Dynamic orthopedic knee brace assembly

a knee brace and dynamic technology, applied in the field of dynamic knee brace assembly, can solve the problems of inability to prevent anterior translation of the tibia, and achieve the effects of simple construction, low manufacturing cost, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

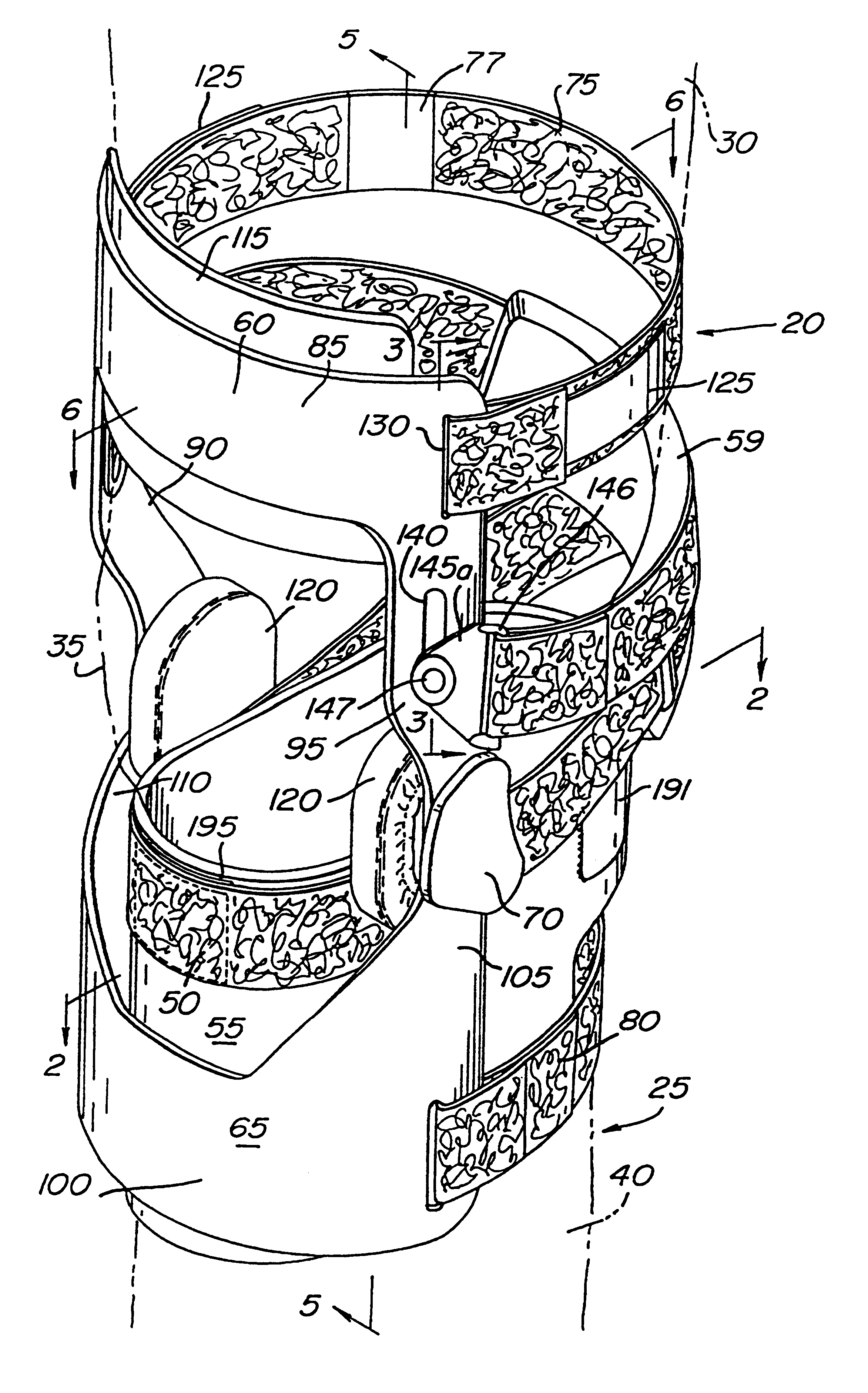

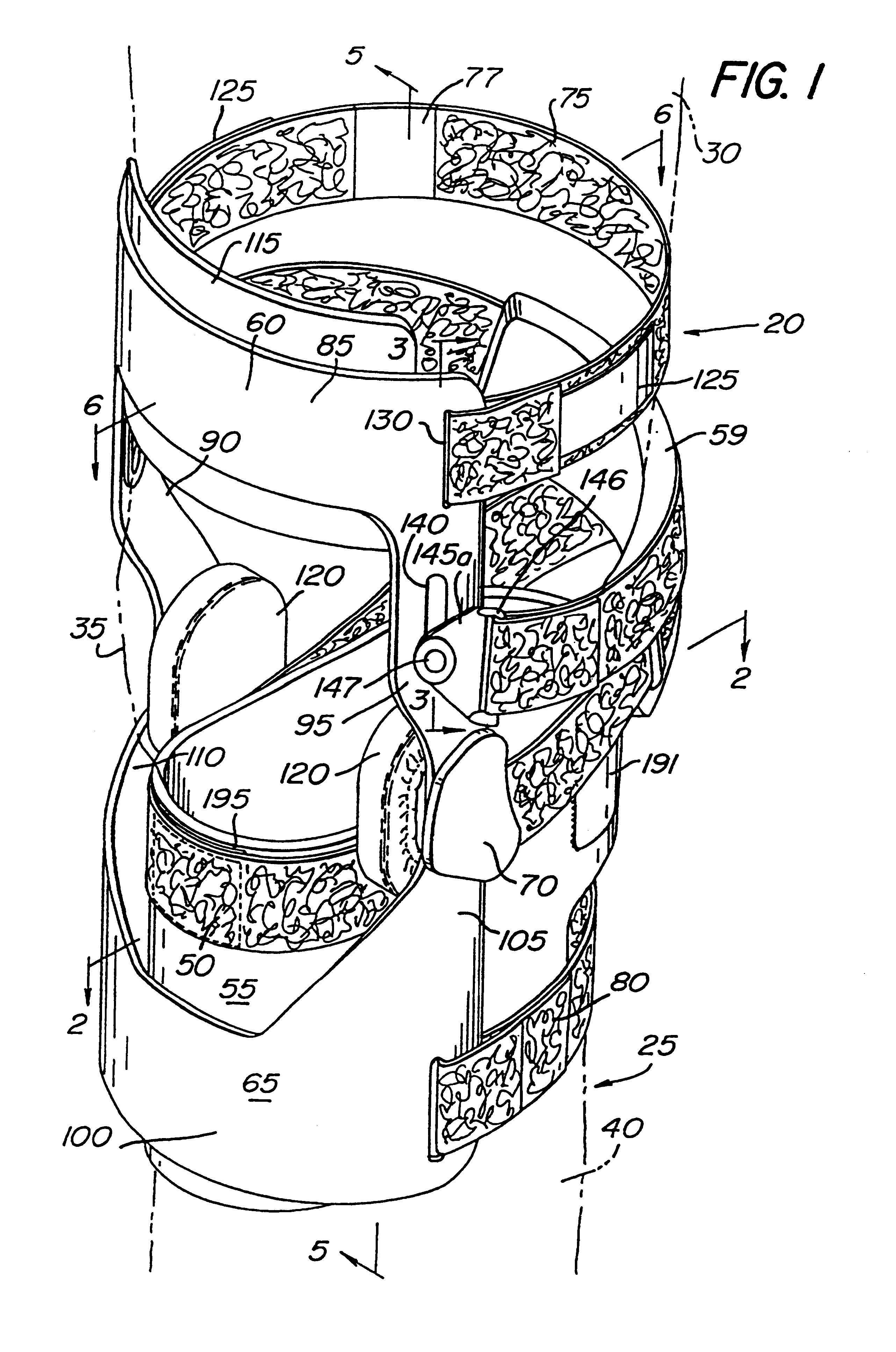

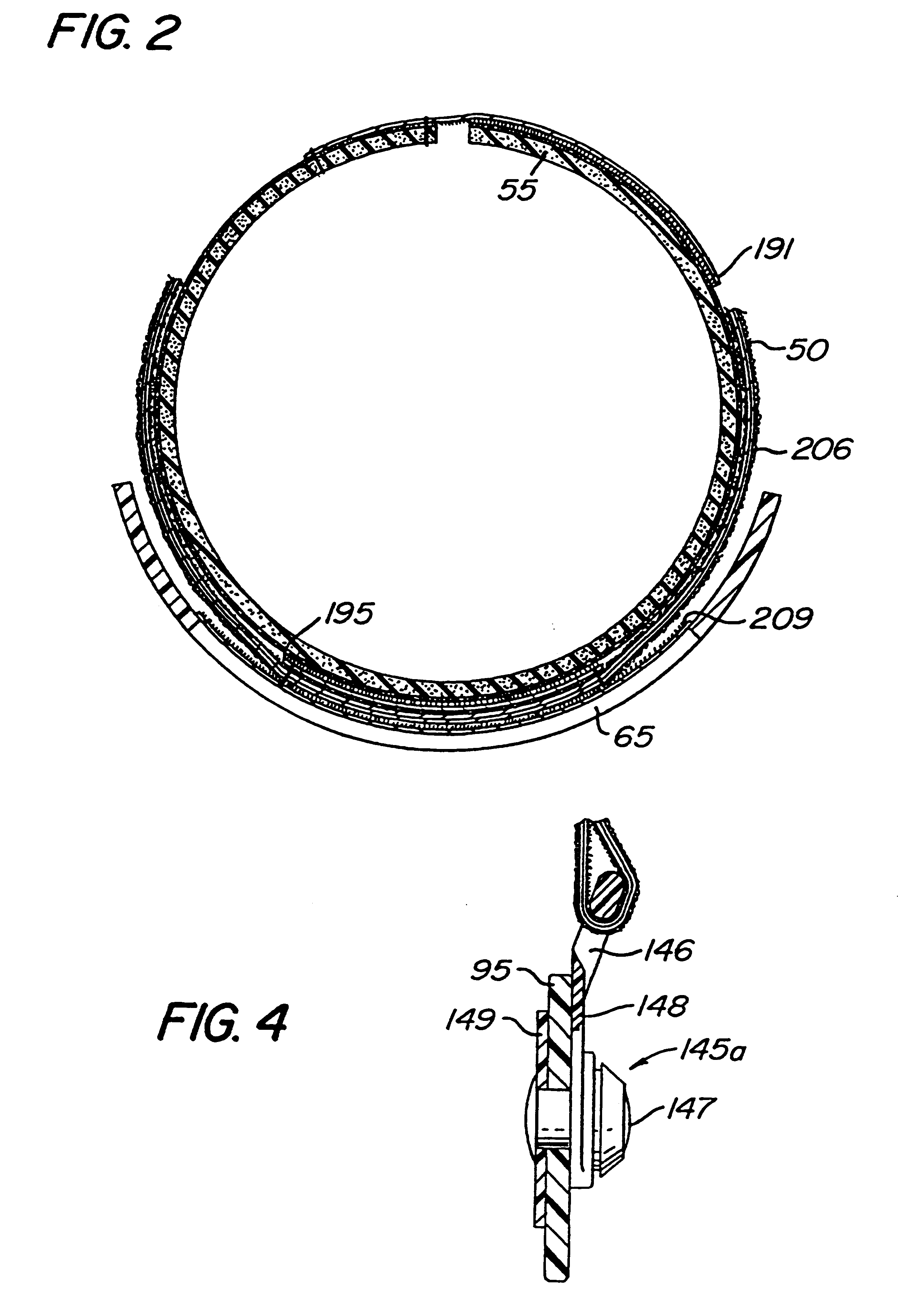

Referring now in greater detail to the various figures of the drawings wherein like reference numerals refer to like parts there is shown at 20 in FIGS. 1, 5 and 7 the dynamic orthopedic knee brace assembly of the present invention. As shown in FIGS. 1 and 5, the knee brace assembly 20 is shown attached to a human left leg 25 (shown in phantom) having a thigh portion 30, a knee 35 and leg portion below the knee 40. The left leg 25 is chosen for convenience only and the brace assembly 20 can be affixed to either the right or left leg. Generally speaking, the knee brace assembly 20 functions to counteract anterior shifting of the tibia when the anterior cruciate ligament in the illustrated leg is missing or damaged. Such anterior shifting of the tibia occurs for a variety of reasons and often occurs when a person is engaging in physical activities that involve sudden turning to the right or to the left, sudden stopping, jumping, running backwards or other types of movement. Where the ...

second embodiment

Referring now to FIGS. 8 and 14, there is shown at 300 the dynamic orthopedic knee brace assembly of the present invention. As best shown in FIG. 14, the knee brace assembly 300 shown therein comprises three basic parts: a bracing component 305, a cross-strap 310 and a sleeve 315. The knee brace assembly 300 functions to counteract anterior shifting of the tibia that can occur during physical activities that involve sudden turning to the right or left, sudden stopping, jumping or running backwards when the anterior cruciate ligament in the illustrated leg is missing or damaged.

As best shown in FIGS. 8 and 14, the bracing component 305 comprises a pair of elongated rigid thigh support members 320 and 325 extending along medial and lateral sides of the thigh, respectively, and a pair of elongated rigid lower leg support members 330 and 335 extending along the medial and lateral sides of the wearer's leg portion below the knee, respectively. The inner ends of the thigh and lower leg su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com