Break away spline misalignment coupling

a coupling and spline technology, applied in the field of torque drives, can solve the problems of breaking away from the coupling, and limiting the side load and wear that occurs, and achieve the effect of no negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]A description of example embodiments of the invention follows.

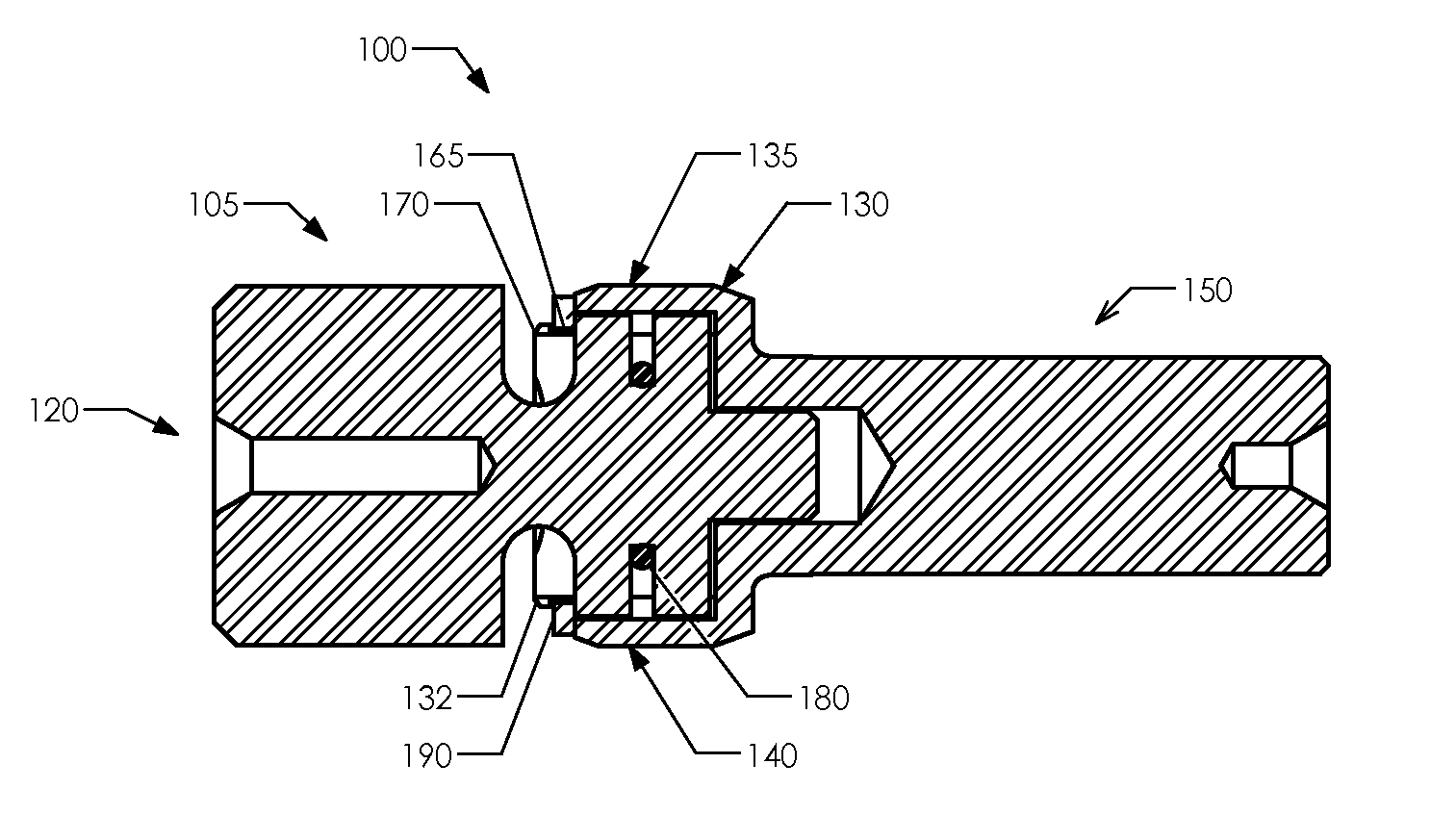

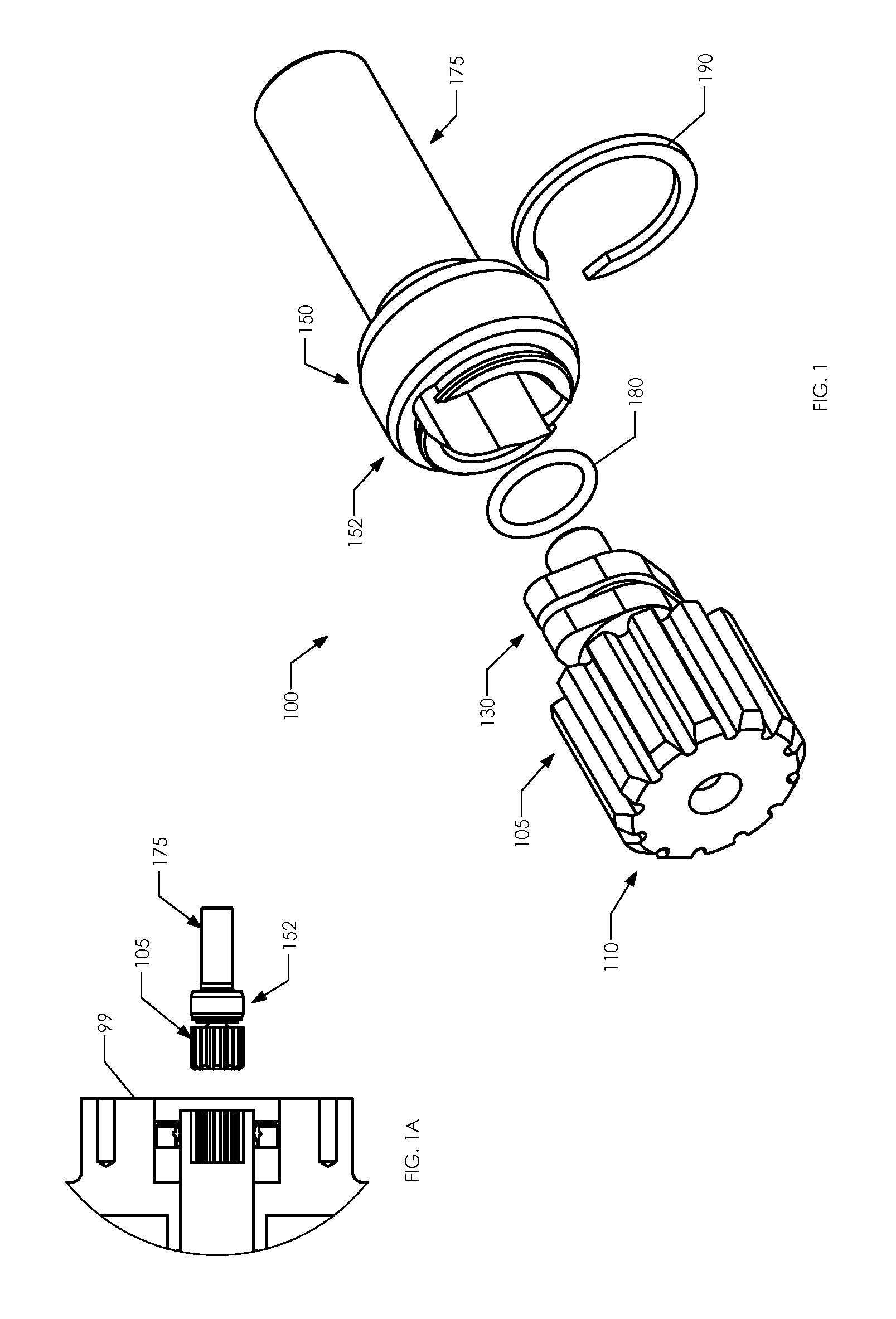

[0025]FIG. 1 is a perspective diagram of a torque-limiting coupling 100 in a disassembled state, comprising a break away spline coupler 105 and a break away spline receiver 150. The break away spline coupler 105 comprises a spline end 110 and a lobe end 130. The break away spline receiver 150 comprises a receiver end 152 and a shaft end 175. In its assembled state, discussed below with reference to FIGS. 4A-4D, the assembled coupler 100 further includes an o-ring 180 and a retaining ring 190.

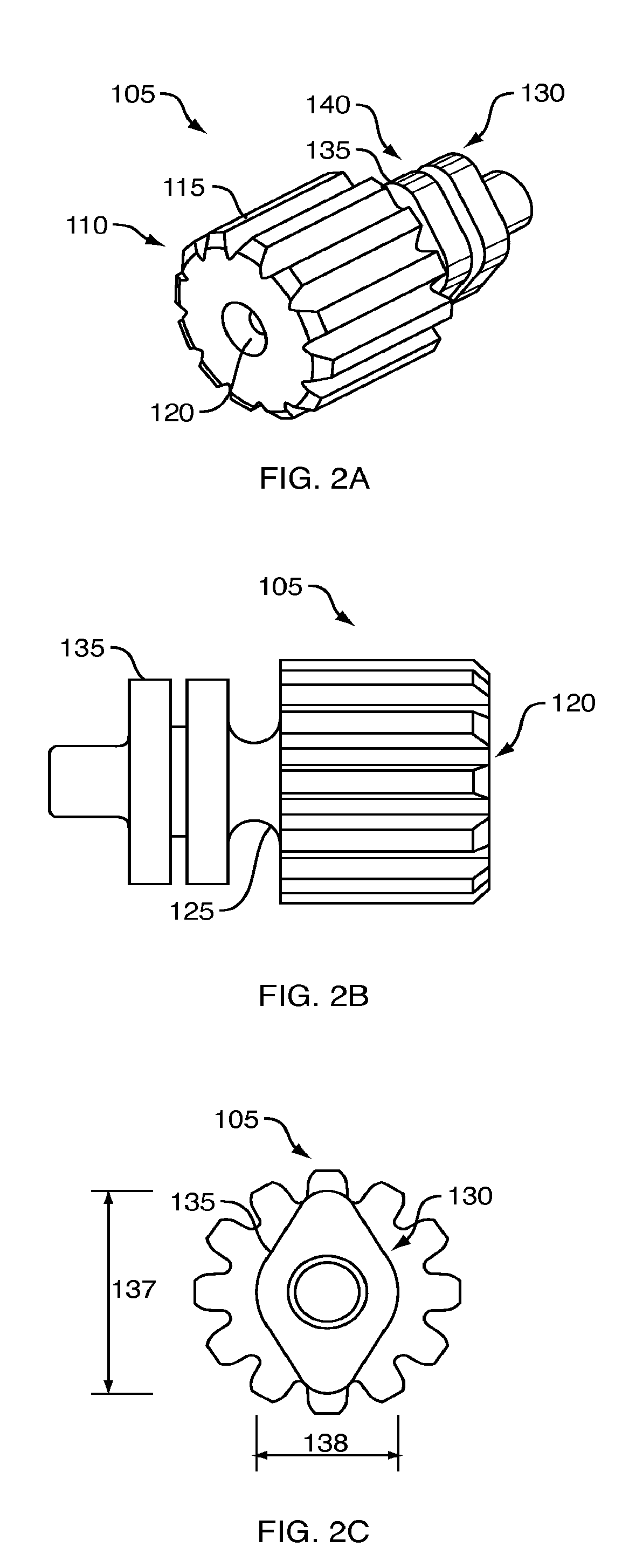

[0026]FIGS. 2A-2F illustrate several views of the break away spline coupler 105 of FIG. 1.

[0027]FIG. 2A is a perspective diagram of the break away spline coupler 105 of FIG. 1. The break away spline coupler 105 comprises a spline end 110 and a lobe end 130. The spline end 110 includes a plurality of longitudinally extending circumferentially spaced splines 115 and is configured to be mated coaxially to a transmission output of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking torque | aaaaa | aaaaa |

| shear stresses | aaaaa | aaaaa |

| cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com