Collectorless direct current motor, driver circuit for a drive and method of operating a collectorless direct current motor

a driver circuit and direct current motor technology, applied in the direction of motor/generator/converter stopper, dynamo-electric converter control, instruments, etc., can solve the problems of impediment to the integration of components and a large amount of additional power loss, and achieve the effect of low power loss in the components and constant operating voltag

Inactive Publication Date: 2002-03-19

PAPST MOTOREN GMBH & CO KG

View PDF37 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

It is an object of the invention to make available a driver circuit for a collectorless direct current motor so as to permit changes in output power and number of revolutions with small amounts of circuitry and at a constant operating voltage; power losses in

Problems solved by technology

Although this does not produce any additional high frequency fields which could interfere with the devices to be ventilated and such a regulation does not produce any additional noise, a cons

Method used

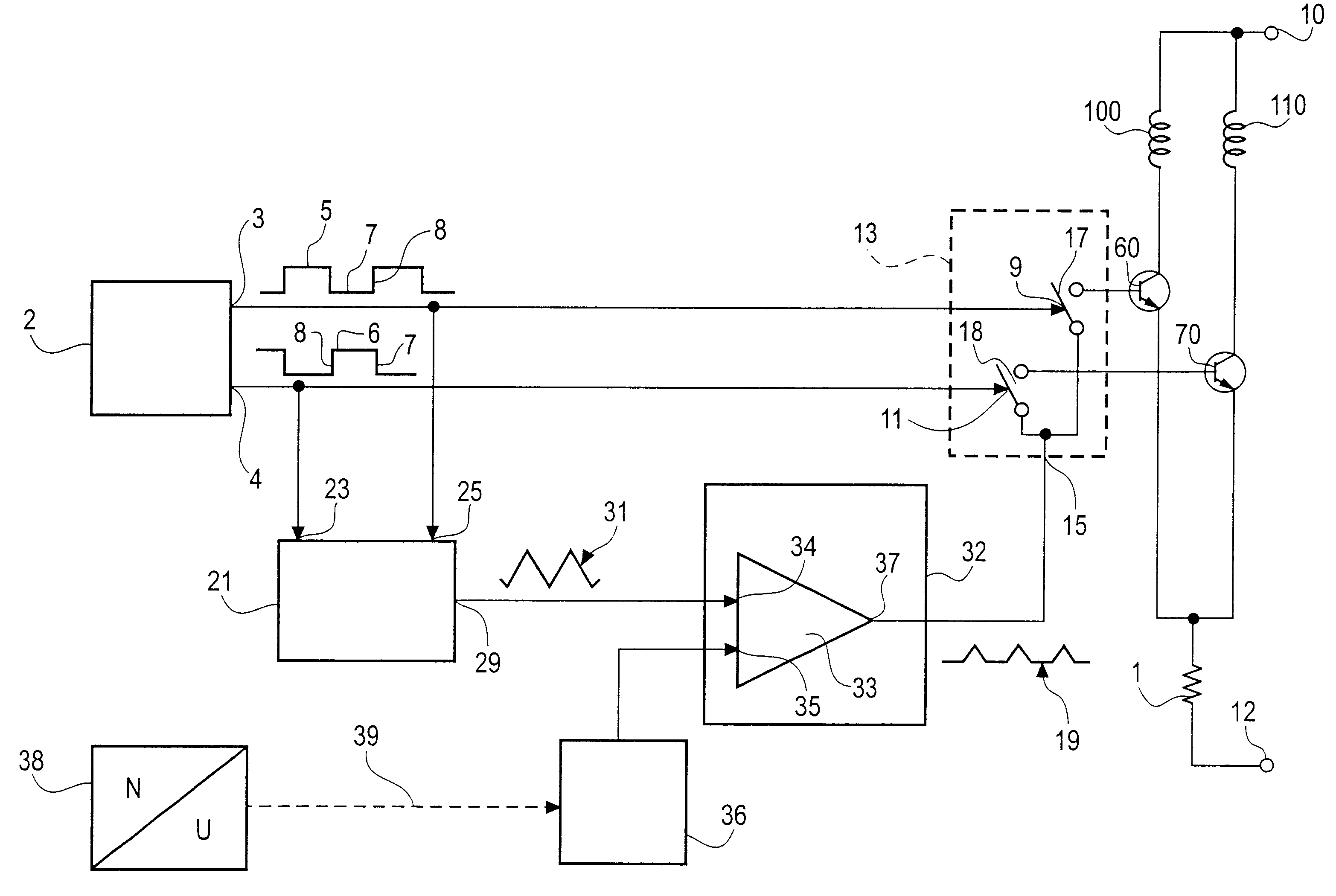

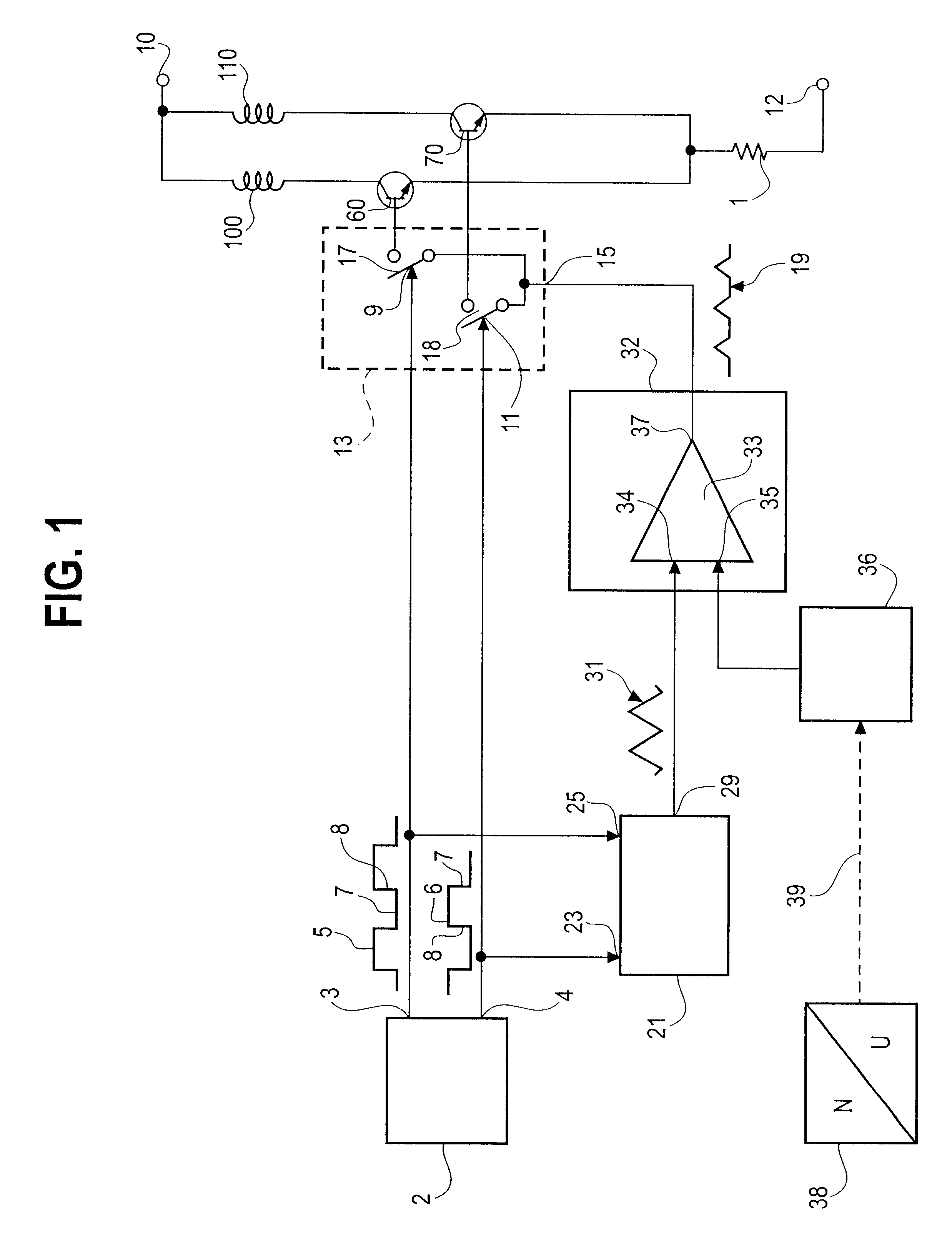

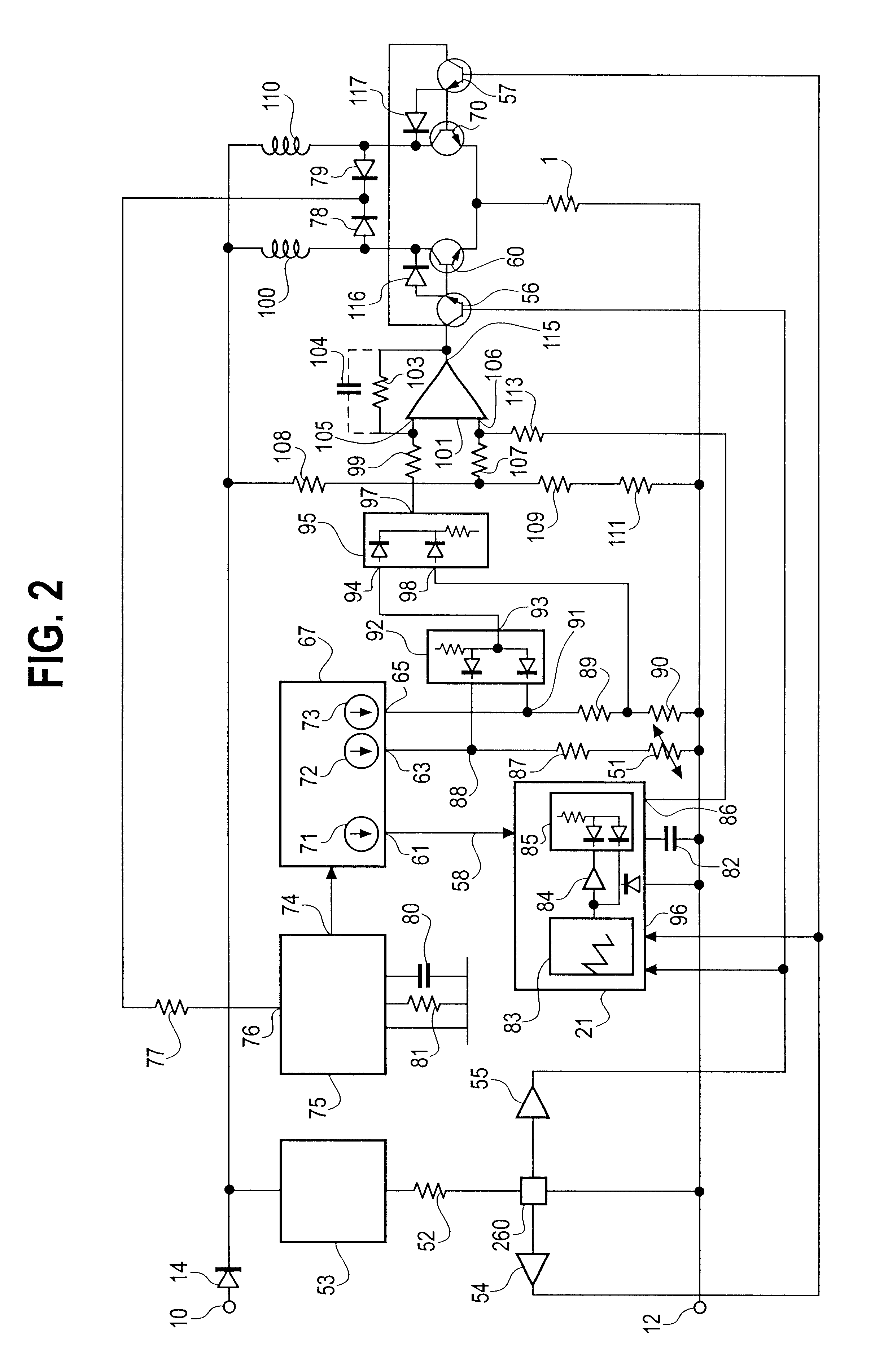

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

A method for the low-loss regulation of a collectorless direct current motor and a semiconductor circuit has, during the commutation phase given by a position sensor and with reduced motor output and number of revolutions, transistors or one end transistor which initially operates temporarily as a switch and thereafter operates temporarily as an analog amplifier element. During the analog period, a current is available which changes slowly according to a ramp function.

Description

BACKGROUND OF THE INVENTIONThe present invention relates to a collectorless direct current motor equipped with a fan or for driving a fan and including a permanent magnet rotor in the field of at least one stator winding and to a method of operating such a motor. In particular, the invention relates to a driver circuit for a collectorless direct current motor including a permanent magnet rotor having at least two poles and at least one stator winding connected to the driver circuit end stage which temporarily operates as a switch and a sensor detecting the position of the rotor, with the control signal fed to the end stage during each commutation phase causing the current in the stator winding to have a ramp-shaped configuration.Such a driver circuit is disclosed in No. DE-OS 3,107,623 and includes an RC member with the aid of which rectangular signals are reshaped to control the direct current motor in order to reduce the steepness of their edges, thus reducing the winding noise of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H02P6/08G05D23/24H02P6/00H02P6/14

CPCG05D23/1913G05D23/24H02P6/08H02P6/14H02P6/34

Inventor MUELLER, ROLF

Owner PAPST MOTOREN GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com