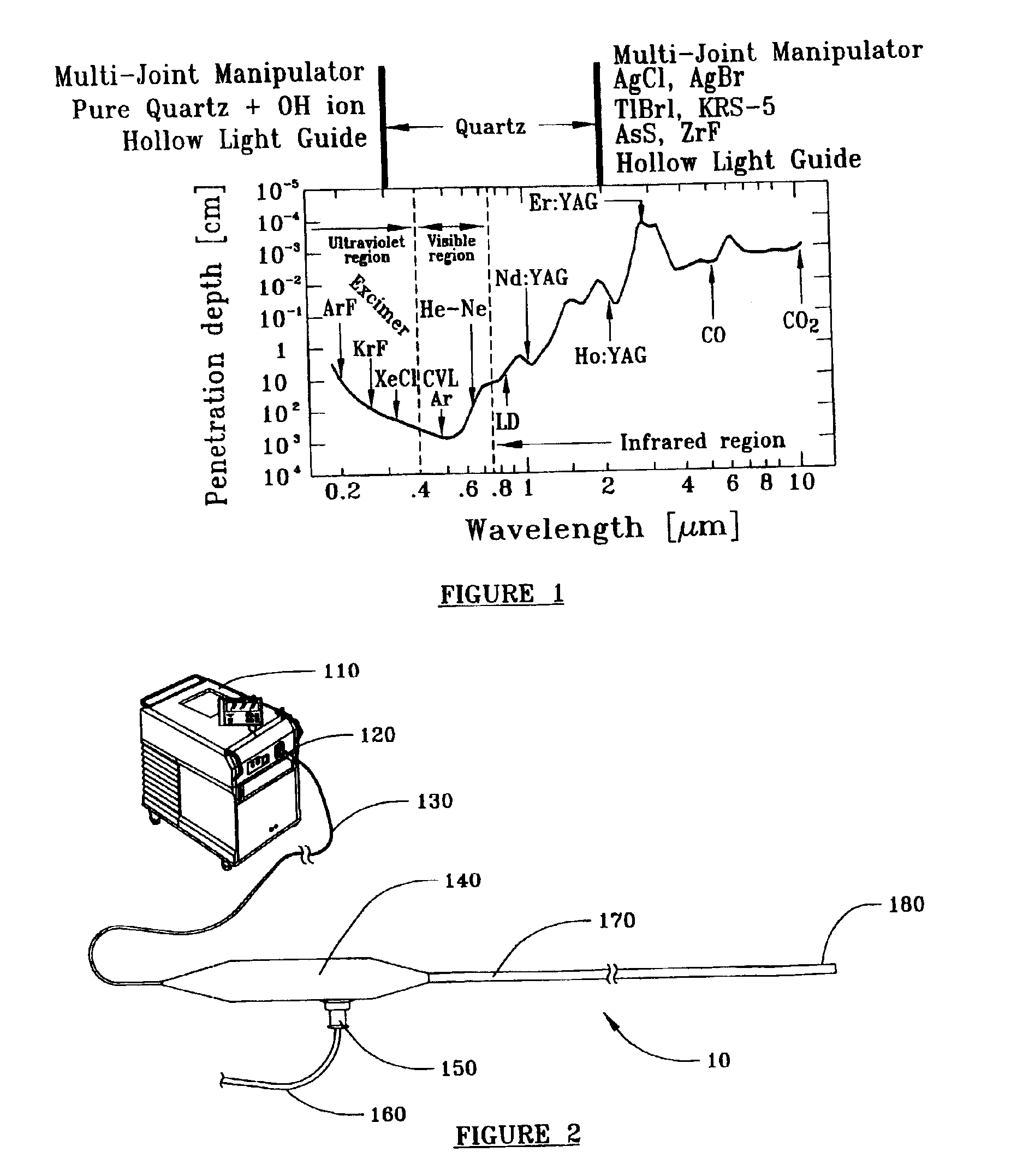

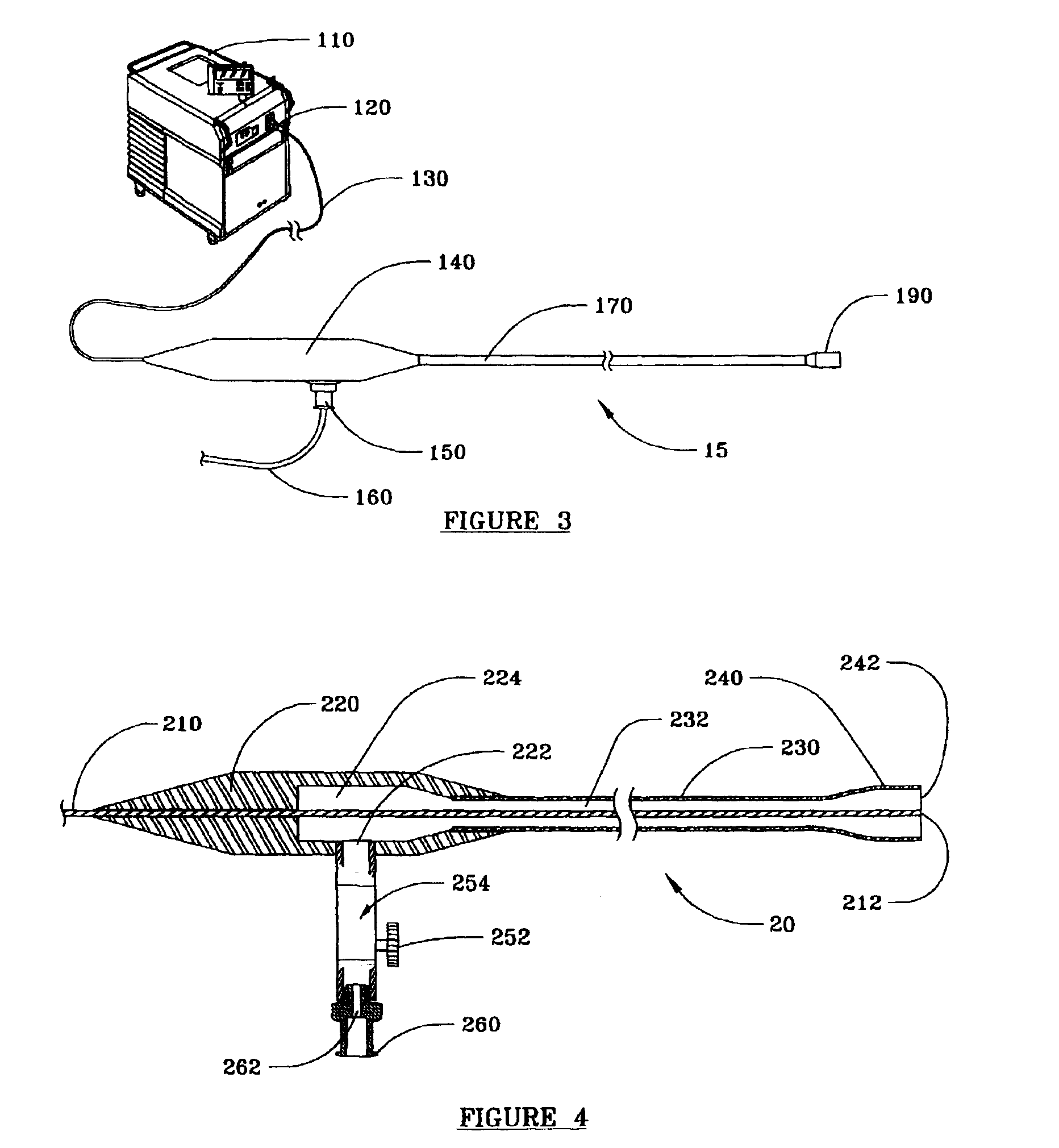

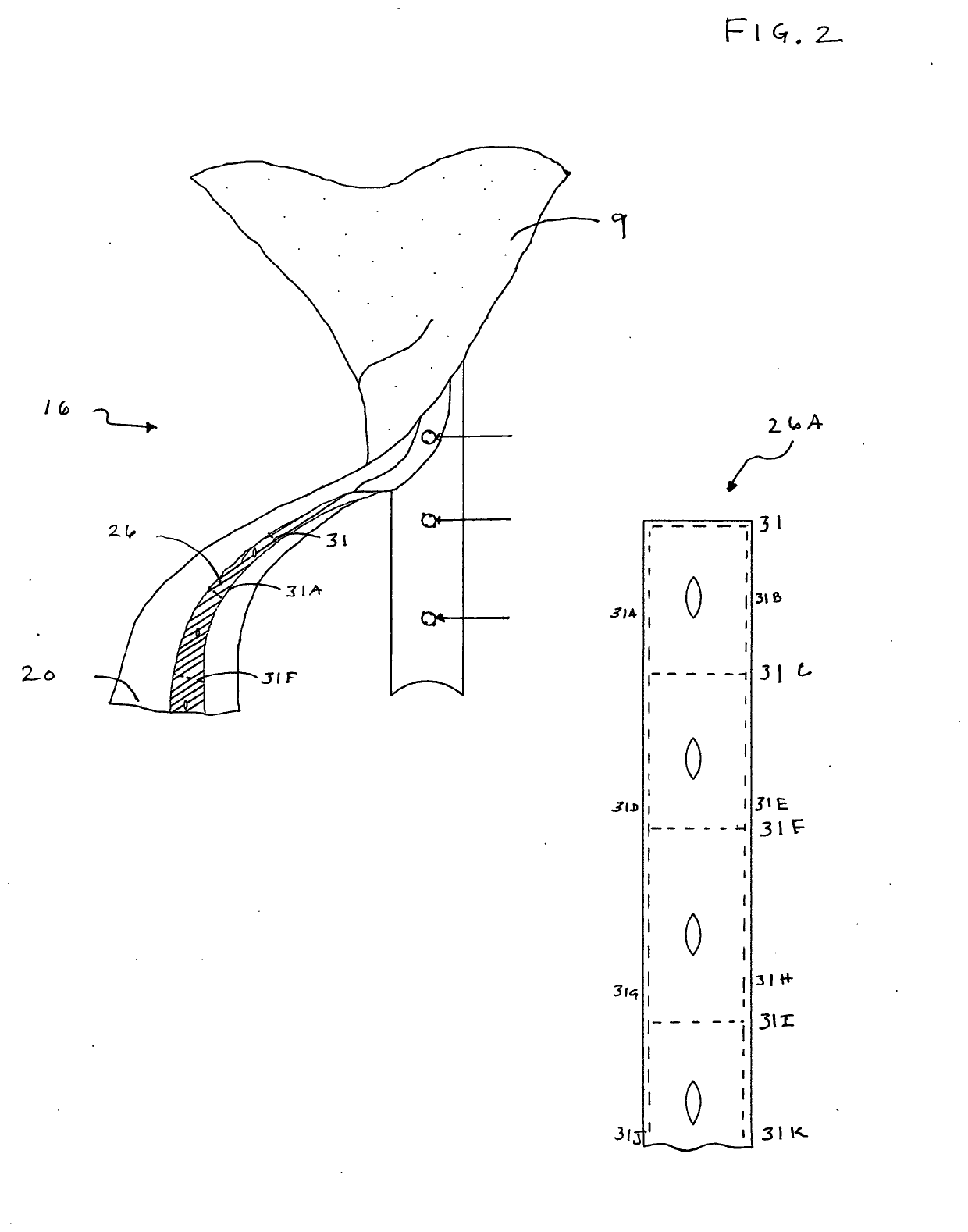

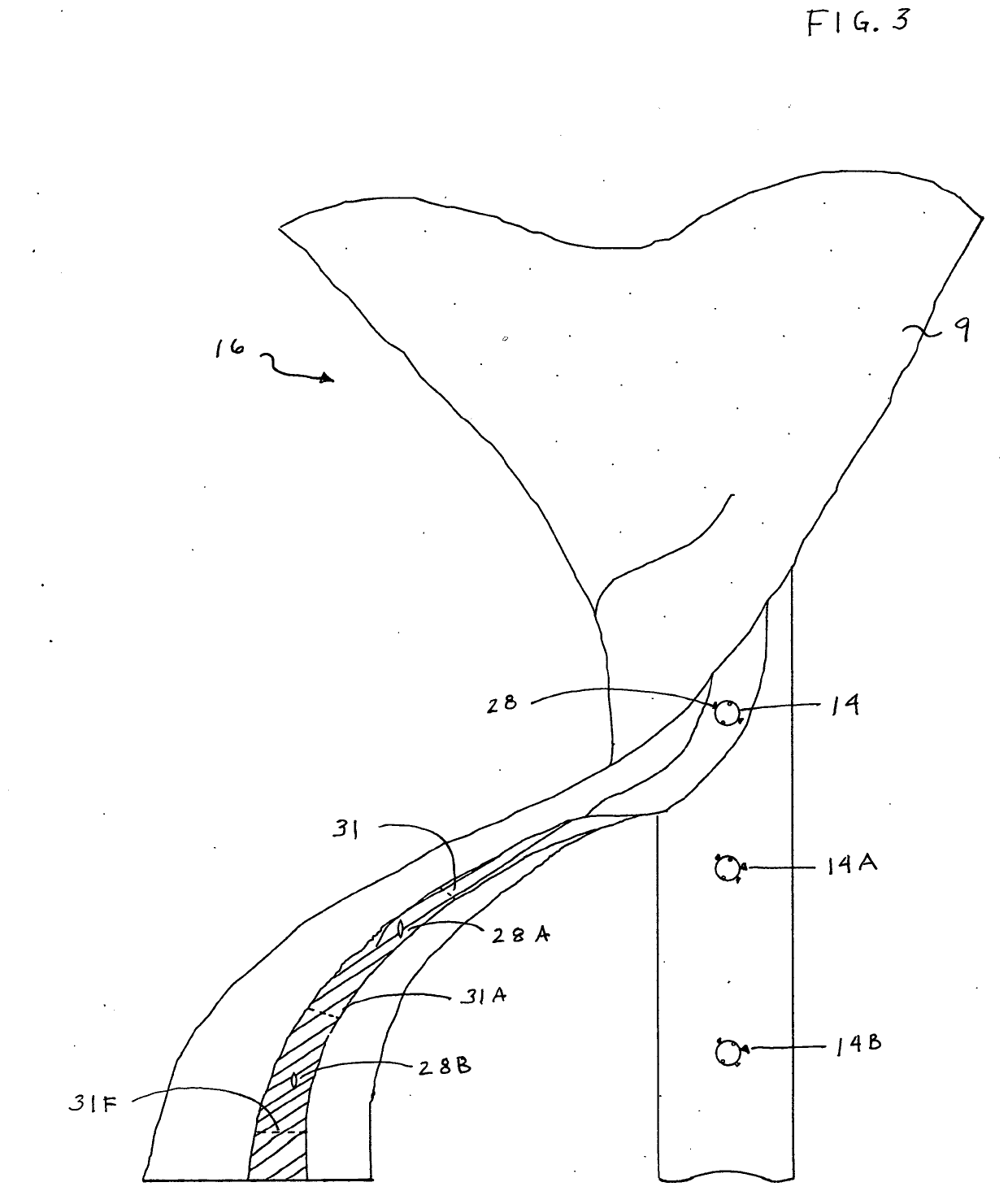

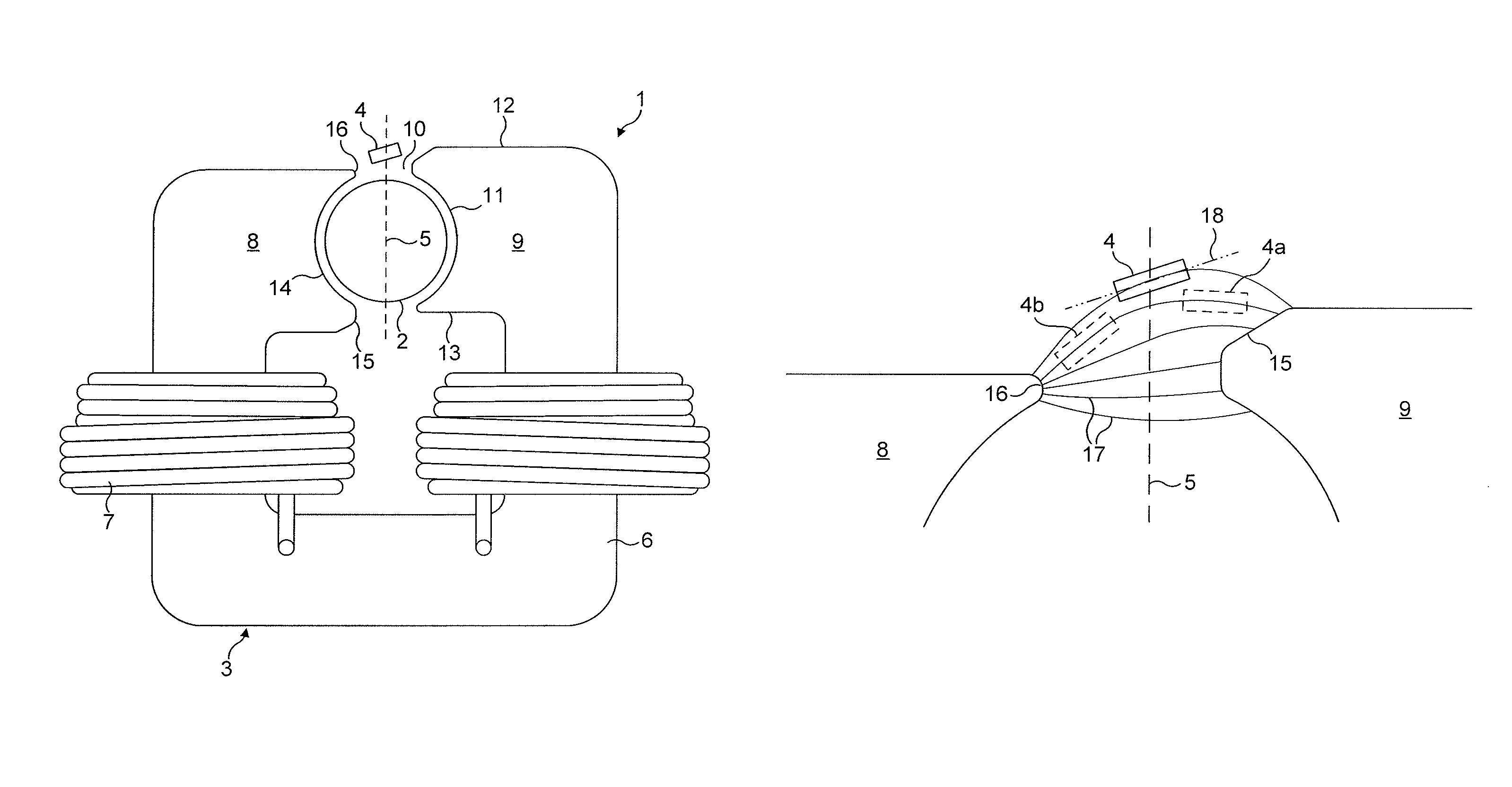

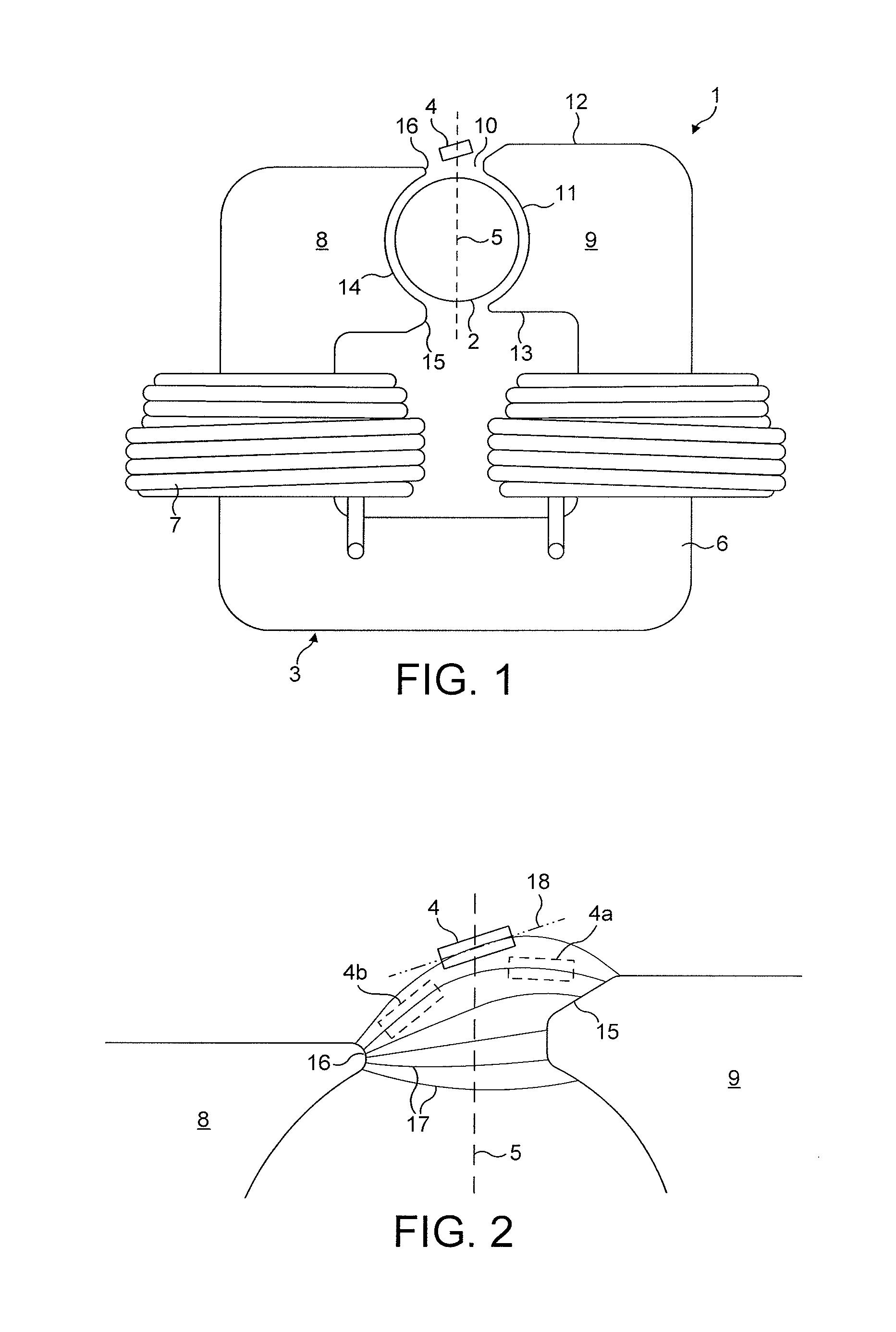

Device and method for delivery of long wavelength laser energy to a tissue site

A laser energy delivery device is provided that is suitable for irradiating a body tissue with relatively long wavelength laser energy in the presence of an aqueous liquid without significant absorption of the laser energy by the liquid. The device includes an elongate hollow sheath that has an open aperture at its distal end portion and closed at its proximal end, a laser energy conduit such as an optical fiber or hollow wave guide, within the sheath, the distal end of the conduit being disposed near the open aperture at the distal end portion of the sheath, and the proximal end of the conduit being adapted for connection to a source of long wavelength laser energy. The sheath also includes an inlet port, spaced from the proximal end of the sheath, and adapted to receive and deliver a biologically compatible gas through the sheath to a body tissue site in contact with the open distal end of the sheath. In use, the open aperture at the distal end portion of the sheath is positioned in contact with a body tissue site. Gas, such as carbon dioxide, infused through the sheath displaces an aqueous liquid from the region between the distal end portion of the sheath and the tissue. Laser energy emitted from the distal end portion of the conduit passes through the substantially liquid-free region at the distal end of the sheath and impinges on the tissue to be irradiated. The laser energy can be used to ablate, vaporize, coagulate or shrink tissue at the target zone without interference from aqueous liquids, which tend to absorb relatively large amounts of long wavelength laser energy and reduce the efficiency of tissue ablation.

Owner:TRIMEDYNE

Device and method for delivery of long wavelength laser energy to a tissue site

A laser energy delivery device and method are provided for irradiating a body tissue with relatively long wavelength laser energy in the presence of an aqueous liquid without significant absorption of the laser energy by the liquid. The device includes an elongate hollow sheath that is open at its distal end and closed at its proximal end, a laser energy conduit such as an optical fiber or hollow waveguide, within the sheath, the distal end of the conduit being disposed near the open distal end of the sheath, and the proximal end of the conduit being adapted for connection to a source of long wavelength laser energy. The sheath also includes an inlet port, spaced from the proximal end of the sheath, and adapted to receive and deliver a biologically compatible gas through the sheath to a body tissue site in contact with the open distal end of the sheath.

Owner:TRIMEDYNE

Pyrolysis Tar Upgrading Using Recycled Product

ActiveUS20150368570A1Pyrolysis tar hydroprocessing is improvedLesser rateRefining to change hydrocarbon structural skeletonTreatment with plural serial stages onlyBoiling pointTar

The invention relates to a process for upgrading pyrolysis tar in the presence of a utility fluid. The utility fluid contains 1-ring and / or 2-ring aromatics and has a final boiling point ≦430° C. The invention also relates to the upgraded pyrolysis tar, and to the use of the upgraded pyrolysis tar, e.g., for fuel oil blending.

Owner:EXXONMOBIL CHEM PAT INC

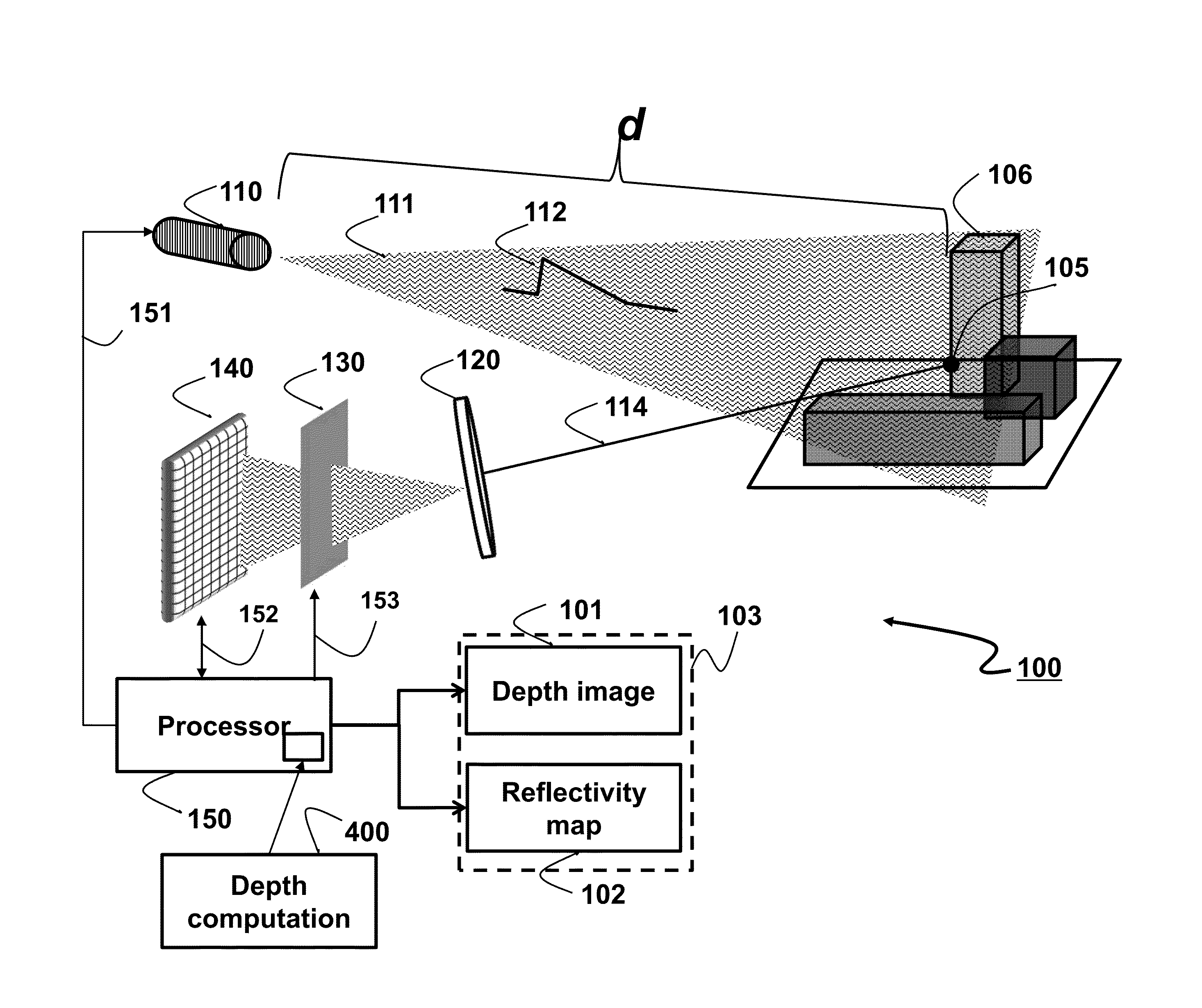

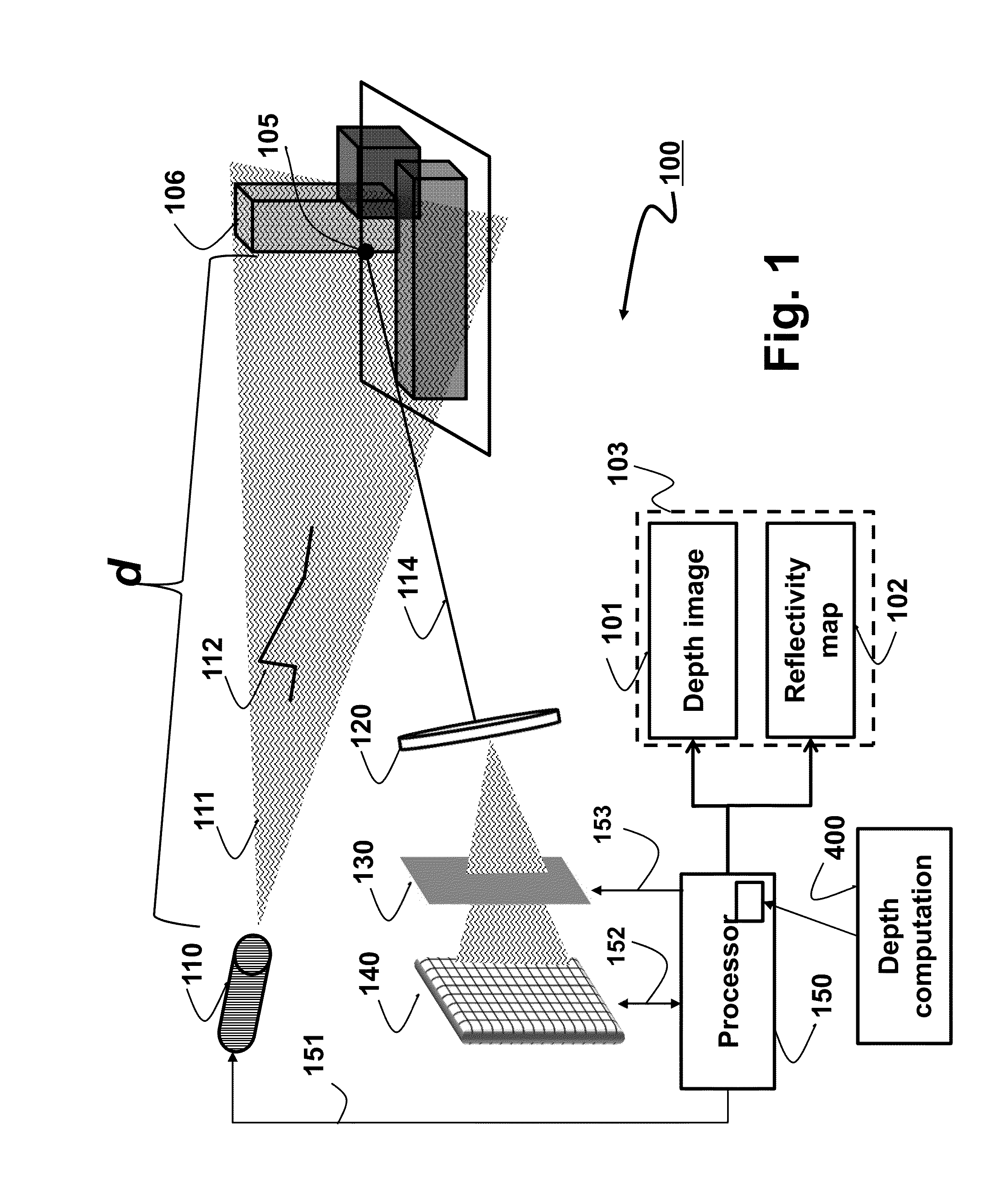

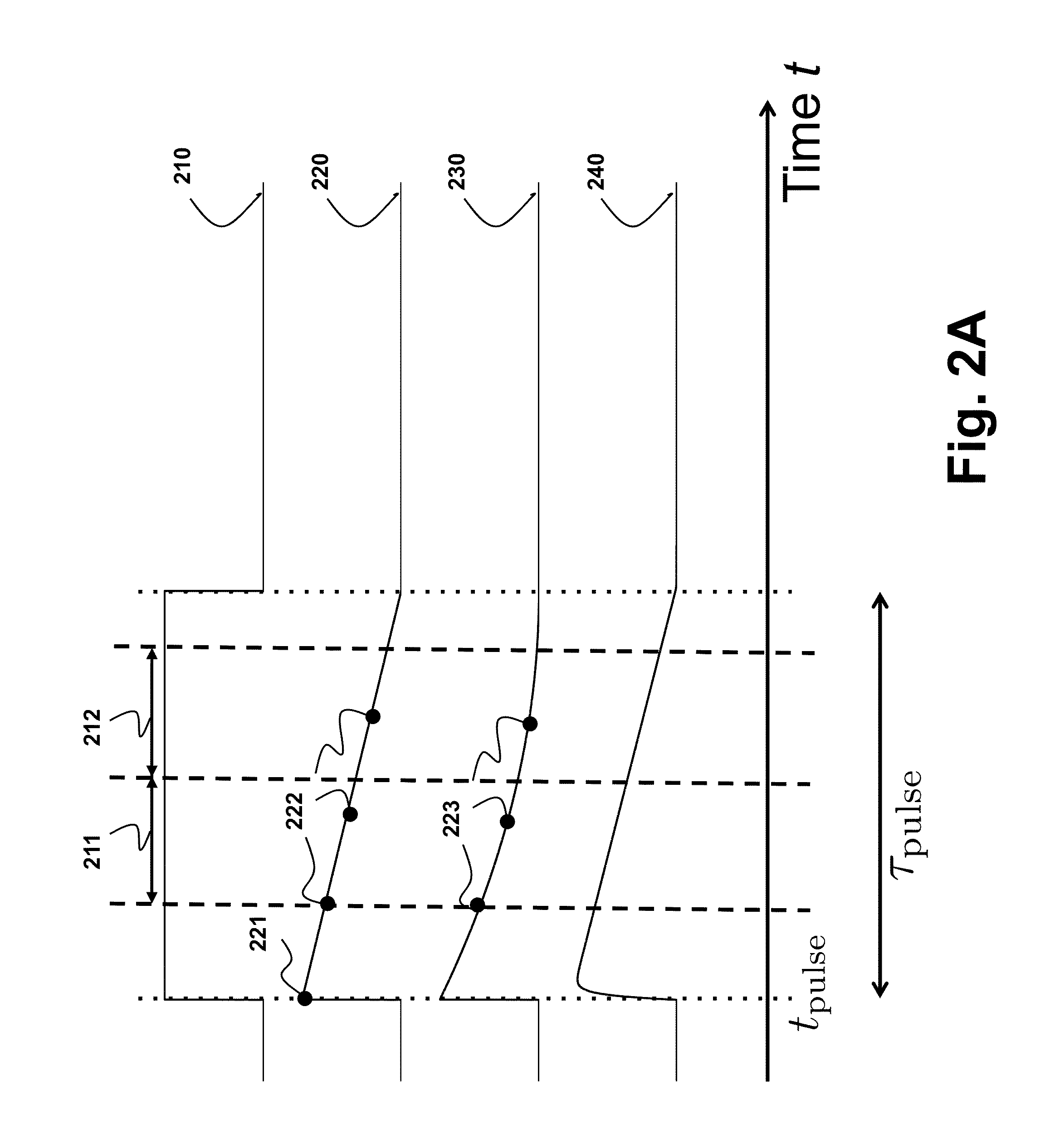

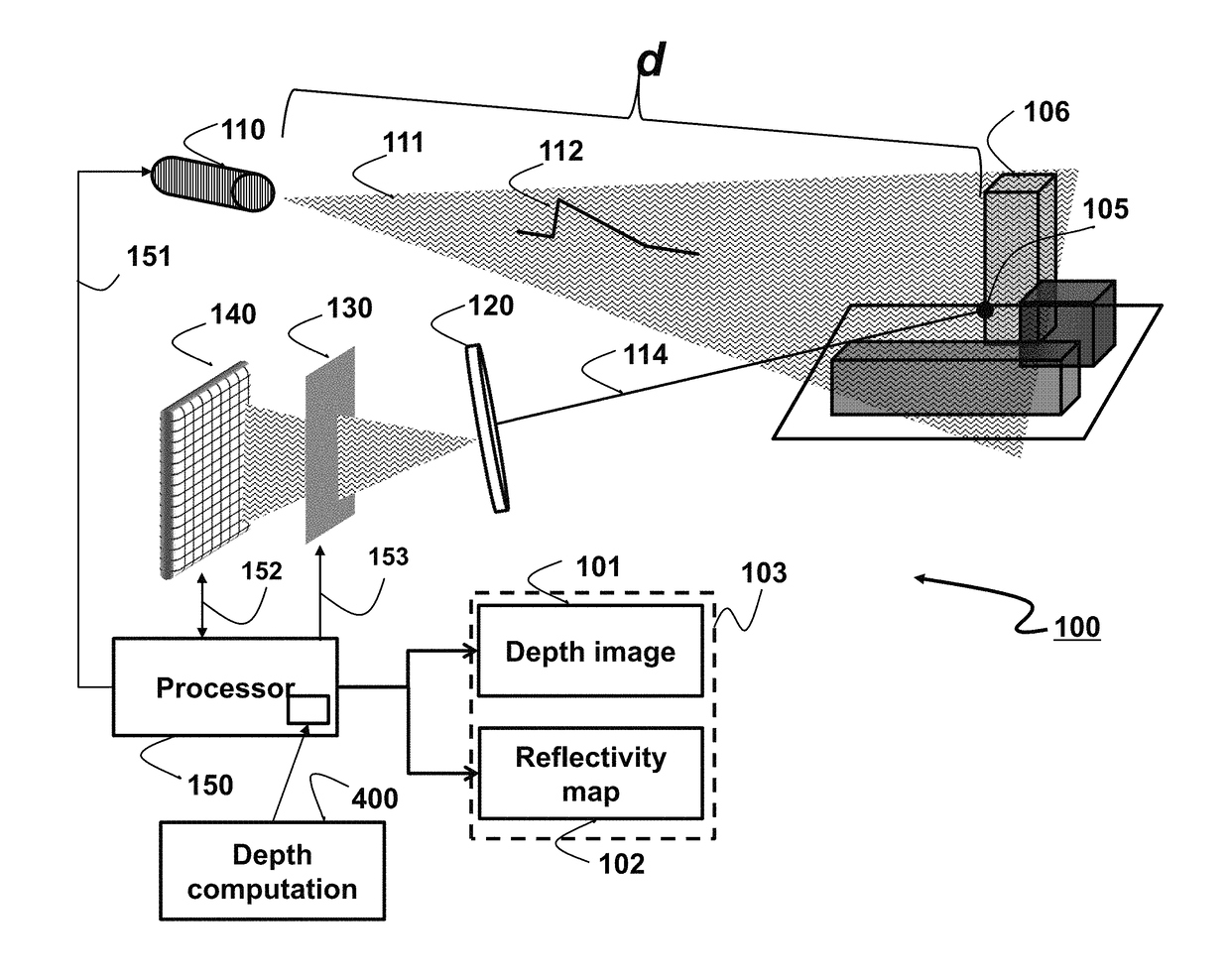

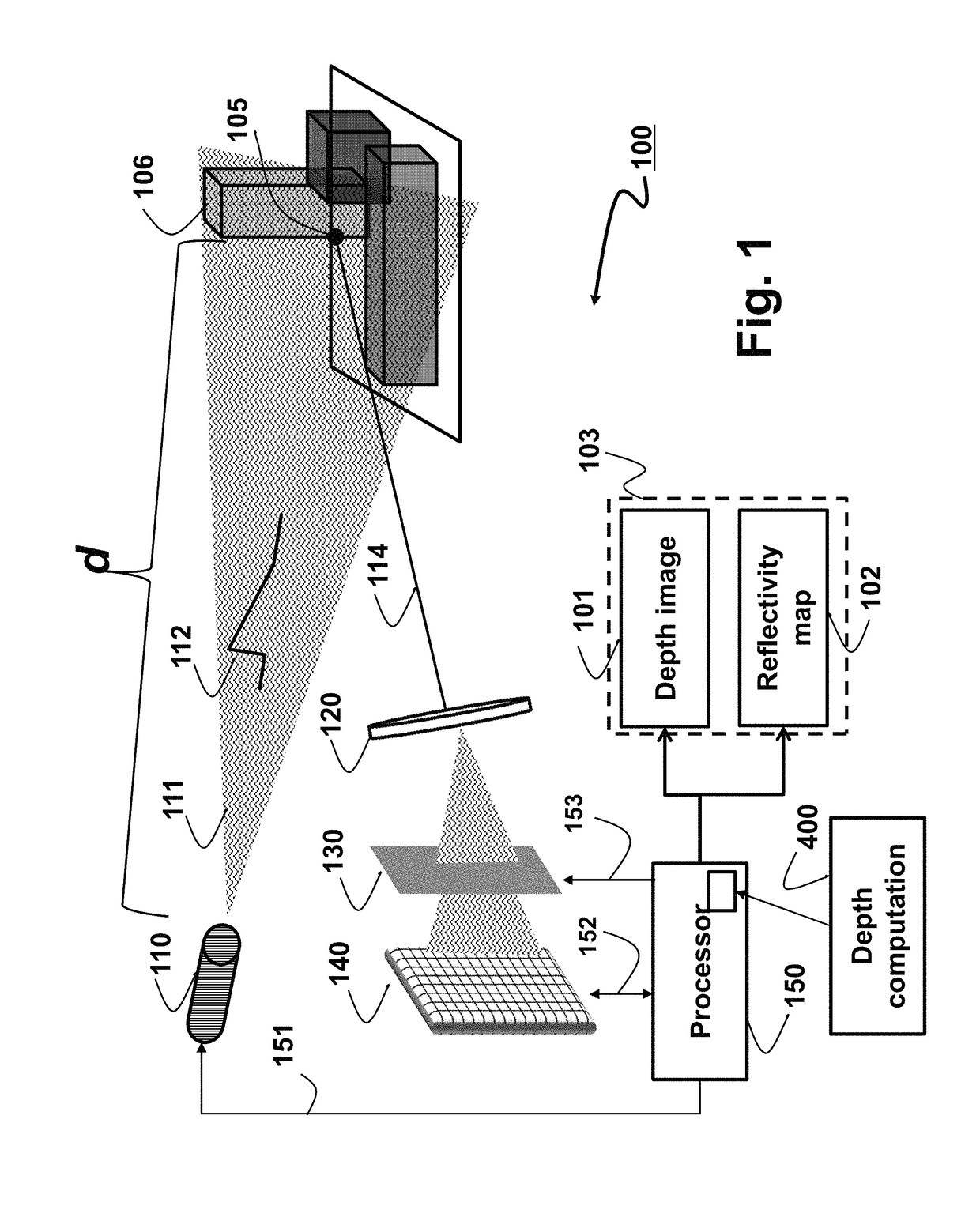

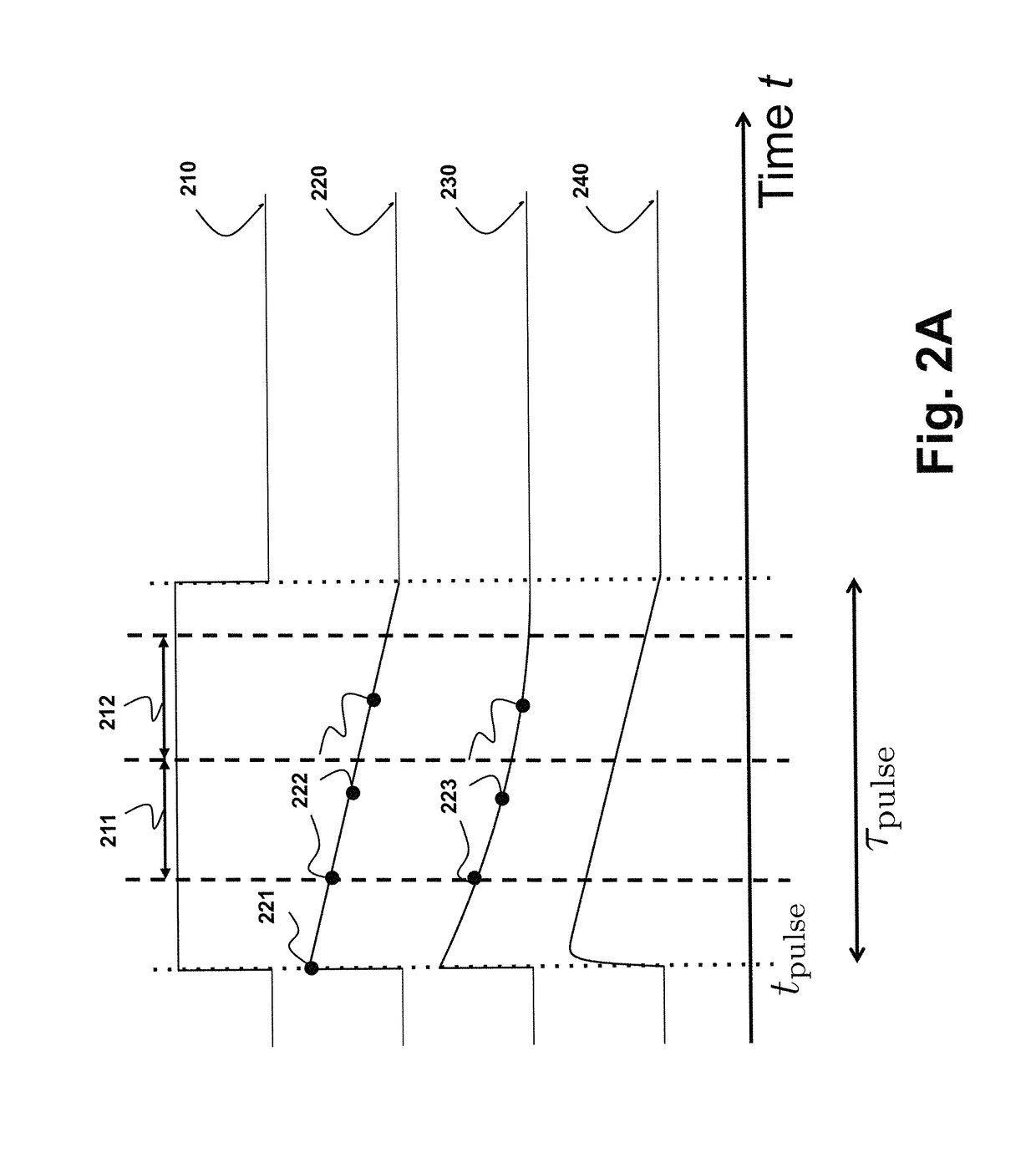

Intensity-Based Depth Sensing System and Method

ActiveUS20160245920A1Improve dynamic rangeImprove uniformityElectromagnetic wave reradiationUltimate tensile strengthDepth perception

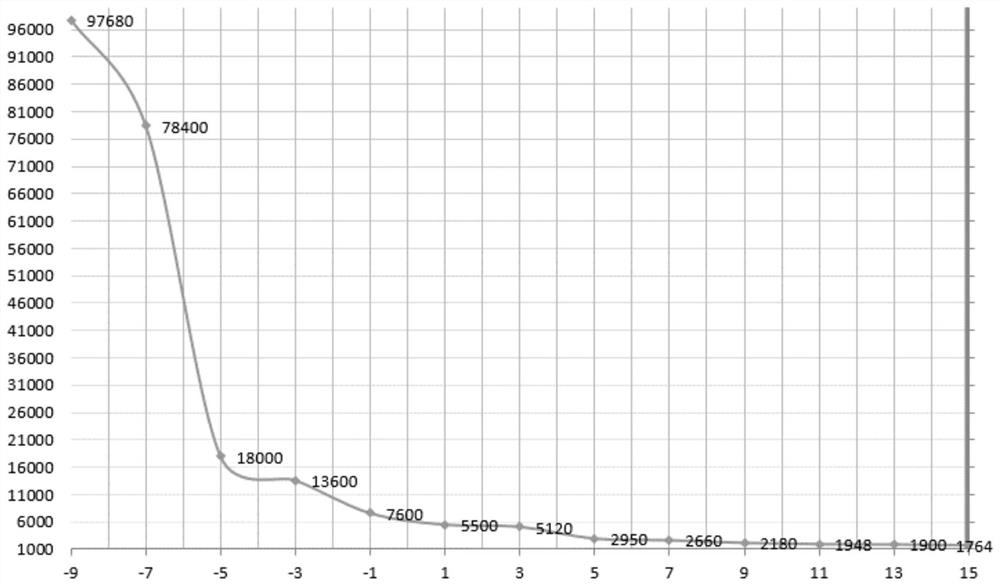

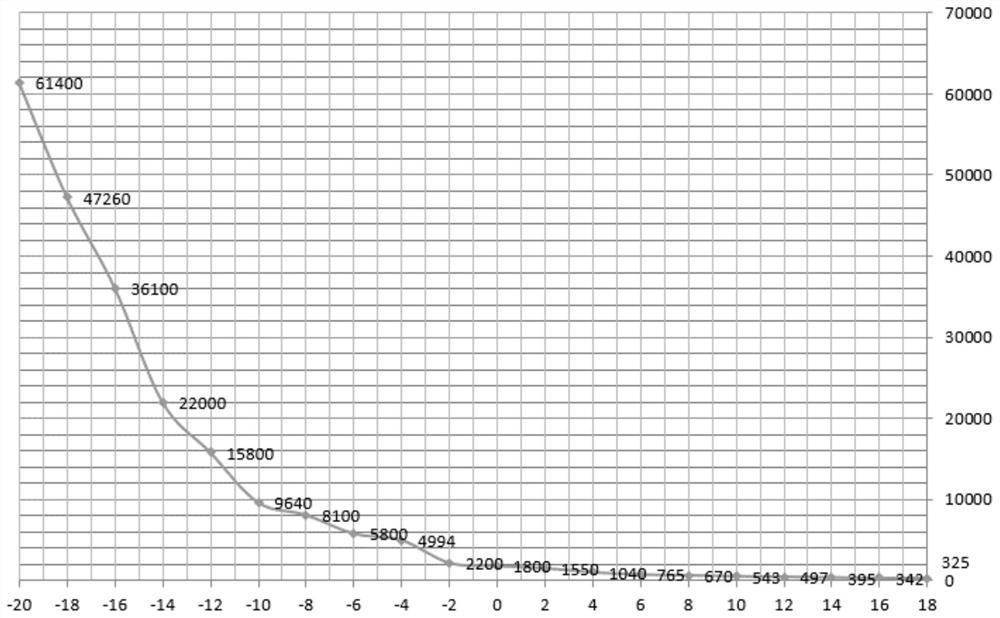

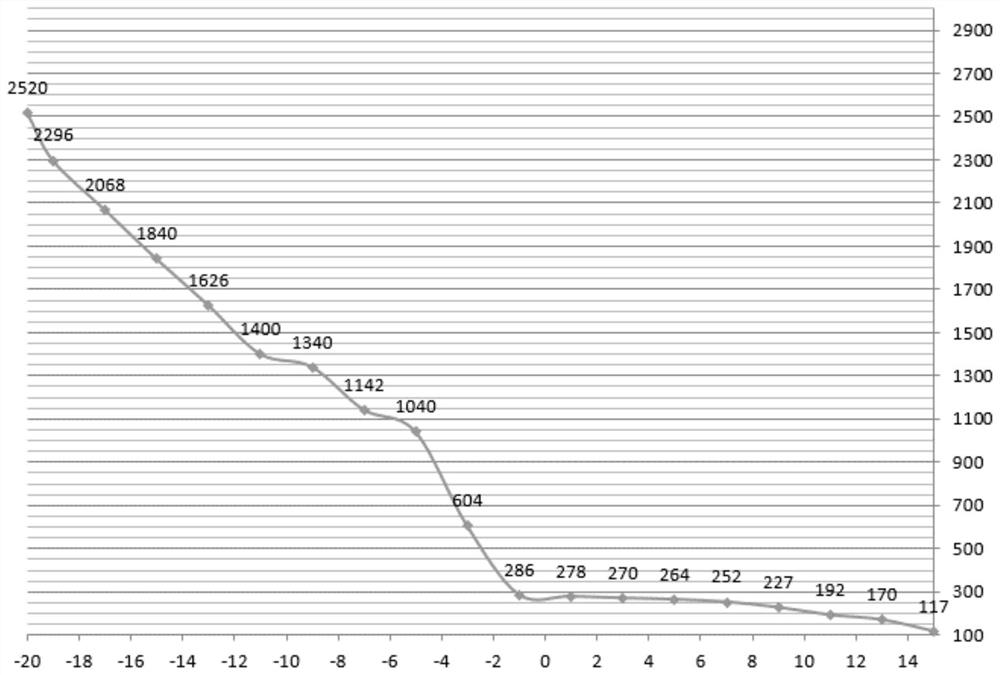

A system for determining a depth image representing distances to points of a scene includes a light source for generating and directing a set of light pulses toward the scene and a set of sensors for detecting and integrating light reflected from the scene. Each sensor is associated with a point in the scene and generates a signal indicative of an amount of light reflected from the point in the scene and reaching the sensor during a period of time. The system includes at least one processor for coordinating operations of the light source and the set of sensors and for determining the depth image having intensity values representing the distances to the points in the scene. The processor commands the light source to generate the set of light pulses including a first pulse with a first intensity profile having portions of identical lengths with different integrated intensities.

Owner:MITSUBISHI ELECTRIC RES LAB INC

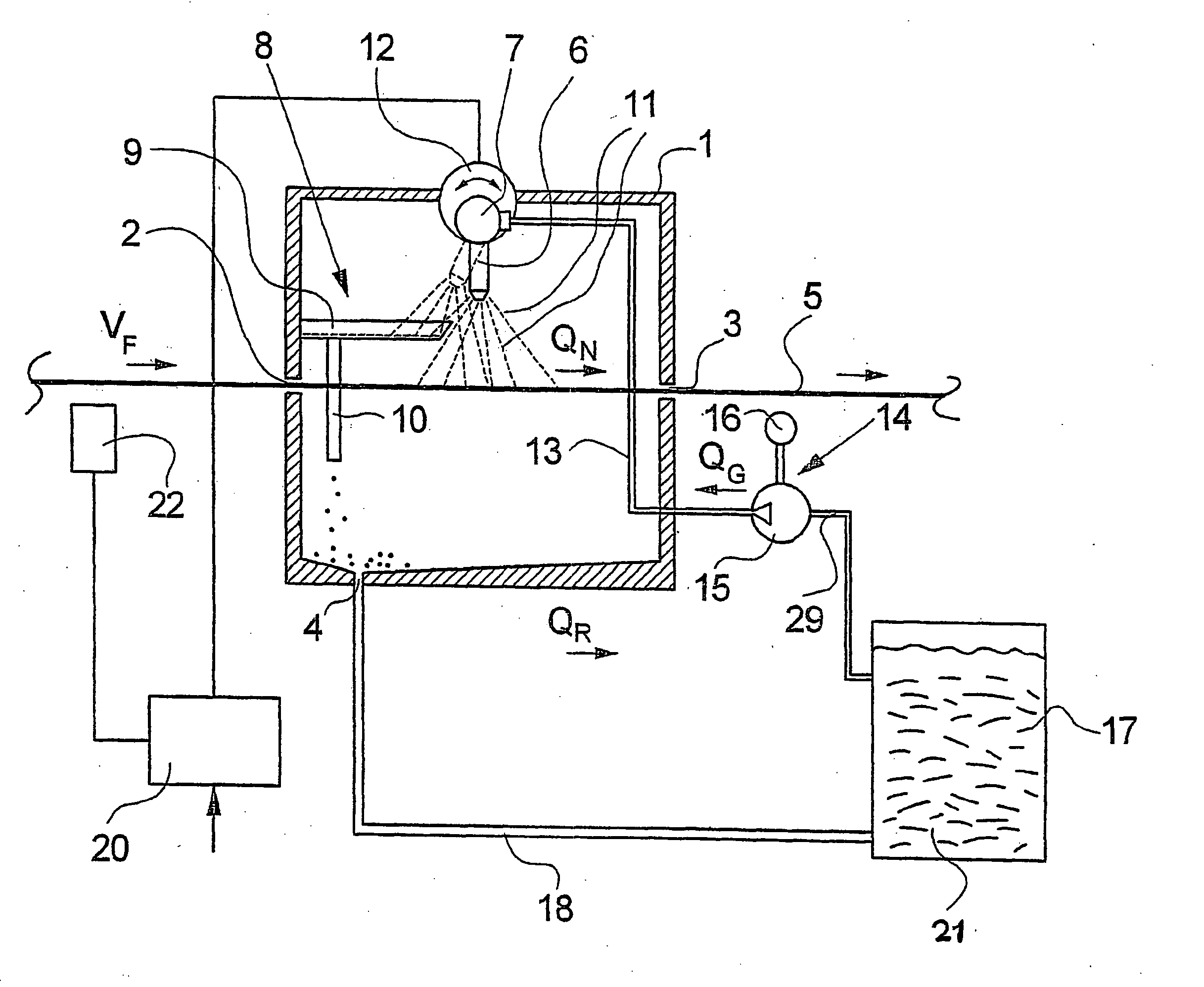

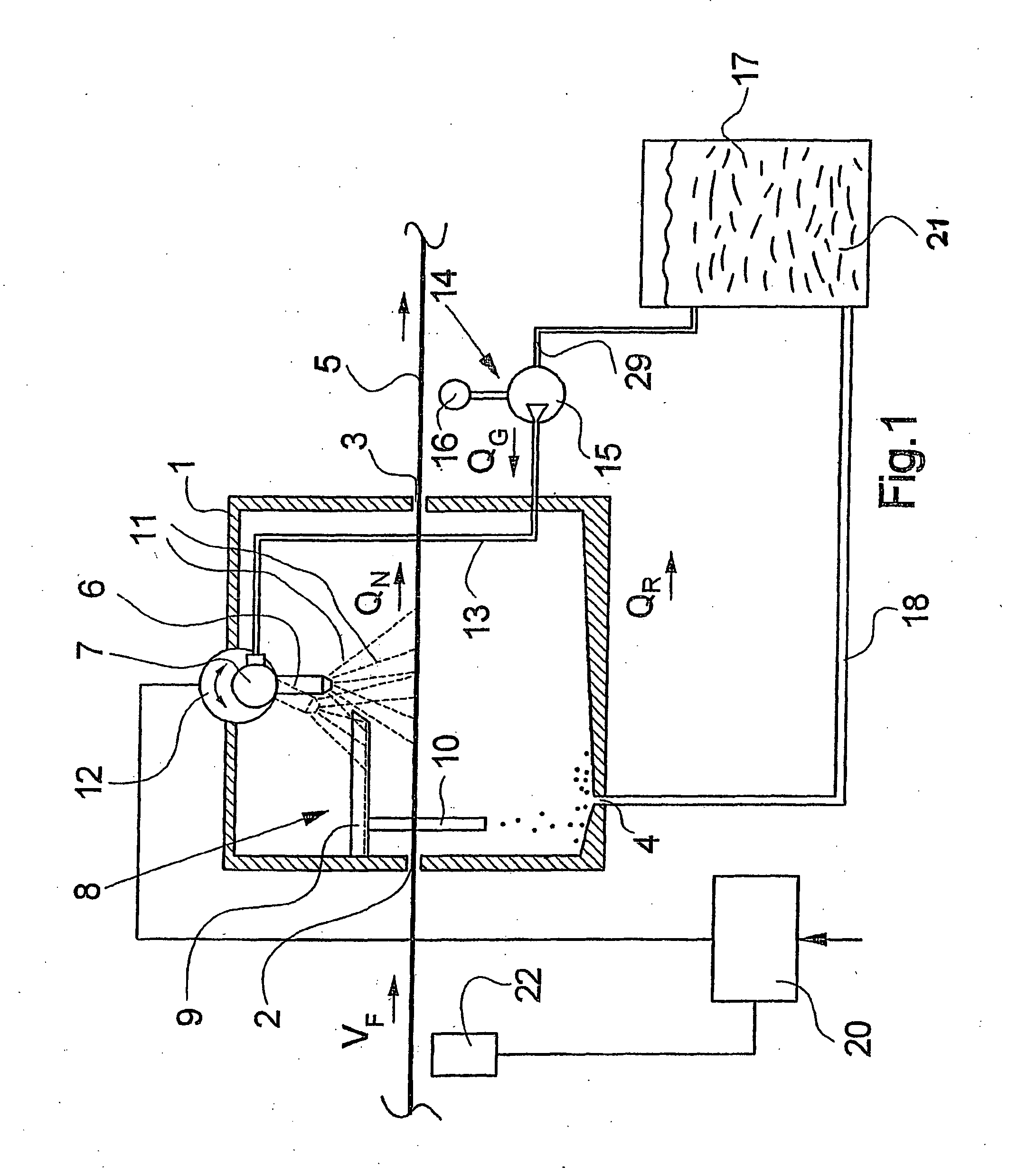

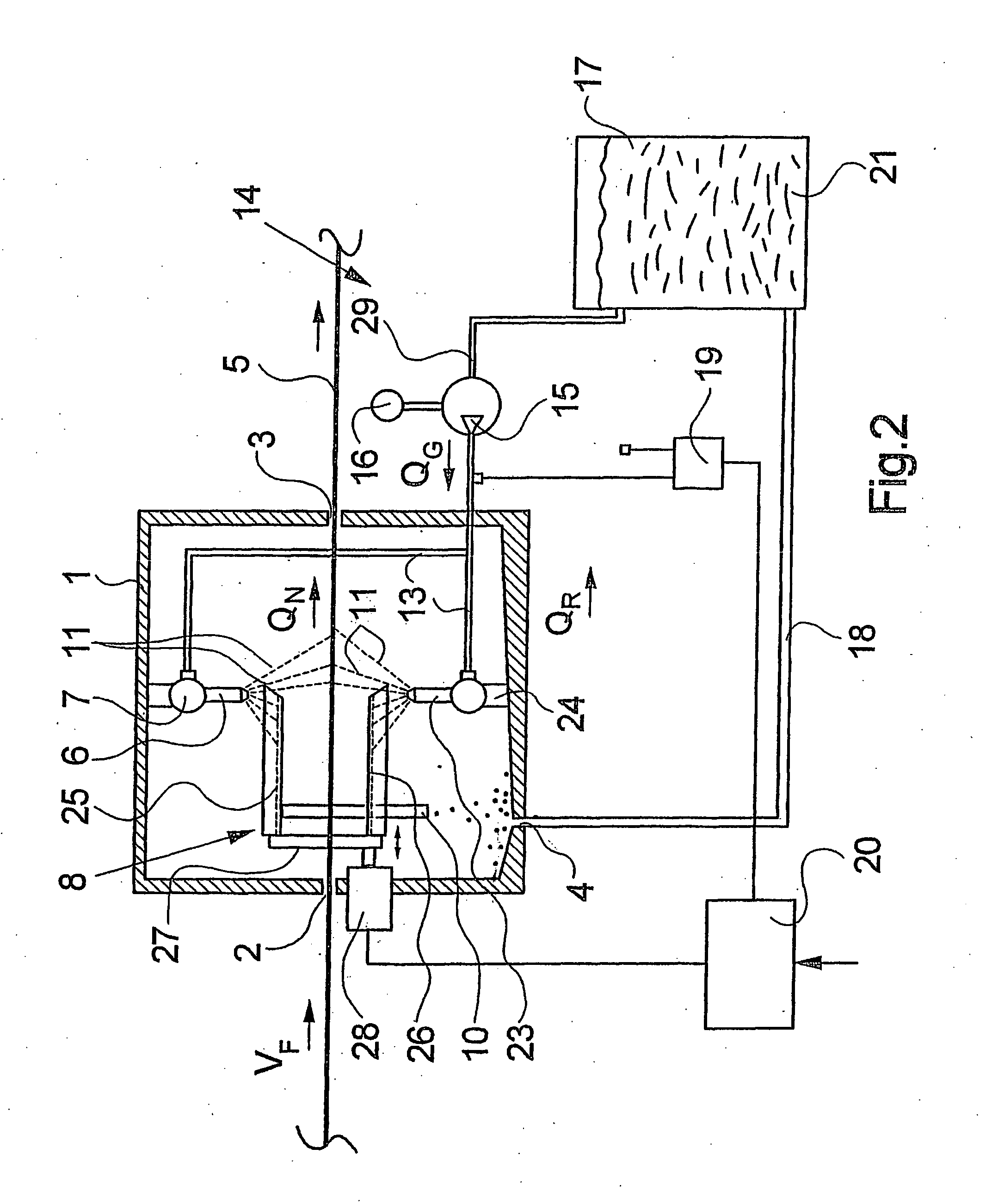

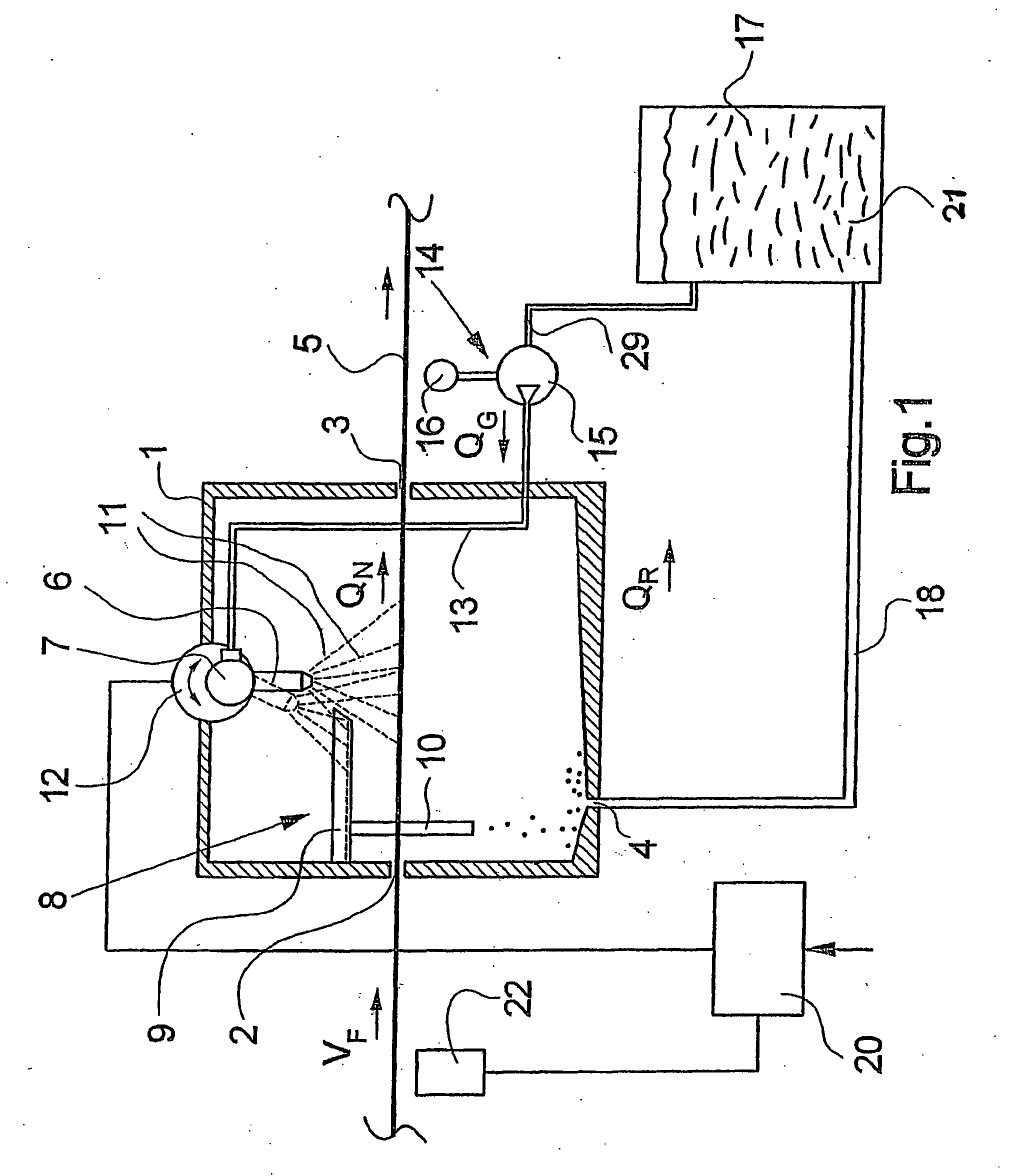

Method and apparatus for wetting a running filament strand

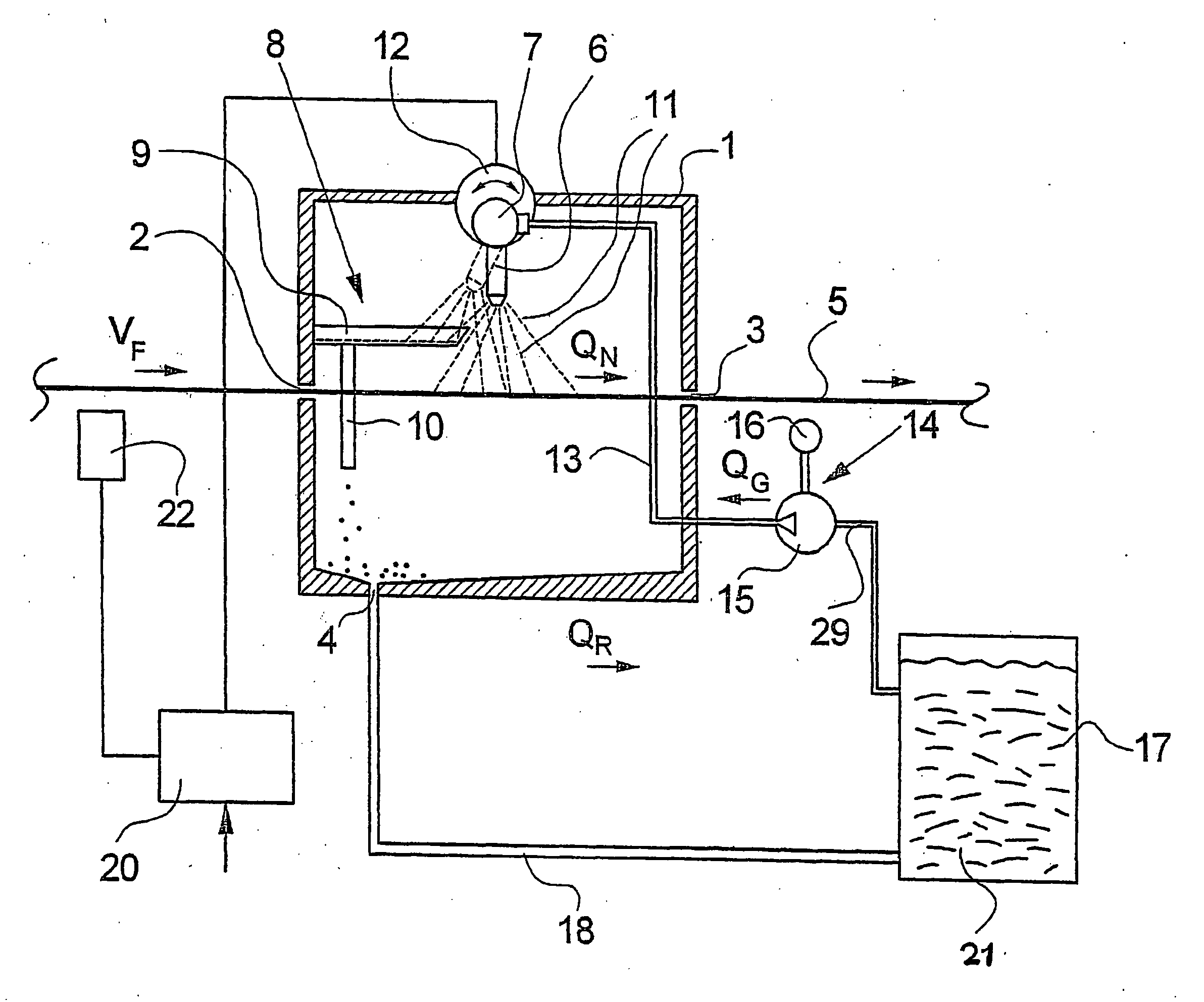

InactiveUS20050015951A1Guaranteed uptimeDegree of shielding is lessenedFilament handlingBeaming machinesEngineeringNozzle

A method and an apparatus for wetting an advancing filament bundle. A fluid is applied by means of a nozzle in the form of a fluid spray jet to the filament bundle advancing in spaced relationship with the nozzle. A portion of the spray jet is shielded before impacting upon the filament bundle, so that the application of fluid to the filament bundle is determined by the degree of shielding of the spray jet. With that, the invention is adapted for finely adjusting the fluid application to the filament bundle.

Owner:SAURER GMBH & CO KG

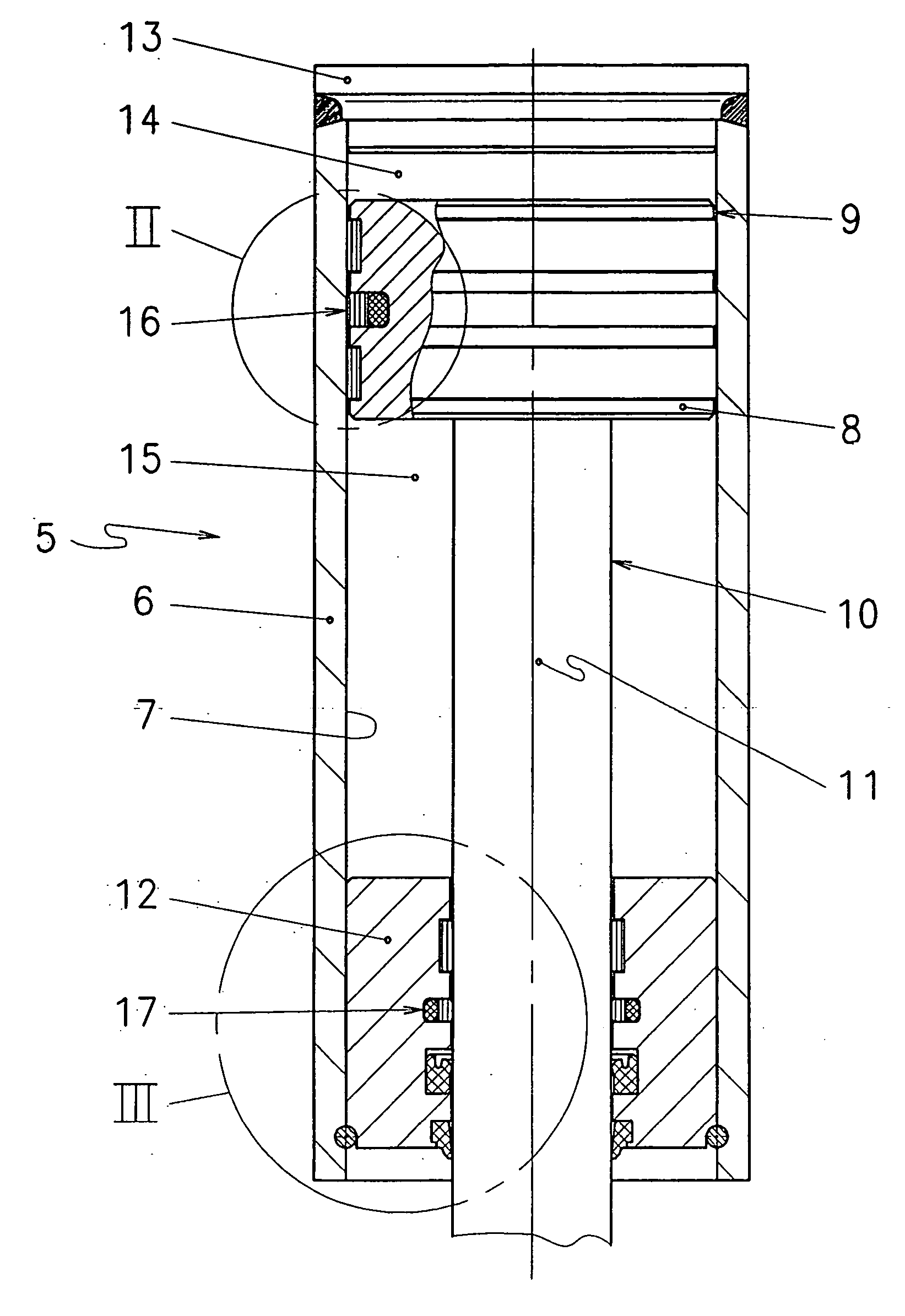

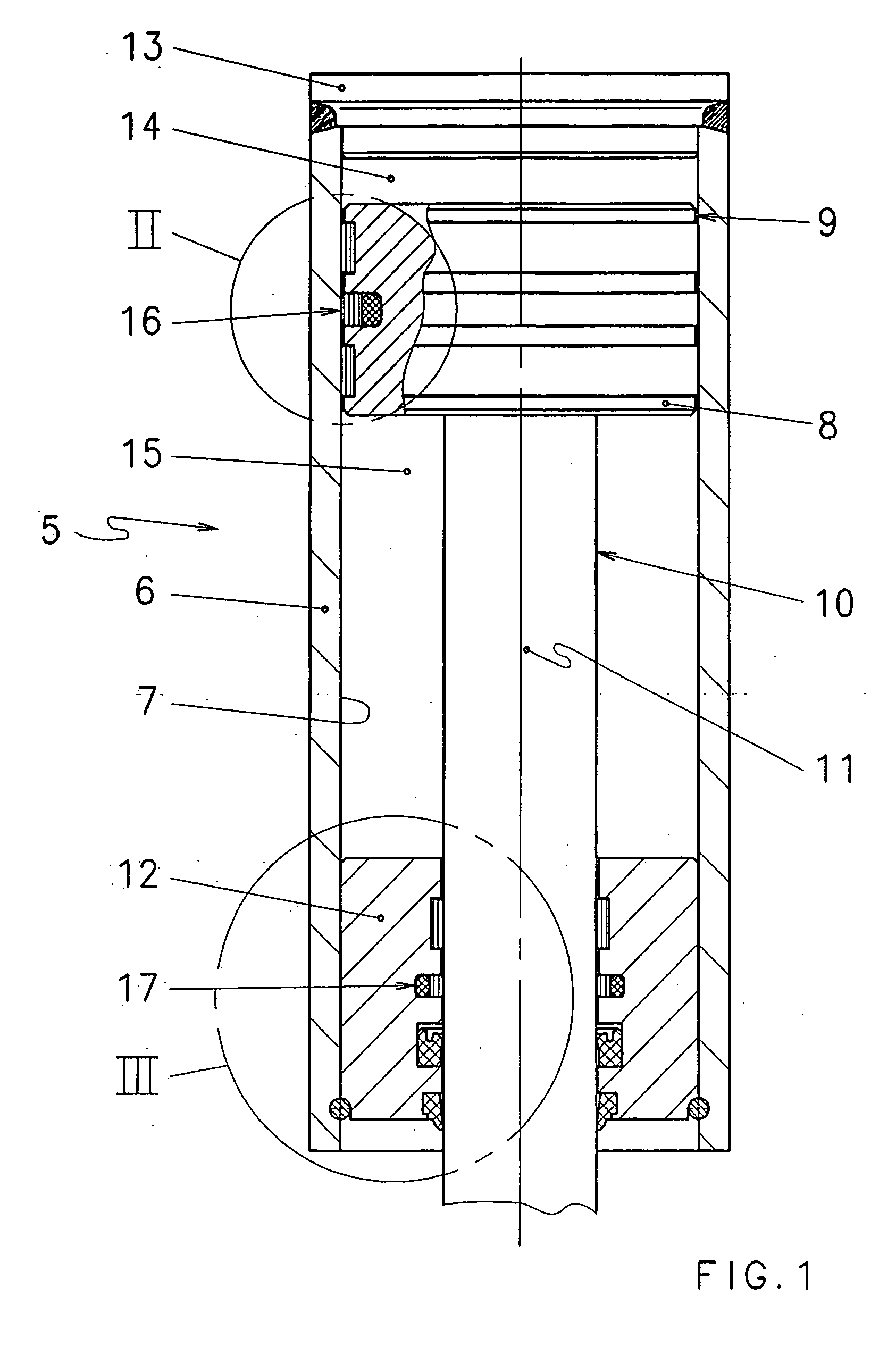

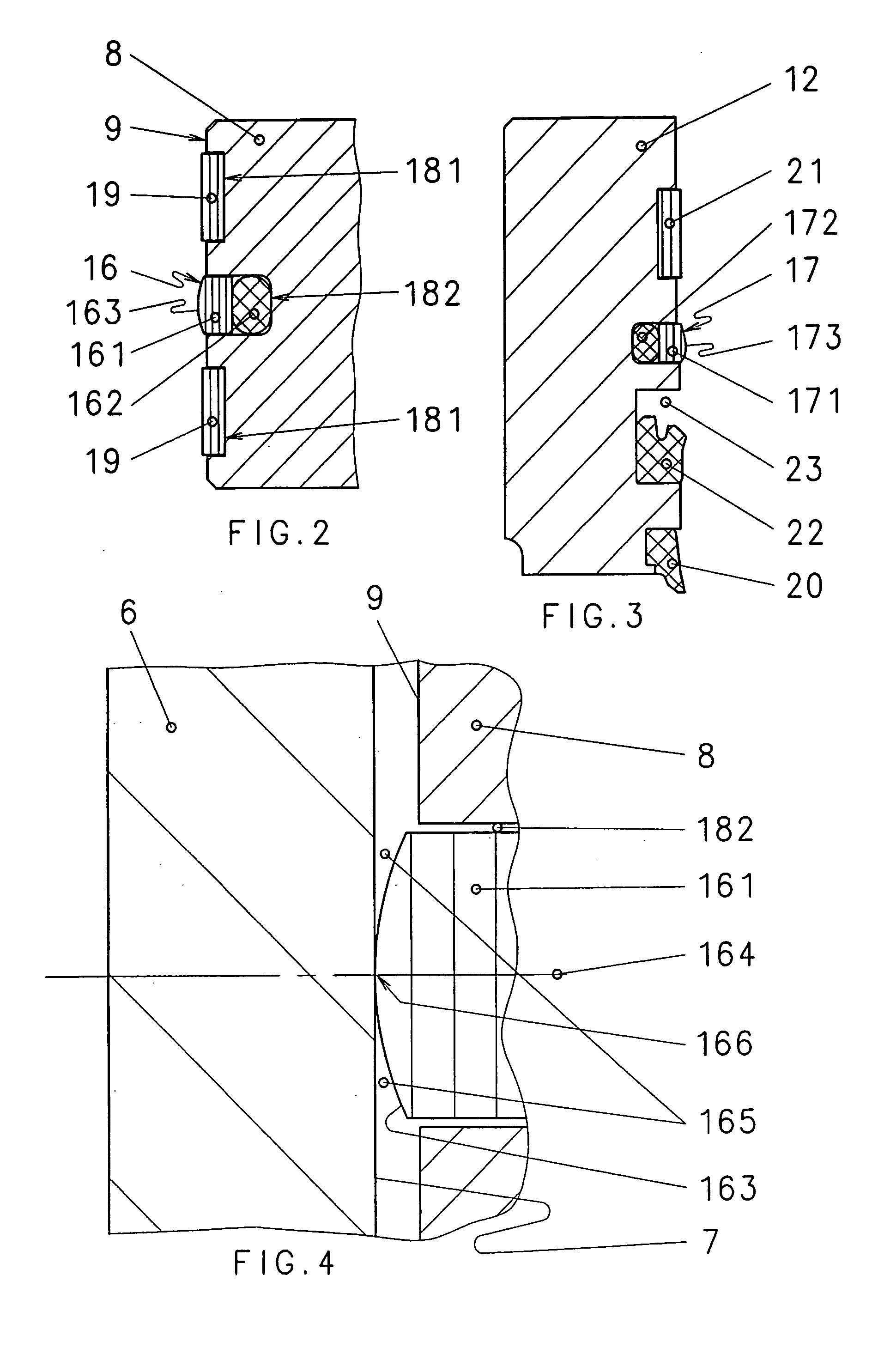

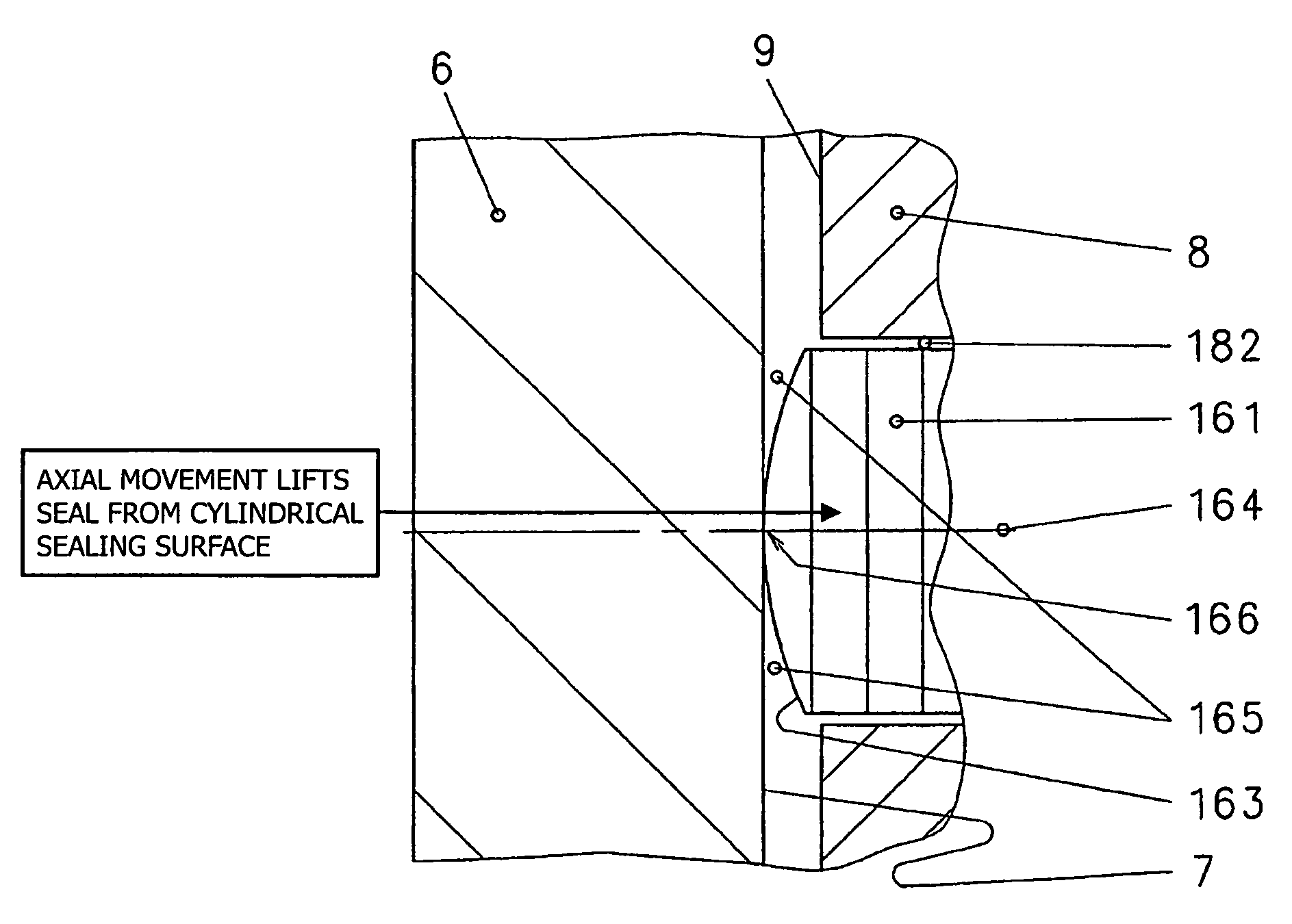

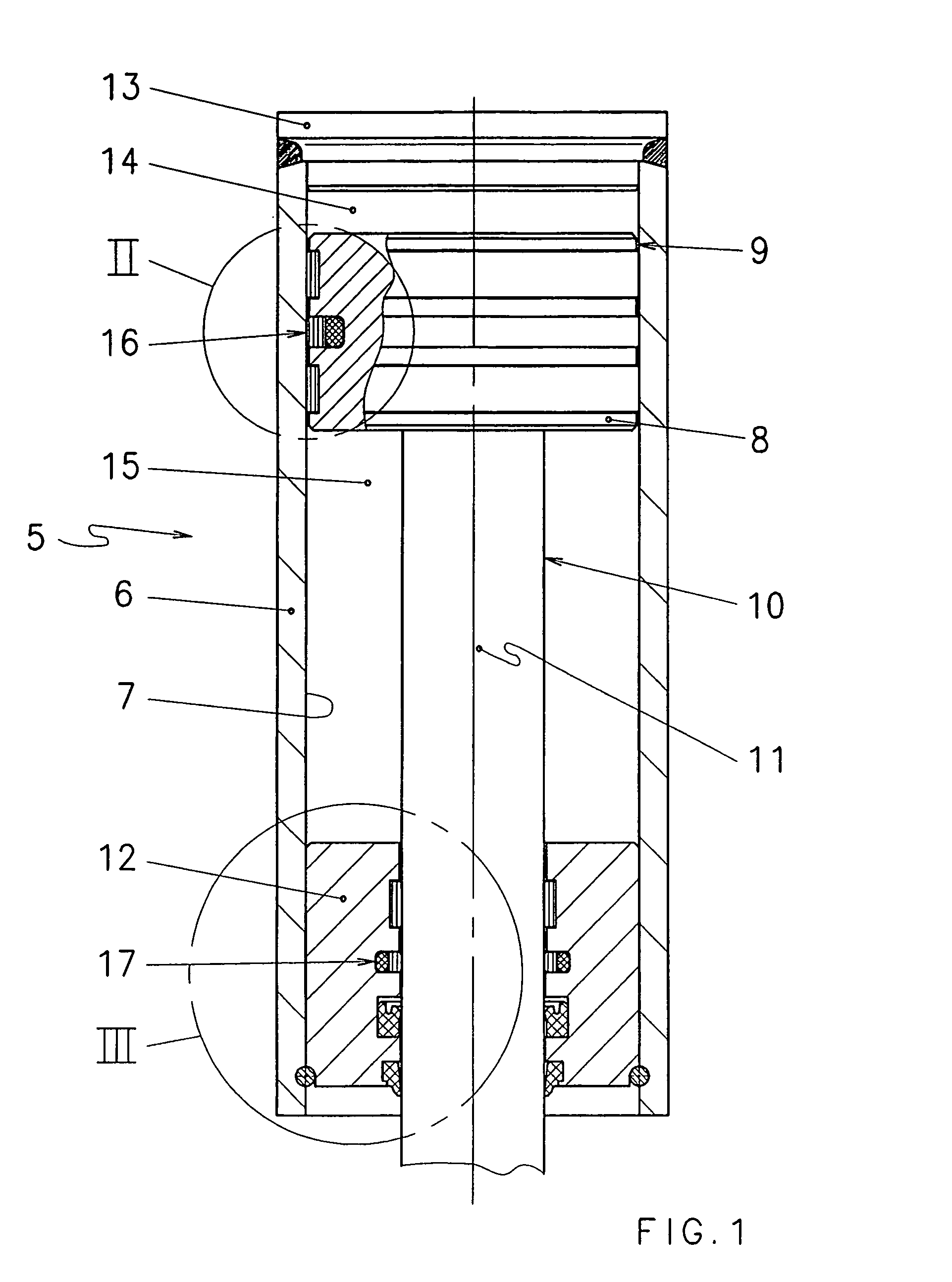

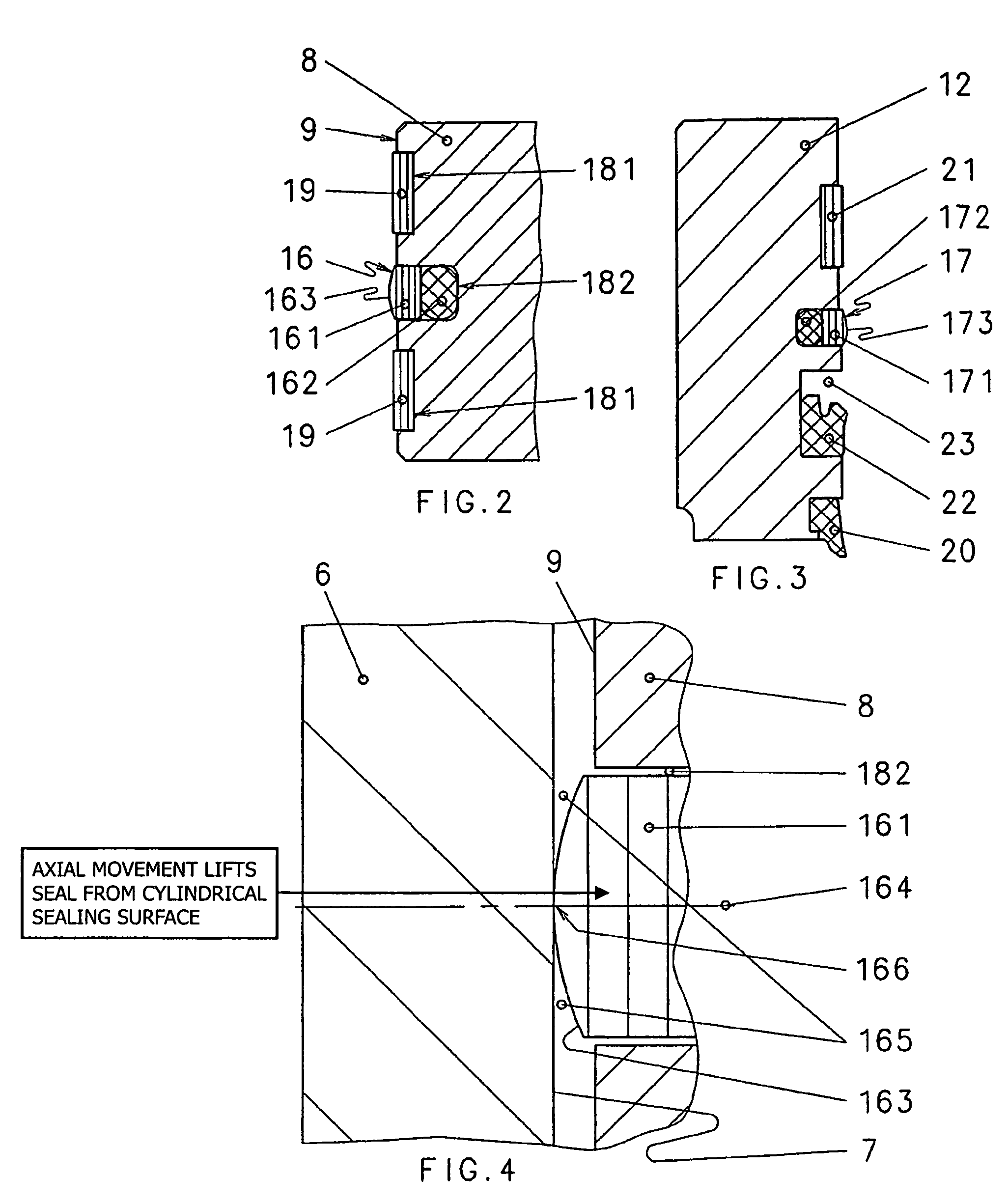

Hydraulic cylinder unit

ActiveUS20060272498A1Reduce the impactFriction minimizationEngine sealsPiston ringsHead partsHydraulic pressure

A hydraulic cylinder unit is provided with a rod seal and / or piston seal which has a surface that deviates from the vertical circular cylindrical surface of the piston head throughhole through which the piston rod passes or the vertical circular cylindrical surface of the cylinder interior while forming respective converging gaps with regard to the rod surface and the interior surface of the cylinder, respectively.

Owner:WEBER HYDRAULIK GMBH

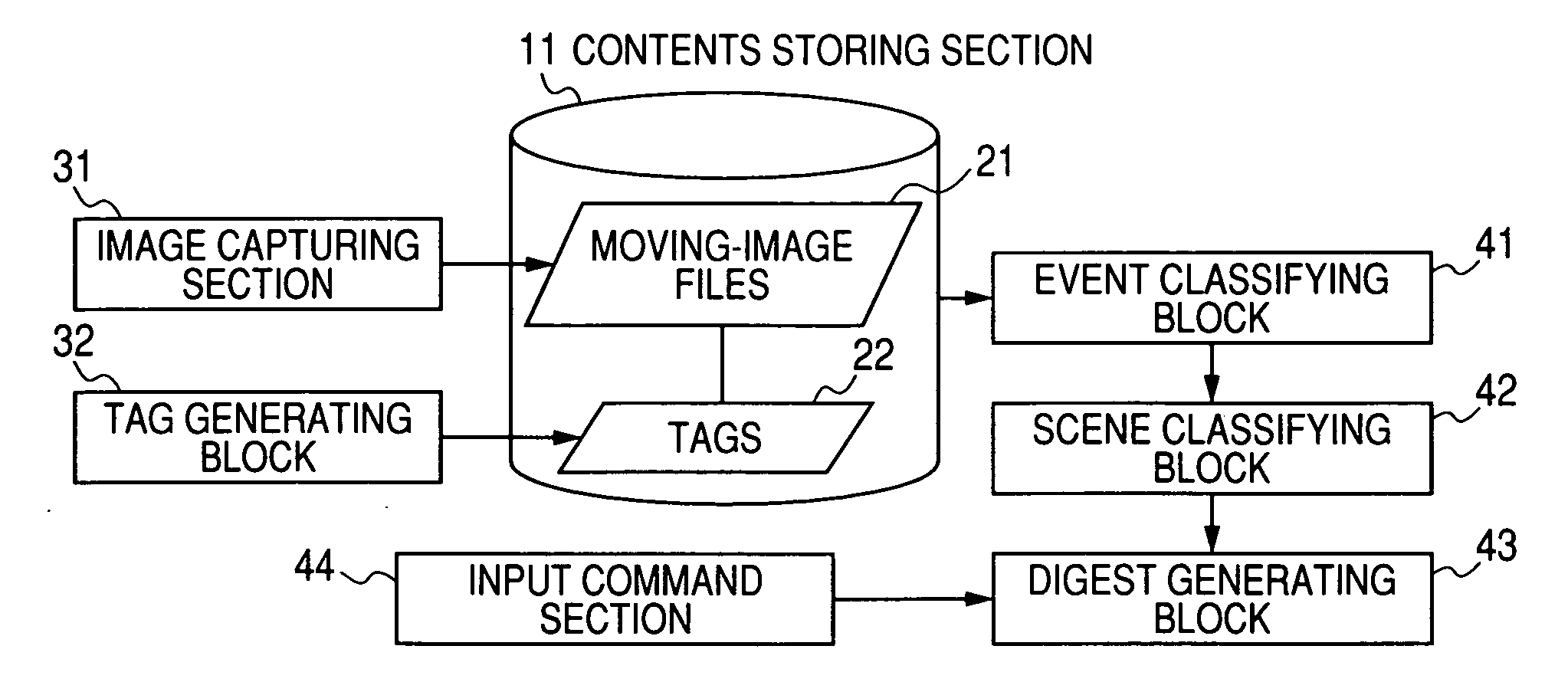

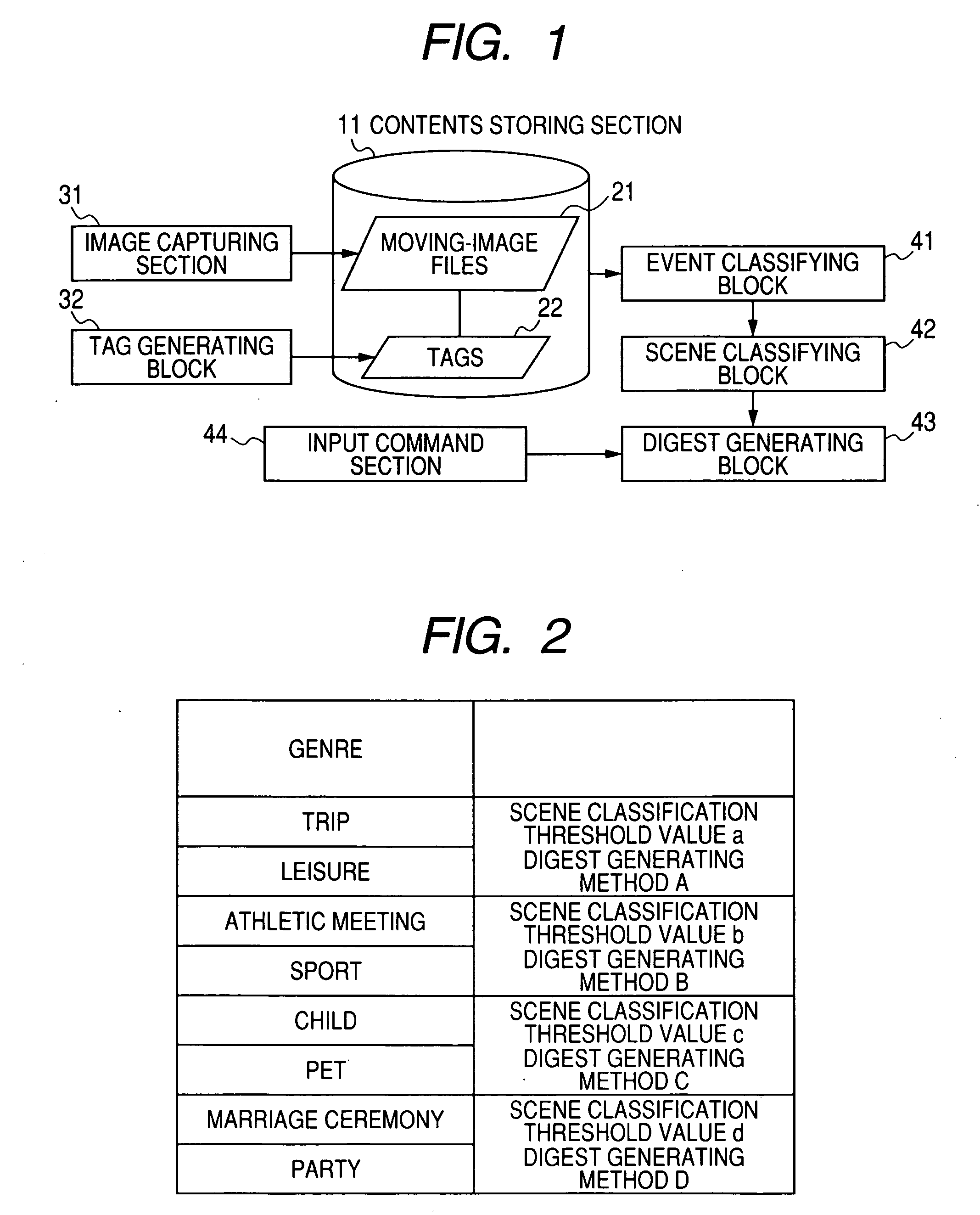

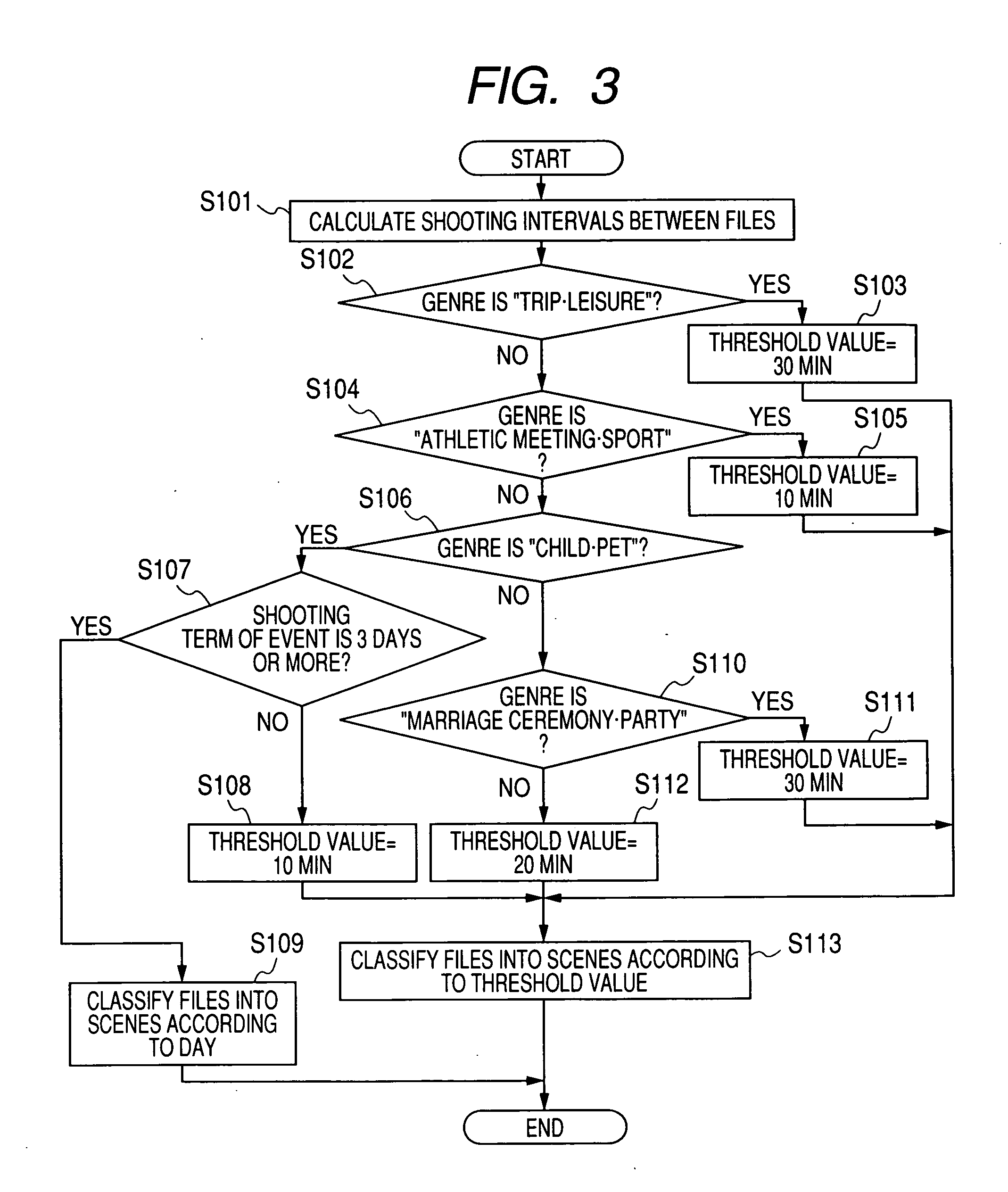

Method and apparatus for generating digest of captured images

InactiveUS20080201379A1Easy to classifyGood portionTelevision system detailsElectronic editing digitised analogue information signalsData miningEvent recognition

Owner:VICTOR CO OF JAPAN LTD

Hydraulic cylinder unit

ActiveUS7762177B2Friction minimizationIncrease frictionEngine sealsPiston ringsHydraulic cylinderEngineering

A hydraulic cylinder unit is provided with a rod seal and / or piston seal which has a surface that deviates from the vertical circular cylindrical surface of the piston head throughhole through which the piston rod passes or the vertical circular cylindrical surface of the cylinder interior while forming respective converging gaps with regard to the rod surface and the interior surface of the cylinder, respectively.

Owner:WEBER HYDRAULIK GMBH

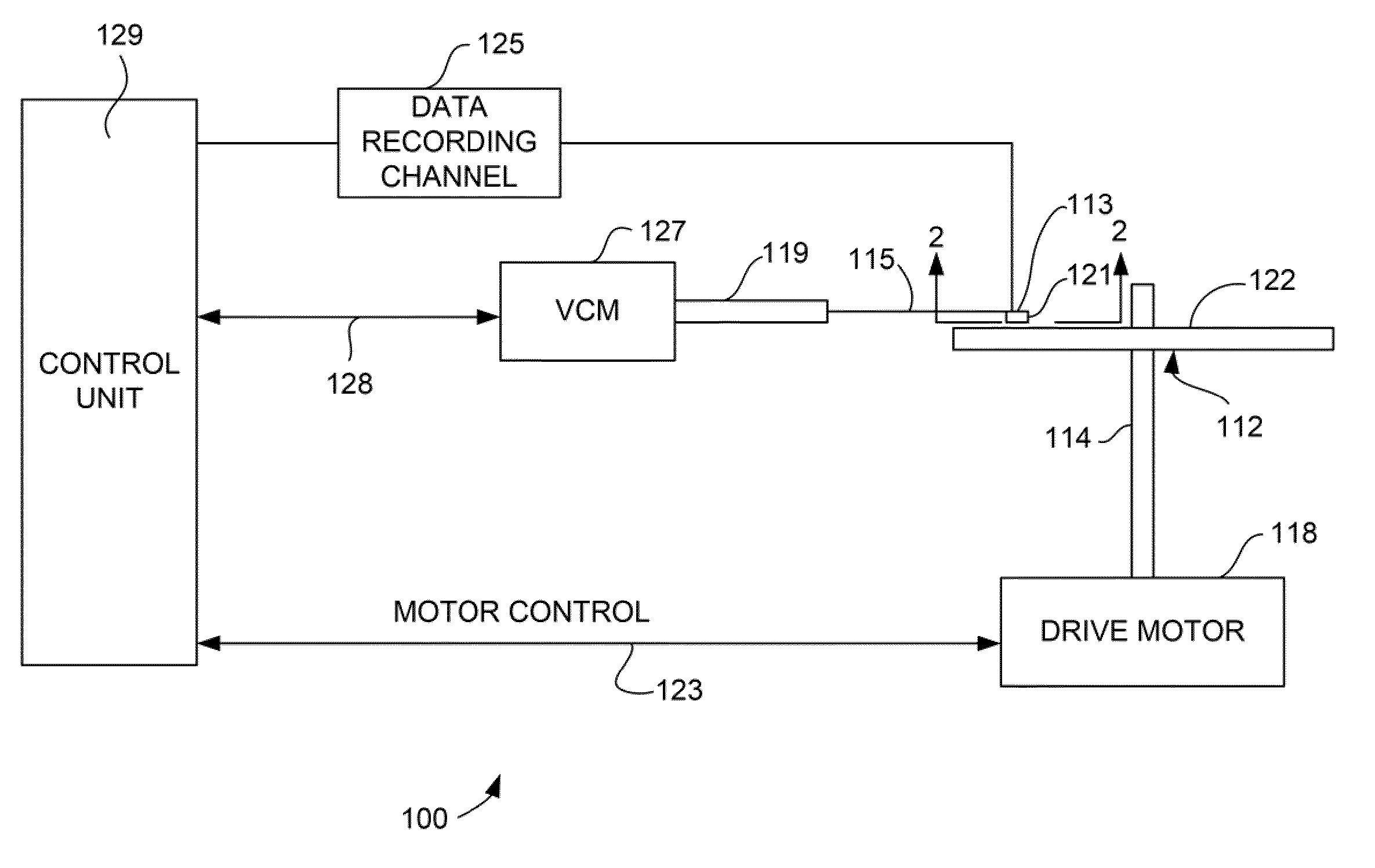

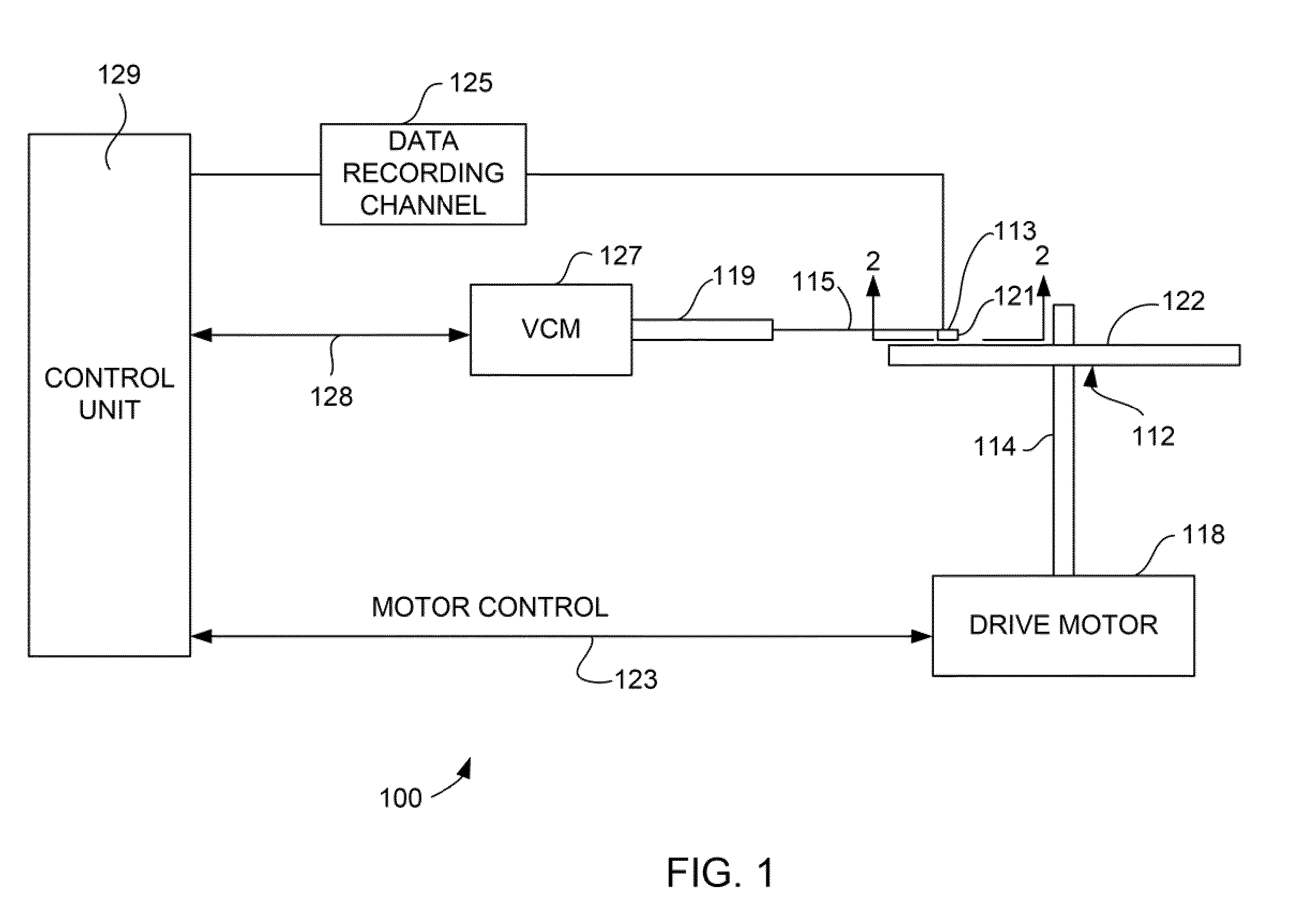

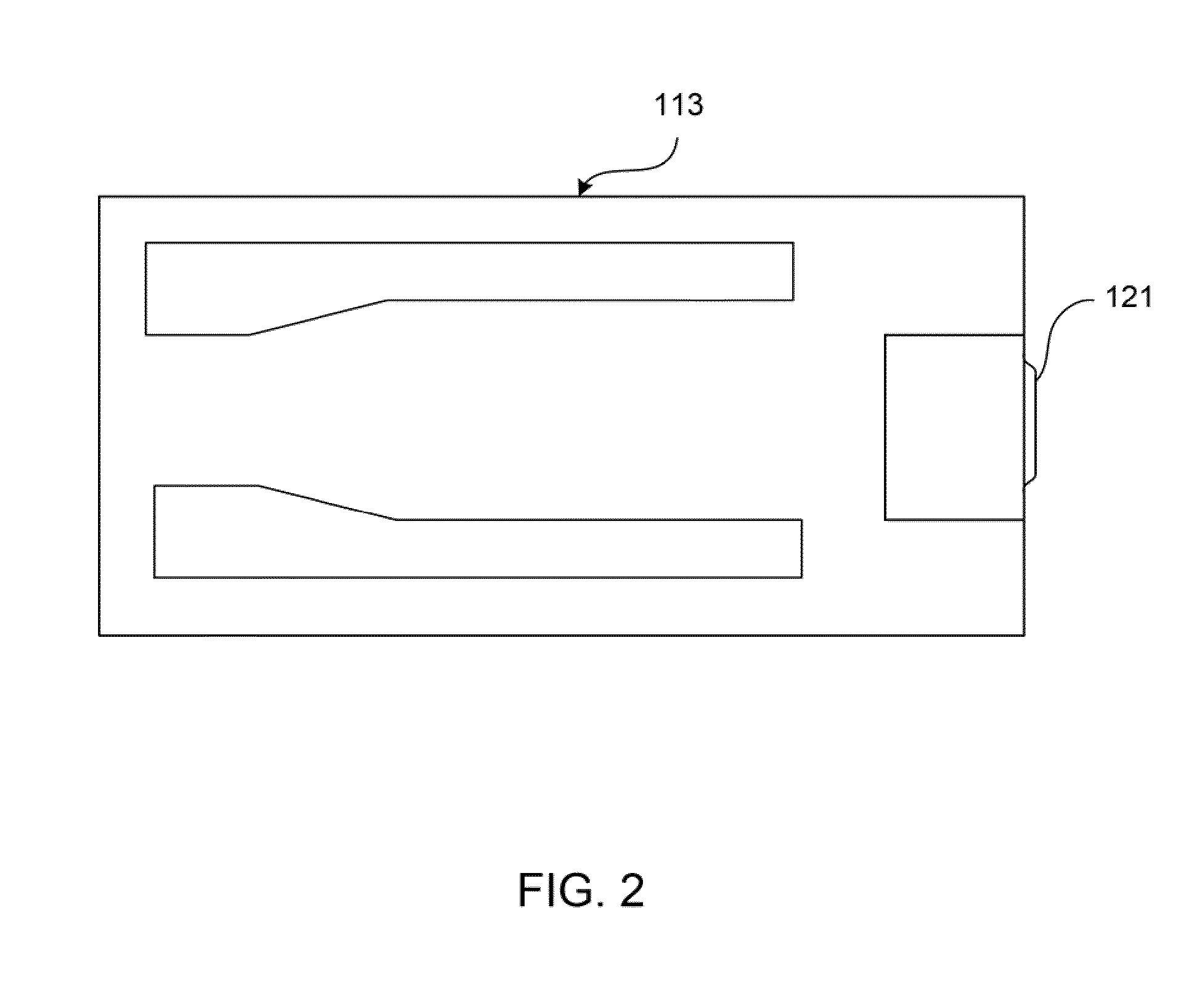

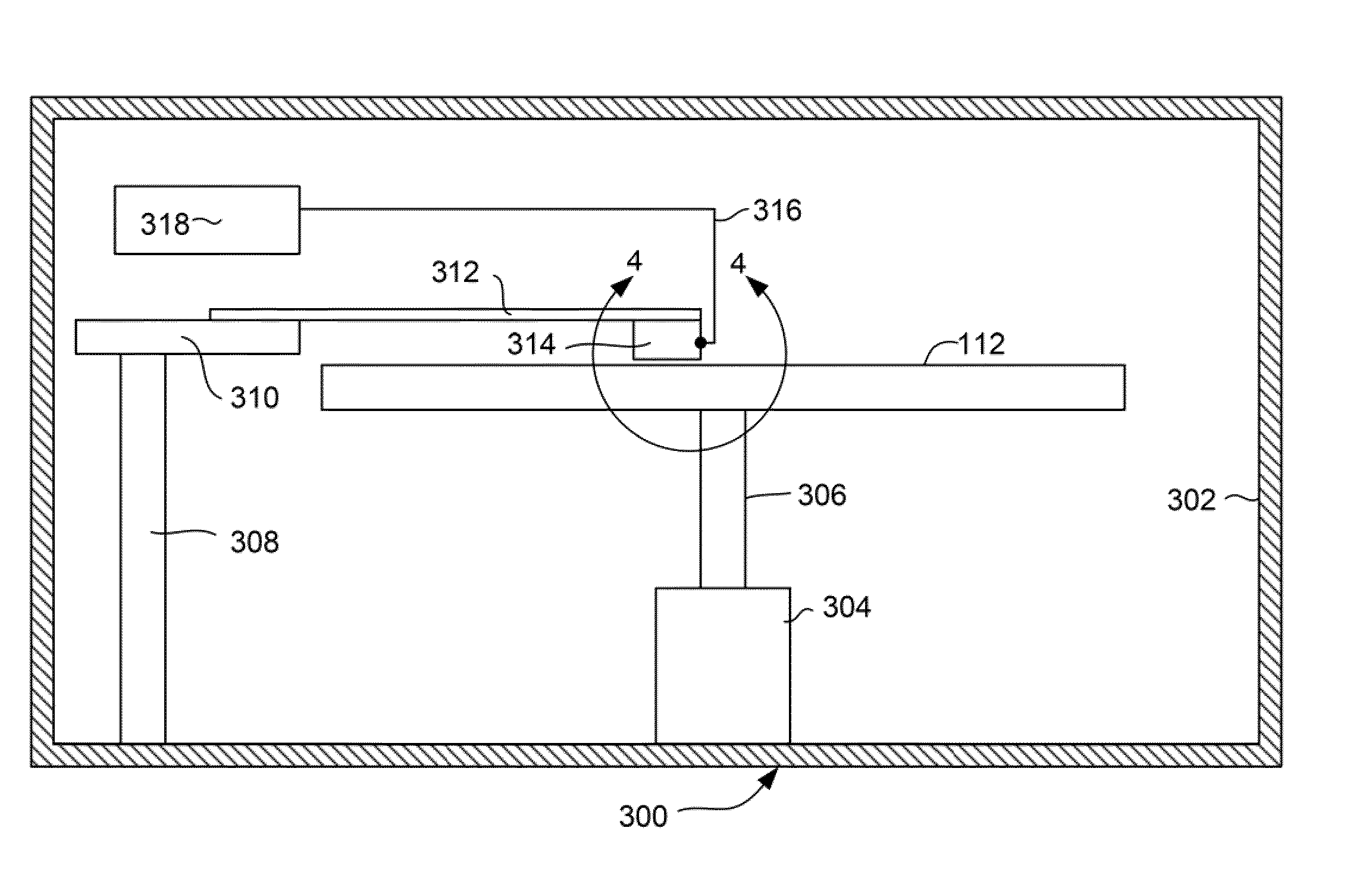

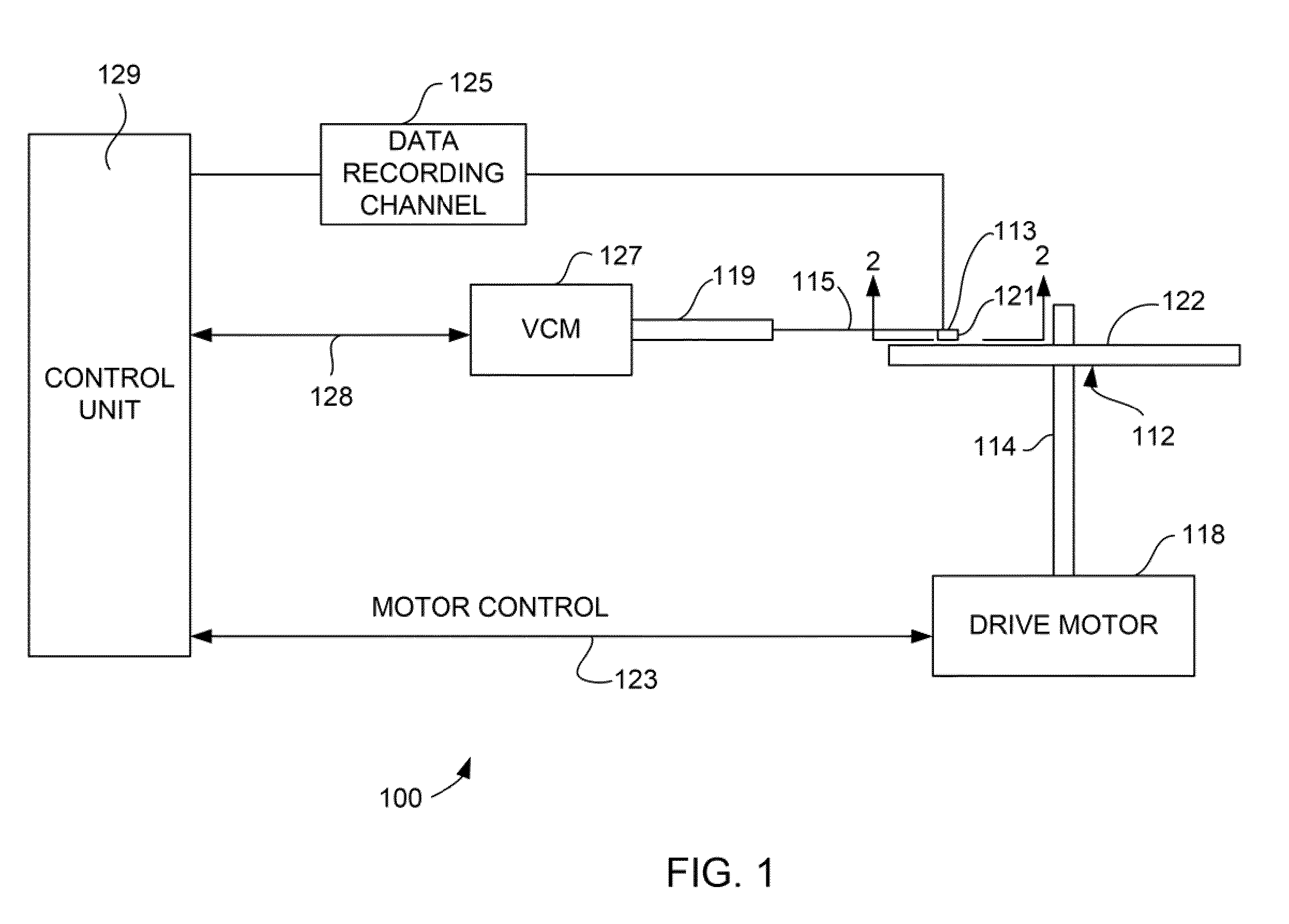

High sensitivity glide sensor using frictional heating

InactiveUS20110149706A1Accurate detectionImprove efficiencyRecord information storageMagnetic property measurementsElectrical resistance and conductanceThermistor

A tool for testing a magnetic disk for use in a magnetic disk drive. The tool detects surface defects or asperities by detecting a change in electrical resistance corresponding to a temperature change in a thermally sensitive layer. The apparatus includes a slider body having a thermally insulating layer formed on an air bearing surface of the slider body and a thermal sensor layer formed on the thermally insulating layer. The thermally insulating layer prevents thermal heat spikes in the thermal sensor layer (such as resulting from contact with an asperity) from dissipating quickly into the slider body itself. The thermal sensor layer is a material that exhibits a change in electrical resistance in response to a change in temperature and is preferably a PTC thermistor material which exhibits a large change in electrical resistance when a transition temperature has been reached.

Owner:WESTERN DIGITAL TECH INC

Intensity-based depth sensing system and method

ActiveUS9897698B2Improve dynamic rangeImprove uniformityElectromagnetic wave reradiationUltimate tensile strengthLight source

A system for determining a depth image representing distances to points of a scene includes a light source for generating and directing a set of light pulses toward the scene and a set of sensors for detecting and integrating light reflected from the scene. Each sensor is associated with a point in the scene and generates a signal indicative of an amount of light reflected from the point in the scene and reaching the sensor during a period of time. The system includes at least one processor for coordinating operations of the light source and the set of sensors and for determining the depth image having intensity values representing the distances to the points in the scene. The processor commands the light source to generate the set of light pulses including a first pulse with a first intensity profile having portions of identical lengths with different integrated intensities.

Owner:MITSUBISHI ELECTRIC RES LAB INC

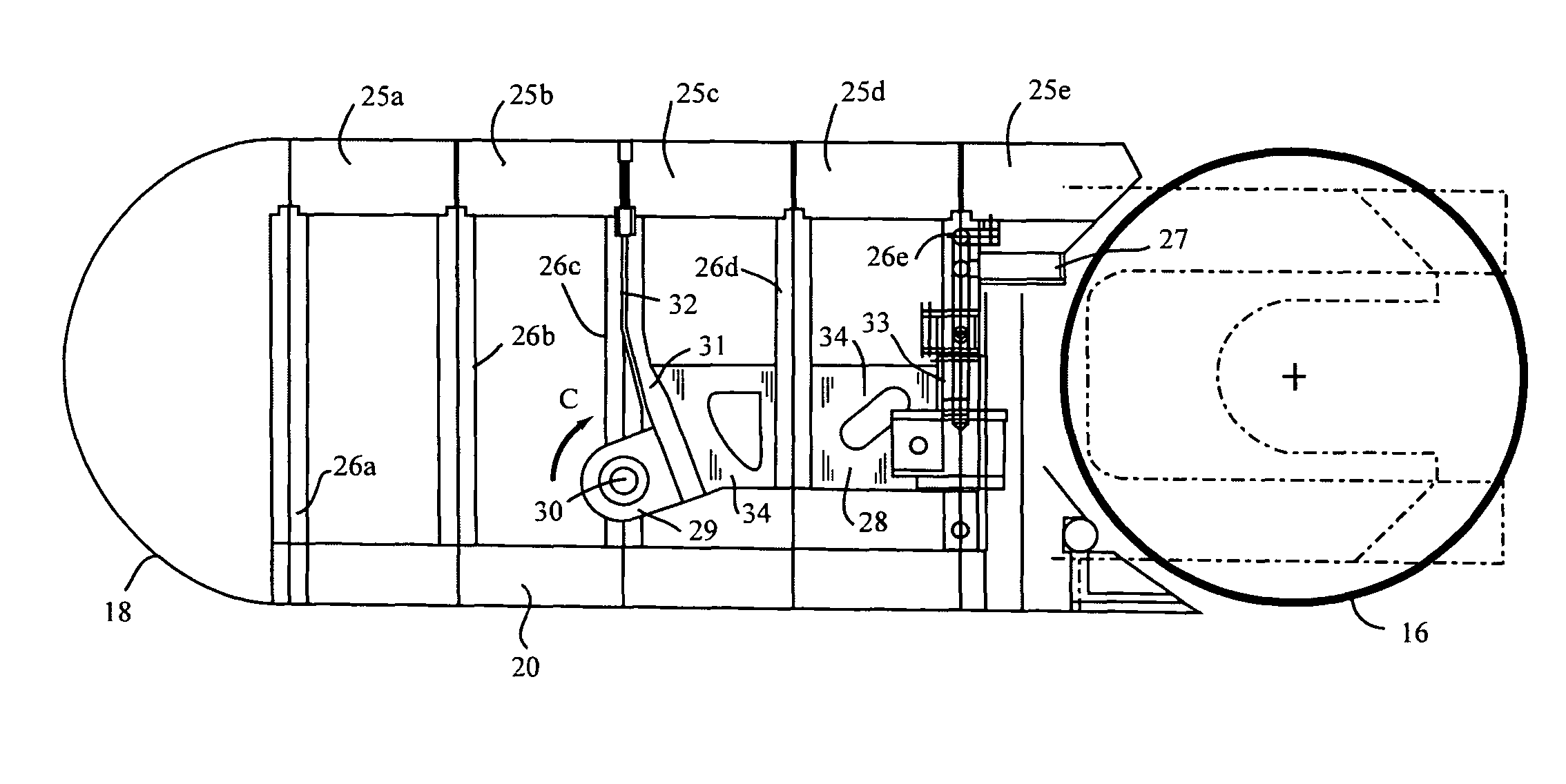

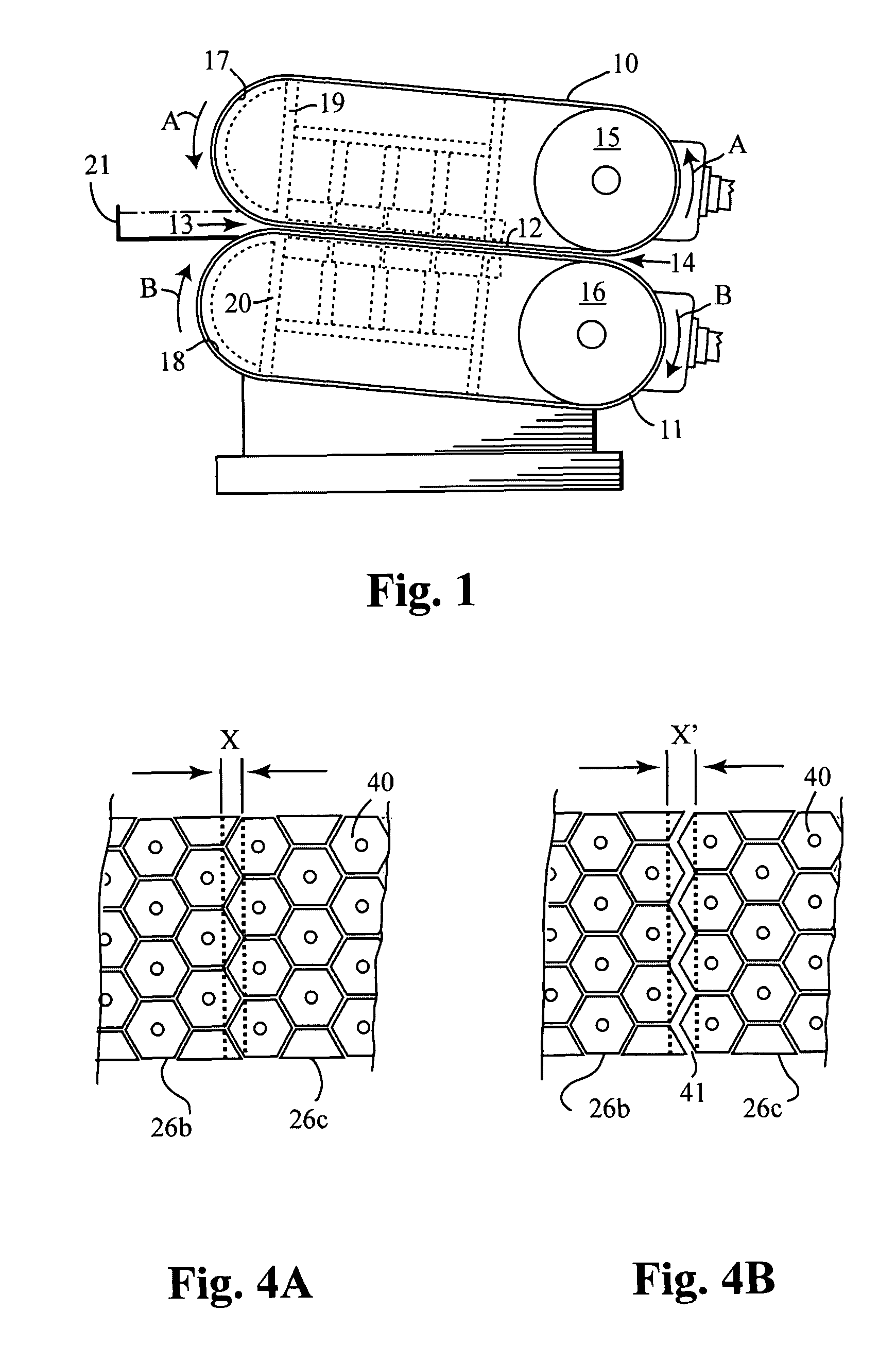

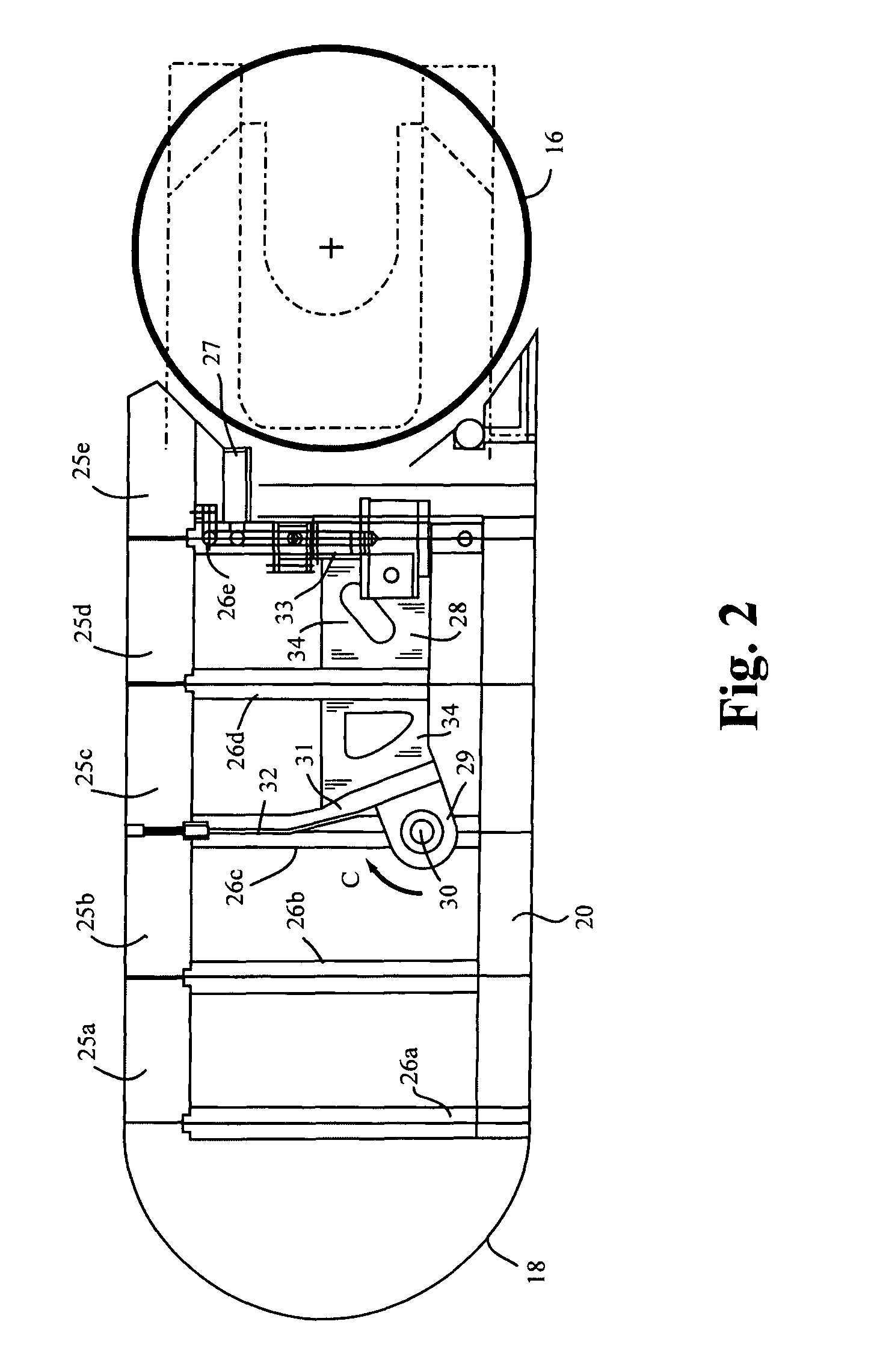

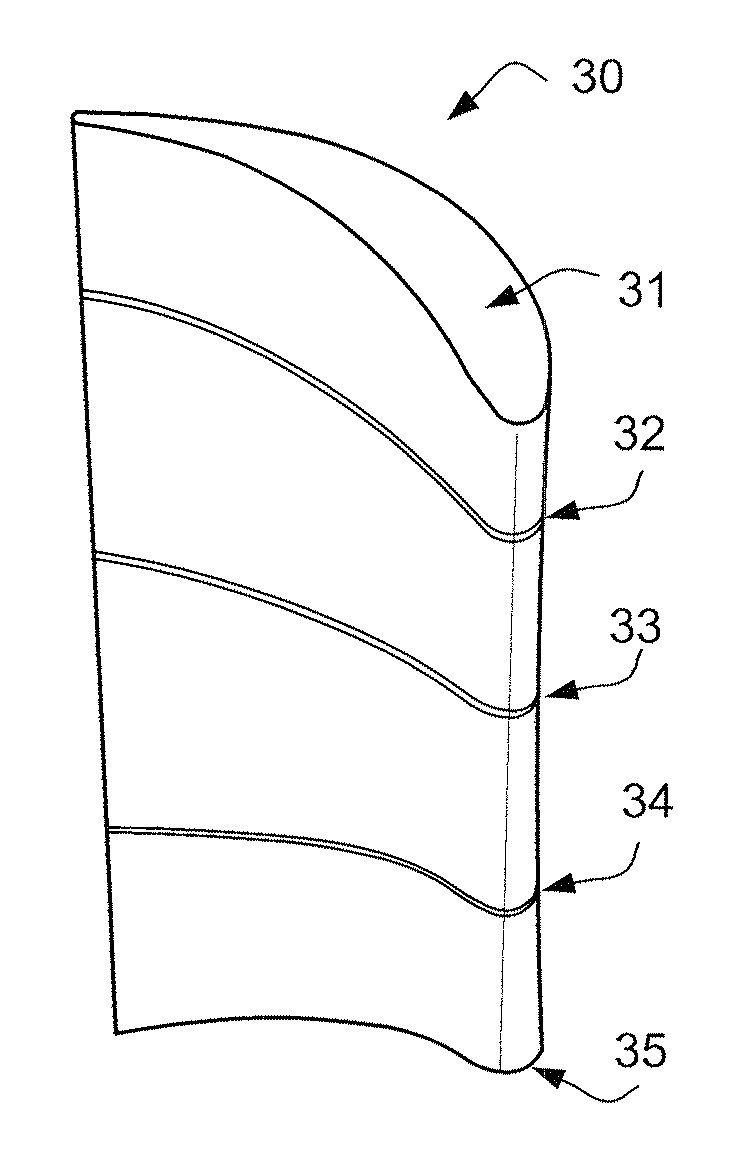

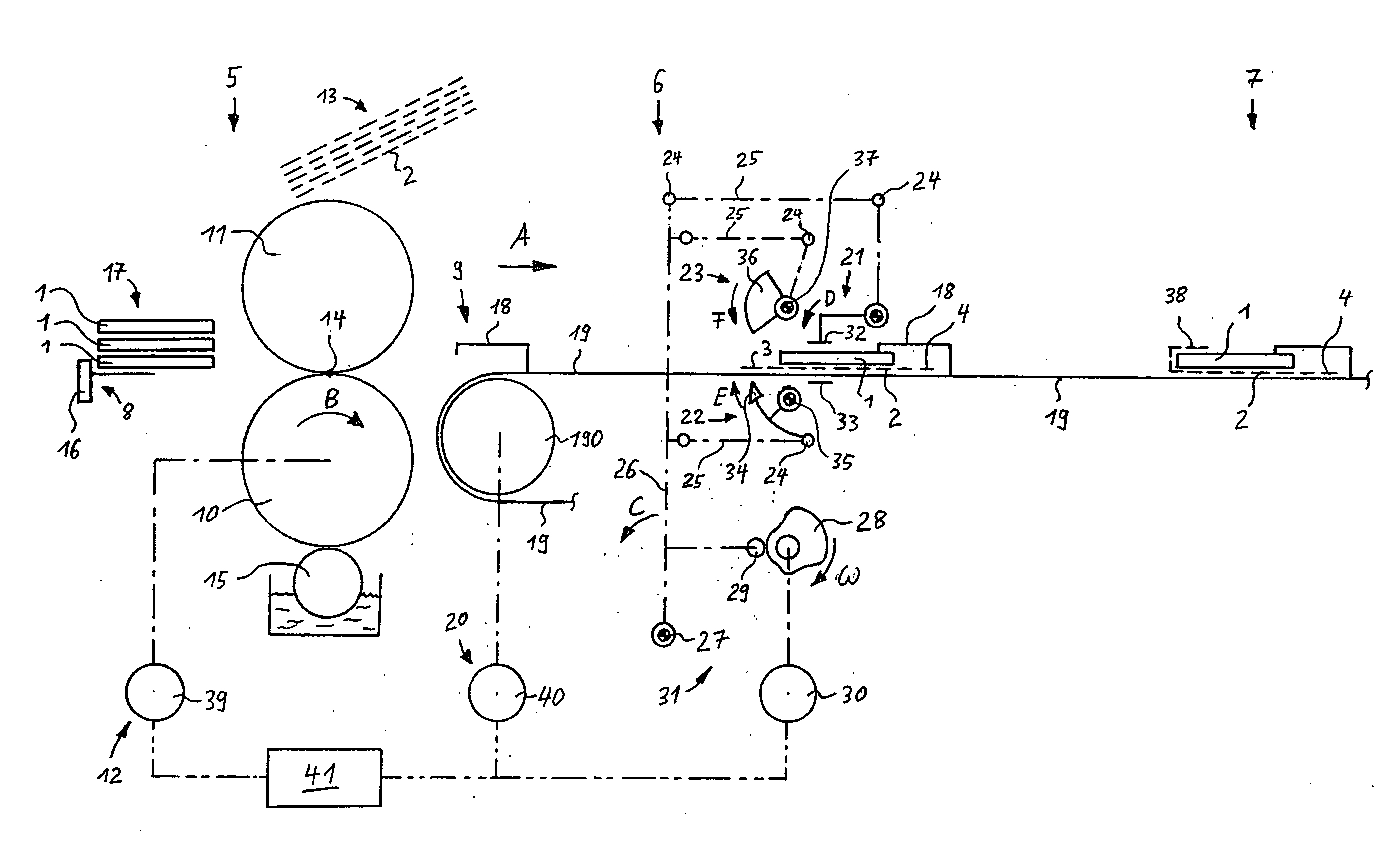

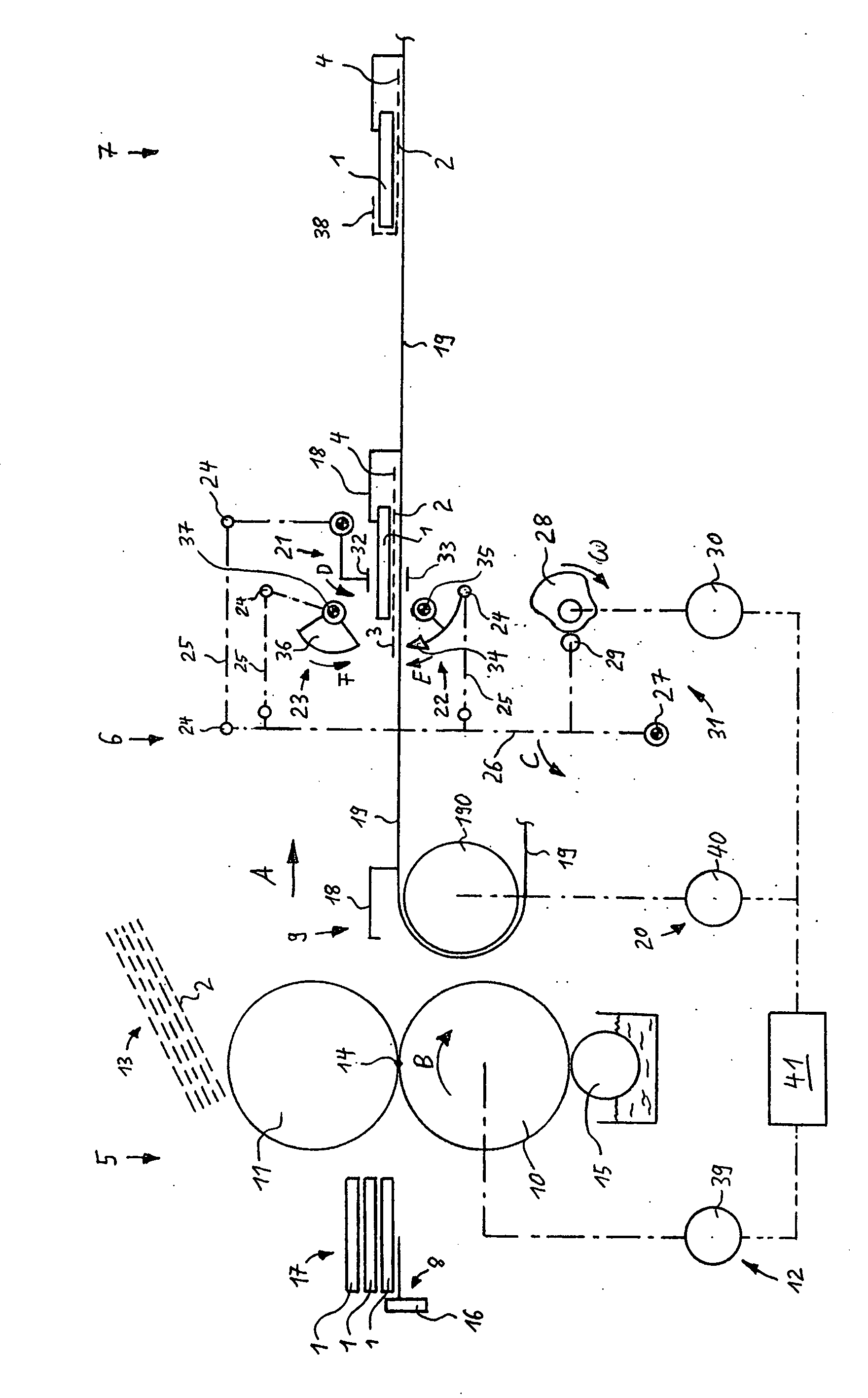

Belt casting machine having adjustable contact length with cast metal slab

A twin-belt casting machine for casting metal strip. The machine is provided with a casting cavity which includes an upstream fixed casting region, in which the belts are in fixed convergent paths in contact with the cast slab, and an adjacent downstream portion in which the belts are adjustable between alignment with the fixed convergent paths and non-alignment therewith (being less convergent or divergent). When the adjustable portions of the paths are moved outwardly relative to the fixed convergent paths, the belts separate from the cast slab at differing predetermined points within the casting cavity. By adjusting the downstream portion of the casting cavity in this manner, the casting machine can operate at essentially constant throughput for a wide range of alloys while ensuring that the cast slab exiting the caster has a temperature within a predetermined range suitable for further rolling to produce sheet product.

Owner:NOVELIS INC

High sensitivity glide sensor using frictional heating

InactiveUS8618793B2Accurate detectionImprove efficiencyRecord information storageMagnetic property measurementsElectrical resistance and conductanceEngineering

A tool for testing a magnetic disk for use in a magnetic disk drive. The tool detects surface defects or asperities by detecting a change in electrical resistance corresponding to a temperature change in a thermally sensitive layer. The apparatus includes a slider body having a thermally insulating layer formed on an air bearing surface of the slider body and a thermal sensor layer formed on the thermally insulating layer. The thermally insulating layer prevents thermal heat spikes in the thermal sensor layer (such as resulting from contact with an asperity) from dissipating quickly into the slider body itself. The thermal sensor layer is a material that exhibits a change in electrical resistance in response to a change in temperature and is preferably a PTC thermistor material which exhibits a large change in electrical resistance when a transition temperature has been reached.

Owner:WESTERN DIGITAL TECH INC

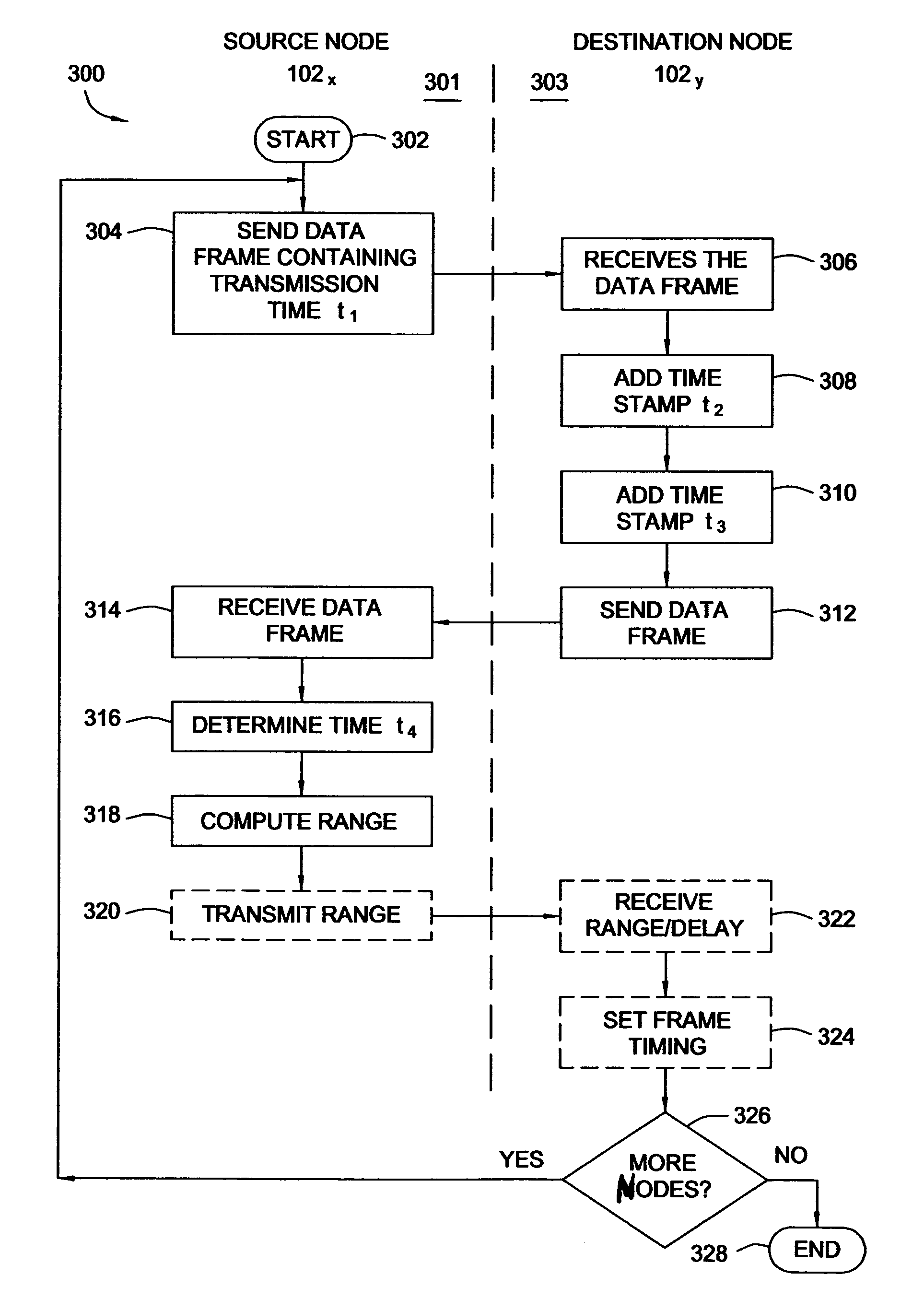

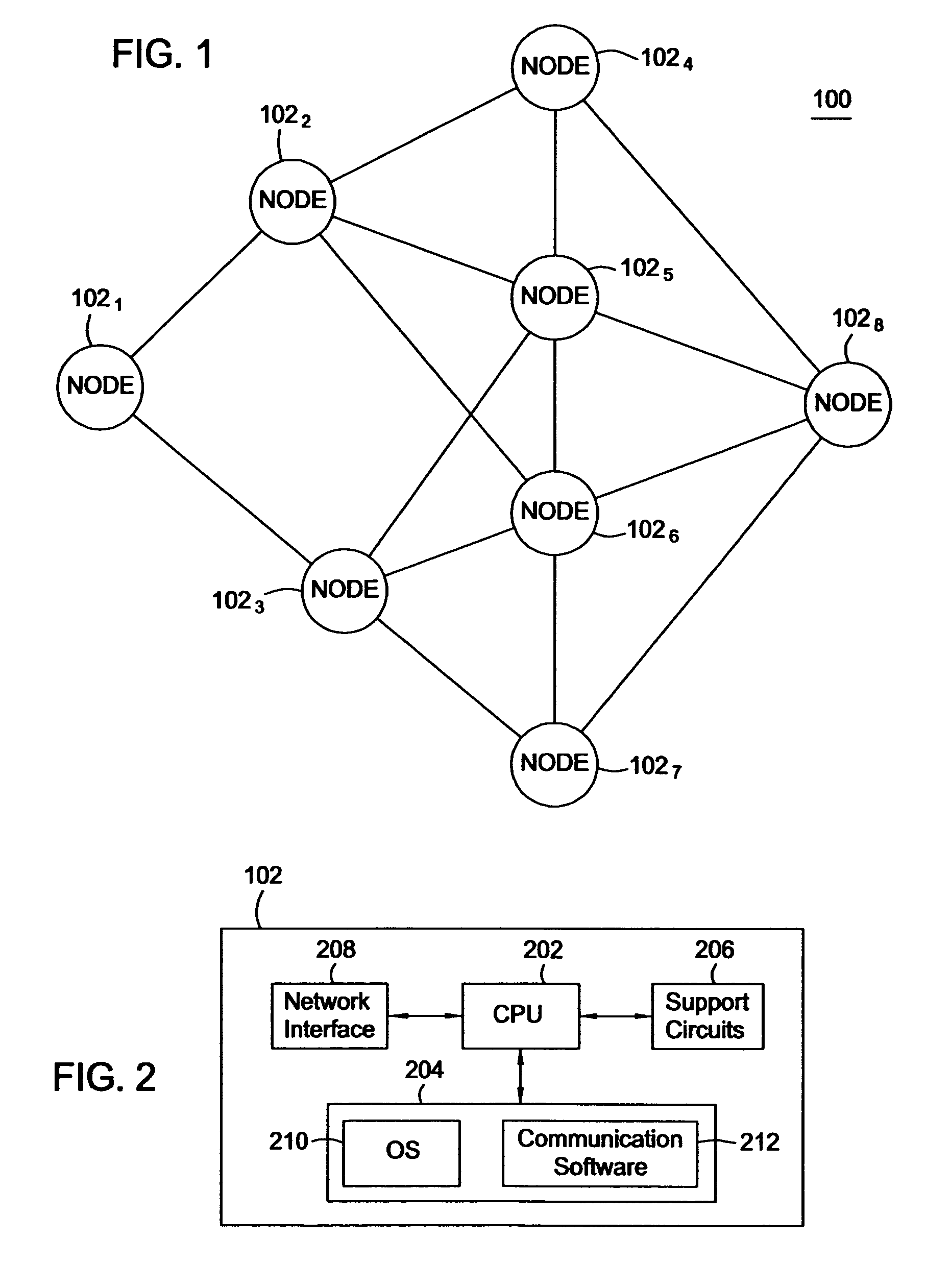

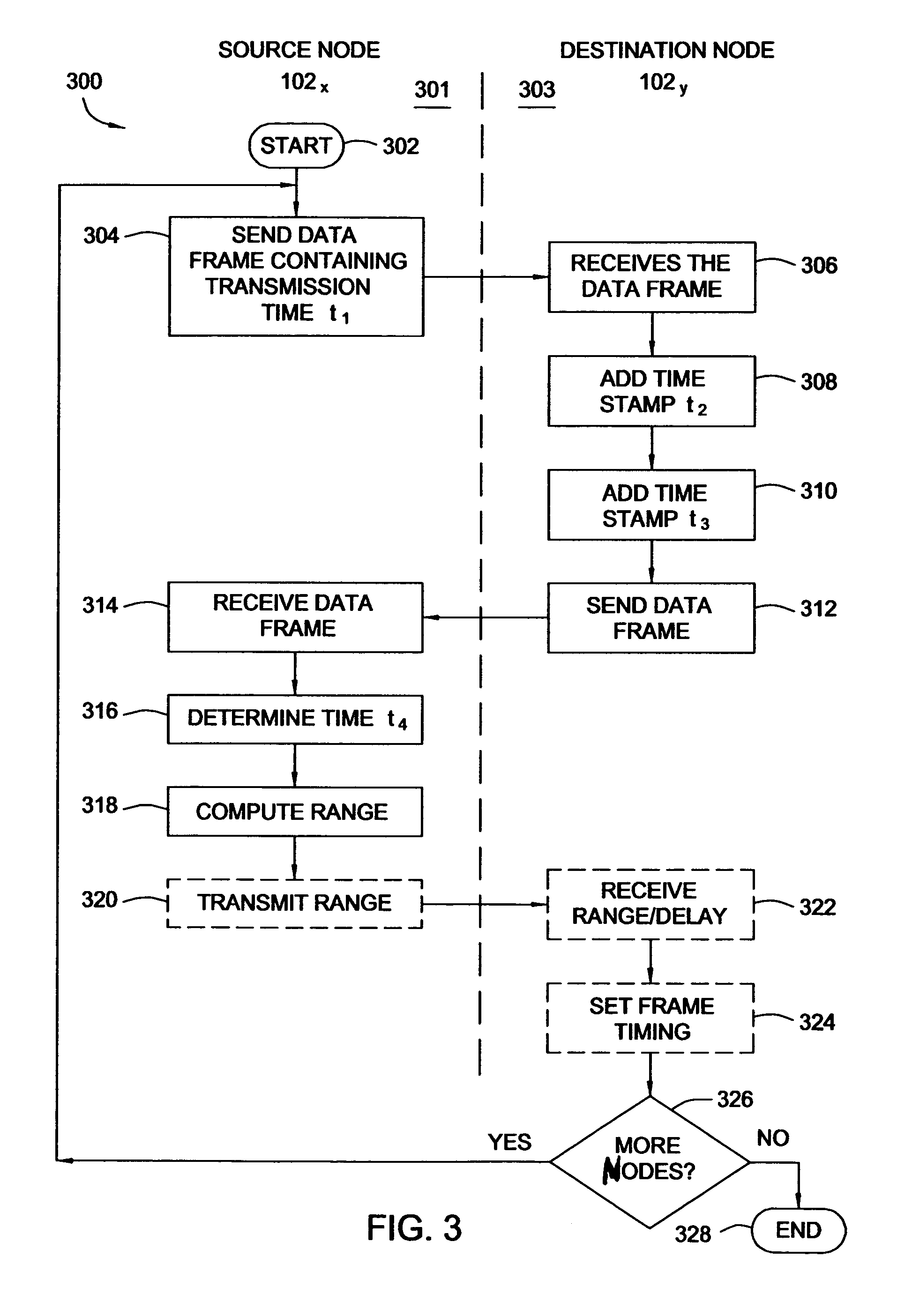

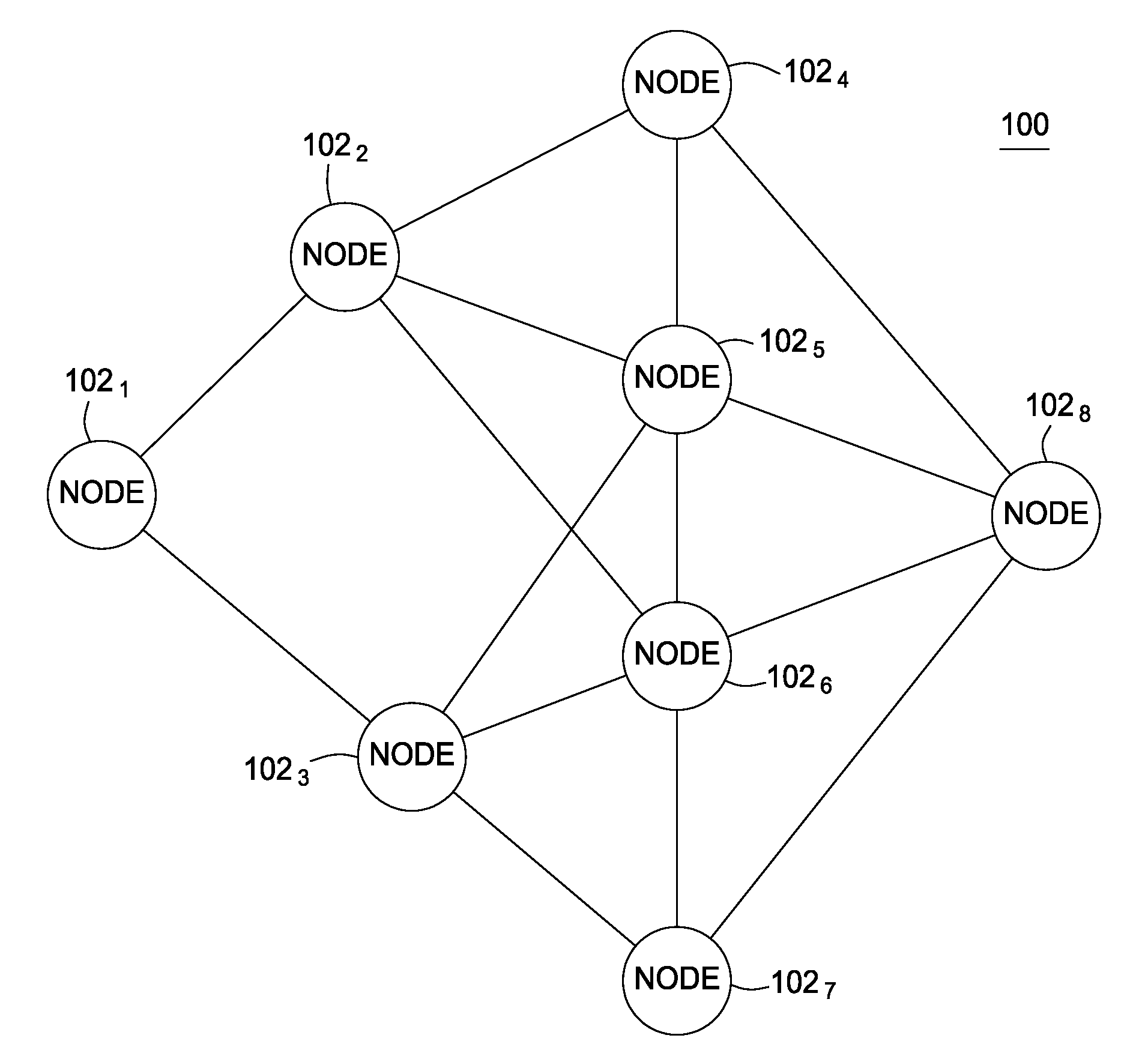

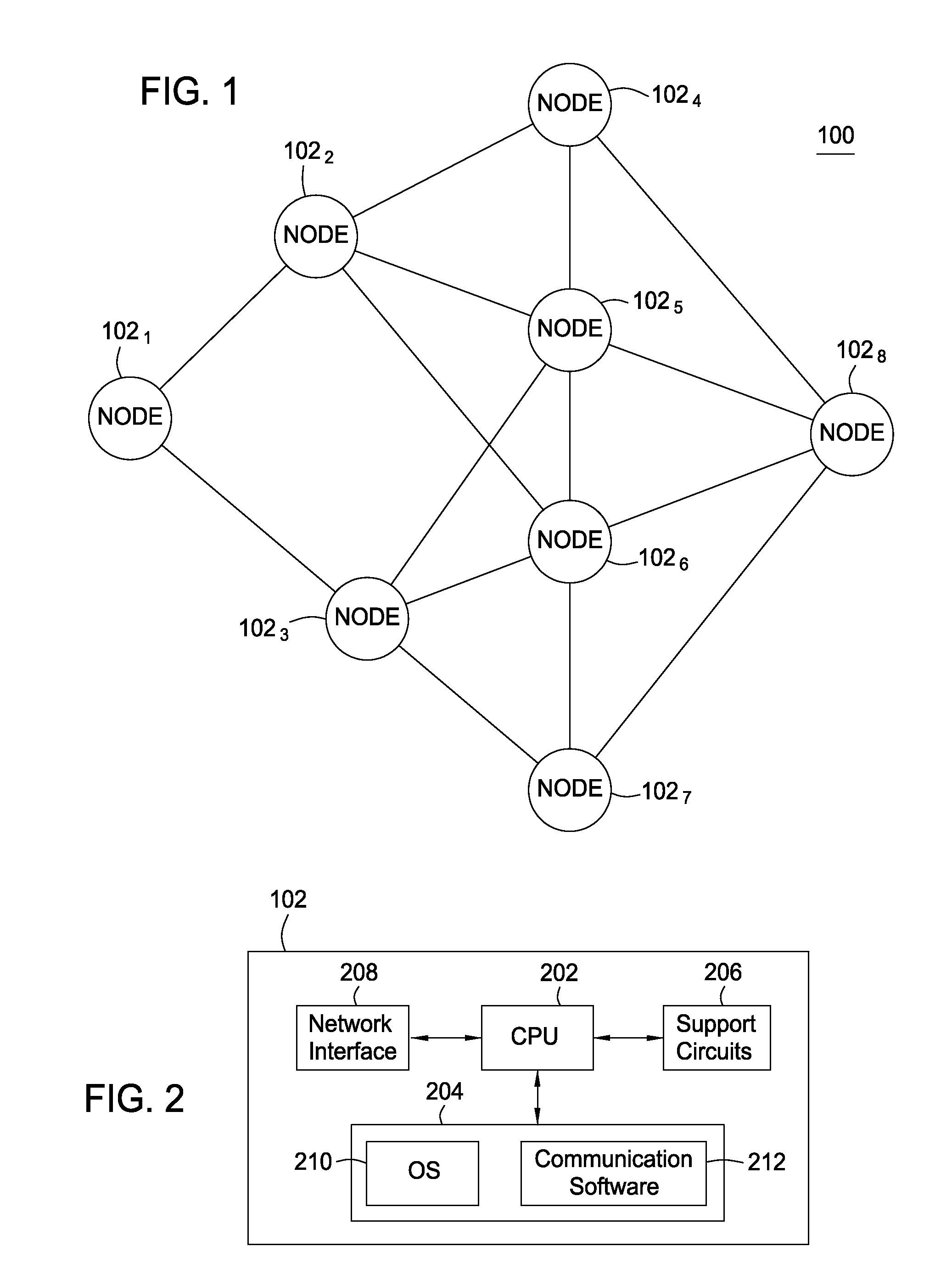

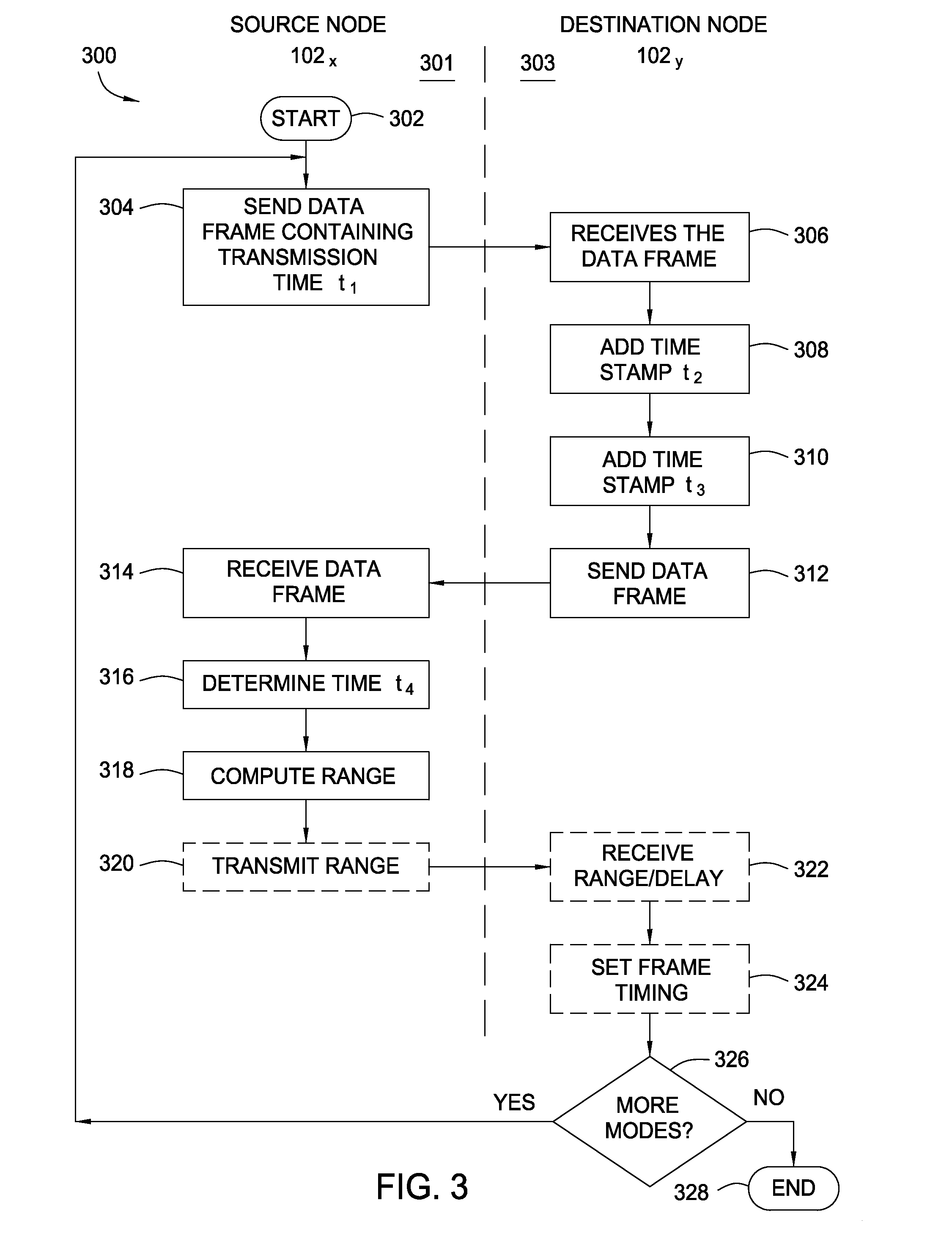

Method and apparatus for efficient transfer of data over a network

ActiveUS7826374B2Improve network efficiencyEfficient transferSynchronisation arrangementError preventionPropagation delaySpecific time

A method and apparatus for improving the efficiency of a network. A source node determines the propagation delay for data to reach a destination node. This enables the source node to transmit data more efficiently by ensuring a greater portion of a specific time slot is used for receiving data by the destination node. The destination node then determines if it is connected to any other nodes, and determines the propagation delay between the other connected nodes. The process continues until a node detects it is not connected to any other nodes for which a propagation delay has not been computed. Thus, each node on the network knows the propagation delay between each node, and the nodes utilize this information to more efficiently transfer data through the network.

Owner:TRILLIANT NETWORKS

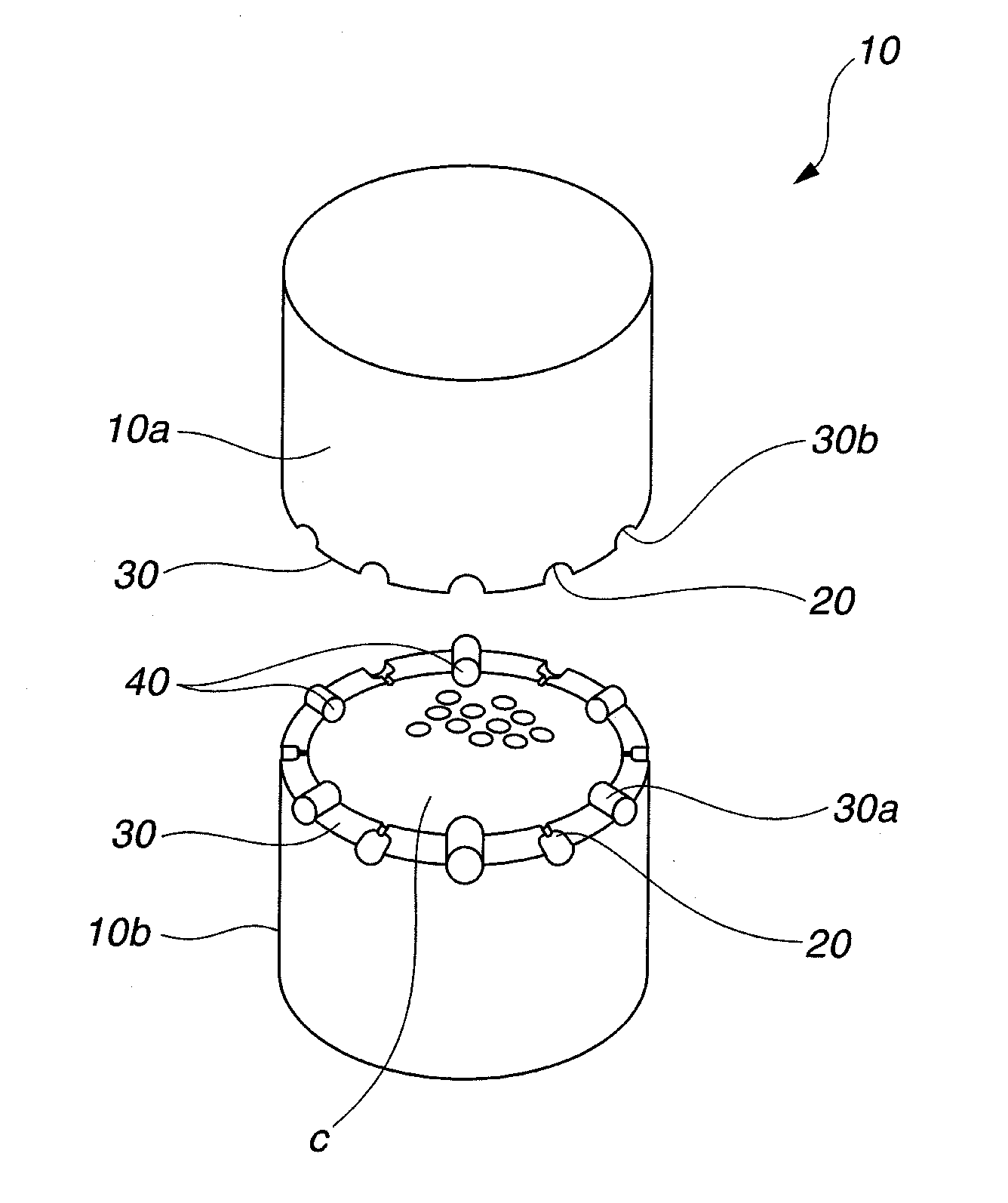

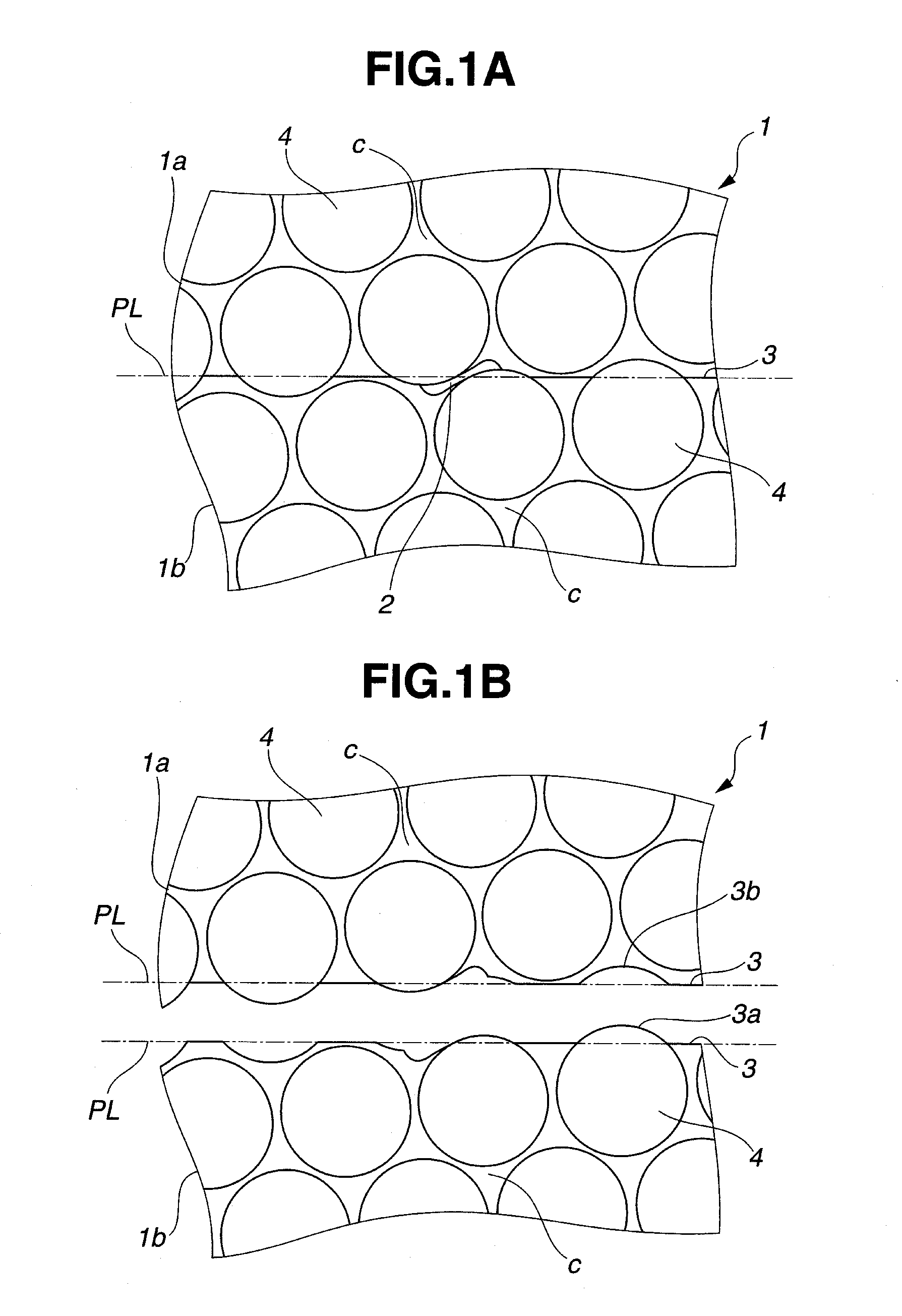

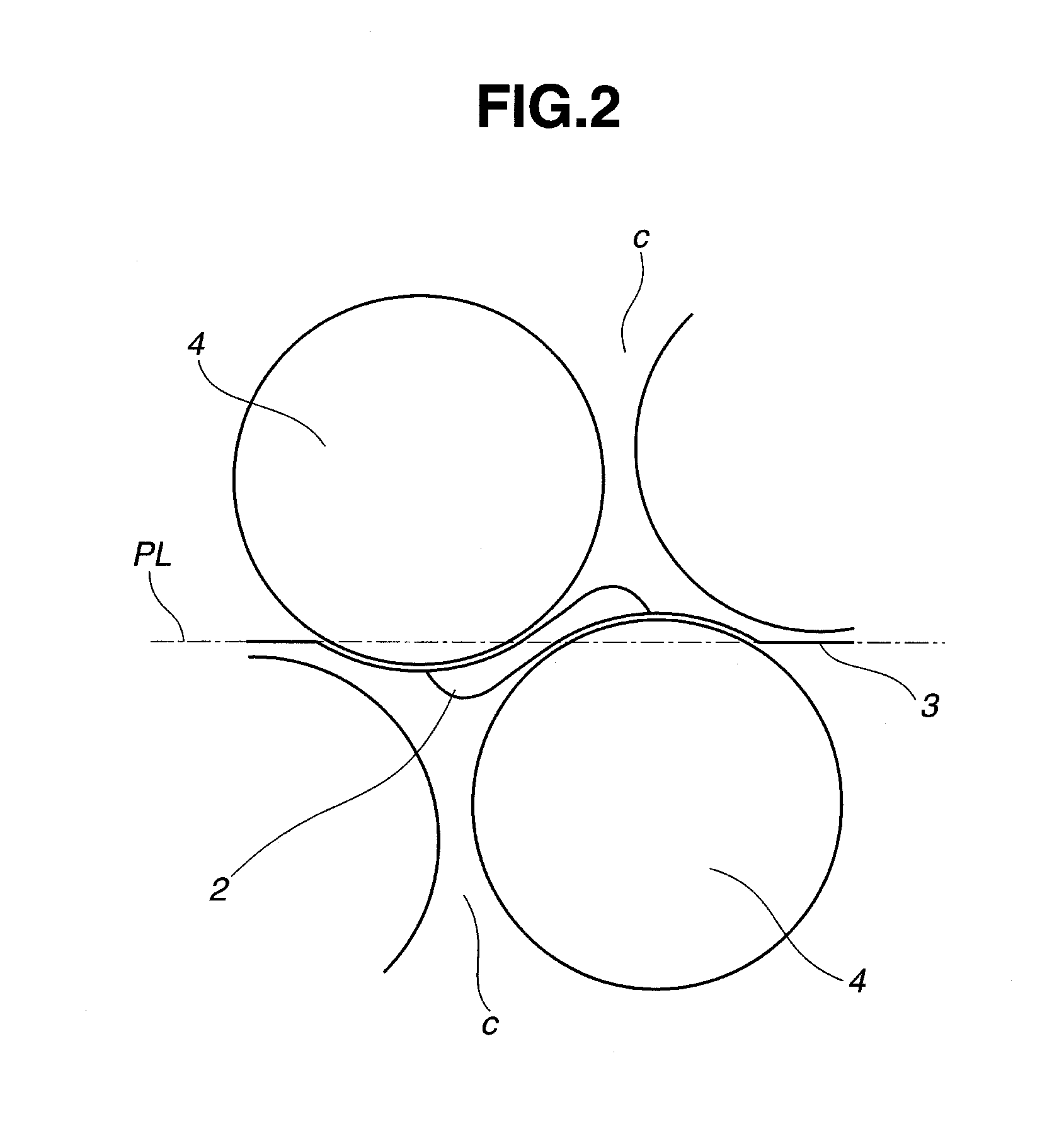

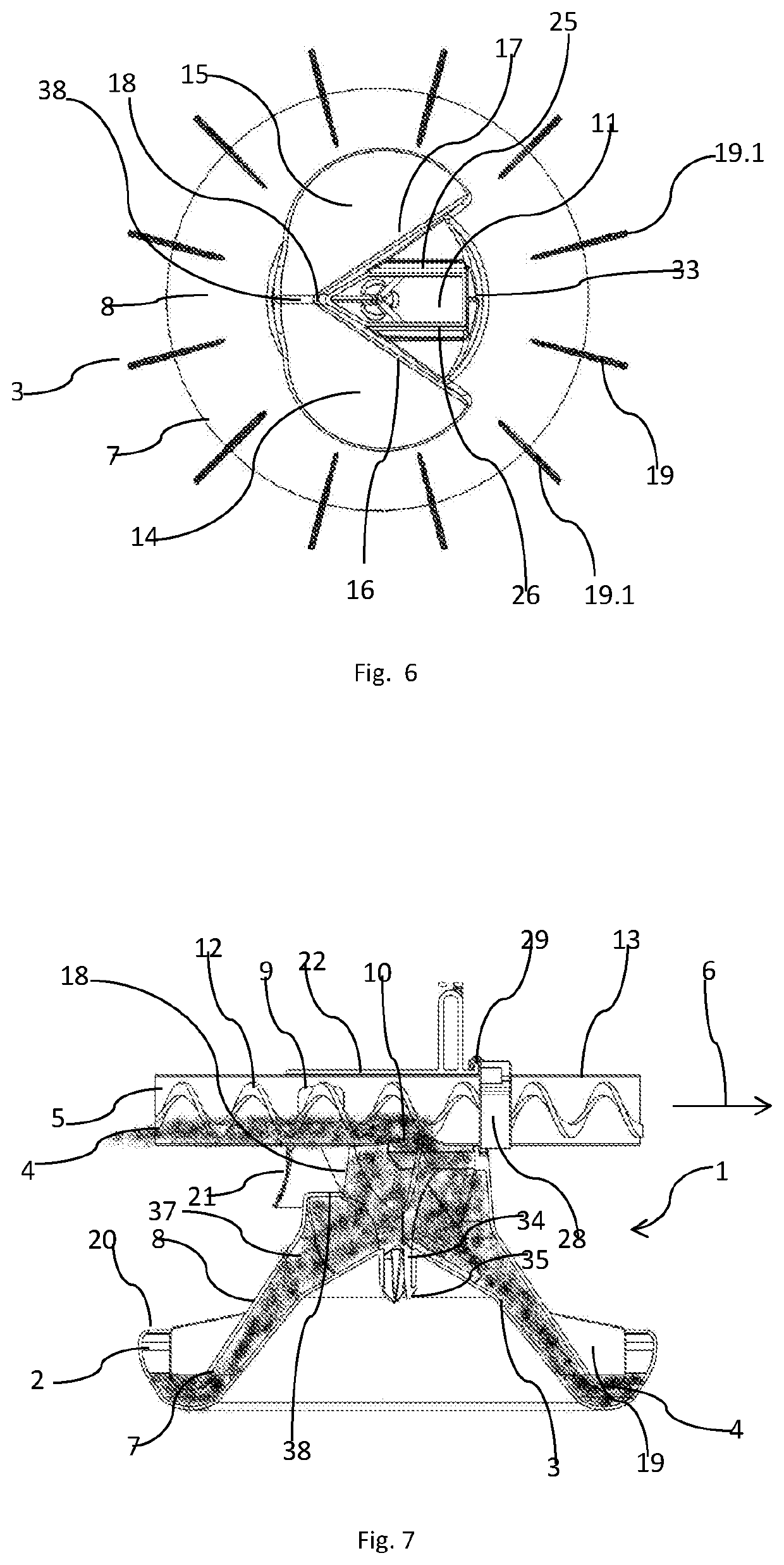

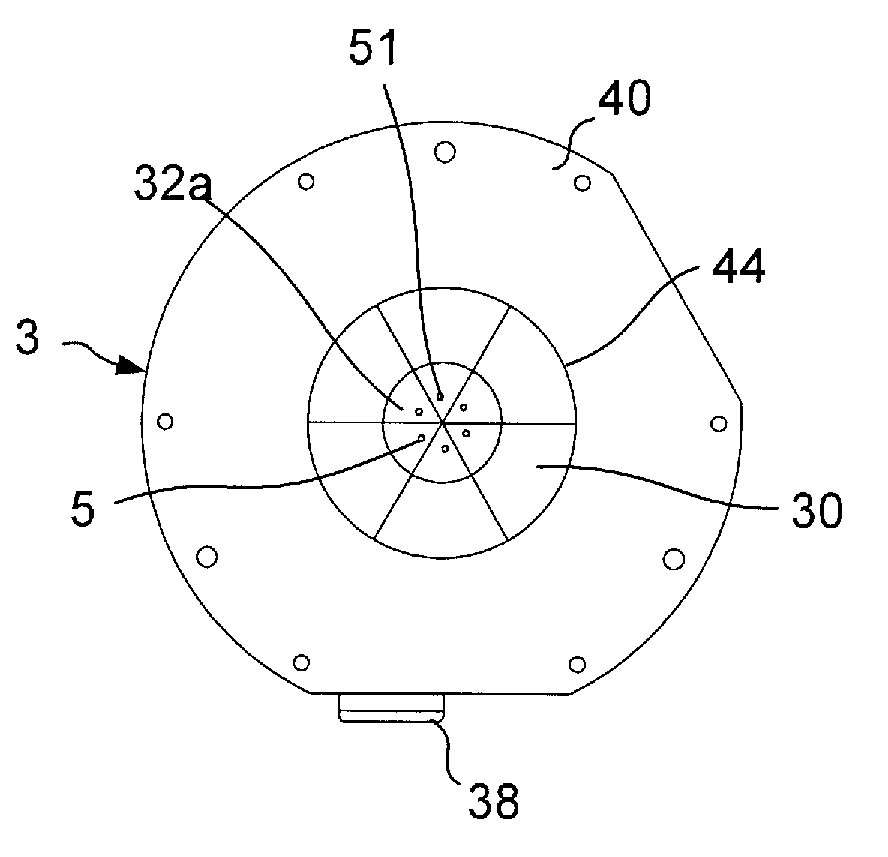

Golf ball mold, golf ball and golf ball manufacturing method

ActiveUS20110160002A1Good symmetryImprove performanceTailstocks/centresConfectioneryProduction rateInjection pressure

The invention provides a golf ball mold that is composed of a plurality of mold parts which removably mate to form a cavity having an inner wall with a plurality of dimple-forming protrusions thereon, wherein a non-circular resin injection port for injecting into the cavity a resin material is formed between a plurality of mutually adjoining dimple-forming protrusions which include a plurality of dimple-forming protrusions that lie across a parting line of the mold. Also provided is a golf ball molded using such a mold, and a golf ball manufacturing method which uses such a mold.By using the golf ball mold of the invention, even when manufacturing golf balls with a high dimple surface coverage on which the dimples are tightly arranged, particularly up to the vicinity of the resin injection port, imbalances in the resin injection pressure and flow rate during injection molding are suppressed, enabling golf balls to be manufactured without giving rise to production problems such as molding defects, scorching, or deformation and eccentricity of the core.Moreover, in the mold of the invention, when equally spaced lines are drawn at 0.05 mm intervals from an inner peripheral wall toward a center axis of a gate having the non-circular resin injection port, by adjusting the cross-sectional size of the gate so that the distance between the center of a region enclosed by the innermost equally spaced line and the inner peripheral wall of the gate is less than 0.5 mm, the molten resin material within the gate area can be efficiently and thoroughly cooled after injection molding, thus giving the finished ball a good appearance and enabling productivity to be enhanced.

Owner:BRIDGESTONE SPORTS

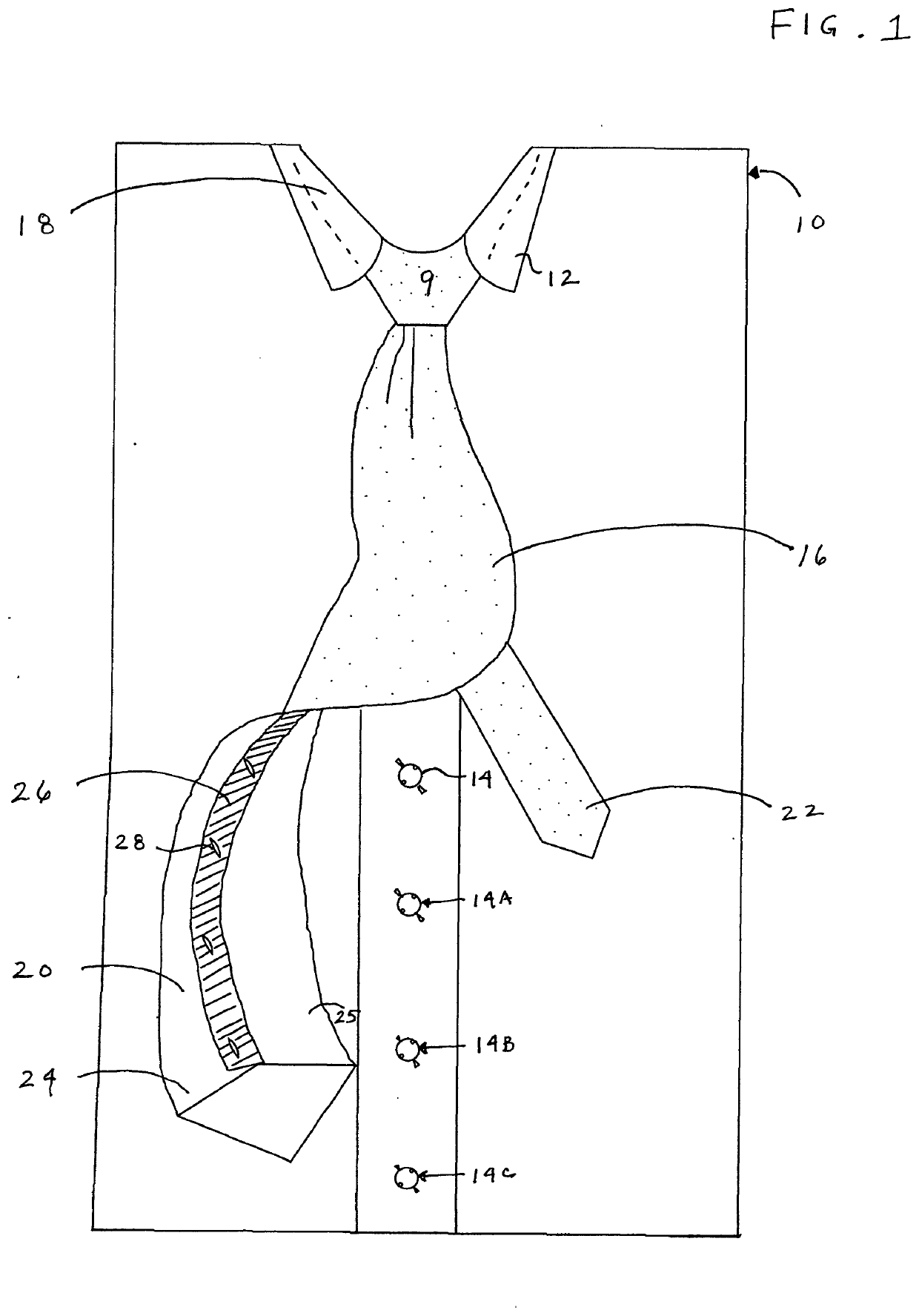

Necktie Lock

ActiveUS20200337397A1Change the wearer's perception about necktiesLength and efficiencyNecktiesSoftware engineeringRelative motion

Owner:BARNSWELL REGINALD

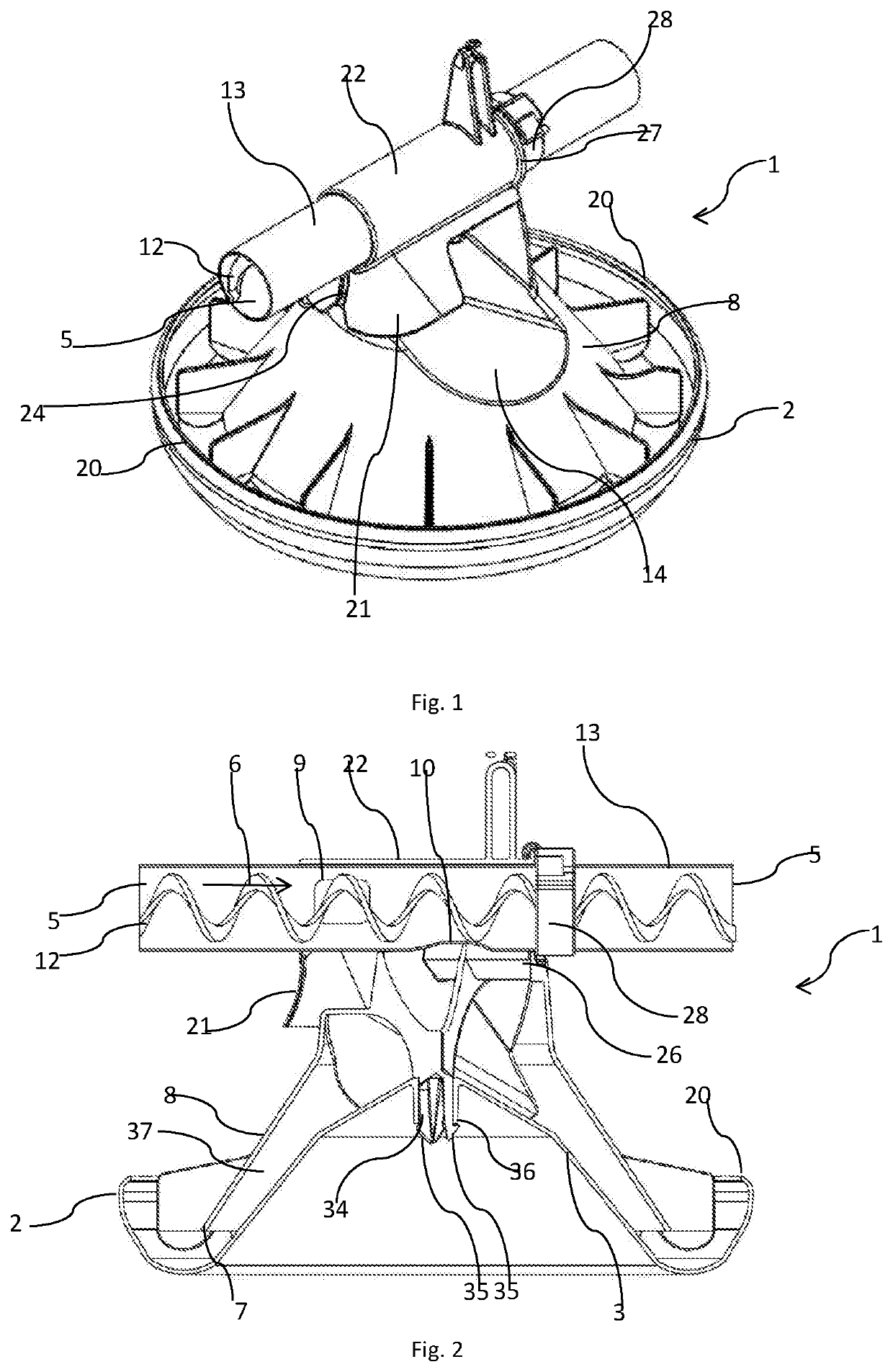

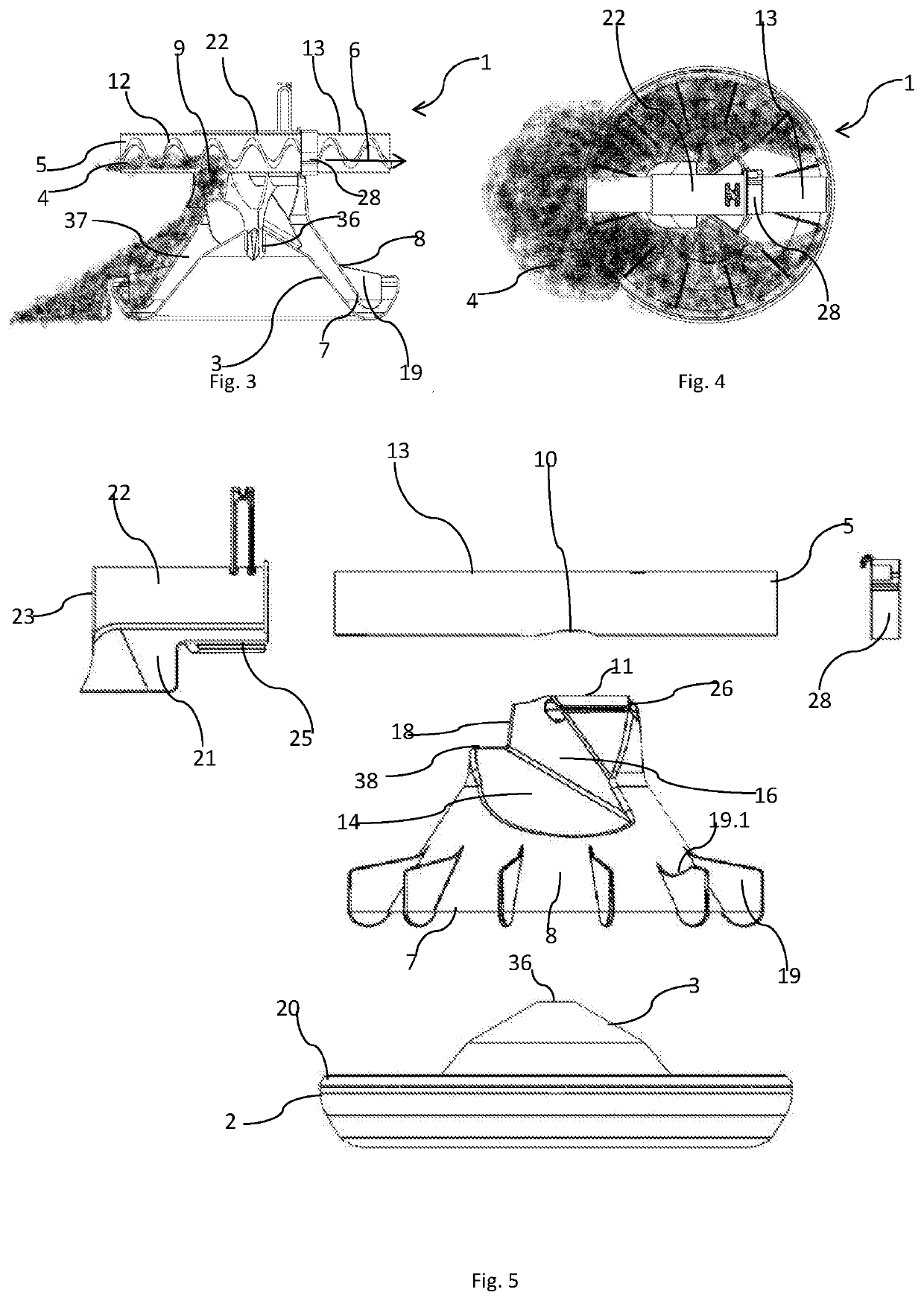

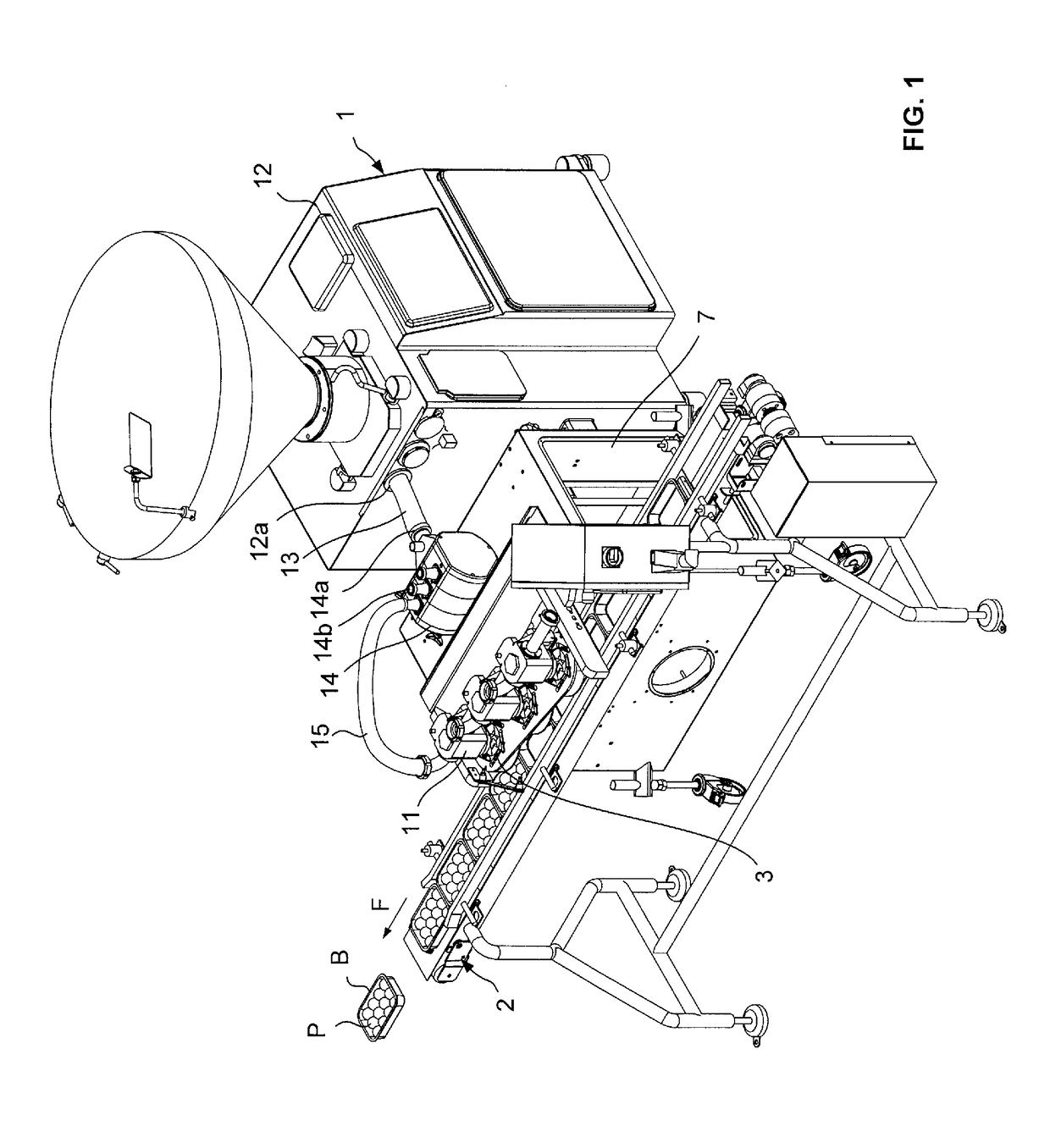

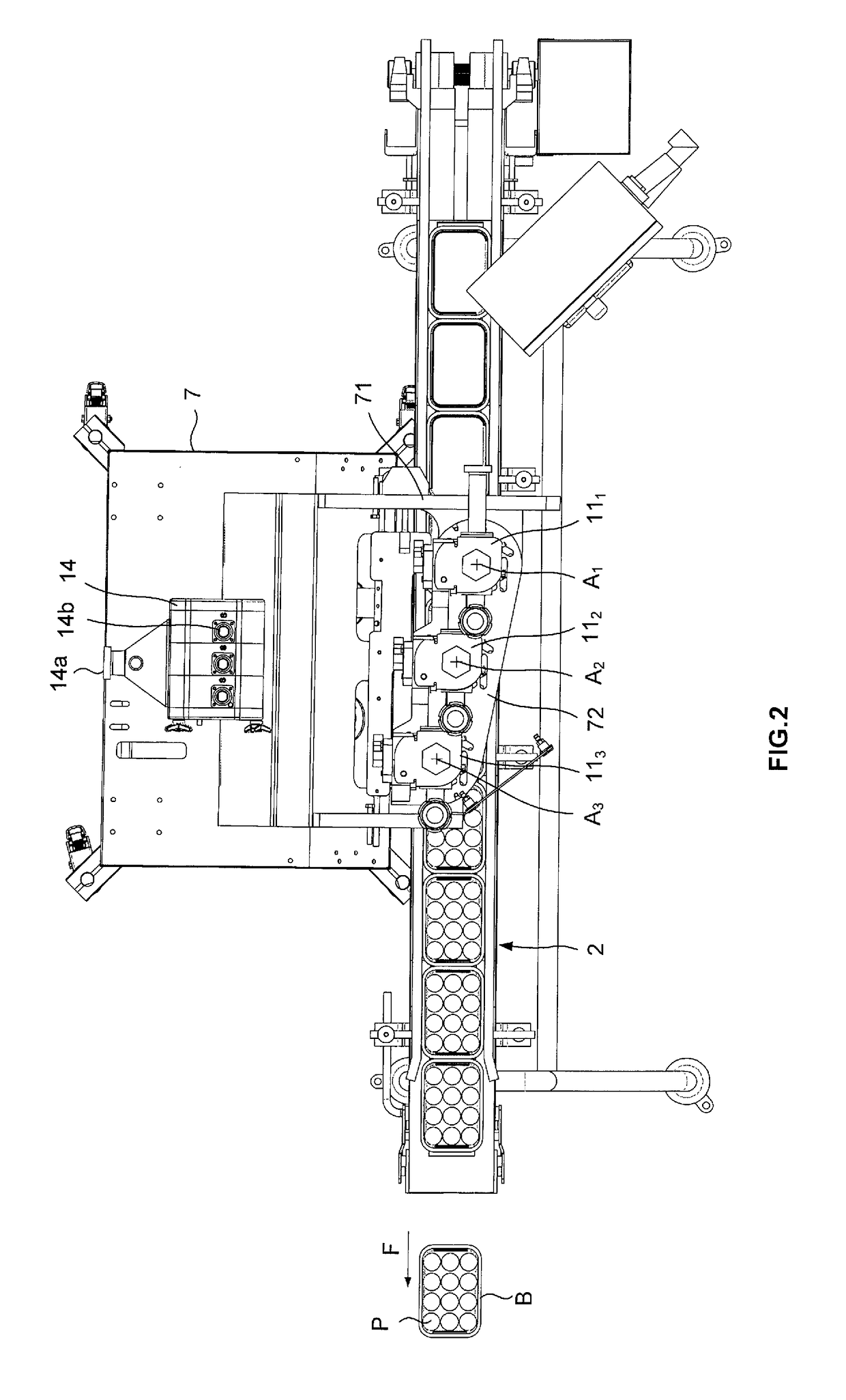

A method of filling feeding pans as well as a feeding system

A feeding system for freely moving poultry or other small animals, comprising a feeding pan (1) having an outer distribution cone (7), wherein an overlying horizontal transport channel (5) for feed is provided above the distribution cone (7), wherein a passage for regular feeding (10) out of the transport channel (5) is provided, and wherein the feed, when passing there through, passes through the opening (11) at the top of the distribution cone (7) to the inner side of the distribution cone (7). Advantageously, and prior to the passage for regular feeding (10) in the direction of movement of the feed, there is a passage for initial feeding (9) out of the transport channel (5), arranged such that the feed passes out of the initial feeding passage and impinges on separate chutes (14, 15) externally on the distribution cone (7), a dividing line (18, 38) between the two chutes (14, 15) being provided in the distribution cone (7).

Owner:LANDMECO OLGOD

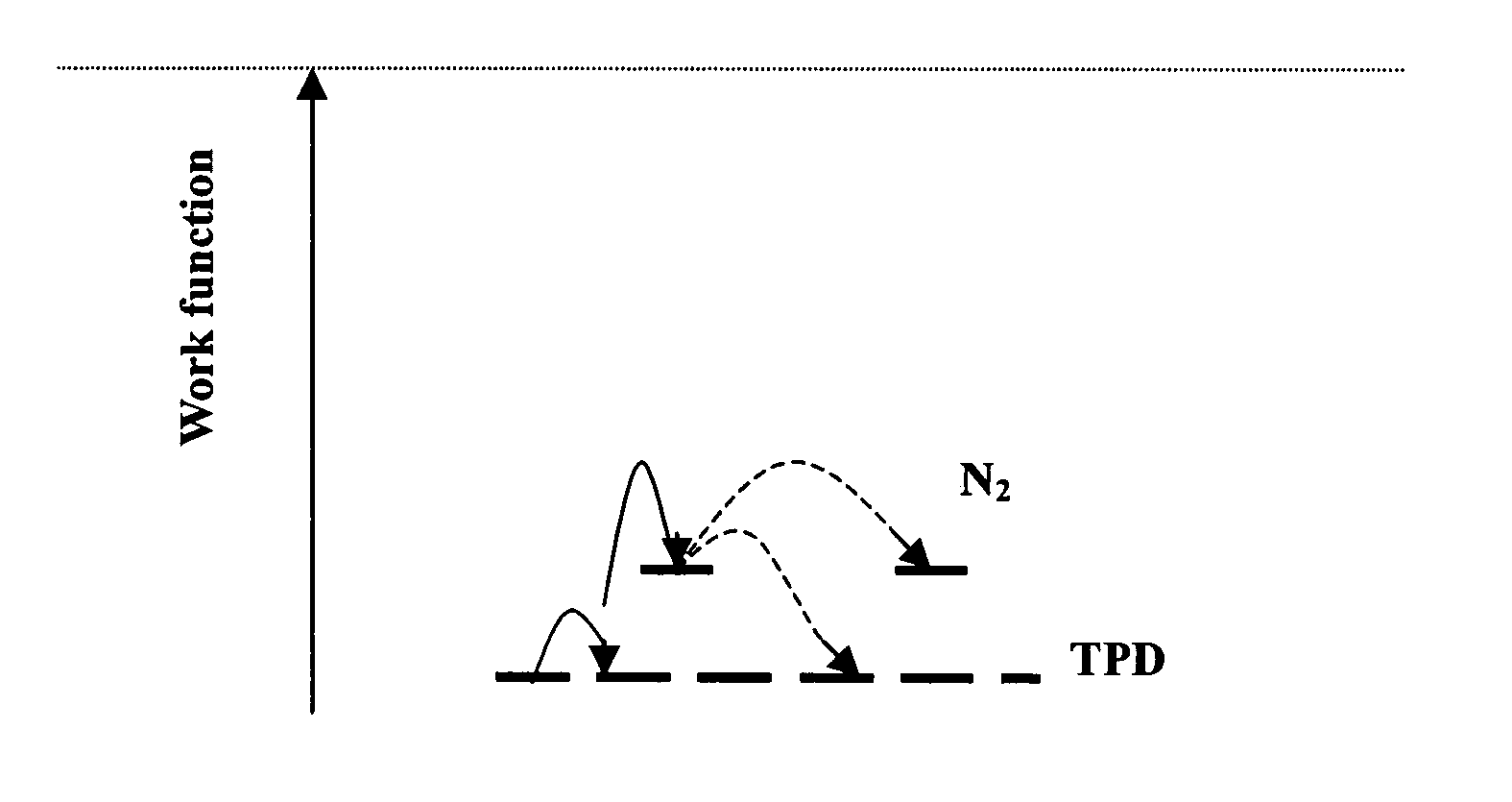

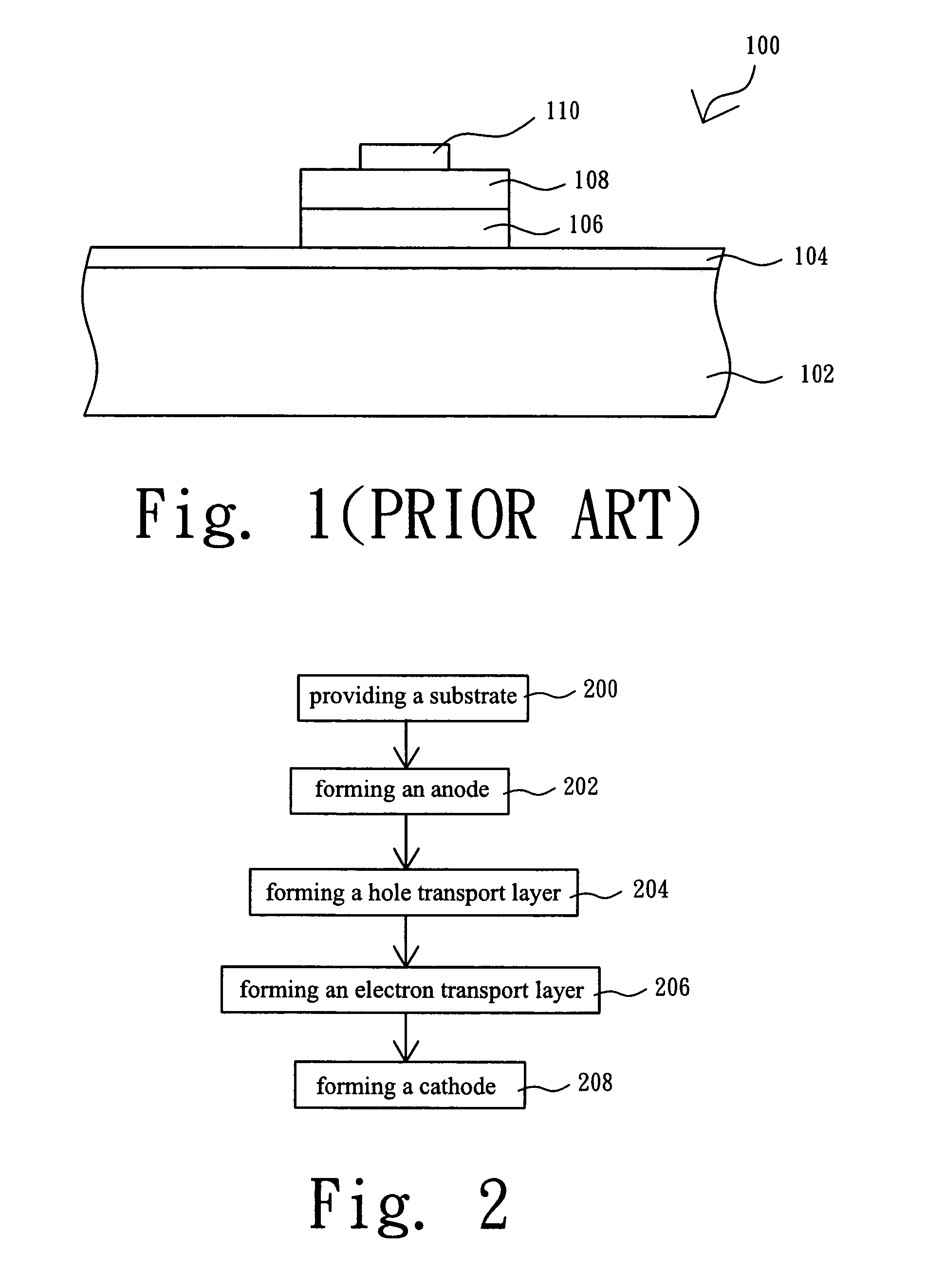

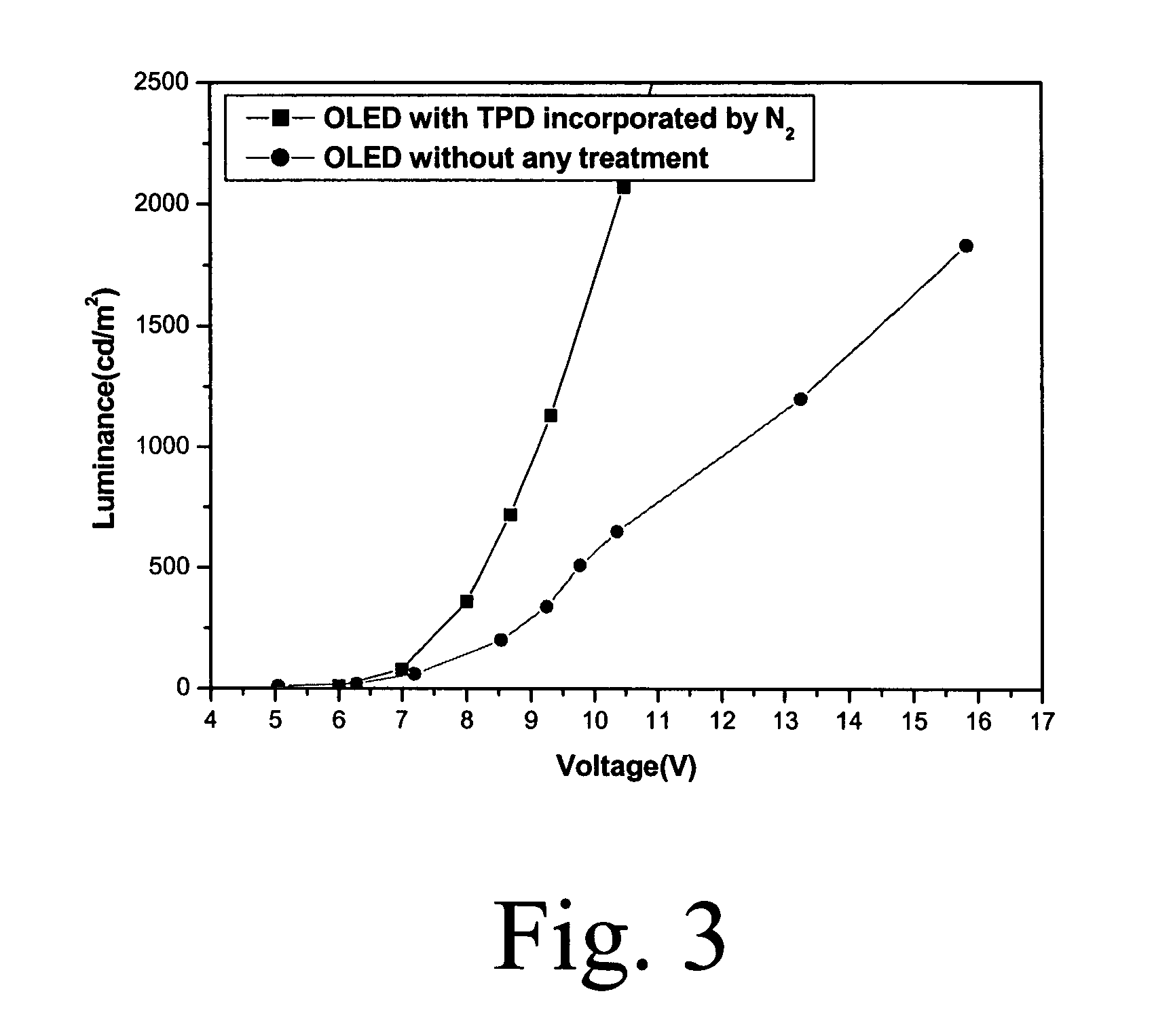

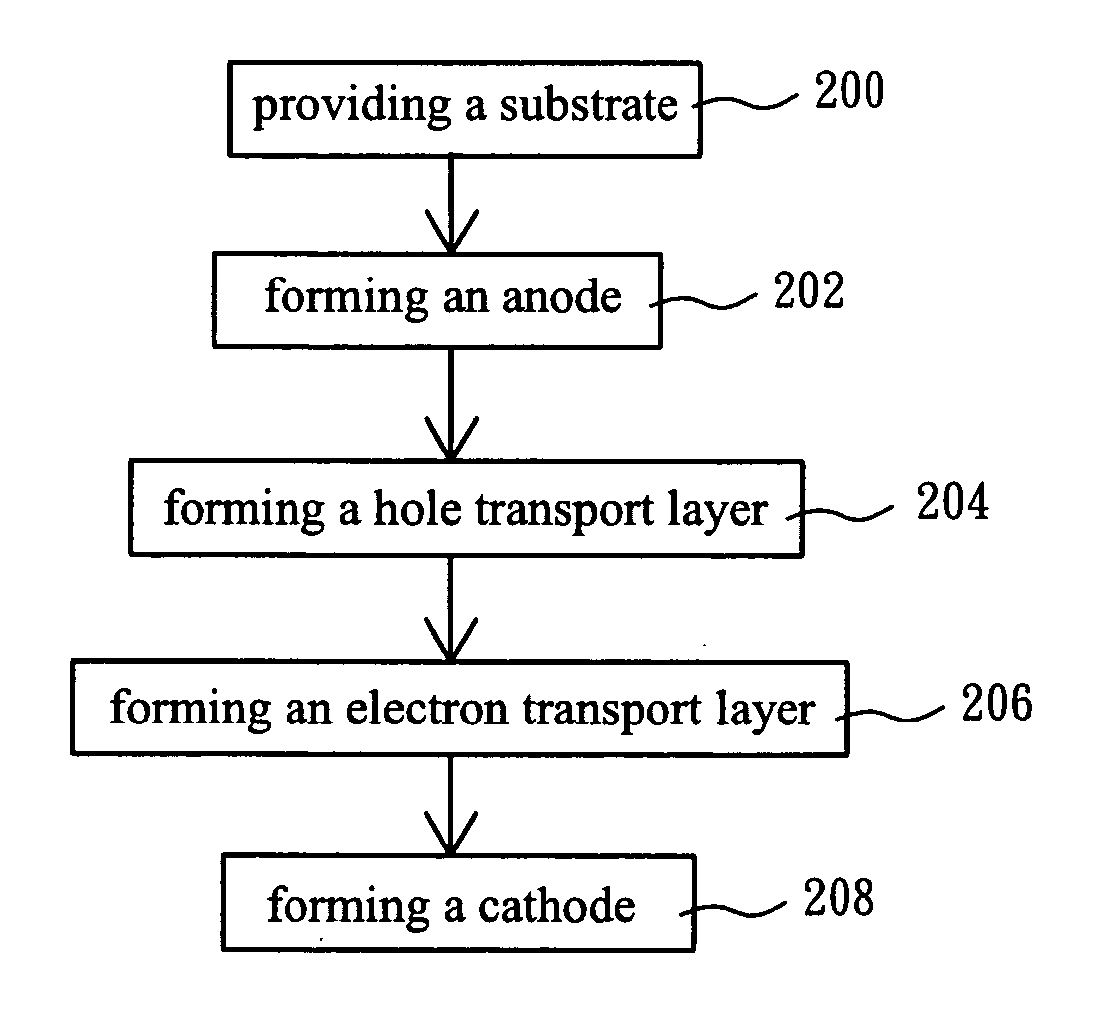

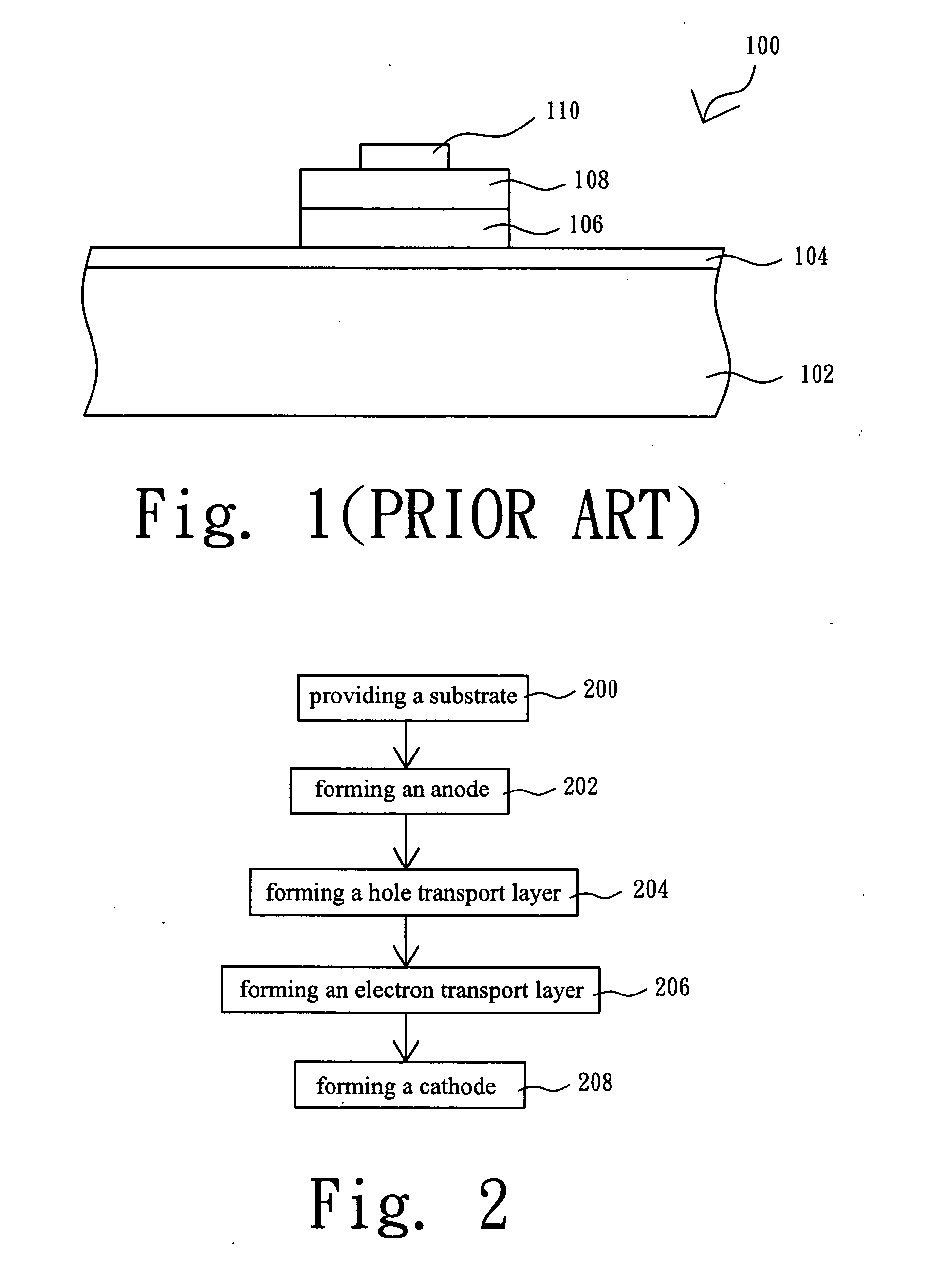

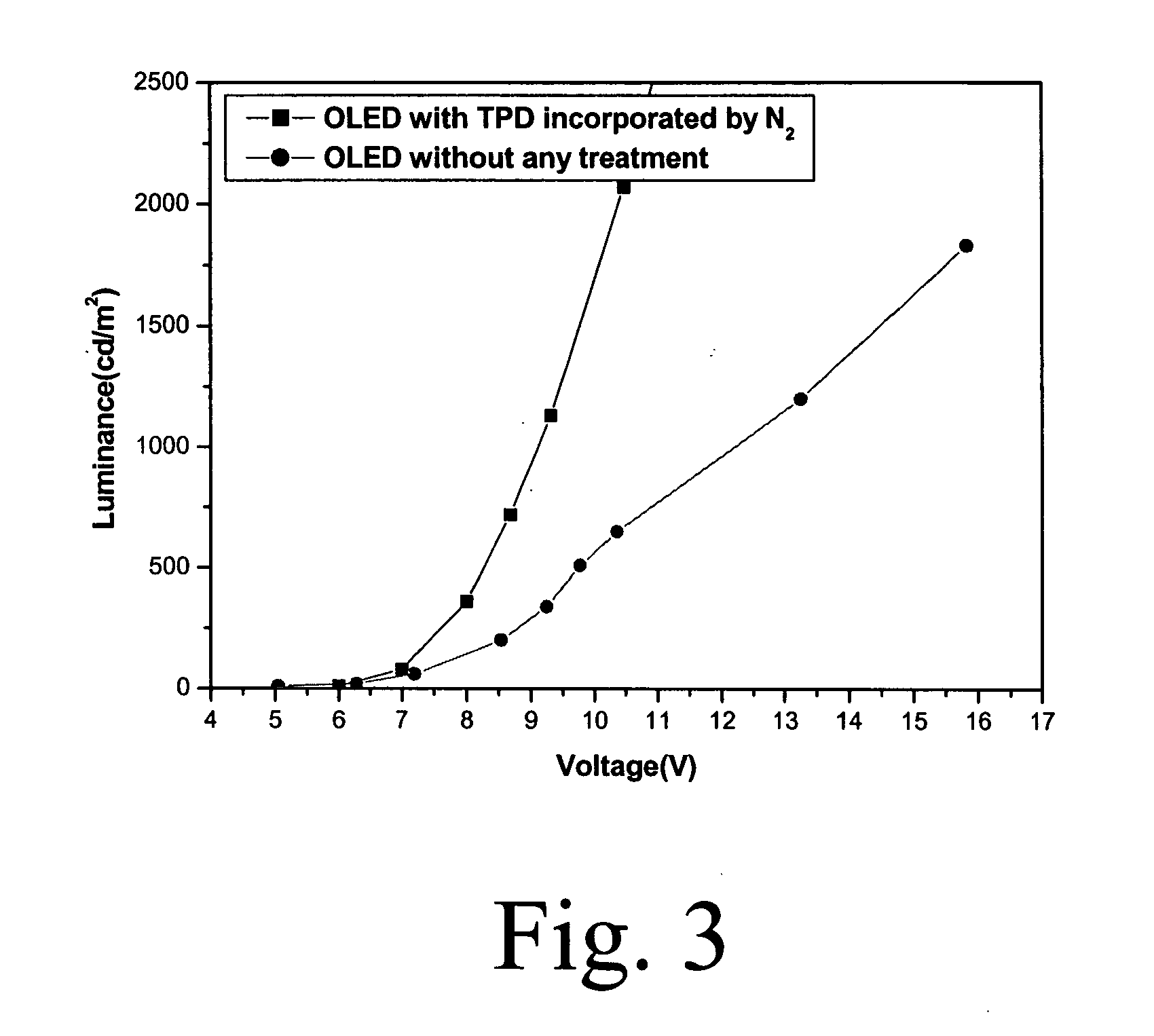

Method for manufacturing organic light-emitting diodes

InactiveUS7048603B2Reduced luminous efficiencyIncrease energy levelDischarge tube luminescnet screensElectroluminescent light sourcesHigh energyHole transport layer

A method for manufacturing organic light-emitting diodes (OLEDs) is disclosed, by adding nitrogen (N2) into the material of a hole transport layer (HTL) and evaporating the nitrogen and the material of the hole transport layer while growing the hole transport layer, so as to dope nitrogen molecules into the hole transport layer. In the hole transport layer, the nitrogen molecules are impurities of higher energy level, and are used to catch holes while the holes transports and trap the holes in the hole transport layer, thereby obtaining an object of improving the luminance efficiency of the organic light-emitting diodes with lower cost.

Owner:NAT CHENG KUNG UNIV

Formula and set for preparing rigid polyurethane foam, preparation method of the same, rigid polyurethane foam, as well as preparation method and application of the rigid polyurethane foam

The invention relates to the technical field of polyurethane foam preparation, and discloses a formula and a set for preparing rigid polyurethane foam, a preparation method of the formula and the set,the rigid polyurethane foam, and a preparation method and application of the rigid polyurethane foam. According to the formula, the first component is prepared from, by mass, 90%-96% of polyether, 2%-5% of a catalyst and silicone oil; a second component comprises the following components in percentage by mass: 70-94.9% of isocyanate, 5-29.9% of a low-temperature foaming agent and a drying agent.The preparation method of the kit comprises the following steps: fully mixing and reacting the components in the first component at 40-60 DEG C to obtain a first mixture; fully mixing and reacting allthe components in the second component sufficiently at the temperature of -20 DEG C to 0 DEG C to obtain the set. The preparation method of the rigid foam comprises the step of mixing and foaming thefirst mixture and the second mixture. The rigid polyurethane foam is prepared by adopting the preparation method. The foam is good in heat conductivity coefficient stability, good in attenuation andsuitable for being applied to a low-temperature heat preservation environment.

Owner:天长市伯士的环保新材料有限公司 +1

Apparatus for wetting a running filament strand

InactiveUS20060188594A1Degree of shielding is lessenedGood portionLiquid surface applicatorsSpray nozzlesEngineeringNozzle

Owner:SAURER GMBH & CO KG

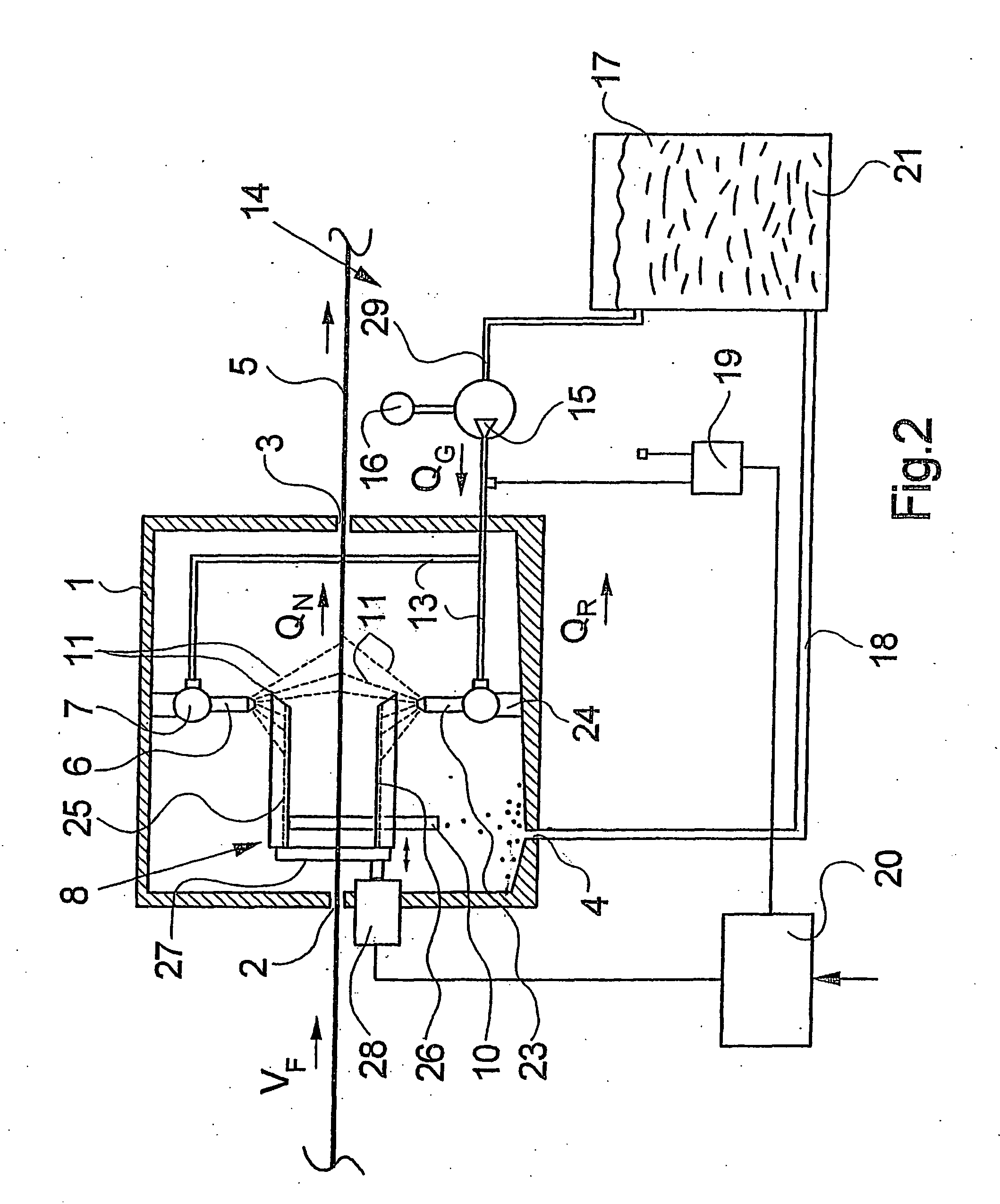

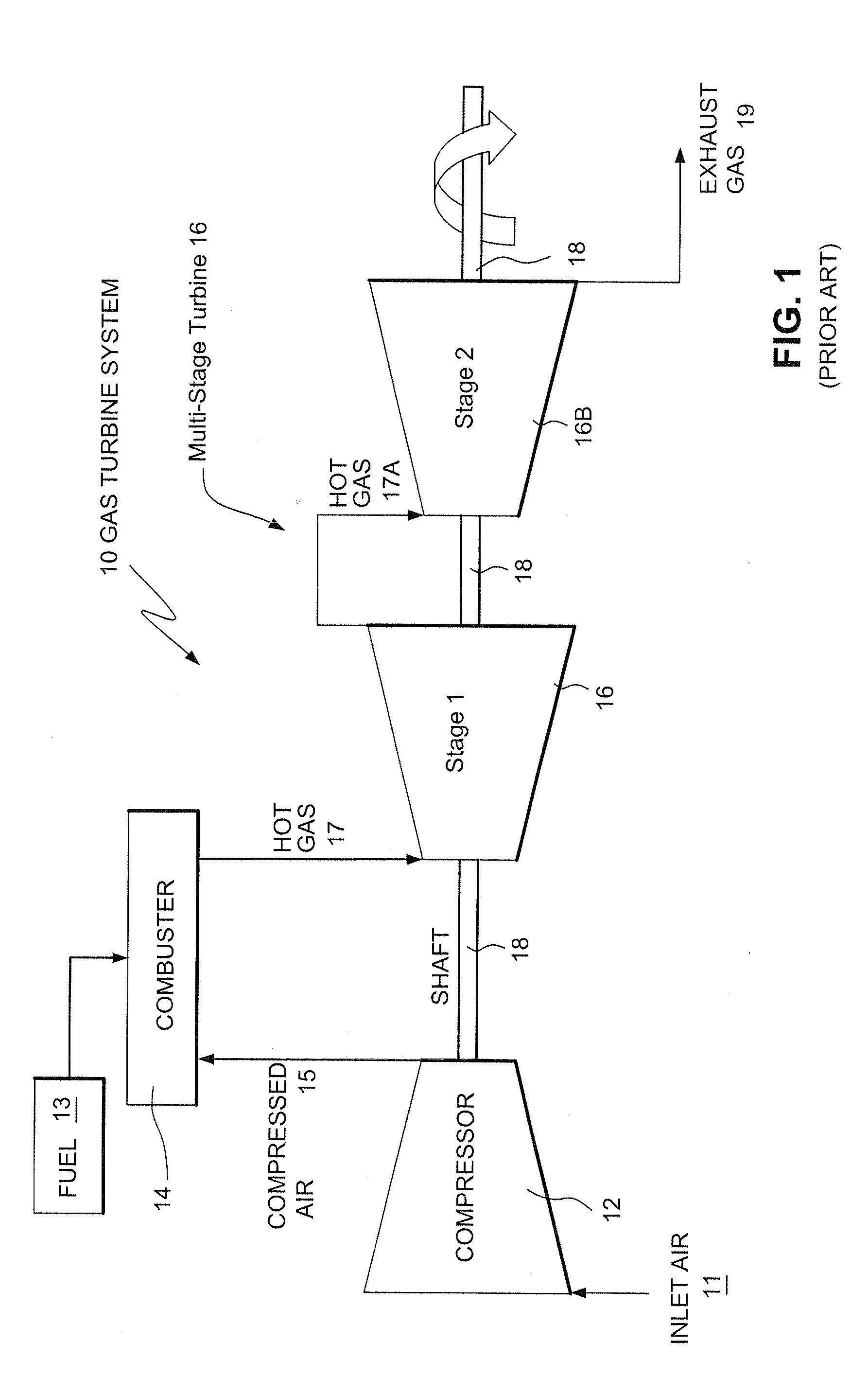

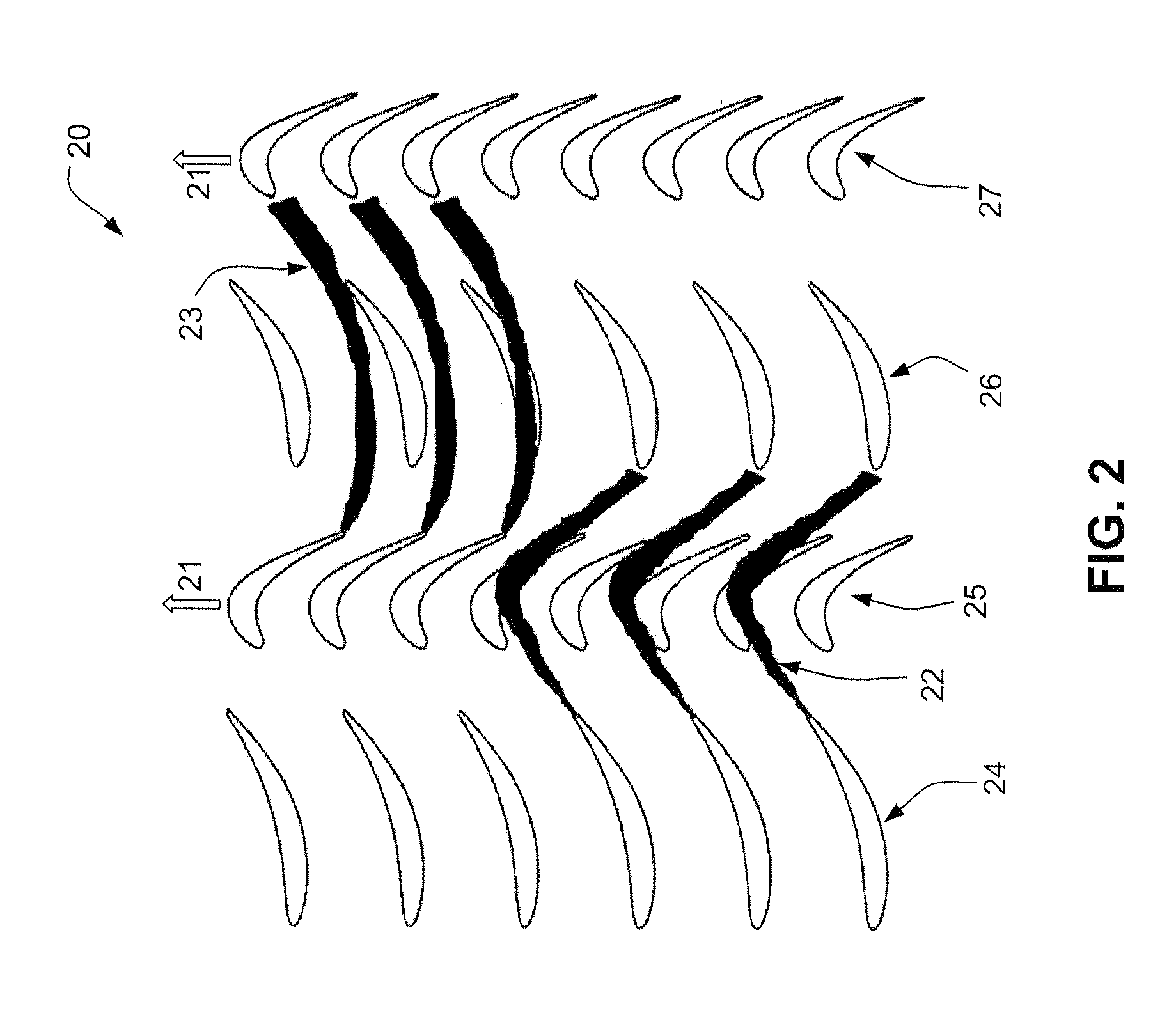

Method of clocking a turbine by reshaping the turbine's downstream airfoils

InactiveUS20140072433A1Reduce the temperatureRaise the potentialBlade accessoriesMachines/enginesLeading edgeTurbine

A method of clocking a turbine is disclosed in which the leading edge of clocked downstream airfoils are bathed by either a low total pressure wake, or a cooled low total temperature wake, or both, by reshaping at least the leading edge of an airfoil along the airfoils' span or radial distance. The improvement is due to the fact that gas turbine wakes tend to be non-linear, such that a straight clocked downstream airfoil will receive a benefit of low total temperature or pressure over a portion of its span, while a restacked airfoil receives a benefit over a greater portion of the airfoil span from turbine hub to casing.

Owner:GENERAL ELECTRIC CO

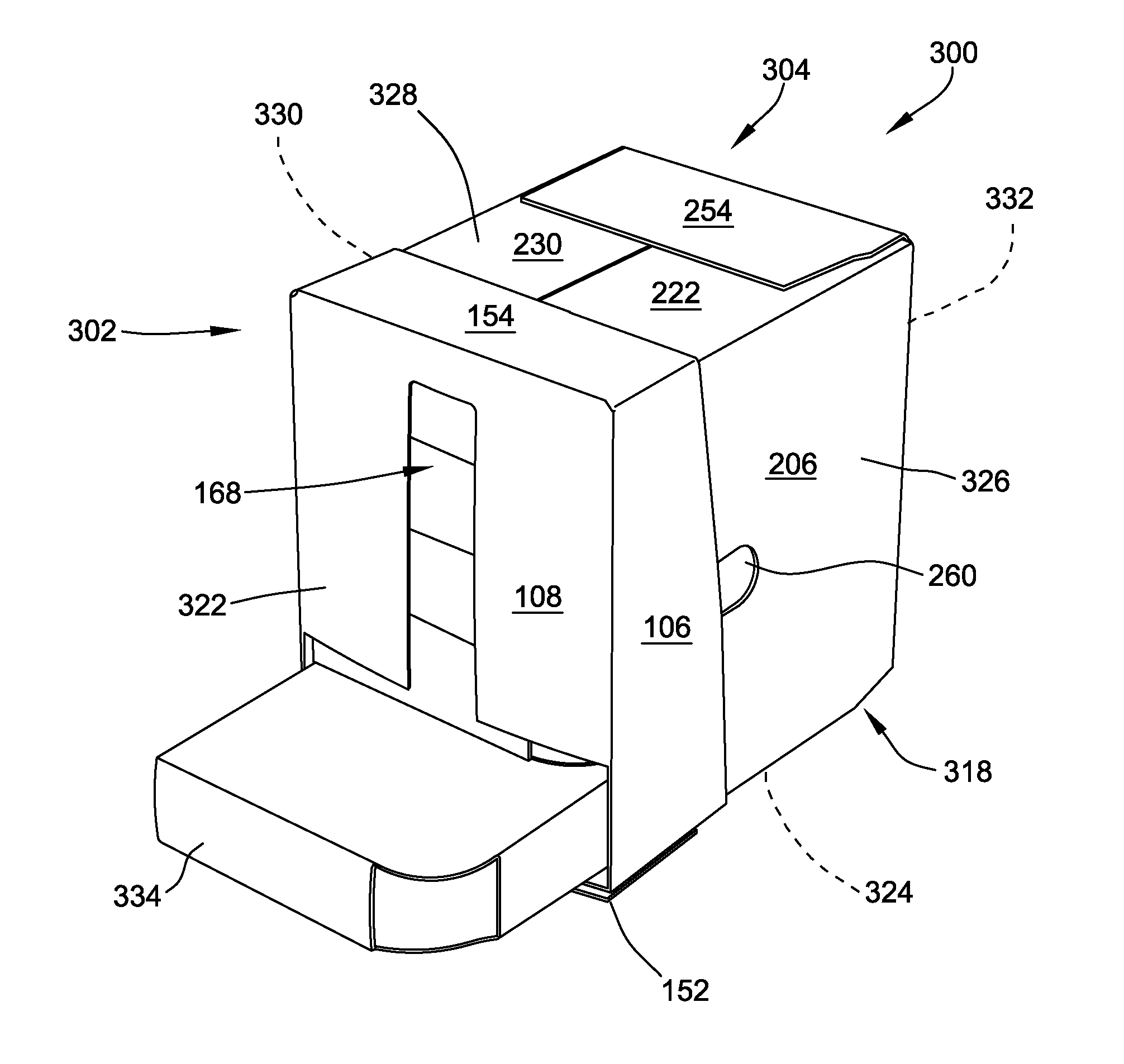

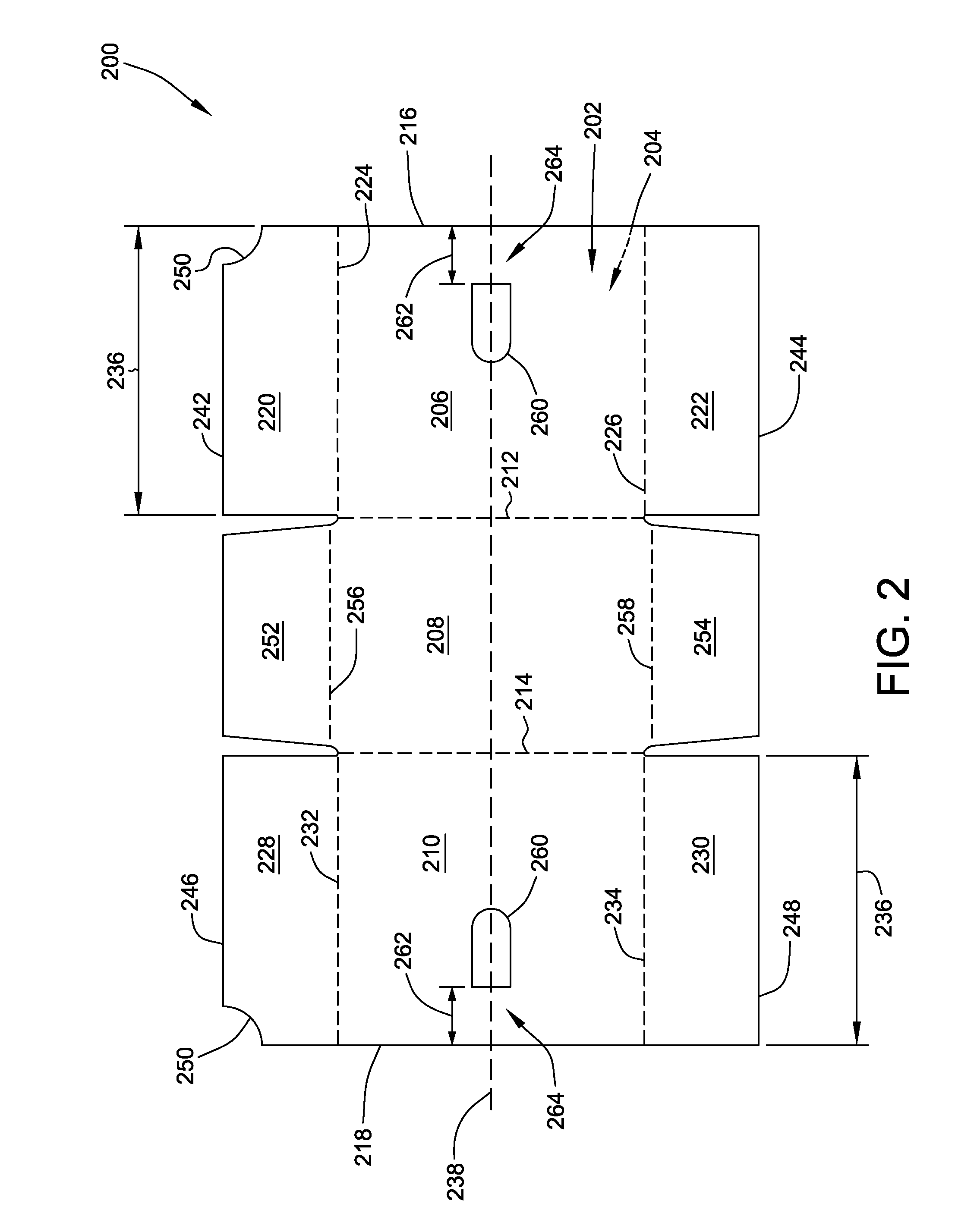

Shipping container convertible into a dispenser container or a display tray

ActiveUS20150203241A1Conveniently removedGood portionContainer/bottle contructionLiquid materialEngineeringShipping container

A convertible shipping container for goods includes a tray portion that includes a first wall. The first wall is configured to be oriented as a front wall of the convertible shipping container in a first display configuration and as a bottom wall of the convertible shipping container in a second display configuration. The convertible shipping container also includes a cover portion removably coupled to the tray portion such that the cover portion is coupled to the tray portion in the first display configuration and is detachable from the tray portion to form the second display configuration.

Owner:WESTROCK SHARED SERVICES LLC

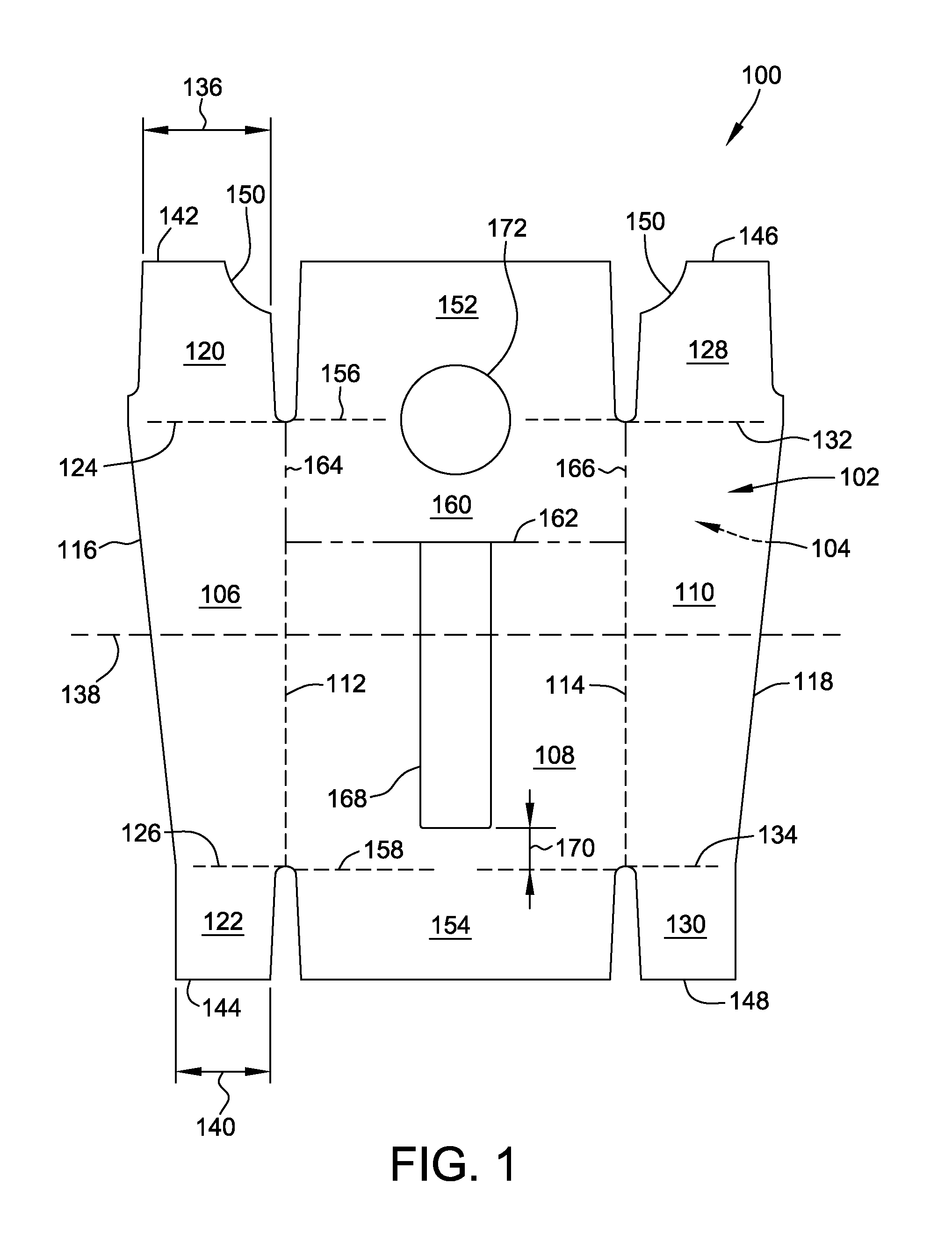

Stator with asymmetric poles and sensor oriented to more accurately determine position of rotor

ActiveUS8432078B2Less sensitiveEfficient powerMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machinePhysics

An electric machine that includes a stator and a Hall-effect sensor. The stator includes a pair of asymmetric poles and the sensor is oriented such that the plane of the sensor is substantially parallel to armature field lines passing through the sensor.

Owner:DYSON TECH LTD

Method and apparatus for efficient transfer of data over a network

ActiveUS20110058494A1Improve network efficiencyEfficient transferSynchronisation arrangementError preventionPropagation delaySpecific time

A method and apparatus for improving the efficiency of a network. A source node determines the propagation delay for data to reach a destination node. This enables the source node to transmit data more efficiently by ensuring a greater portion of a specific time slot is used for receiving data by the destination node. The destination node then determines if it is connected to any other nodes, and determines the propagation delay between the other connected nodes. The process continues until a node detects it is not connected to any other nodes for which a propagation delay has not been computed. Thus, each node on the network knows the propagation delay between each node, and the nodes utilize this information to more efficiently transfer data through the network.

Owner:TRILLIANT NETWORKS

Process and arrangement for covering a flat blank with a cover

InactiveUS20070093371A1Increase angular velocityReduction of angular velocityBoxes/cartons making machineryBookbinding casesCardboardCycle time

Owner:MICHAEL HORAUF MASCHFAB

Method and machine for the production of portions, including means for ejecting said portions

ActiveUS9877491B2Improve productivityGood portionPackaging meatDough homogenization and dividing combinationCompressed fluidEngineering

The invention relates to a method and a device for the production of portions from at least one continuous strand of a food product, in particular for the production of meatballs. The machine comprises: an extrusion device which can deliver a continuous strand in a vertical direction, and a portioning device that includes at least one cutting system. The cutting system comprises cutting elements (30) which can be moved transversely to the vertical direction between an open position, in which the strand passes between the cutting elements, and a closed position for cutting the strand and forming portions of the food product. In addition, each cutting system comprises ejection means (5) for ejecting the forming portions downwards from the cutting elements. The ejection means include at least one lower channel (5, 105) that is fluidly connected to a compressed fluid such that compressed fluid can be injected into the lower channel when the lower channel is in a closed position. The lower channel is formed in a body of the corresponding cutting element.

Owner:MAREL FRANCE

Method for manufacturing organic light-emitting diodes

InactiveUS20050101218A1Reduced luminous efficiencyIncrease energy levelElectroluminescent light sourcesSolid-state devicesHigh energyHole transport layer

A method for manufacturing organic light-emitting diodes (OLEDs) is disclosed, by adding nitrogen (N2) into the material of a hole transport layer (HTL) and evaporating the nitrogen and the material of the hole transport layer while growing the hole transport layer, so as to dope nitrogen molecules into the hole transport layer. In the hole transport layer, the nitrogen molecules are impurities of higher energy level, and are used to catch holes while the holes transports and trap the holes in the hole transport layer, thereby obtaining an object of improving the luminance efficiency of the organic light-emitting diodes with lower cost.

Owner:NAT CHENG KUNG UNIV

Regulation of bcl-2 gene expression

InactiveUS20050170377A1Growth inhibitionHigh sensitivitySugar derivativesGenetic material ingredientsCancer cellOligomer

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com