A cleaning agent for coking and carbon deposits in wood-based panel equipment

A carbon deposit cleaning agent and wood-based panel technology, which is applied in the field of cleaning agents, can solve the problems of cleaning method wear, coking of wood-based panel equipment, coking and carbon deposits are difficult to clean, and harmful to human body, etc., to achieve good permeability, excellent cleaning effect, alkali Sexually low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 437.5g of phenylene 50# base oil, 2.5g of oleic acid diethanolamide, 25g of isopropanolamide, 25g of ethylenediamine oleate, 5g of polyisobutylene succinimide (T154), 5g of ultra-high base number sulfonate Calcium acid calcium (T106D) 5g, stir at room temperature, and institute's cleaning agent solution is turbid state, and this cleaning agent is recorded as: embodiment 1

[0038] Add the prepared cleaning agent solution into the container, then soak the piercing needle numbered b in the container, and then carry out the cleaning test in an oven at 80°C for 6 hours, and observe the layering of the cleaning agent solution at the 3rd hour , assisted stirring to make it evenly mixed again. After the test, take out the needle b, and then wipe it with a paper towel to observe the removal effect of coking and carbon deposits.

Embodiment 2

[0040] Weigh 437.5g of phenylene 50# base oil, 2.5g of oleic acid diethanolamide, 15g of isopropanolamide, 35g of ethylenediamine oleate, 5g of polyisobutylene succinimide (T154), and ultra-high base number sulfonate Calcium acid calcium (T106D) 5g, stir at room temperature, and institute's cleaning agent solution is turbid state, and this cleaning agent is recorded as: embodiment 2

[0041] Add the prepared cleaning agent solution into the container, then soak the piercing needle numbered c in the container, and then carry out the cleaning test in an oven at 80°C for 6 hours, and observe the layering of the cleaning agent solution at the 3rd hour , assisted stirring to make it evenly mixed again. After the test, take out the needle c, and then wipe it with a paper towel to observe the removal effect of coking and carbon deposits.

Embodiment 3

[0043]Weigh 437.5g of phenylene 50# base oil, 2.5g of oleic acid diethanolamide, 35g of isopropanolamide, 15g of ethylenediamine oleate, 5g of polyisobutylene succinimide (T154), ultra-high base number sulfonate Calcium acid calcium (T106D) 5g, stir at room temperature, and gained cleaning agent solution is turbid state, and this cleaning agent is recorded as: embodiment 3

[0044] Add the prepared cleaning agent solution into the container, then soak the piercing needle numbered d in the container, and then carry out the cleaning test in an oven at 80°C for 6 hours, and observe the layering of the cleaning agent solution at the 3rd hour , assisted stirring to make it evenly mixed again. After the test, take out the needle d, and then wipe it with a paper towel to observe the removal effect of coking and carbon deposits.

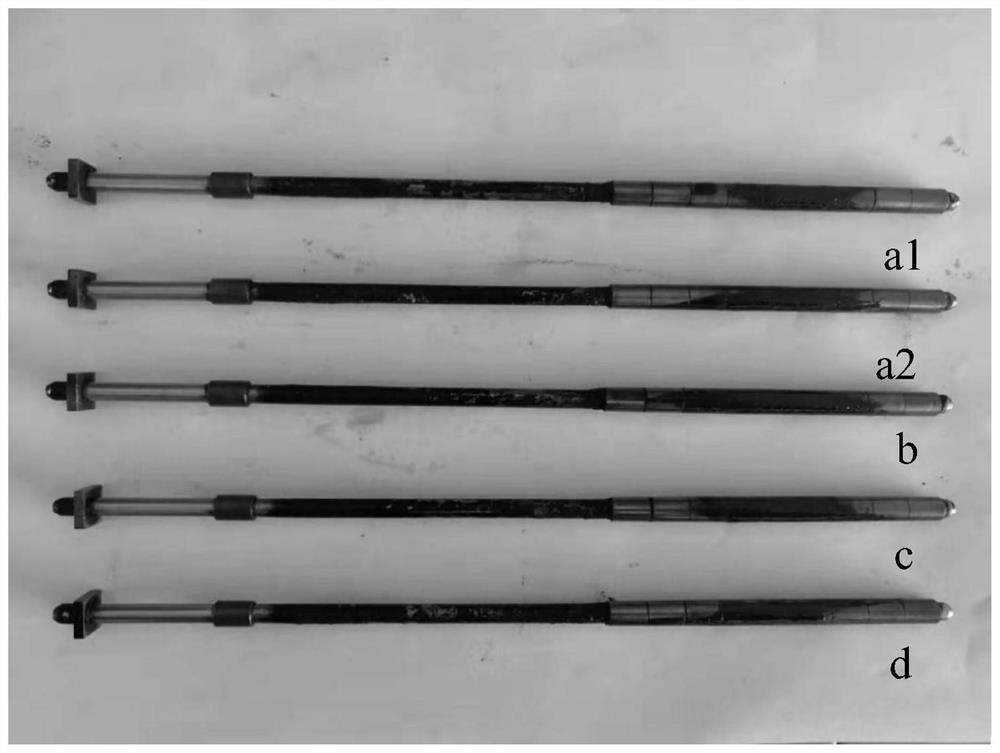

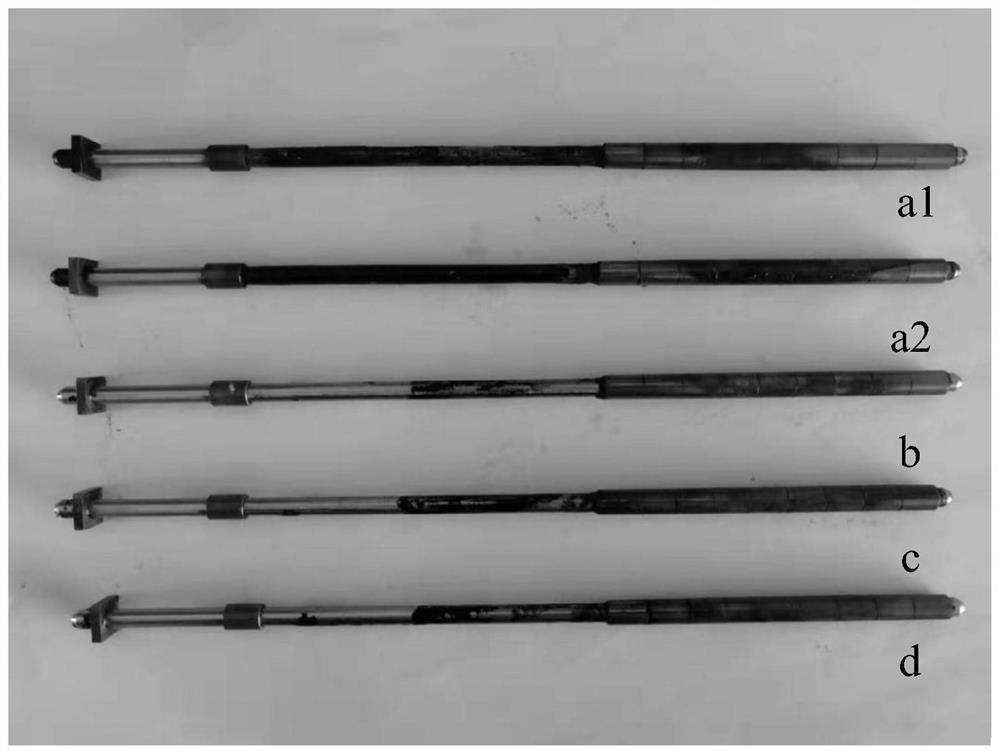

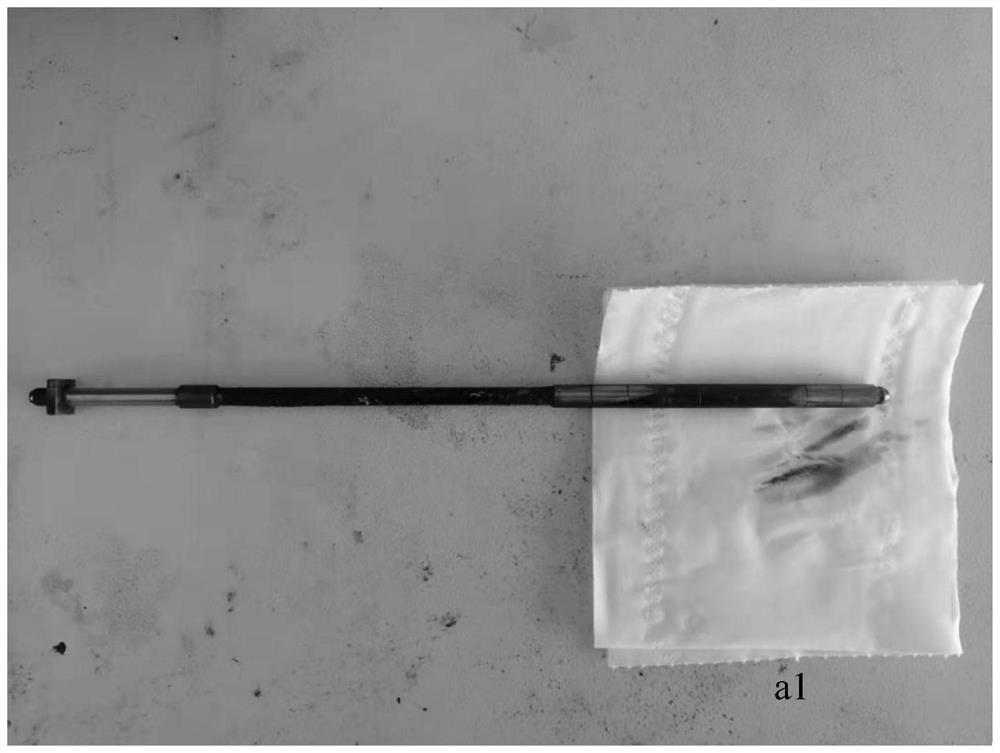

[0045] Cleaning Test Results: Observations figure 1 and figure 2 It can be seen that after 6 hours of immersion, the coke and carbon deposits on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com