Attachable electro-impulse de-icer

a technology of electro-impulse de-icer and attached coil, which is applied in the direction of de-icing equipment, aircraft components, transportation and packaging, etc., can solve the problems of accumulating ice on aircraft wings and other structural members in flight, affecting the effect of ice-shedding action, and affecting the effect of ice-shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

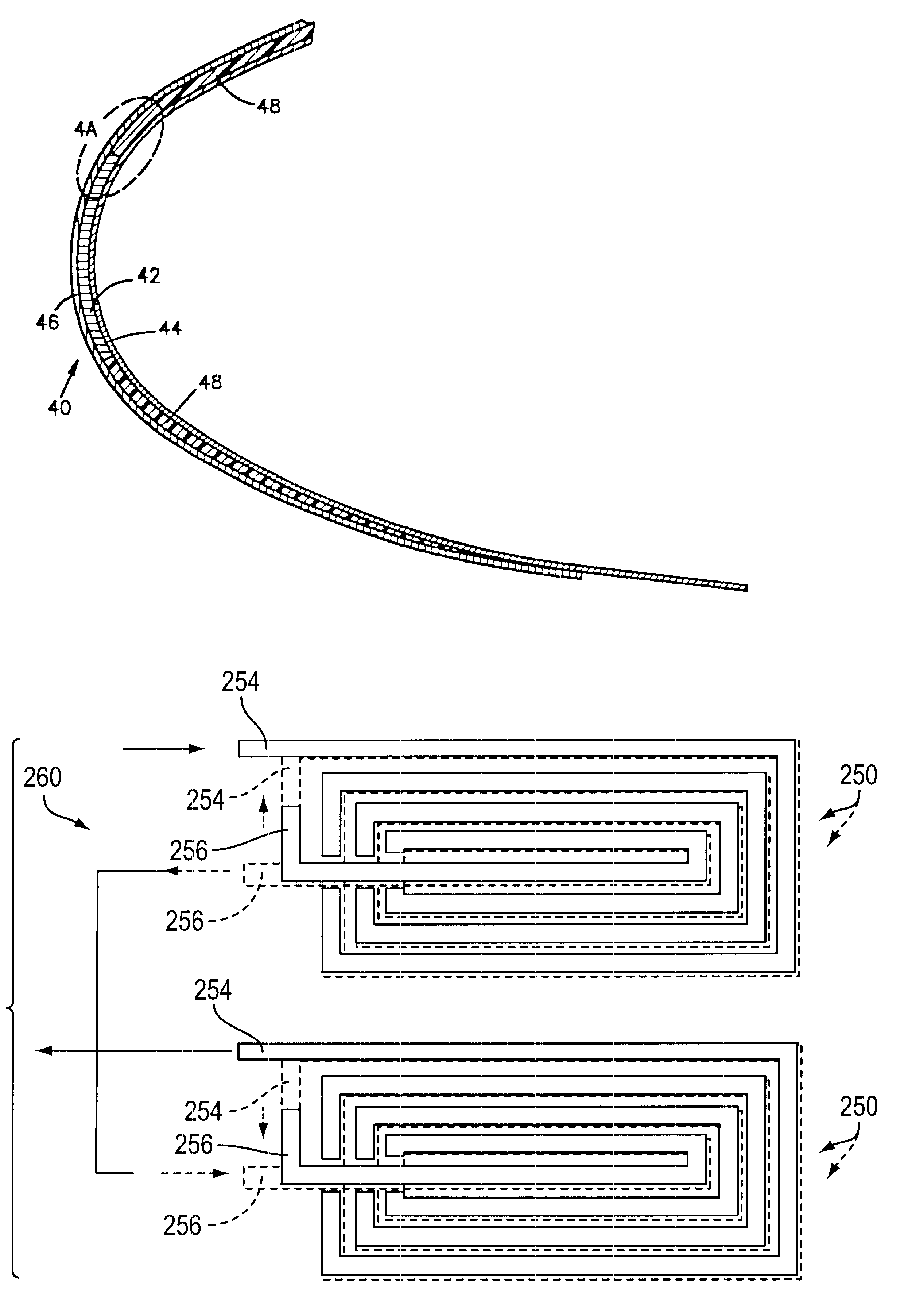

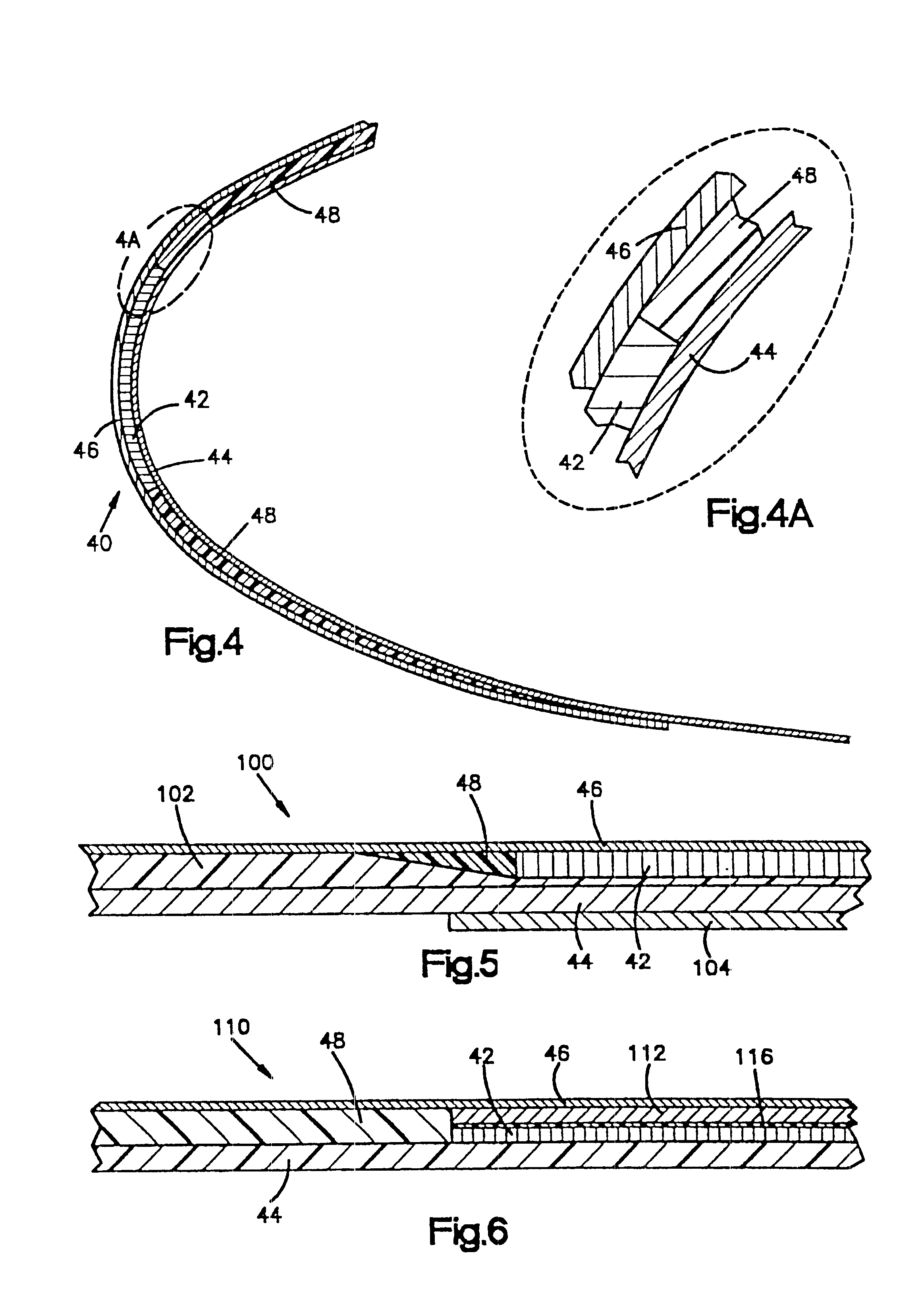

The present invention provides a technique especially adapted for de-icing the leading edges of structural members. De-icing is the removal of ice subsequent to its formation upon a leading edge. A leading edge is that portion of a structural member that functions to meet and break an airstream impinging upon the surface of the structural member. Examples of leading edges are the forward portions of wings, stabilizers, struts, nacelles, rotors, and other housings and protrusions first impacted by an airstream.

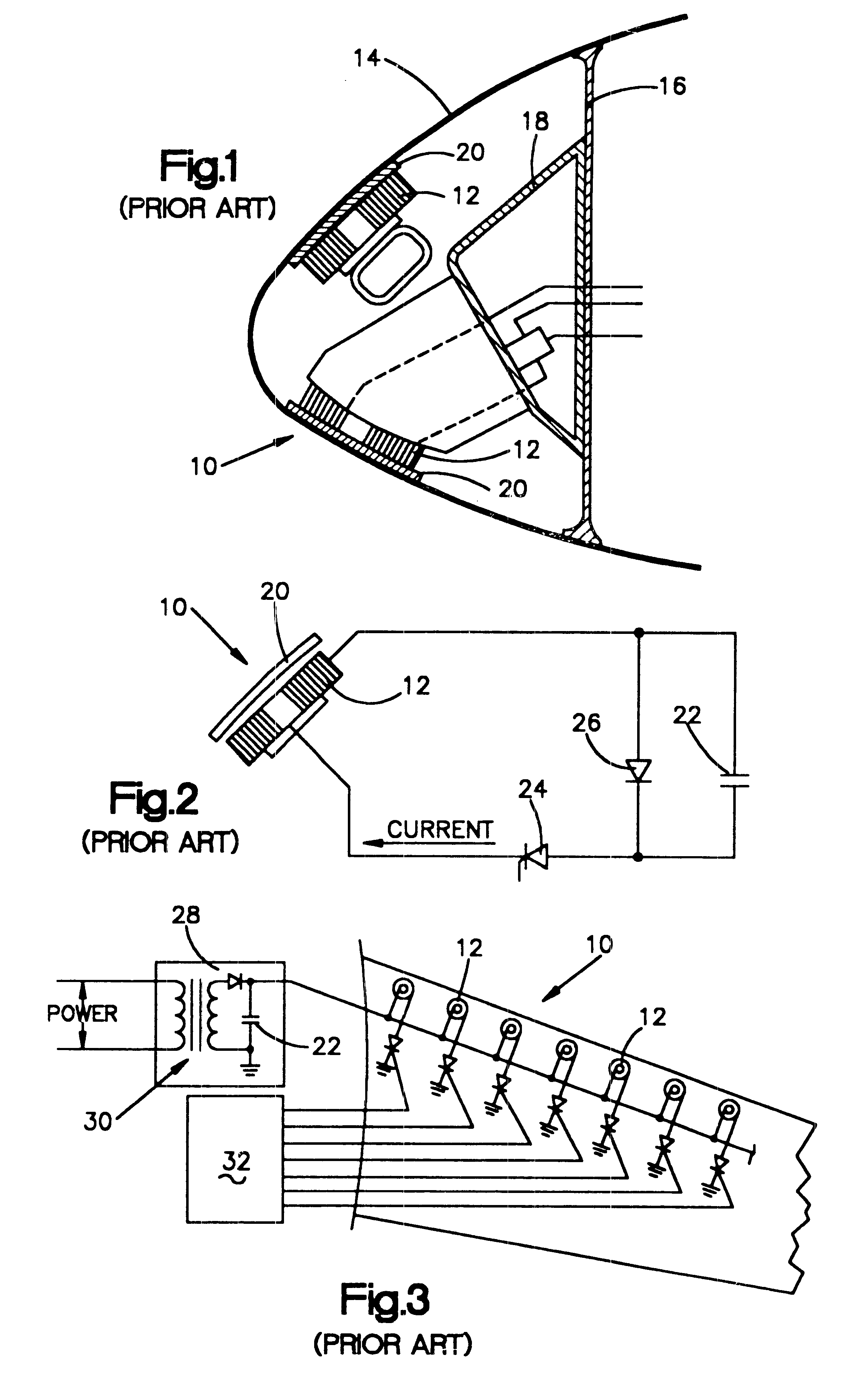

FIGS. 1-3 illustrate a known mechanical de-icer 10 and electrical circuitry thereof. The de-icer 10 includes first and second coils 12 that are disposed with a structural member (such as a wing) 14 near the backside of the leading edge thereof. The surface of the structural member 14 is made of metal such as aluminium which will be referred to as the "skin." The coils 12 are mounted to a spar 16 by means of a mounting bracket 18. The coils 12 are circular in plan view. A circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com