Recalibrating a multi-color imaging system

a multi-color imaging and recalibrating technology, applied in the field of multi-color imaging technology, can solve the problems of uncalibrated imaging system, inability to accurately represent the output of the target imaging system, and increased possibility of drift and systematic shift affecting the color respons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

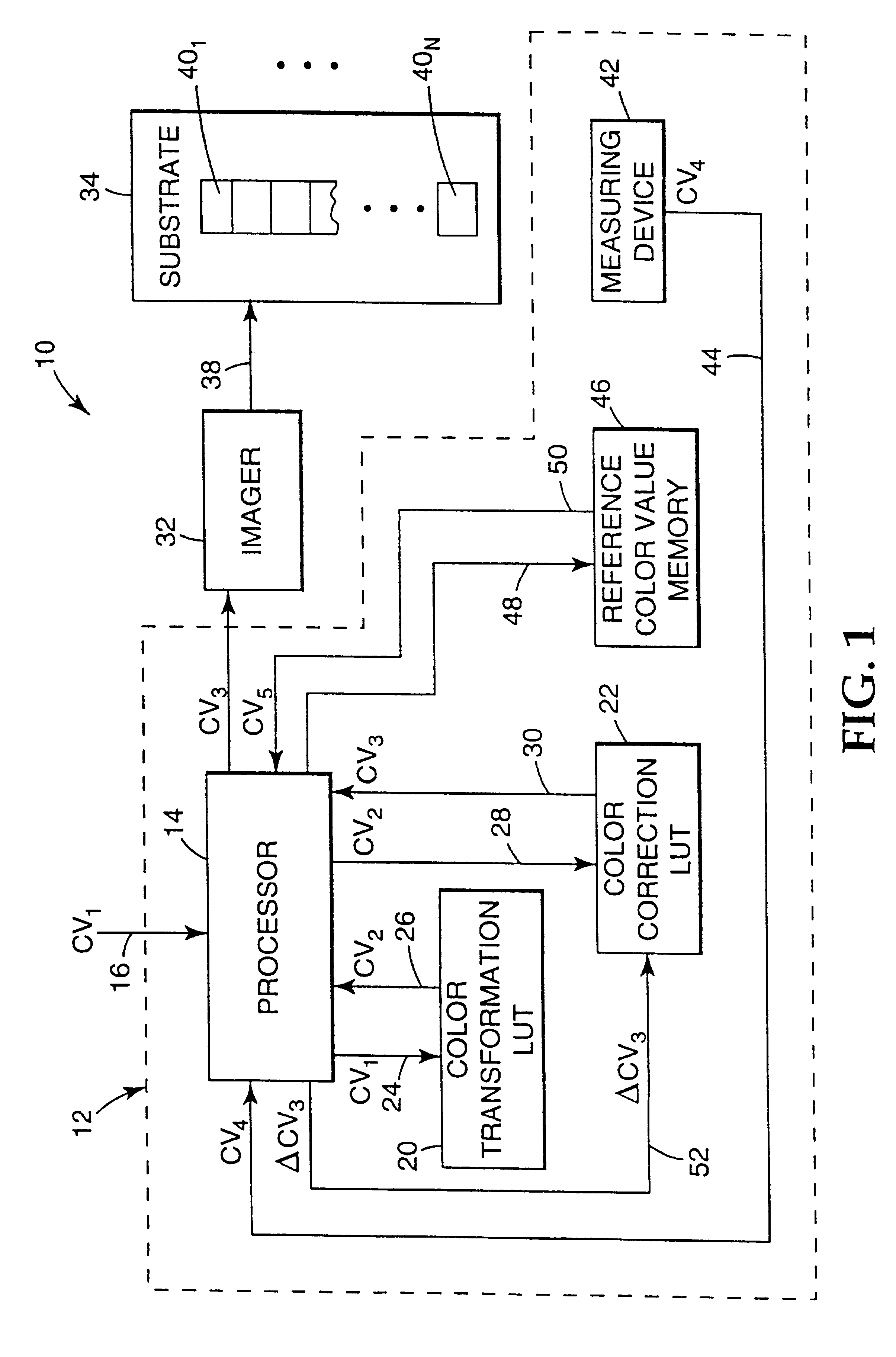

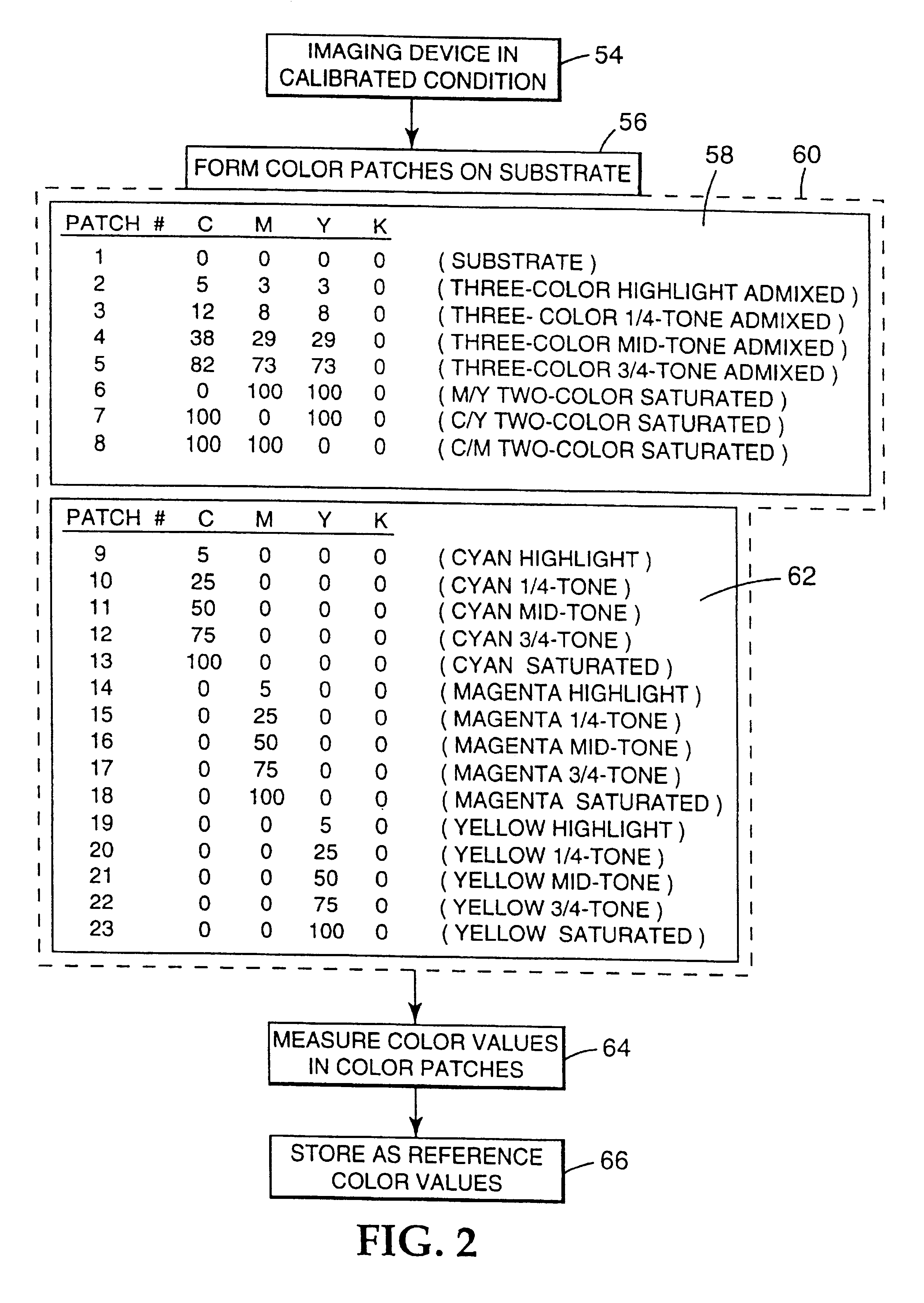

A CMYK proof of an image was made using the 3M Rainbow.TM. digital proofing system as imaging system 10. The color imaging system targeted by the 3M Rainbow system was the 3M Matchprint.TM. III proofing system. The proof was generated by first selecting the MP3 color transform in the color management software provided with the 3M Rainbow.TM. digital proofing system. The MP3 color transform was in the form of a multi-dimensional color transformation LUT, such as LUT 20 in FIG. 1. The MP3 color transform implemented a color transformation function for simulation of the 3M Matchprint.TM. III proofing system. Application of the MP3 color transform to input color values CV.sub.1 produced color-transformed input color values CV.sub.2. Manual adjustments then were made to input color values CV.sub.2 via a color correction LUT, such as LUT 22 in FIG. 1, to produce input color values CV.sub.3 sufficient to produce an acceptable visual match between the output of the 3M Rainbow.TM. imaging sy...

example 2

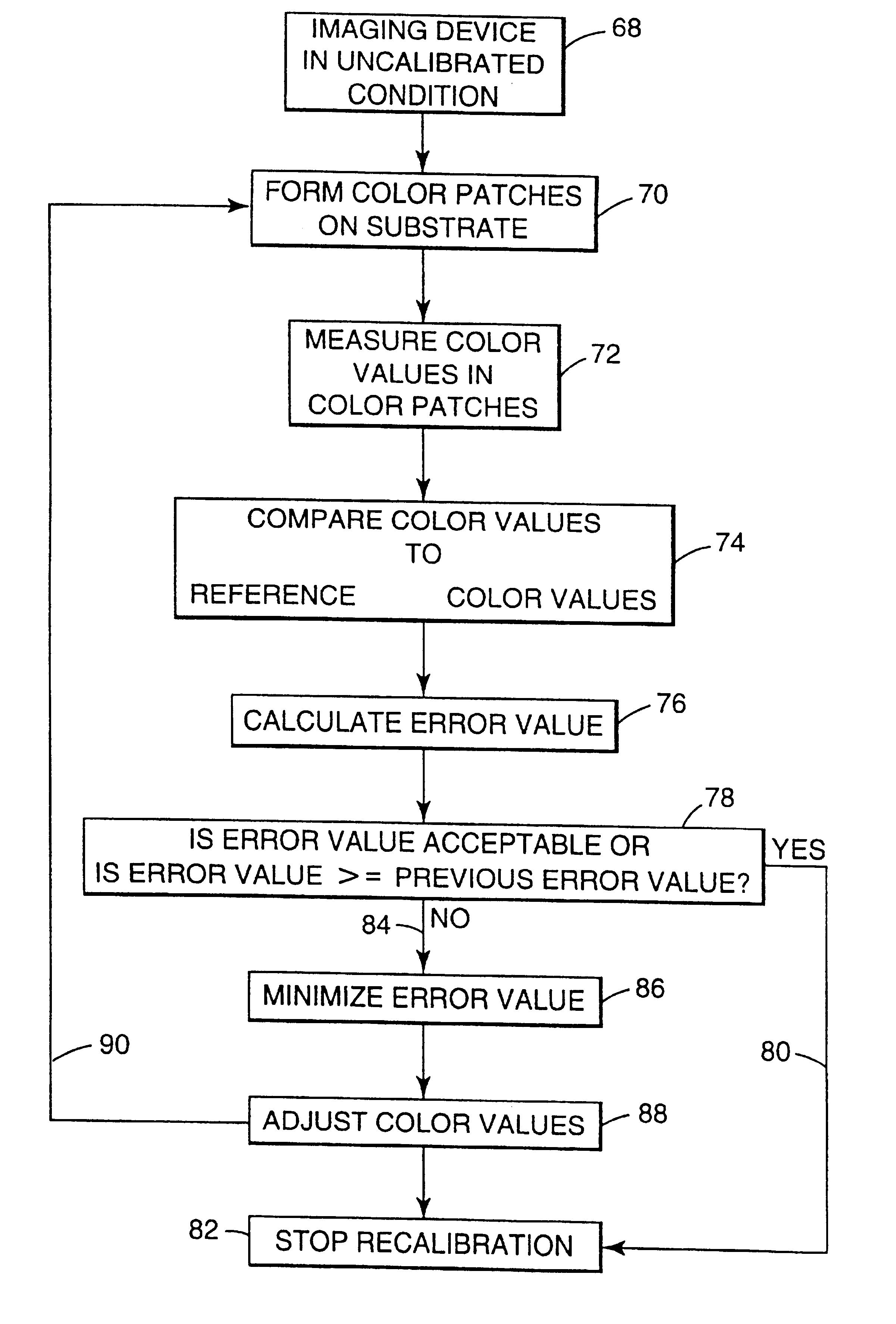

A recalibration procedure substantially similar to that described with respect to EXAMPLE 1 above was performed using the quick recalibration procedure described with reference to FIGS. 2 and 3. The quick recalibration procedure required the formation of only seven color patches, and the measurement of only eight, including the unimaged substrate patch. The results of the quick recalibration mode were similar to those of the comprehensive calibration mode, but slightly less accurate. The results are set forth below:

Average .DELTA.E Uncalibrated Proof 2.37 Recalibrated Proof (Three Iterations) 0.92

as the color model F.sub.1 '(x) is improved, the above results will improve. Also, a convergence parameter can be employed to implement only a partial correction, thereby reducing the effects of noise plus error in F.sub.1 '(x).

example 3

A recalibration procedure substantially similar to that described with respect to EXAMPLES 1 and 2 above was performed using the comprehensive recalibration procedure described with reference to FIGS. 2 and 3. In this EXAMPLE, a first 3M Rainbow.TM. color proofer ("proofer 1") was recalibrated using a reference data target created on a different 3M Rainbow.TM. proofer ("proofer 2"). Proofer 1 was at the low end of color response tolerance for a 3M Rainbow.TM. proofer. In this EXAMPLE, the black color channel was recalibrated in parallel with the CMY channels. The black was essentially recalibrated to an acceptable level after one iteration and the CMY channels were found to show no further improvement in recalibration after three iterations.

FIG. 4 is a color space plot illustrating relative color responses of proofer 1 and proofer 2, as represented by red, green, blue, and yellow coordinates, prior to application of the recalibration procedure. In FIG. 4, the uncalibrated color resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com