A kind of preparation method of reconstituted tobacco leaf coating liquid

A technology for reconstituted tobacco leaves and coating solution, which is applied in the preparation of tobacco, tobacco, and tobacco treatment, etc. It can solve the problems of affecting the application effect of coating solution, insufficient fragrance of coating solution, single aroma of coating solution, etc., and achieve good physical Adsorption performance and stability, improvement of fine fiber retention rate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

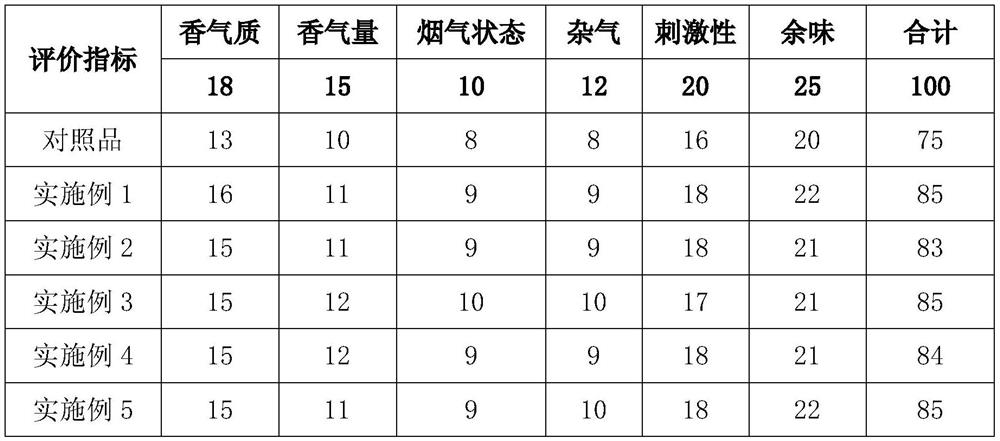

Examples

Embodiment 1

[0021] A kind of preparation method of reconstituted tobacco leaf coating liquid provided in embodiment 1 is characterized in that concrete steps comprise:

[0022] (1) Add 15 times of tap water to the mixture of tobacco stems, tobacco powder and secondary tobacco leaves, and after mixing evenly, conduct dynamic countercurrent extraction at 40°C for 1.2 hours, and obtain insoluble slurry and extract after the extraction is completed;

[0023] (2) Utilize the 300nm aperture inorganic ceramic filter membrane to filter the extract to obtain filtrate A and retentate A;

[0024] (3) Use potassium dihydrogen phosphate to adjust the pH value of the retentate A to 4.5, and add 0.6% glucosidase to the retentate A after adjusting the pH value, place it at 75° C., and perform enzymatic hydrolysis for 60 minutes;

[0025] (4) add its weight 6% chitosan aqueous solution (chitosan content is 7.0% in its chitosan aqueous solution) to the enzymolysis solution that step (3) obtains, stir and m...

Embodiment 2

[0029] A kind of preparation method of reconstituted tobacco leaf coating liquid provided in embodiment 2 is characterized in that concrete steps comprise:

[0030] (1) Add 9 times of tap water to the mixture of tobacco stems, tobacco powder and secondary tobacco leaves, and after mixing evenly, conduct dynamic countercurrent extraction at 55°C for 0.5h, and obtain insoluble slurry and extract after the extraction is completed;

[0031] (2) Utilize the 300nm aperture inorganic ceramic filter membrane to filter the extract to obtain filtrate A and retentate A;

[0032] (3) Use potassium dihydrogen phosphate to adjust the pH value of the retentate A to 6.1, and add 1.2% glucosidase to the retentate A after adjusting the pH value, place it at 58° C., and perform enzymatic hydrolysis for 50 minutes;

[0033] (4) add its weight 10% chitosan aqueous solution (chitosan content is 4.5% in its chitosan aqueous solution) in the enzymolysis solution that step (3) obtains, stir and mix, l...

Embodiment 3

[0037] Embodiment 3, a kind of preparation method of reconstituted tobacco leaf coating liquid is characterized in that concrete steps comprise:

[0038] (1) Add 7 times of tap water to the mixture of tobacco stems, tobacco powder and secondary tobacco leaves, and after mixing evenly, conduct dynamic countercurrent extraction at 65°C for 1.2 hours, and obtain insoluble slurry and extract after the extraction is completed;

[0039](2) Utilize the 300nm aperture inorganic ceramic filter membrane to filter the extract to obtain filtrate A and retentate A;

[0040] (3) Use potassium dihydrogen phosphate to adjust the pH value of the retentate A to 5.3, and add 0.9% glucosidase to the retentate A after adjusting the pH value, place it at 60° C., and perform enzymatic hydrolysis for 45 minutes;

[0041] (4) add its weight 12% chitosan aqueous solution (chitosan content is 3.5% in its chitosan aqueous solution) in the enzymolysis solution that step (3) obtains, stir and mix, leave st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com