Multilevel cascade voltage source inverter with seperate DC sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

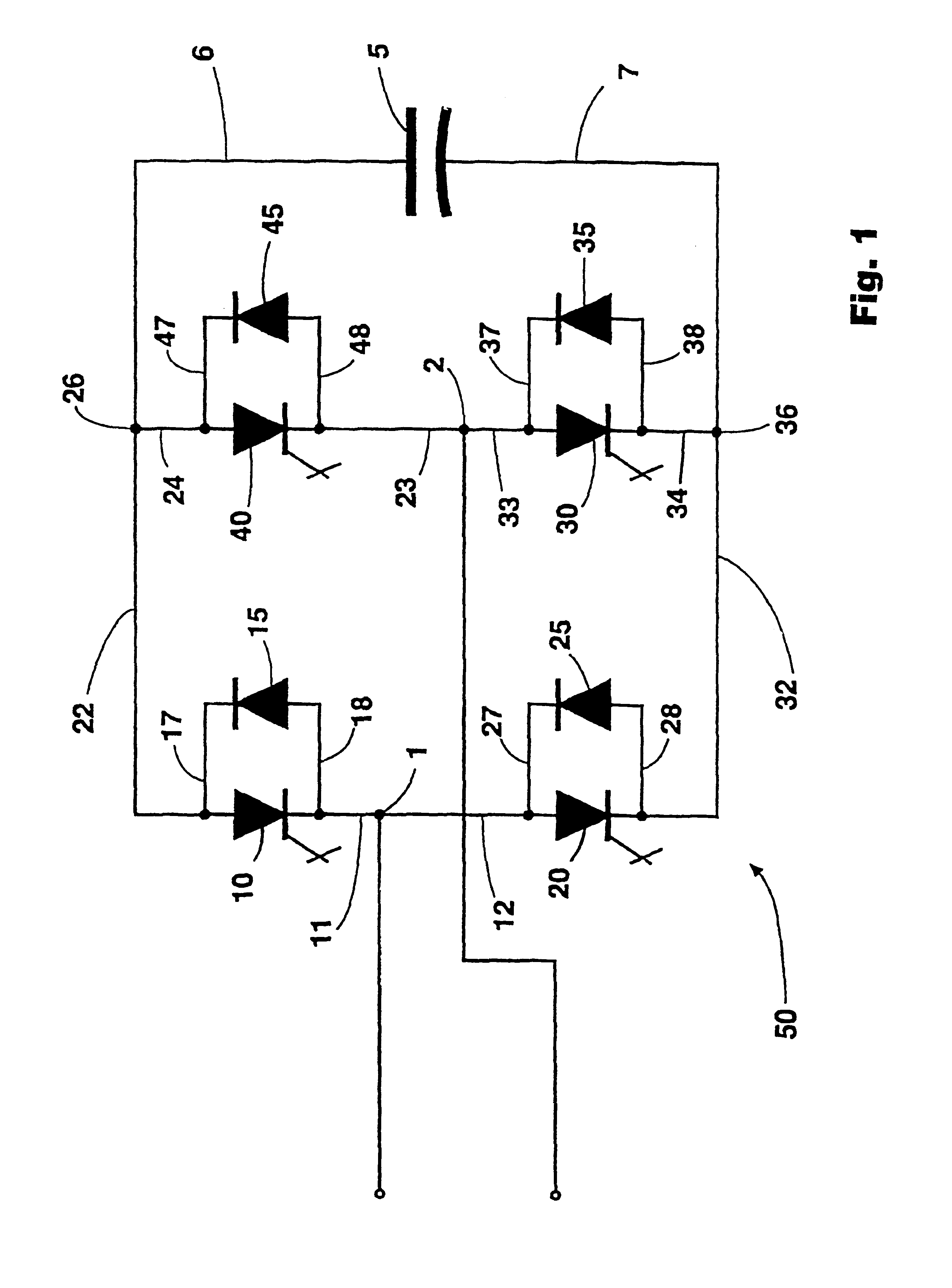

SINGLE-PHASE EMBODIMENT

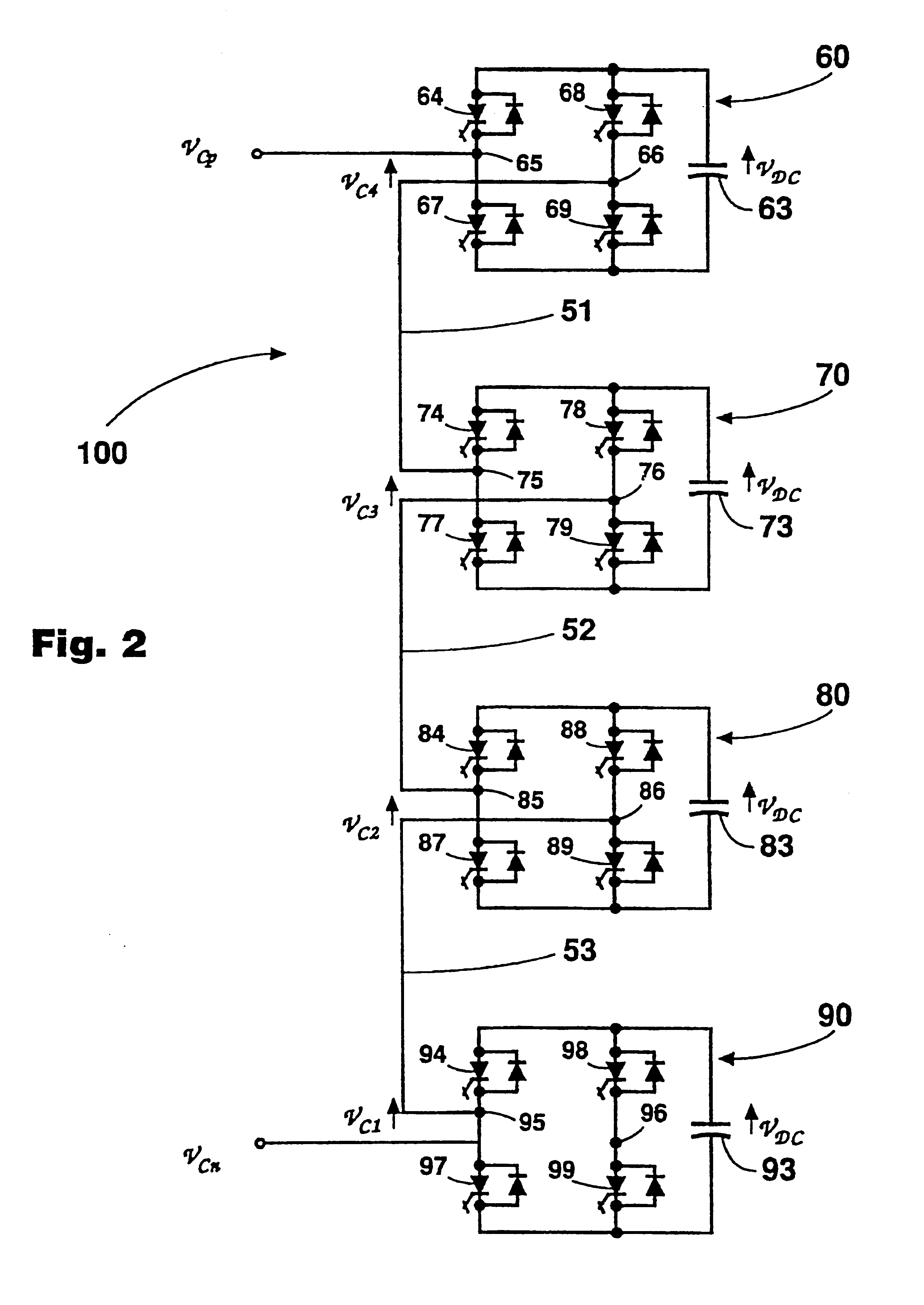

FIG. 2 shows the single-phase embodiment 100 of the multilevel cascade inverter having separate DC voltage sources. The single-phase embodiment 100 comprises n FBI units 60, 70, 80 and 90 wherein n is determined by: ##EQU1##

wherein M is the number of output voltage levels generated by the multilevel cascade inverter during a half fundamental cycle.

FBI units 60 and 70 are interconnected between primary node 75 and secondary node 66 by conductor 51. FBI units 70 and 80 are interconnected between primary node 85 and secondary node 76 by conductor 52. FBI units 80 and 90 are interconnected between primary node 95 and secondary node 86 by conductor 53. The primary node 65 of the first FBI unit 60 in the multilevel cascade inverter functions as the output of the cascade inverter single-phase embodiment 100. The secondary node 96 of the last FBI unit 90 in the multilevel cascade inverter functions as the reference of the cascade inverter single-phase embodiment 100. ...

example

An SVG system using the delta connected embodiment of a 21-level cascade inverter having 10 FBI units per phase is connected directly to a 13 kV distribution system. The SVG capacity is .+-.50 MVAR. I.sub.SVG =2.22 kA, I=1.282 kA, L.sub.C =3%, MI.sub.min =0.6385, MI.sub.max =0.8054, V.sub.dc =2 kV and .epsilon.=.+-.5%. At the rated load of +50 MVAR, [.theta..sub.1, .theta..sub.2. . . .theta..sub.i ]=[0.0334, 0.1840, 0.2491, 0.3469, 0.4275, 0.5381, 0.6692, 0.8539, 0.9840, 1.1613] rad. For this SVG system, the total required capacitance of DC capacitors can be calculated as C=370 mF. The required capacitance for a comparable conventional multipulse inverter will be C.sub.dc =332 mF. Therefore, the ratio C / C.sub.dc approached unity at 1.11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com