Heat dissipation structure for light bulb assembly

a technology for heat dissipation structure and light bulb, which is applied in the direction of discharge tube main electrodes, light and heating apparatus, semiconductor devices of light sources, etc., can solve the problems of high power and energy consumption, short service life, and difficulty in heat dissipation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

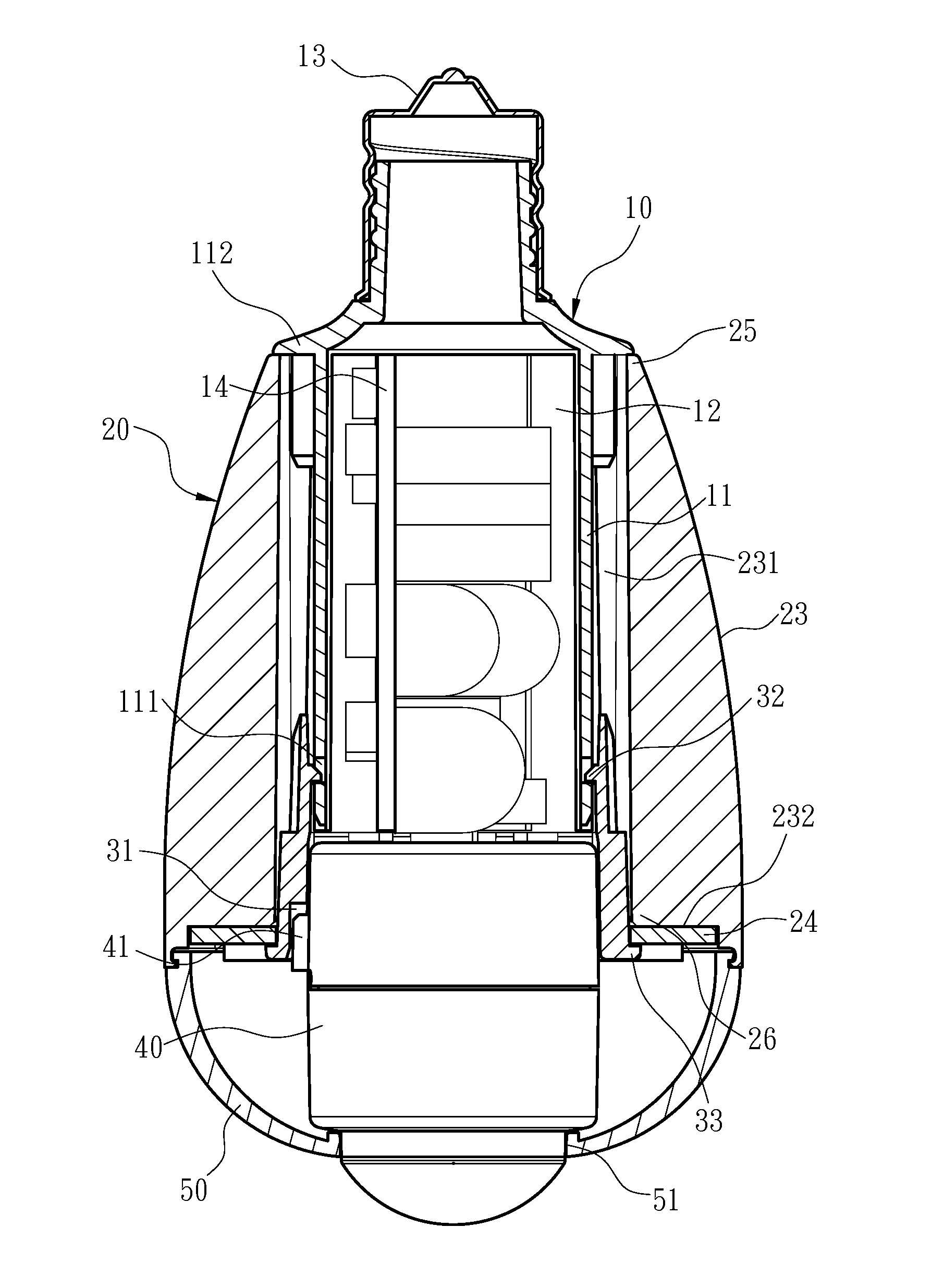

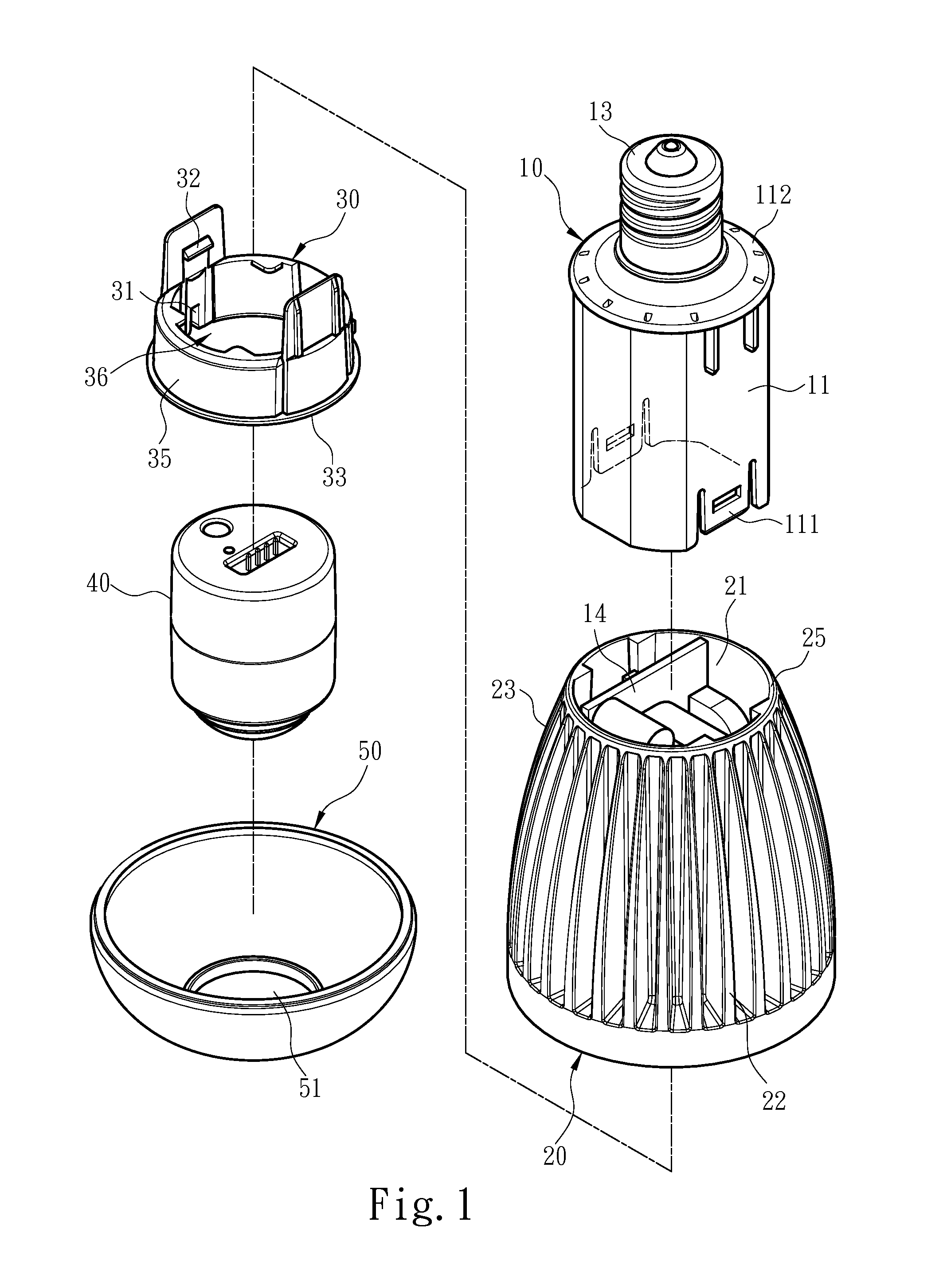

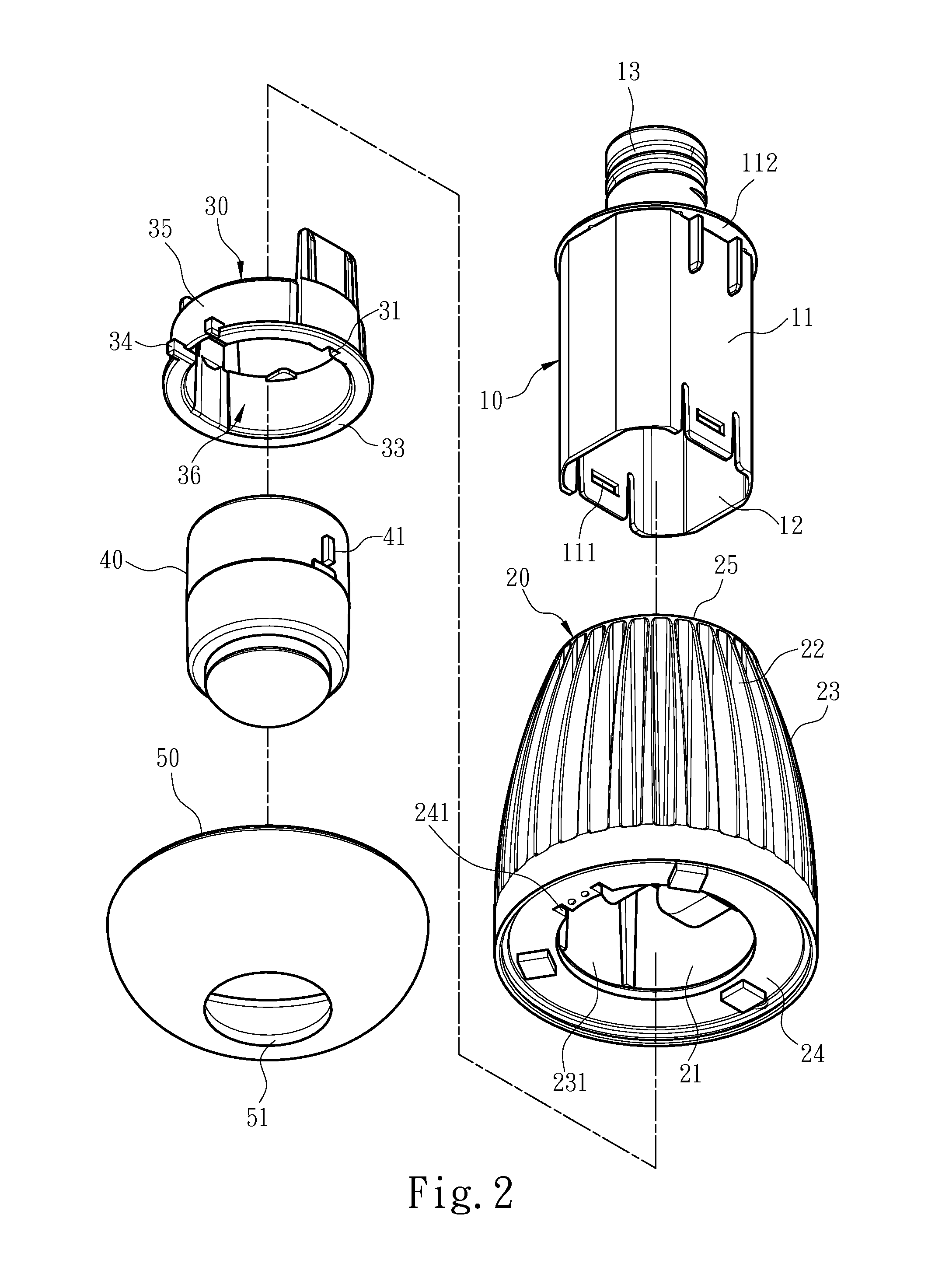

[0023]FIGS. 1 and 2 are a perspective view showing the exploded components of a heat dissipation structure for a light bulb assembly according to the present invention. As shown in FIGS. 1 and 2, the heat dissipation structure for the light bulb assembly of the present invention comprises a holder 10, a heat dissipating cover 20 fitted on an outer peripheral side of the holder 10, and a light seat 30 connected to the holder 10. The holder 10 includes a metal connector 13 (i.e., a main connector) electrically connected thereon to obtain an external power, a socket 11 connected with the metal connector 13, and a receiving space 12 defined in the socket 11 to receive a circuit board 14. One end of the socket 11 is connected with the light seat 30, and the light seat 30 is used for installing a LED light 40. The LED light 40 is electrically connected to the circuit board 14. Thereby, the LED light 40 allows to obtain an external power source processed by the circuit board 14.

[0024]The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com